Professional Documents

Culture Documents

HF515

Uploaded by

P Singh KarkiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HF515

Uploaded by

P Singh KarkiCopyright:

Available Formats

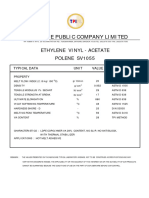

TECHNICAL DATA SHEET

HF515

Metallized Low COF Film

METALLIZED BOPP FILM

DESCRIPTION :

Gulf Pack HF515 is a heat sealable film, one side treated and metallized with high purity Metallized Surface

aluminum; other side untreated with low coefficient of friction (COF) property.

properties.

Treated Metal Receptive Layer

PRODUCT FEATURES: APPLICATIONS :

One side aluminum coated As inner web for adhesive lamination

Low coefficient of friction (COF) Packaging for moisture & odor sensitive OPP Core Layer

Excellent metal adhesion & web flatness food stuffs as coffee, snack foods,

Good optical density chips, cookies, etc. Untreated Heat Sealable Layer

Outstanding barrier to moisture, gas & odors. Surface printed for ice cream and

Excellent light barrier enhances shelf life candy over wrap

Good resistance to oils fats & flex cracking Specialty as gift wrap & flower designing

PROPERTIES UNIT TYPICAL VALUES TEST METHOD.

Microns 18 20 25 30

Thickness ASTM D 374

Gauge 72 80 100 120

g/m2 16.38 18.20 22.75 27.30

Grammage

lbs/ream 10.1 11.2 14.0 16.8

PHYSICAL *GPIM

m2/kg 61.05 54.95 43.96 36.63

Yield

in2/lb 43,000 38,700 31,000 25,800

Coefficient of Friction (Film/Film) 0.25 ASTM D 1894

Surface Tension (Treated Side) dynes/cm 38 ASTM D 2578

OPTICAL Optical Density % 2.0 GPIM

*MD 15

kg/mm2

*TD 27

Tensile Strength at Break ASTM D 882

MD 21,330

MECHANICAL psi

TD 38,394

MD 170

Elongation at Break % ASTM D 882

TD 50

MD < 4.0 GPIM

Thermal Shrinkage % (120o C (248oF),

TD < 2.0 5 min, air)

Heat Seal Range oC (oF) 105 – 140 (221 – 284) GPIM

THERMAL

g/15mm 275 GPIM

(130oC, 1bar, 1sec)

Heat Seal Strength (Film/Film)

lb/0.59in 0.60 GPIM

(266oF, 14.5psi, 1 sec)

Water Vapor Permeability g/m2/24h 0.80 ASTM F 1249

(W.V.T.R.) g/100in2/24h 0.051 (38oC / 90% RH)

BARRIER

Oxygen Transmission Rate cc/m2/24h 90 ASTM D 3985

( O.T.R.) cc/in2/24h 5.80 (23oC / 0% RH)

* GPIM – Gulf Pack Internal Method *MD – Machine Direction *TD – Transverse Direction

Gulf Pack HF515 films comply with EU Regulation 10/2011/EC and USA FDA Code of Federal Regulations CFR21 section 177.1520 (c) 1.1 and are suitable

for use in packaging, carrying and transporting foodstuffs.

The information contained in this technical leaflet illustrates typical values only and are to the best of our knowledge. Since the conditions under which

our films may be used are beyond our control, such values are declared without warranty or guarantee.

Bi-axially oriented polypropylene films age with time and will exhibit deterioration of some properties if not stored in a suitable environment at a

temperature 30oC or below. We strongly advise our customers to use recommended storage conditions and consume products before 3 months from date

of production in our plant.

Gulf Pack HF515 standard surface treatment location is on the outer side (O); other treatment preference can be arranged upon agreement with the sales

representative before order processing.

Detailed advice regarding other specific applications of Gulf Pack HF515 and other films in the Gulf Pack range is available upon request.

Gulf Packaging Industries Ltd. sales@gulfpack.com.sa www.gulfpack.com.sa Last update : 26-Oct-2014

You might also like

- Fluid Mechanics: Properties, Viscosity and ApplicationsDocument77 pagesFluid Mechanics: Properties, Viscosity and ApplicationsvijaynieNo ratings yet

- Katzung Questions PDFDocument29 pagesKatzung Questions PDFChristian Solis100% (1)

- 09 Safe Handling of ChemicalsDocument23 pages09 Safe Handling of ChemicalsOladimeji Taiwo100% (1)

- Dubai Municipality G+12 Concrete & Shoring QuestionsDocument7 pagesDubai Municipality G+12 Concrete & Shoring QuestionsMohammed Nasih Vettathur100% (2)

- Case Studies in Boiler FailuresDocument14 pagesCase Studies in Boiler Failuresparthi2006576880% (5)

- ΔL, SIF, Hoop Stress, API StandardsDocument3 pagesΔL, SIF, Hoop Stress, API StandardsVijay KumarNo ratings yet

- Ceng204P Separation Processes I Coursework 1: 1. Problem DescriptionDocument3 pagesCeng204P Separation Processes I Coursework 1: 1. Problem DescriptionKaren Chong Yap100% (1)

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Water Steam Chemistry OptimizationDocument4 pagesWater Steam Chemistry OptimizationAshish ParasharNo ratings yet

- Polyurea Resistance ChartDocument1 pagePolyurea Resistance ChartTanmay GorNo ratings yet

- Strain Gauges DatasheetDocument100 pagesStrain Gauges DatasheetSantiago UrgilesNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- Technical Information on SCOT Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information on SCOT Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- PVDC Coated Nylon Film Nxo: Technical InformationDocument1 pagePVDC Coated Nylon Film Nxo: Technical InformationIvan TedjaNo ratings yet

- Flexmetprotect C-CNM-M: Technical Data SheetDocument1 pageFlexmetprotect C-CNM-M: Technical Data Sheetminni choubeyNo ratings yet

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- Excellent barrier and gloss properties of PTM polyester filmDocument1 pageExcellent barrier and gloss properties of PTM polyester filmHamdy AkkadNo ratings yet

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- B-TVS-M: Metallized BOPP FilmDocument2 pagesB-TVS-M: Metallized BOPP FilmSayed FathyNo ratings yet

- BPC - BG HD 7000fDocument1 pageBPC - BG HD 7000fSLKM Engineering & ConsultantsNo ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- PVDC Coated Pet Film Spo: Technical InformationDocument1 pagePVDC Coated Pet Film Spo: Technical InformationIvan TedjaNo ratings yet

- Blown film resin for high-impact packagingDocument2 pagesBlown film resin for high-impact packagingAli RazuNo ratings yet

- TDS HMTDocument1 pageTDS HMTKarthiNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- LL7420D Linear Low Density Polyethylene ResinDocument1 pageLL7420D Linear Low Density Polyethylene ResinFahad MohamedNo ratings yet

- SABIC® LDPE - HP0322N - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0322N - Global - Technical - Data - SheetThamimNo ratings yet

- AC410Document1 pageAC410P Singh KarkiNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- 3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9Document1 page3 Zxepfrwec 6 Eiofni 13 A 6 Ajjmhvomyv 9vikramNo ratings yet

- Riblene FF20Document2 pagesRiblene FF20Stefan PopaNo ratings yet

- Ptfe - G400Document1 pagePtfe - G400Alessio Di BellaNo ratings yet

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- SABIC® LDPE - HP2023JN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2023JN - Global - Technical - Data - SheetSarvesh SinghNo ratings yet

- High Barrier Metallized PET Film for PackagingDocument1 pageHigh Barrier Metallized PET Film for PackagingAngga PrasetyoNo ratings yet

- Lldpe - Sabic® Lldpe - 118NJ PDFDocument2 pagesLldpe - Sabic® Lldpe - 118NJ PDFNilay TanrıverNo ratings yet

- SCG D777CDocument1 pageSCG D777Cbhoopendra singhNo ratings yet

- LTL BOPP Film Properties & ApplicationsDocument2 pagesLTL BOPP Film Properties & ApplicationsQUALITY CONTROLNo ratings yet

- SABIC® LDPE - HP4024WN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP4024WN - Global - Technical - Data - SheetTOMALO FREENo ratings yet

- UmaPET - AODocument1 pageUmaPET - AOñeNo ratings yet

- SABIC® LDPE - HP0323NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP0323NN - Global - Technical - Data - SheetRubenMurguiaNo ratings yet

- Innoplus (GC Marketing) LL7835ADocument1 pageInnoplus (GC Marketing) LL7835AOscar Tan IIINo ratings yet

- TDS HBMDocument1 pageTDS HBMP Singh KarkiNo ratings yet

- H6105JUDocument1 pageH6105JUhunghiepvanNo ratings yet

- 1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsDocument2 pages1695012734-2058787459-h-t-nh-a-ldpe-hp0724nn-tdsChu ChuNo ratings yet

- Linear Low Density Polyethylene Resin for General Purpose FilmDocument1 pageLinear Low Density Polyethylene Resin for General Purpose FilmNitin MaheshwariNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Sabicr Ldpe Hp4023wnDocument2 pagesSabicr Ldpe Hp4023wnFarah bennourNo ratings yet

- SABIC® LLDPE - 218WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 218WJA - Americas - Technical - Data - Sheetdiana sarmientoNo ratings yet

- Sabic Lldpe 118Wsj: Linear Low Density PolyethyleneDocument2 pagesSabic Lldpe 118Wsj: Linear Low Density PolyethyleneFahad MohamedNo ratings yet

- LDPE-HP0723JNDocument2 pagesLDPE-HP0723JNChu ChuNo ratings yet

- Product Data: Titanlene Ldf250YzDocument1 pageProduct Data: Titanlene Ldf250YzchinchotarngNo ratings yet

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIINo ratings yet

- SV1055Document1 pageSV1055akankshas06No ratings yet

- B-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmDocument2 pagesB-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmSayed FathyNo ratings yet

- Product Data: Titanlene Ldf200GgDocument1 pageProduct Data: Titanlene Ldf200GgchinchotarngNo ratings yet

- TDS (CPP Lamination-30Document1 pageTDS (CPP Lamination-30Zaheer AbbasNo ratings yet

- SCG Ldpe D777CDocument1 pageSCG Ldpe D777Ctariquekhan143No ratings yet

- SCGC LSP L2420J Technical Datasheet ProvisionalDocument3 pagesSCGC LSP L2420J Technical Datasheet Provisionalakankshas06No ratings yet

- ASTM UT404 Eng 240223Document1 pageASTM UT404 Eng 240223MERVENo ratings yet

- Highshrink PT814Document1 pageHighshrink PT814Hemant Kumar PathakNo ratings yet

- SABIC® LDPE - HP2022NN - Global - Technical - Data - SheetDocument2 pagesSABIC® LDPE - HP2022NN - Global - Technical - Data - Sheetselman gürbüzNo ratings yet

- UmaPET - TFDocument3 pagesUmaPET - TFLuz Angela GuerreroNo ratings yet

- TDS BOPP Blanco LSG57 y 60 - EUDocument2 pagesTDS BOPP Blanco LSG57 y 60 - EUEmmanuel AlvarezNo ratings yet

- TDS BB120 Eng 220216Document1 pageTDS BB120 Eng 220216QcNo ratings yet

- DTM Bonding Primer: Protective & Marine CoatingsDocument4 pagesDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Lldpe - LL7410D PDSDocument1 pageLldpe - LL7410D PDSchinchotarngNo ratings yet

- SABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDocument2 pagesSABIC® LLDPE - 118WJA - Americas - Technical - Data - SheetDiana SarmientoNo ratings yet

- Resume: Personal DetailsDocument2 pagesResume: Personal DetailsP Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part7 PDFDocument1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part7 PDFP Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part4Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part4P Singh KarkiNo ratings yet

- Outdoor Clothing, Footwear, Bags and Gear Brand in India - WildcraftDocument1 pageOutdoor Clothing, Footwear, Bags and Gear Brand in India - WildcraftP Singh KarkiNo ratings yet

- Outdoor Gear Brand Wildcraft ProfileDocument1 pageOutdoor Gear Brand Wildcraft ProfileP Singh KarkiNo ratings yet

- Contractor TipsDocument3 pagesContractor TipsTanmay VegadNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part2Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part2P Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part6Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part6P Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part5Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part5P Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part3Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part3P Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part1Document1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part1P Singh KarkiNo ratings yet

- Clothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part9 PDFDocument1 pageClothing, Footwear, Bags and Gear Brand in India - Wildcraft - Part9 PDFP Singh KarkiNo ratings yet

- Weight Calculation From Available Length Width in MM and Weight in Micron For FilmDocument1 pageWeight Calculation From Available Length Width in MM and Weight in Micron For FilmP Singh KarkiNo ratings yet

- PDFSigQFormalRep PDFDocument1 pagePDFSigQFormalRep PDFJim LeeNo ratings yet

- Change Your DNS Servers On Windows - NordVPN Customer SupportDocument7 pagesChange Your DNS Servers On Windows - NordVPN Customer SupportP Singh KarkiNo ratings yet

- Weight Calculation From Available Length Width in MM and Weight in Micron For FilmDocument1 pageWeight Calculation From Available Length Width in MM and Weight in Micron For FilmP Singh KarkiNo ratings yet

- About Germany Part9Document4 pagesAbout Germany Part9P Singh KarkiNo ratings yet

- Change Your DNS Servers On Windows - NordVPN Customer SupportDocument7 pagesChange Your DNS Servers On Windows - NordVPN Customer SupportP Singh KarkiNo ratings yet

- About Germany Part8Document5 pagesAbout Germany Part8P Singh KarkiNo ratings yet

- About Germany Part7Document5 pagesAbout Germany Part7P Singh KarkiNo ratings yet

- About Germany Part3Document5 pagesAbout Germany Part3P Singh KarkiNo ratings yet

- About Germany Part6Document5 pagesAbout Germany Part6P Singh KarkiNo ratings yet

- Ratio & Proportion Part 4Document1 pageRatio & Proportion Part 4P Singh KarkiNo ratings yet

- About Germany Part5Document5 pagesAbout Germany Part5P Singh KarkiNo ratings yet

- About Germany Part2Document5 pagesAbout Germany Part2P Singh KarkiNo ratings yet

- Ratio & Proportion Part 1Document5 pagesRatio & Proportion Part 1P Singh KarkiNo ratings yet

- About Germany Part4Document5 pagesAbout Germany Part4P Singh KarkiNo ratings yet

- Germany Visit Part 1Document5 pagesGermany Visit Part 1P Singh KarkiNo ratings yet

- Ratio & Proportion Part 3Document5 pagesRatio & Proportion Part 3P Singh KarkiNo ratings yet

- Ratio & Proportion Part 2Document5 pagesRatio & Proportion Part 2P Singh KarkiNo ratings yet

- K3 Skema Cemerlang Set 1Document4 pagesK3 Skema Cemerlang Set 1annurshah05No ratings yet

- Theory of PlasticityDocument10 pagesTheory of Plasticitybabu1434100% (1)

- Ans No. 4-Conservation of Mass Equation-: + Known As Continuity EquationDocument4 pagesAns No. 4-Conservation of Mass Equation-: + Known As Continuity EquationHimanshu TrivediNo ratings yet

- FM Lab ManualDocument70 pagesFM Lab ManualRishi PatilNo ratings yet

- Non-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementDocument7 pagesNon-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementstevensurandomNo ratings yet

- IPA Report Copper Velocity and Temperature April 2015 PDFDocument13 pagesIPA Report Copper Velocity and Temperature April 2015 PDFasastreNo ratings yet

- Onqor: Product BulletinDocument2 pagesOnqor: Product BulletinAhmed ChahineNo ratings yet

- Astm 2Document5 pagesAstm 2carlos salinasNo ratings yet

- Performance Task 2 Melting and Boiling PointsDocument1 pagePerformance Task 2 Melting and Boiling PointsVannie MonderoNo ratings yet

- Phase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsDocument8 pagesPhase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsAsshole FuckerNo ratings yet

- Tissue Culture: Very Short Answer QuestionsDocument4 pagesTissue Culture: Very Short Answer QuestionskzrdurNo ratings yet

- Everything About Alkynes - Q&ADocument22 pagesEverything About Alkynes - Q&AJoostGoNo ratings yet

- Clean Light-Colored Bricks SafelyDocument1 pageClean Light-Colored Bricks SafelymutazsalihNo ratings yet

- Decolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's ProcessDocument5 pagesDecolorization and Organic Removal From Palm Oil Mill Effluent by Fenton's Processagungtiyo21No ratings yet

- Wave Properties of Particles ExplainedDocument19 pagesWave Properties of Particles ExplainedAmanda BoltonNo ratings yet

- Gasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™Document1 pageGasket Assembly Stress Recommendations: Compressed Sheet, GRAPH-LOCK®, GYLON® and Gylon Epix™dilo0987No ratings yet

- Electricity PowerPoint-0Document34 pagesElectricity PowerPoint-0Ryan P. YapNo ratings yet

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDocument9 pagesXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuNo ratings yet