Professional Documents

Culture Documents

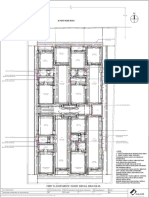

Top Bracing Beams Plan Extract Part 1

Uploaded by

SemeeeJuniorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Top Bracing Beams Plan Extract Part 1

Uploaded by

SemeeeJuniorCopyright:

Available Formats

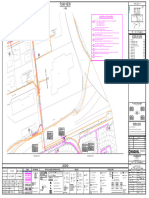

TOP BRACING BEAMS PLAN EXTRACT FROM +1.

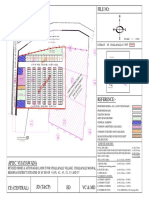

80 LEVEL PLAN (Part 1) K-PLAN

SCALE 1:100 SCALE 1:100 SCALE 1:2000

953

1177

Cut off the pile's head of the piles that are 1690

interfering for the necessary height and provide in

the cast of the capping beam the formwork for the

design hole.

A

PART 1 The capping beam bars must be interrupted near PART 2

the hole, with hook end. S

A SECANT PILE Ø120

L=18.5m D

STR.07

S SECANT PILE Ø120 SECANT PILE

1 2 3 4 5 L=18.5m L=18.5m

A

SHEET PILE TYPE

S

A LARSSEN 430 L=20.00m A S A S A S A S A S A S A

0*

26

45°

EB

168

HEB 260*

190

8

290

23

4580

HEB 400*

PROVISIONAL D

STR.07

STEEL BEAM

191

B

1690 981 1136 771 C C

STR.07 STR.07

273

24

170

0

H

EB

24

45°

SHEET PILE TYPE

26

C T T T T T T

0*

LARSSEN 430 L=20.00m T

SECANT PILE Ø120 T NOTE: The exact placement of the seawater intake is to be defined on the basis of the

+5.35 L=18.5m SECANT PILE Ø120

SECANT PILE Ø120 R.C. PILE Ø80 recommendations of the client. Possible interferences between the new design piles

190

L=18.5m D CAPPING BEAM 140x155 L=18.5m T R.C. PILE Ø80 head level +3.80

STR.07

head level +3.80 and the existing piles are to be resolved in site with the Director of the structural works.

CAPPING BEAM 140x115

SECANT PILE Ø120 SECANT PILE Ø120 CONCRETE WALL Th.100cm TO BE

+5.35

L=18.5m L=18.5m BUILD IN 2 PHASES

CAPPING BEAM 140x155 CAPPING BEAM 140x155

529

SHEET PILE TYPE +5.35

190

A LARSSEN 430 L=20.00m

2 A

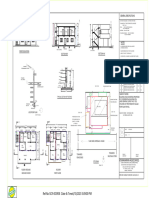

REQUIREMENTS FOR THE MATERIALS OF THE STRUCTURES

*

190 190 SECANT PILE Ø120 CONCRETE WALL Th.100cm TO BE

BRACING BEAM 50x40

160 THIN CONCRETE FOR BACKGROUND INTERNAL FINISHING:

L=18.5m

BRACING BEAM 50x40

BRACING BEAM 50x40

BRACING BEAM 50x40

BRACING SLAB 340x40

290

BUILD IN 2 PHASES (SUB-FOUNDATION) Compressive strength class (N/mm²): C35/45

SECANT PILE Ø120

346

D L=18.5m Compressive strenght class (N/mm²): C16/20 Environmental exposure class (EN 206-1): XC4+XS3+XA3

2183

SECANT PILE Ø120 D T Dose of concrete: 150 kg of cement type EN 197 CEM I 32.5 per Maximum aggregate size Dmax=25mm

502

STR.07

DESIGN HOLE L=18.5m CAPPING BEAM 140x155 R.C. PILE Ø80 cubic meter of mix. Water/cement ratio =0.45

B SECANT PILE Ø120 head level +3.80 Minimum content cement Portland 42.5: >360Kg/mc

DESIGN HOLE x155 B

G B E AM 140 L=18.5m SHEET PILE TYPE FOUNDATION SLABS, WALLS IN CONTACT WITH Consistency class = S4/S5 or reference slump 230±30mm

CAPPIN +5.35

4 LARSSEN 430 L=20.00m

CONCRETE WALL Th.100cm TO BE SOIL,INTERNAL WALLS, CONCRETE SLABS, BRACING Class of chloride content = Cl 0.4

273

BUILD IN 2 PHASES BEAMS AND SLABS, UNREINFORCED SECANT PILES, Additive superfluidising retardant, prospect 11.1;11.2 (EN 934-2)

218

BRACING BEAM 50x40

+5.35 340 Additive retardant (for very warm climates) prospect 2 (EN 934-2)

CAPPING BEAM 140x155

REINFORCED SECANT PILES, FOUNDATION PILES:

529

BRACING BEAM 100x40 BRACING BEAM 100x40 BRACING BEAM 100x40 Aggregate without harmful or virtually reactive minerals to alkali

SHEET PILE TYPE +5.35 190 Compressive strength class (N/mm²): C35/45

(EN 932-3)

100

BRACING SLAB 340x40

R.C. PILE Ø80 Environmental exposure class (EN 206-1): XC4+XS3+XA3

C LARSSEN 430 L=20.00m BRACING BEAM 100x40 C head level +3.80 R.C. PILE Ø80 Maximum aggregate size Dmax=25mm

CEM IV 42,5R (EN 197-1) with Silica fly ash or Silica fumes in

DESIGN HOLE partial substitution of concrete.

T head level +3.80 Water/cement ratio =0.45

190

R.C. PILE Ø80 Silica fly ash or Silica fumes (EN450 and EN 13263 part 1 and 2)

752

R.C. PILE Ø80 R.C. PILE Ø80 +5.35 Minimum content cement Portland 42.5: >360Kg/mc

Bleeding water volume <01%

+5.35 Consistency class = S4/S5 or reference slump 230±30mm

24

CONCRETE WALL Th.100cm TO BE DESIGN HOLE Protection of the formed surfaces (unformwork surfaces) with

T Class of chloride content = Cl 0.4

BUILD IN 2 PHASES

42

DESIGN HOLE

E T T T T T T T

Additive superfluidising retardant, prospect 11.1;11.2 (EN 934-2)

extruded expanded polystyrene with width 50mm for at least

0*

seven days.

190

26

Additive retardant (for very warm climates) prospect 2 (EN 934-2)

529

529

425 45° The removing of formwork from the concrete structure or the

EB

170

50 500 50 516 50 519 Aggregate without harmful or virtually reactive minerals to alkali

517 50 486 50 511 minimum duration of moist maturation of the concrete to be made

H

273

(EN 932-3)

BRACING BEAM 50x40

BRACING BEAM 50x40

BRACING BEAM 40x40

BRACING BEAM 50x40

0

trough the coating of the unformwork surfaces with wet geotextile

24

PROVISIONAL

BRACING BEAM 50x40

BRACING BEAM 50x40

Low hydration heat cement type LH (EN 197/1-2006) with unity

DESIGN HOLE STEEL BEAM every 24 hours.

CONCRETE WALL Th.100cm TO BE CONCRETE WALL R.C. PILE Ø80 F hydration heat at 7 days <= 270J/g .

Into the concrete mixture must be added a waterproofing additive

HEB 400*

BUILD IN 2 PHASES Silica fly ash or Silica fumes (EN450 and EN 13263 part 1 and 2)

DESIGN HOLE Th.100cm like MICROPLUS BETONSAFE in amount of 25kg every 1mc of

191

BRACING BEAM 100x40 SHEET PILE TYPE Bleeding water volume <01%

HEB 260*

340 TO BE BUILD concrete.

Protection of the formed surfaces (unformwork surfaces) with

2183

979

100

D IN 2 PHASES D LARSSEN 430 L=20.00m Into the concrete mixture must be added an additive to reduce

A extruded expanded polystyrene with width 50mm for at least

SECANT PILE Ø120 cracking and improve the waterproofing based on propylenic

seven days.

290

R.C. PILE Ø80 R.C. PILE Ø80 L=18.5m multifilament fiber and fibrillated mesh like FIBRE ECOMIX 190

DESIGN HOLE 340 The removing of formwork from the concrete structure or the

168

190 190 in amount of 750gr every 1mc of concrete.

SHEET PILE TYPE +5.35 DESIGN MEP HOLE minimum duration of moist maturation of the concrete to be made

H

10

trough the coating of the unformwork surfaces with wet geotextile

EB

LARSSEN 430 L=20.00m 45° STEEL FOR PROVISIONAL METAL STRUCTURE

every 24 hours.

26

SECANT PILE Ø120 G A S A S A S A S A S A

BRACING SLAB 340x40

S A Standars and steelgrade:

0*

DESIGN HOLE DESIGN HOLE S Into the concrete mixture must be added a waterproofing additive

BRACING BEAM 50x40

529

529

+5.35 DESIGN HOLE Mechanical hot rolled hollow profile as EN 10210-1

DESIGN HOLE L=18.5m like MICROPLUS BETONSAFE in amount of 25kg every 1mc of

CAPPING BEAM 140x155

CONCRETE WALL Th.100cm TO BE Mechanical hot rolled tubular profile as EN 10210-2

214

concrete.

BUILD IN 2 PHASES Mechanical cold rolled tubular profile as EN 10219-2

S Into the concrete mixture must be added an additive to reduce

Mechanical hot rolled open profile as EN 10034 e EN 10025

cracking and improve the waterproofing based on propylenic

R.C. PILE Ø80 R.C. PILE Ø80

752

R.C. PILE Ø80 A multifilament fiber and fibrillated mesh like FIBRE ECOMIX 190

S275 J0 (t≤40 mm) fyk= 275 N/mm² ftk=430 N/mm²

in amount of 750gr every 1mc of concrete.

(t>40 mm) fyk= 255 N/mm² ftk=410 N/mm²

+5.35

E E

100

BRACING BEAM 100x40 REINFORCED CONCRETE STEEL BARS:

190 Steel should be protect by corrosion with galvanized coating as

B B Steel Type B450C

BRACING BEAM 100x40 BRACING BEAM 100x40 BRACING BEAM 100x40 A BS 729.

Characteristic yield strength fyk≥fynom=450N/mm²

219

BRACING BEAM50x40

BRACING BEAM 50x40

BRACING BEAM 50x40

BRACING BEAM 50x40

BRACING SLAB 340x40

273

+5.35 Characteristic ultimate tensil strength ftk≥ftnom=540N/mm²

DESIGN HOLE BOLTS, NUTS AND WASHERS:

3

6

DESIGN HOLE 9 Elongation ductility requirement (Agt)k≥7.5% (fractile 10%)

13

Bolted connections as EN ISO 4016:2002 and EN ISO 5592:1968

11 C AP PI 1690

F NG B E

AM 140

SECANT PILE Ø120

L=18.5m

F STEEL FOR SHEET PILES

Bolt class 8.8 (EN ISO 898-1:2001 and BS 3692)

x155 Nuts class 8; washers' and plates' steel C50 (EN 10083-2:2006)

Steel Type S 270 GP

502

The bolts must be fitted with a washer under the screw head and

SHEET PILE TYPE CAPPING BEAM 140x155 Characteristic yield strength fyk≥fynom=270N/mm²

A washer under the nut.

LARSSEN 430 L=20.00m

CAPPING BEAM 140x155

SECANT PILE Ø120 Characteristic ultimate tensil strength ftk≥ftnom=430N/mm²

The bolts must be marked with the manufacturer's instructions

345

DESIGN HOLE L=18.5m SECANT PILE Ø120

290

and the class of resistance.

190 190

L=18.5m 1 Bolts vertically will have the screw head facing up and die down.

*

+5.35

+5.35 CONCRETE COVER

G 190 G The net concrete cover means counted starting

· Foundation piles 70 mm

CAPPING BEAM 140x155

*: the steel beams are provisional, are necessary only for the · Secant piles 70 mm

from the outer surface of the bracket, if present.

CAPPING BEAM 140x155

SECANT PILE Ø120

L=18.5m

underground construction phases. When the structure is ·

·

Foundation slabs

Concrete walls

70 mm

70 mm

If the bracket is not present, (example: floors),

A it's counted starting from the outer surface of

CAPPING BEAM 140x155

SECANT PILE Ø120

completed must be removed. ·

·

Bracing Beams and Slabs

Concrete slabs

30 mm

70 mm

the armature nearest the formwork.

L=18.5m

131 EXTRACT FROM +1.80 LEVEL PLAN (Part 2)

1690 981 1136 771

SCALE 1:100

4 5

1 2 3 4 5

Cut off the pile's head of the piles that are

interfering for the necessary height and provide in

the cast of the capping beam the formwork for the

design hole.

1136 771

SANSO' ENGINEERING

*

The capping beam bars must be interrupted near Beam to be scrapped after the maturation of the

the hole, with hook end. concrete cast of the slab on the ground floor

Eng. EMILIANO SANSO'

Projects - Structure - Consulting

14/11/2014 1:100 / 1:50 / 1:20 STR.06.1 14.07.10

A JUBAIL SEAWATER INTAKE

SECANT PILE Ø120

L=18.5m

SECANT PILE Ø120 SECANT PILE Ø120

346

L=18.5m L=18.5m

SECANT PILE Ø120

L=18.5m

S SECANT PILE Ø120

C L=18.5m

A S A S A S A S A S B

S

13

S S A

A

6

218

S 190

A

C S

190 S

NOTE: The piles from groundfloor level should be SECANT PILE Ø120 C

realized from groundlevel but the cast must be interrupted at L=18.5m

share of the pile head shown in the drawings. A

NOTE: The piles from underground floor should be TOP BRACING BEAMS PLAN

realized from underground level (at the bottom of excavation) S

but the cast must be interrupted at share of the pile head

shown in the drawings.

190

A

529

NOTE: The line of secant piles designed in plan refers to the

center of piles S

NOTE: R.C. PILE Ø80 SECANT PILE Ø120

NOTE: The study of dewatering will be done by a L=18.5m

All quotas must be checked at the work start head level +3.80 A

specialized company that will propose to the designer and

the geologist the project for drainage depending on the

NOTE: specific site also in function of the pumping test that will be T T T S D

done after the realization of sheet pile

All levels are referred to zero level of architectural project R.C. PILE Ø80

head level +3.80 A

NOTE: The geologist should inspect the soil during the

NOTE: excavation and backfill phase in order to ensure that suitable CONCRETE WALL Th.100cm TO BE

materials have been reached, and to detect that foundation S

All dimensions shown on the drawings refer to the crude structure. you BUILD IN 2 PHASES SECANT PILE Ø120

are placed on materiales recommended by geological report.

529

must check these with architectural direction, according to the flooring's

A L=18.5m

thikness

NOTE: Any loose materials remaining on the base and the

190

side of the foundation excavations shall be removed by

NOTE: S

manual technique in the event that excavation of foundations

For the exact shape and intersection of main walls refer to the

are taken below the design level, this extra depth shall be

architectural drawings and structural drawing of walls. For eventually

differences between structural and architectural drawings refer to the

filled with concrete class 10N/mmq. A

architectural ones

NOTE: The excavated material must not be accumulated on 190

E

S

the sides of the excavation but transported off the island. C S A

219

NOTE: S A 190

Following the executive version of architectural and plant engineering NOTE: After the realization of the secant pile will be realized S A

S

6

pumping tests to determine the quantity and the diameter of 9

13

projects, structural design shall be subjected to changes

11 A

the wells, and the flow rate of the pumps necessary to drain

C

S A S A S A S A S F

the excavation. S

NOTE (PARTICULARS): SECANT PILE Ø120

NOTE: Check the dimensions and perimeter of L=18.5m

For the sections, the foundations and slabs details see the specific pre-excavation depending on site logistics and machines that SECANT PILE Ø120

345

drawings. The particulars are typical and they must be adapted at the need to access it. Consider also any machines access to the L=18.5m SECANT PILE Ø120

other similar cases

sides of the excavation in the site logistics L=18.5m

You might also like

- A1 PDFDocument1 pageA1 PDFPIERO JESUSNo ratings yet

- 40 Feet Wide Road: First Floor Brick Work Detail DrawingDocument1 page40 Feet Wide Road: First Floor Brick Work Detail DrawingPriya DarshiniNo ratings yet

- Marketing Gallery Pancang Podomoro ParklandDocument1 pageMarketing Gallery Pancang Podomoro ParklandAditya PurnamaNo ratings yet

- Detour ShiftDocument1 pageDetour ShiftinforumdocsNo ratings yet

- P1 ReeDocument1 pageP1 ReeHUGO VARGAS LIJERONNo ratings yet

- Sample Details (2nd)Document1 pageSample Details (2nd)Md SuruzzamanNo ratings yet

- De - R.C8.02.03.00 - Plan Dispunere Goluri InstalatiiDocument1 pageDe - R.C8.02.03.00 - Plan Dispunere Goluri InstalatiiMihai DimaNo ratings yet

- Nurse Call ,Clock and Queuing SystemDocument9 pagesNurse Call ,Clock and Queuing Systemmousa abdallaNo ratings yet

- Relish GateDocument1 pageRelish GateAffan IqbalNo ratings yet

- Sheet 3 PDFDocument1 pageSheet 3 PDFudhav cNo ratings yet

- September FlautaDocument1 pageSeptember FlautaJuan PlazaNo ratings yet

- Llorarás UTP-PianoDocument4 pagesLlorarás UTP-PianoJ.A.N.S xdNo ratings yet

- Playas de Carmen (1) - 1Document1 pagePlayas de Carmen (1) - 1Silvia FigueredoNo ratings yet

- Apiic Challapalli An & IpDocument1 pageApiic Challapalli An & IpAPSFC VijayawadaNo ratings yet

- 729 PBM SD Ele 00 03 R0Document1 page729 PBM SD Ele 00 03 R0Aizhar John QuindozaNo ratings yet

- TNGIM - Hall LayoutDocument1 pageTNGIM - Hall LayoutAshish Angelz ExhibitionsNo ratings yet

- 01) Trumpet 1 - El Año ViejoDocument2 pages01) Trumpet 1 - El Año ViejoAdrianyNo ratings yet

- Detail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5Document1 pageDetail Buttress (4X) Section 4 - 4 Detail Buttress (4X) Section 5 - 5joselito navarroNo ratings yet

- g214599 Hmod 65 Paulander DR Kitchener DWGDocument2 pagesg214599 Hmod 65 Paulander DR Kitchener DWGJhonn StevNo ratings yet

- AllisonDocument1 pageAllisoncarlos audel verduzco vidriosNo ratings yet

- Circo Mix Trompeta DoDocument1 pageCirco Mix Trompeta DoFRANCISCO CLARAMONTE PATERNANo ratings yet

- Ray Charles - Hit The Road Jack - EASYDocument2 pagesRay Charles - Hit The Road Jack - EASYIda MorettiNo ratings yet

- G216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgDocument5 pagesG216338-Hmod-Near 80 Black Walnut Dr-Kitchener-DwgJhonn StevNo ratings yet

- John Williams - Schindlers List Main Theme For Violin and PianoDocument5 pagesJohn Williams - Schindlers List Main Theme For Violin and PianoEnrique Motolinia JuarezNo ratings yet

- PERI TRIO Formwork For Tank-LayoutDocument1 pagePERI TRIO Formwork For Tank-LayoutAhmed Salah El DinNo ratings yet

- Ploteo Final Bloque I-R2 0+860.00 - 2+080.00Document1 pagePloteo Final Bloque I-R2 0+860.00 - 2+080.00huichoNo ratings yet

- Pastime FlûteDocument1 pagePastime FlûteMeliodas SamaNo ratings yet

- Pastime FlûteDocument1 pagePastime FlûteMeliodas SamaNo ratings yet

- PLM Layout JSC GENERALDocument1 pagePLM Layout JSC GENERALuqNo ratings yet

- Structural Design of SHORING SYSTEMDocument25 pagesStructural Design of SHORING SYSTEMWaseq VastiNo ratings yet

- Zeiss CeilingDocument1 pageZeiss CeilingShantanuNo ratings yet

- Allegro CantabileDocument3 pagesAllegro CantabileAngela GohNo ratings yet

- Valley Metro System MapDocument1 pageValley Metro System MapLục Ẩn ĐạtNo ratings yet

- SKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLDocument1 pageSKEMA - TV - LG - 21FU3RL - Pdffilename - UTF-8SKEMA-20TV-20LG-2021FU3RLyusrianto Nusamaine windewani100% (2)

- All of MeDocument6 pagesAll of MeHilcias SalazarNo ratings yet

- Reception Lobby REVISEDDocument1 pageReception Lobby REVISEDhimanshu sainiNo ratings yet

- 1-ModelDocument1 page1-Modeljoselito navarroNo ratings yet

- Drainage System Detail LegendDocument1 pageDrainage System Detail Legenddothi aiuyenNo ratings yet

- 04 11 12 Garcia Calderon JheysonDocument1 page04 11 12 Garcia Calderon JheysonJheyson Garcia CalderonNo ratings yet

- Platform ADocument1 pagePlatform ACosmescu AnaNo ratings yet

- (Steps Going To Deck Roof) : LegendDocument1 page(Steps Going To Deck Roof) : LegendLowie Torres TonioNo ratings yet

- Cco-U551-070743-090000-0003 R1Document1 pageCco-U551-070743-090000-0003 R1gregorio martinezNo ratings yet

- ASF 607-02 - AD-518 (Rev - A)Document1 pageASF 607-02 - AD-518 (Rev - A)Haseeb RazviNo ratings yet

- BM1 X 973.941 Y 1068.308: Jl. Prabu RangkasariDocument1 pageBM1 X 973.941 Y 1068.308: Jl. Prabu Rangkasaripp banjaratmaNo ratings yet

- Proposed BulkheadDocument1 pageProposed BulkheadJohn Michael LimNo ratings yet

- CF-1, CF-3, Ceiling Mounted Vent Cap LegendDocument1 pageCF-1, CF-3, Ceiling Mounted Vent Cap LegendJohn Michael LimNo ratings yet

- Flower Duet From Lakm by Lo Delibes Transcription For Violin and Piano-PianoDocument3 pagesFlower Duet From Lakm by Lo Delibes Transcription For Violin and Piano-Pianomarcus martin100% (1)

- Flower Duet Piano Sheet MusicDocument3 pagesFlower Duet Piano Sheet Musicmarcus martinNo ratings yet

- SCR 003938Document1 pageSCR 003938jeplgpbmcNo ratings yet

- Perfil Eje Canal: PLANTA: (3+000 - 3+503.25)Document1 pagePerfil Eje Canal: PLANTA: (3+000 - 3+503.25)carlos portalatino la rosaNo ratings yet

- Facade Front-Elevation: at Axis ADocument1 pageFacade Front-Elevation: at Axis AsartajNo ratings yet

- 4124 Ai Du 21710020VS01 Is03 - CheckprintDocument1 page4124 Ai Du 21710020VS01 Is03 - CheckprintamitNo ratings yet

- BP MDBDocument1 pageBP MDBOm KumarNo ratings yet

- F 1646 A-4 Elevator Sections May 01 2018Document1 pageF 1646 A-4 Elevator Sections May 01 2018autocadplease6213No ratings yet

- Plan - J04 - Restaurant Table: Legends & FinishesDocument1 pagePlan - J04 - Restaurant Table: Legends & FinishesHoward RoarkNo ratings yet

- Approved Siteplan Noida 117Document1 pageApproved Siteplan Noida 117Qwerty QwertyNo ratings yet

- Siteplan 1Document1 pageSiteplan 1muhammadulil abrorNo ratings yet

- Merry Go Round of LifeDocument6 pagesMerry Go Round of LifeJose GarciaNo ratings yet

- Siteplan 2Document1 pageSiteplan 2muhammadulil abrorNo ratings yet

- Instant Assessments for Data Tracking, Grade 1: Language ArtsFrom EverandInstant Assessments for Data Tracking, Grade 1: Language ArtsNo ratings yet

- Corprate Clients ChargesDocument1 pageCorprate Clients ChargesSemeeeJuniorNo ratings yet

- Inpatient Pre Authorization FormDocument1 pageInpatient Pre Authorization FormSemeeeJuniorNo ratings yet

- GBV Q1 Additional DataDocument2 pagesGBV Q1 Additional DataSemeeeJuniorNo ratings yet

- Cpi 092019Document3 pagesCpi 092019SemeeeJuniorNo ratings yet

- Provision For Hire of Transport Plant and EquipmentDocument42 pagesProvision For Hire of Transport Plant and EquipmentSemeeeJuniorNo ratings yet

- What Is The Meaning of 1 Corinthians 69-11Document2 pagesWhat Is The Meaning of 1 Corinthians 69-11SemeeeJuniorNo ratings yet

- Major Surgery - ORIFDocument1 pageMajor Surgery - ORIFSemeeeJuniorNo ratings yet

- Blood Issuing FormDocument3 pagesBlood Issuing FormSemeeeJuniorNo ratings yet

- Blood Issuing FormDocument2 pagesBlood Issuing FormSemeeeJuniorNo ratings yet

- Alternate Row Colors in Grids with JSDocument1 pageAlternate Row Colors in Grids with JSSemeeeJuniorNo ratings yet

- Upper BCDocument1 pageUpper BCSemeeeJuniorNo ratings yet

- Blood Issuing FormDocument2 pagesBlood Issuing FormSemeeeJuniorNo ratings yet

- Ines 2Document1 pageInes 2SemeeeJuniorNo ratings yet

- Blood Issuing FormDocument3 pagesBlood Issuing FormSemeeeJuniorNo ratings yet

- Ineos 2Document1 pageIneos 2SemeeeJuniorNo ratings yet

- KyeopDocument1 pageKyeopSemeeeJuniorNo ratings yet

- Alternate Row Colors in Grids with JSDocument1 pageAlternate Row Colors in Grids with JSSemeeeJuniorNo ratings yet

- Bhutan Tender for Solar Home & Street Lighting SystemsDocument1 pageBhutan Tender for Solar Home & Street Lighting SystemsSemeeeJuniorNo ratings yet

- ST DesignDocument2 pagesST DesignSemeeeJuniorNo ratings yet

- Blood Issuing Form.Document2 pagesBlood Issuing Form.SemeeeJuniorNo ratings yet

- OlerDocument2 pagesOlerSemeeeJuniorNo ratings yet

- Liaison Healthcare Pre-Authorization NoticeDocument1 pageLiaison Healthcare Pre-Authorization NoticeSemeeeJuniorNo ratings yet

- GTH 79Document2 pagesGTH 79SemeeeJuniorNo ratings yet

- KyerDocument1 pageKyerSemeeeJuniorNo ratings yet

- Ki LowerDocument4 pagesKi LowerSemeeeJuniorNo ratings yet

- GTH 12Document3 pagesGTH 12SemeeeJuniorNo ratings yet

- Stdesign 2Document3 pagesStdesign 2SemeeeJuniorNo ratings yet

- Understanding an Institution Through Student AttachmentDocument1 pageUnderstanding an Institution Through Student AttachmentSemeeeJuniorNo ratings yet

- ST Design3 PDFDocument6 pagesST Design3 PDFSemeeeJuniorNo ratings yet

- Nhif Application PDFDocument1 pageNhif Application PDFSemeeeJuniorNo ratings yet

- 现在分词作状语Document27 pages现在分词作状语Vincent XinNo ratings yet

- Book of DevilsDocument29 pagesBook of Devilsdragonblack6No ratings yet

- Variations Within SupersessionismDocument18 pagesVariations Within SupersessionismAnonymous ZPZQldE1LNo ratings yet

- Kalki: 3 PuranasDocument7 pagesKalki: 3 PuranasSowjanyaKarnamNo ratings yet

- Sentence: Simple Sentence & Compound SentenceDocument4 pagesSentence: Simple Sentence & Compound SentenceRizky MayaNo ratings yet

- The Divine Mercy PRAYER AND CHAPLETDocument3 pagesThe Divine Mercy PRAYER AND CHAPLETBeni Brendz Quizon JanairoNo ratings yet

- BEED 2-1 Policarpio, Maricris V - Research EtruscanDocument9 pagesBEED 2-1 Policarpio, Maricris V - Research EtruscanMaricris ValenzuelaNo ratings yet

- LiteratureDocument14 pagesLiteraturetawas20No ratings yet

- MSCY 511/611 Take-home quiz #3 - Tanut VongsoontornDocument1 pageMSCY 511/611 Take-home quiz #3 - Tanut VongsoontornTanut VongsoontornNo ratings yet

- SevanavankDocument4 pagesSevanavankBoris ČelebićNo ratings yet

- Prayer To Break Off Generational CursesDocument5 pagesPrayer To Break Off Generational CursesRonald ManyamaNo ratings yet

- Ad Mad 2012Document29 pagesAd Mad 2012Aman KukrejaNo ratings yet

- Aladdin's Magical Lamp and GenieDocument5 pagesAladdin's Magical Lamp and GenieLeachez Bbdear BarbaNo ratings yet

- SwallaDocument1 pageSwallaHarold AlonsoNo ratings yet

- Review of Julian Apostata by Richard KleinDocument7 pagesReview of Julian Apostata by Richard Kleinj.miguel593515No ratings yet

- TBT 03 Plan To Help A Friend Flannel Graph Color enDocument8 pagesTBT 03 Plan To Help A Friend Flannel Graph Color enMyWonderStudio100% (64)

- English 6Document3 pagesEnglish 6PrinsesangmanhidNo ratings yet

- An Audio Tale of Revenge and DeceptionDocument27 pagesAn Audio Tale of Revenge and DeceptionSara Lo0% (1)

- Ba Zi. The Four Pillars of Destiny. Understanding Character Relationships and Potential Through Chinese Astrology PDFDocument172 pagesBa Zi. The Four Pillars of Destiny. Understanding Character Relationships and Potential Through Chinese Astrology PDFHappybaby100% (5)

- Mirabai Classics of Immortal Verses.Document154 pagesMirabai Classics of Immortal Verses.Hasibuan Santosa100% (1)

- Victor Hugo-The Last Day of A Condemned ManDocument29 pagesVictor Hugo-The Last Day of A Condemned ManIshan Marvel50% (2)

- Learn English With Ted TalksDocument2 pagesLearn English With Ted TalksHassan J. QawasNo ratings yet

- ASTMDocument18 pagesASTMtaya14010% (1)

- 1 Thessalonians 5:12-28 Dennis Mock Sunday, FebruaryDocument4 pages1 Thessalonians 5:12-28 Dennis Mock Sunday, Februaryapi-26206801No ratings yet

- TimeBomb PDFDocument4 pagesTimeBomb PDFEduardoNo ratings yet

- PIPPIN: The Fosse LinesDocument11 pagesPIPPIN: The Fosse LinesGibson DelGiudice100% (2)

- Contemporary World QuizDocument16 pagesContemporary World QuizPrincess Jhoie Corpuz0% (1)

- Citizen Kane Script by Herman J. Mankiewicz and Orson Welles PDFDocument135 pagesCitizen Kane Script by Herman J. Mankiewicz and Orson Welles PDFFlavio Roberto Mota100% (2)

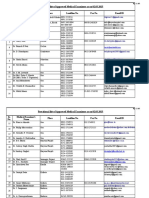

- List Provisional Medicalexaminer 020315Document10 pagesList Provisional Medicalexaminer 020315Arnav JoshiNo ratings yet

- AH312 Art National Socialism A Soika A Meyer PDFDocument11 pagesAH312 Art National Socialism A Soika A Meyer PDFJohn SebastianNo ratings yet