Professional Documents

Culture Documents

Adjusting Hard Points Tutorial

Uploaded by

rudey18Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adjusting Hard Points Tutorial

Uploaded by

rudey18Copyright:

Available Formats

Adams/Car Tutorial

Modifying Suspension Hardpoints

Warning: Remember to change your working directory before you begin this lesson. If you do not,

Adams may not work correctly. Also remember to move everything you wish to keep from the working

directory before you log off. See the Opening Files tutorial for more information.

Overview

In ADAMS/Car hardpoints are the building blocks for larger components. The hardpoints are

essentially the joint locations for the parts of the vehicle. In ADAMS/Car you will move

suspension hardpoints to change suspension kinematics, steering hardpoints to change steering

characteristics, etc. For example, you can move the outer steering tierod connection to the

upright to adjust Ackermann steering. When you move a hardpoint, ADAMS/Car moves the

joint location to the position you specify. The actual connections at the hardpoints are modeled

as ideal joints with specified degrees of freedom or bushings with 6 degrees of freedom and joint

stiffnesses.

The FSAE and Mini-Baja frames have no role in defining hardpoint locations. Hardpoints

mounted to the frame are all connected to a rigid chassis. The image of the frame has no

structural role in ADAMS/Car.

Common abbreviations found while modifying the suspension are found below.

hp[lr] hardpoint left or right

arb anti roll bar

lca lower control arm

prod push rod

uca upper control arm

Control Arm Hardpoints

The suspension control arm geometry defines suspension properties such as roll center, motion

ratio and camber profile. With ADAMS/Car you can adjust the control arm geometry by

adjusting hardpoints and then simulate wheel travel to determine the kinematics for the new

geometry. The FSAE model has independent suspensions front and rear. The Mini-Baja model

has independent front suspension and an independent or rear swing arm suspension. To modify

the control arm of an open suspension subsystem click Adjust>Hardpoint>Table and the

Hardpoint Modification Table will appear.

Version 1.0 6/18/2008 1

Below are the hardpoint tables for the FSAE and Mini-Baja front suspensions with the upper and

lower control arm hardpoints highlighted.

Version 1.0 6/18/2008 2

Mini-Baja Swing Arm

The swing arm found on the Mini-Baja can not be simulated by its self. A full vehicle assembly

must be opened to simulate swing arm motion.

Pushrod, Bellcrank & Shock Hardpoints (FSAE)

When modifying the bell crank placement on the FSAE model you must enter the position of the

joint connection to the chassis (hpl_bellcrank_pivot) and a point to define the rotation axis

(hpl_bellcrank_pivot_orient). The other points defining the bell crank are the pushrod, anti-roll

bar and shock connections (hpl_prod_to bellcrank and hpl_shock_to_bellcrank). The

connection of the pushrod to the upright is hpl_prod_outer. The shock connection to the chassis

is hpl_shock_to_chassis. If you wish to design a pullrod suspension converting the pushrod

system is simply a matter of changing the geometry of the components. The image of the

bellcrank is defined by the positions of the bellcrank pivot, pushrod location, and anti-roll bar.

When these connections move the image of the bellcrank will update.

The Mini-Baja has a simpler suspension design and the shocks mount directly to the

control/swingarm and chassis. The shock is modeled with two hardpoints; one to the control

arm or swing arm and one to the chassis.

Anti-Roll Bar Hardpoints (FSAE)

The hardpoints of the anti-roll bar geometry is modified using the fsae_front_arb subsystem with

the exception of the connection to the bell crank (hpl_ arblink_to_bellcrank) which is modified

on the fsae_front_susp subsystem. The anti-roll bar bushing mount (hpl_arb_bushing_mount) is

listed in the fsae_front_susp subsystem but cannot be modified there. You will need to move the

hardpoint hpl_arb_bushing to coincide with the anti-roll bar system to insure the system works

properly. Having hardpoints hpl_arb_bushing and hpl_arb_bend at the same point works well.

Version 1.0 6/18/2008 3

hpl_arblink_to_bellcrank

hpl_droplink_to_arb

hpl_arb_bushing

hpl_arb_middle

hpl_arb_bend

Steering Hardpoints

In the FSAE steering system the steering rack placement is defined by the location of the inner

tierods found on the front suspension subsystem. When the inner tierod positons move the rack

moves with them. The pinion and rack do no have to coincide to work properly. ADAMS uses

input and output communicators to relay the displacement information. The model has two

joints between the steering wheel and pinion, and can be placed with creating an angle between

intermediate shafts.

Version 1.0 6/18/2008 4

Steering intermediate

joints

The Mini-Baja steering shaft must be straight from the pinion (hps_pinion_pivot) to the steering

wheel center (hps_steering_wheel_center). Between the pinion and steering wheel center are

two intermediate points (hps_intermediate_shaft_forward and

hps_intermediate_shaft_rearward). You will need to move these points to create a straight

steering shaft from the steering wheel to the pinion. The shaft must be straight in order for the

steering to work properly. In the template the pinion and rack are coincident. This does not have

to be the case. You could move the steering rack and inner tierods forward and leave the pinion

Version 1.0 6/18/2008 5

and steering shaft in its original position. There does not have to be a visible connection between

the pinion and the rack.

Pinion and rack are

coincident in template

hps_intermediate_shaft_forward

hps_intermediate_shaft_rearward

Version 1.0 6/18/2008 6

Modifying the FSAE Front Suspension

Obtain and save the FSAE template. Open ADAMS/Car and add the database to the session by

clicking Tools>Database Management>Add to Session. Navigate to the location you have

saved the FSAE template to add.

Open the FSAE front suspension assembly by clicking File>Open>Assembly. Navigate to the

FSAE assemblies.tbl folder and select fsae_front_with_steer.

The default units for the FSAE model are millimeter, kilogram, and newtons. Change the units

to inches, pounds mass, and pounds force by going to Settings>Units.

Version 1.0 6/18/2008 7

Click the IPS button at the bottom of the window to change the units. Click OK.

Version 1.0 6/18/2008 8

From the menu select Modify> Adjust> Table.

The Hardpoint Modification Table will appear. Click the arrow in the top center to see the

subsystems that have hardpoints that you can adjust. Notice the front suspension, steering, and

anti-roll bar subsystems make up this assembly and have hardpoints you can modify. The origin

for the assembly is at an arbitrary location. Placement of the hardpoints will need to be made

relative to other hardpoints in the suspension.

Subsystems

Hardpoints to show

Version 1.0 6/18/2008 9

At the bottom left of the Hardpoint Modification Table you have the option to view the left,

right, or both sides of the vehicle. If left or right is selected then you will be entering changes for

that side of the vehicle but changing both sides symmetrically. To modify the hardpoints for the

front suspension make sure fsae_front_susp is selected and simply enter a new value for the

loc_x, loc_y, or loc_z positions. Then click OK or Apply to make the changes.

Six points determine the control arm geometry at one wheel. For the upper and lower control

arms there are outer, front and rear hardpoint locations. The names for theses hardpoints are

hpl_lca_front, hpl_lca_outer, hpl_lca_rear, hpl_uca_front, hpl_uca_outer, and hpl_uca_rear.

New position values can be entered into the table.

Looking at the model space, notice the coordinate axes at the bottom left-hand corner of the

window has the positive x-direction towards the rear and the positive y-direction towards the

right from the driver’s perspective. Obtain a front view of the assembly by right clicking on the

workspace and selecting Front. With the Hardpoint Modification Table open change the loc_y

values for hpl_uca_front and hpl_uca_rear from -7.876 to -12 and click Apply. Notice that the

inboard upper control arm connections have been moved outward from the center of the vehicle

thus shortening them.

Version 1.0 6/18/2008 10

Now adjust the outboard lower control arm connection changing both the kingpin and caster

angles. Reduce the kingpin angle by making the loc_y value for hpl_lca_outer -26 and observe

the change in kingpin. Now obtain a side view of the assembly by holding “r” + left mouse

button to rotate. Change the loc_x position for hpl_lca_outer to -23, click Apply and observe the

increase in caster angle.

The pushrod, bellcrank, and shock parts in the template are not planar at the design position and

the pivot orient is not perpendicular to the face of the bellcrank. Make the following changes to

the system to create a planar system with a perpendicular pivot orient. When done making

changes click Apply. Rotate the system to confirm the pushrod, bellcrank, and shock are planar.

hpl_prod_outer (-18.2, 27.1, 0.1), hpl_prod_to_bellcrank (-17.2, -9.9, 17.4),

hpl_ bellcrank_pivot (-14.2, -10, 17.1), hpl_bellcrank_pivot_orient (-14.6, -2.9, 10.1),

hpl_shock_to_bellcrank(-15.2, -8.3, 18.9), hpl_shock_to_chassis (-5.2, -8, -18.7),

hpl_arblink_to_bellcrank( -15.2,-8.3,-18.9).

Version 1.0 6/18/2008 11

Adjust the steering tierod by making the following modifications. Click Apply and notice that the

steering rack moves with the placement of the inner tierod.

hpl_tierod_inner (-14, -12, 3), hpl_tierod_outer (-18,-23, 3)

Move the wheel center to the following position. Click Apply and observe the change in wheel

position.

hpl_wheel_center (-21.5 -27.6, 6)

Select the anti-roll bar subsystem in the Hardpoint Modification Table. View the anti-rollbar

subsystem be clicking View>Subsytem, and selecting fsae_front_arb. To insure the system

works properly you will need to move the hardpoint hpl_arb_bushing to coincide with the anti-

roll bar system. Move the anti-roll bar to the following positions and click Apply.

hpl_arb_bend (-20.2, -8.3, 23), hpl_arb_bushing (-20.2, -8, 23),

hpl_arb_middle (-20.2, 0, 23), hpl_droplink_to_arb(-20.2,-8.3,-18.9)

Additional Information:

There are a few points in the Mini-Baja suspensions that are not used directly for the suspension.

The front suspension has drive shaft and subframe mounts. The drive shaft is used in the rear

suspension.

These

hardpoints

are not used

Mini-Baja front suspension

Version 1.0 6/18/2008 12

These

hardpoints

are not

used

Mini-Baja rear suspension

Warning: Remember to change your working directory before you begin this lesson. If you do not,

Adams may not work correctly. Also remember to move everything you wish to keep from the working

directory before you log off. See the Opening Files tutorial for more information.

Version 1.0 6/18/2008 13

You might also like

- 12 Things to Know about Suspension Engineering for Lifted JeepsDocument7 pages12 Things to Know about Suspension Engineering for Lifted JeepsPeter SchmidtNo ratings yet

- Adams Car AnalysisDocument146 pagesAdams Car AnalysisAnderson MoribeNo ratings yet

- Rear Steer InstructionsDocument6 pagesRear Steer InstructionsFernando KinematNo ratings yet

- Connections Joints ADAMSDocument8 pagesConnections Joints ADAMSSantiago MolinaNo ratings yet

- Slot.it HRS 1/32 scale universal chassis adapts to many bodiesDocument9 pagesSlot.it HRS 1/32 scale universal chassis adapts to many bodiesangel erguera martinezNo ratings yet

- Double Wishbone SuspensionDocument2 pagesDouble Wishbone SuspensionAkash MahajanNo ratings yet

- WheelController SetupDocument13 pagesWheelController SetupSlow Pork FFNo ratings yet

- Adjust Suspension Hardpoints to Replicate 2011 Hybrid Formula 1 SetupDocument4 pagesAdjust Suspension Hardpoints to Replicate 2011 Hybrid Formula 1 SetupyagoegayNo ratings yet

- Brake Balance BAR: and Twin Master Cylinder Hydraulic Braking SystemDocument20 pagesBrake Balance BAR: and Twin Master Cylinder Hydraulic Braking SystemHasnain SaleemNo ratings yet

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- 4b2dc6_de77b69bcbe7425b93786e8d8c2477faDocument17 pages4b2dc6_de77b69bcbe7425b93786e8d8c2477famysecondacc788No ratings yet

- Slash Spec Racing Setup GuideDocument9 pagesSlash Spec Racing Setup GuideTodd AlexanderNo ratings yet

- Upright DesignDocument5 pagesUpright DesignFiras HelouNo ratings yet

- Double Wishbone SuspensionDocument5 pagesDouble Wishbone SuspensionalexmarieiNo ratings yet

- NAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeDocument10 pagesNAFEMS Auto Unified CAE Analysis For A Leaf Spring TypeIndranil BhattacharyyaNo ratings yet

- Quick Car Setup Guide Williams Toyota FW31Document8 pagesQuick Car Setup Guide Williams Toyota FW31maferioNo ratings yet

- Modal and Stress Analysis of Lower Wishbone Arm Along With TopologyDocument7 pagesModal and Stress Analysis of Lower Wishbone Arm Along With TopologyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Technical Tuning Tips for ZF Sachs DampersDocument6 pagesTechnical Tuning Tips for ZF Sachs DampersJason QuinnNo ratings yet

- Commodore - S Garage #10 - Track Bar - IracingDocument4 pagesCommodore - S Garage #10 - Track Bar - IracingHitesh VashistNo ratings yet

- Peterbilt Essentials Module5 Axles SuspensionsDocument20 pagesPeterbilt Essentials Module5 Axles Suspensionsnorth-piligrim100% (5)

- 1/10TH SCALE 4WD RACECAR SETUP GUIDEDocument40 pages1/10TH SCALE 4WD RACECAR SETUP GUIDEShefin ShukkoorNo ratings yet

- Balancing of Shaft CouplingsDocument5 pagesBalancing of Shaft CouplingsSulagna Roy100% (1)

- Front Suspension OverviewDocument10 pagesFront Suspension OverviewDurganshuNo ratings yet

- Irjet V7i480Document7 pagesIrjet V7i480DushyantNo ratings yet

- Emerson Power Transmission Corp. JRM11.PDF Types of Coupling BalanceDocument12 pagesEmerson Power Transmission Corp. JRM11.PDF Types of Coupling BalanceLasse HansenNo ratings yet

- Alignment Angles ExplainedDocument4 pagesAlignment Angles ExplainedAnonymous QiMB2lBCJLNo ratings yet

- Design UprightDocument5 pagesDesign UprightJohn HopkinsNo ratings yet

- Steady State Handling: B C D FDocument5 pagesSteady State Handling: B C D FFabio MiguelNo ratings yet

- Chapter 01 Introducing Lotus Suspension AnalysisDocument4 pagesChapter 01 Introducing Lotus Suspension AnalysisEhhyeyiNo ratings yet

- Irjet V7i51227Document7 pagesIrjet V7i51227Ashbin BIJUNo ratings yet

- Suspension ReportDocument5 pagesSuspension Reportadithiyan saravananNo ratings yet

- 07 E65+Suspension+&+Steering PDFDocument21 pages07 E65+Suspension+&+Steering PDFMshiboniumNo ratings yet

- Tms700e13 SM Ctrl512 01 Spanish With Alignment SuppDocument390 pagesTms700e13 SM Ctrl512 01 Spanish With Alignment SuppVictor VegaNo ratings yet

- Linked PDFDocument244 pagesLinked PDFroparts clujNo ratings yet

- Change a Stepper MotorDocument10 pagesChange a Stepper MotorJorge GomisNo ratings yet

- Analysis For Suspension Hardpoint of Formula SAE Car Based On Correlation TheoryDocument6 pagesAnalysis For Suspension Hardpoint of Formula SAE Car Based On Correlation TheoryAJHAY BABU J KNo ratings yet

- Camaro High Performance Suspension TuningDocument5 pagesCamaro High Performance Suspension TuningSarawoot Watechagit100% (1)

- Balanced SuspensionDocument13 pagesBalanced SuspensionRonald GeorgeNo ratings yet

- Concept 10.5 Dual Disc Installation InstructionsDocument6 pagesConcept 10.5 Dual Disc Installation Instructionstanijk444No ratings yet

- Design of Formula SAE Brake SystemsDocument6 pagesDesign of Formula SAE Brake SystemsFuinha120194No ratings yet

- Understanding Crankshaft BalancingDocument5 pagesUnderstanding Crankshaft BalancingVontrex DergonNo ratings yet

- Mounting Wheel Rim To Servo - Author - Jason JodarskiDocument6 pagesMounting Wheel Rim To Servo - Author - Jason Jodarskia_ekisNo ratings yet

- Frame - NoteDocument26 pagesFrame - NoteYudha UfikNo ratings yet

- Ackermann Steering GeometryDocument6 pagesAckermann Steering Geometry29 - Heaven JosiahNo ratings yet

- TMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFDocument414 pagesTMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFJhonnatan Alexis roaNo ratings yet

- Design Modification and Harmonic Analysis of Rocker ArmDocument3 pagesDesign Modification and Harmonic Analysis of Rocker ArmRaja VenkateshNo ratings yet

- Driveline Instructions 1Document3 pagesDriveline Instructions 1Pete Da HeatNo ratings yet

- Getting Started with Flexible BodiesDocument24 pagesGetting Started with Flexible BodiesEmir EsimNo ratings yet

- Balance Bar SetupDocument5 pagesBalance Bar SetupRaviJoshiNo ratings yet

- 93LH 2Document72 pages93LH 2prueba5No ratings yet

- Gear Box ReportDocument39 pagesGear Box ReportNisar HussainNo ratings yet

- Driveshaft Vibration AnalysisDocument8 pagesDriveshaft Vibration AnalysisPrasadNo ratings yet

- Technical Information About Steering Gears and Steering PumpsDocument37 pagesTechnical Information About Steering Gears and Steering PumpsVictor BalasNo ratings yet

- Spring Rate CalculatorDocument29 pagesSpring Rate CalculatorMari MuthuNo ratings yet

- Risa FoundationDocument14 pagesRisa Foundationpolin27No ratings yet

- Boss Boss Boss BOSS 302 302 302 302: S S S SDocument6 pagesBoss Boss Boss BOSS 302 302 302 302: S S S S2791957No ratings yet

- Flexible Bodies Tutorial: Working with Flexible Suspension ComponentsDocument24 pagesFlexible Bodies Tutorial: Working with Flexible Suspension Componentsmaliq12No ratings yet

- Shock Absorber Basics: Adjustability Costs Money. How Fast Do You Want To Go?Document4 pagesShock Absorber Basics: Adjustability Costs Money. How Fast Do You Want To Go?bile007mNo ratings yet

- Chevy Differentials: How to Rebuild the 10- and 12-BoltFrom EverandChevy Differentials: How to Rebuild the 10- and 12-BoltRating: 5 out of 5 stars5/5 (8)

- Vehicle Chassis Normal Frequency Analysis and Design OptimizationDocument20 pagesVehicle Chassis Normal Frequency Analysis and Design Optimizationrudey18No ratings yet

- Nav 009Document10 pagesNav 009Vishnu Vardhan Reddy YerasiNo ratings yet

- FEM Stress Analysis of Light Vehicle ChassisDocument5 pagesFEM Stress Analysis of Light Vehicle ChassisSankalp SharmaNo ratings yet

- An Investigation of Disc Brake Rotor Using FeaDocument12 pagesAn Investigation of Disc Brake Rotor Using Fearudey18No ratings yet

- Entry Fee - 2018Document2 pagesEntry Fee - 2018rudey18No ratings yet

- Finite Element Analysis of An ANSI Roller Chain SprocketDocument3 pagesFinite Element Analysis of An ANSI Roller Chain SprocketSuman RajNo ratings yet

- Crashworthiness Analysis of Fe Truck Chassis Model Using Ls - DynaDocument10 pagesCrashworthiness Analysis of Fe Truck Chassis Model Using Ls - Dynarudey18No ratings yet

- Brake Squeal Noise - Finite Element AnalysisDocument6 pagesBrake Squeal Noise - Finite Element Analysisrudey18No ratings yet

- Design of Lightweight Disc Brake Using Finite Element Analysis and Taguschi TechniqueDocument11 pagesDesign of Lightweight Disc Brake Using Finite Element Analysis and Taguschi Techniquerudey18No ratings yet

- Component Fatigue Behaviour and Life Prediction of Steering Knuckle Using Fea PDFDocument6 pagesComponent Fatigue Behaviour and Life Prediction of Steering Knuckle Using Fea PDFrudey18No ratings yet

- Analysis of Chassis Parts Using Catia Fea: Lee Dong JaeDocument20 pagesAnalysis of Chassis Parts Using Catia Fea: Lee Dong JaeAditya VenkatesanNo ratings yet

- Adams ChassisDocument4 pagesAdams Chassisrudey18100% (1)

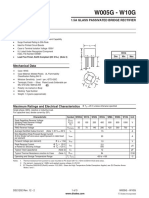

- w10g - Passivated Bridge RectifierDocument3 pagesw10g - Passivated Bridge Rectifierrudey18No ratings yet

- Adventure Trial - 4x4Document60 pagesAdventure Trial - 4x4rudey18No ratings yet

- Moto Adventure TrialDocument52 pagesMoto Adventure Trialrudey18No ratings yet

- Performanceparameters 130314093018 Phpapp01Document19 pagesPerformanceparameters 130314093018 Phpapp01rudey18No ratings yet

- Extreme 4x4Document54 pagesExtreme 4x4rudey18No ratings yet

- Extreme MotoDocument48 pagesExtreme Motorudey18No ratings yet

- Commercial Vehicles and MAN Trucks GuideDocument34 pagesCommercial Vehicles and MAN Trucks Guiderudey18No ratings yet

- Br1010 Full Bridge RectifierDocument4 pagesBr1010 Full Bridge Rectifierrudey18No ratings yet

- TPA3116D2 15-W, 30-W, 50-W Filter-Free Class-D Stereo Amplifier Family With AM AvoidanceDocument44 pagesTPA3116D2 15-W, 30-W, 50-W Filter-Free Class-D Stereo Amplifier Family With AM Avoidancekishore_bulli6666No ratings yet

- Kbpc3504 Full Bridge RectifierDocument2 pagesKbpc3504 Full Bridge Rectifierrudey18No ratings yet

- TPA3110D2 15-W Fil Ter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™Document36 pagesTPA3110D2 15-W Fil Ter-Free Stereo Class-D Audio Power Amplifier With Speakerguard™zidi elektronikNo ratings yet

- How Differential WorksDocument23 pagesHow Differential Worksjohnplaya1234100% (1)

- TDA8932B: 1. General DescriptionDocument48 pagesTDA8932B: 1. General Descriptionrudey18No ratings yet

- Academic Calendar 2014-15-15Document13 pagesAcademic Calendar 2014-15-15rudey18No ratings yet

- Research PolicyDocument29 pagesResearch Policyrudey18No ratings yet

- New 1224201435702pmarai Academy Brochure 191214Document2 pagesNew 1224201435702pmarai Academy Brochure 191214rudey18No ratings yet

- NASCAR & Chemical Reactions!Document12 pagesNASCAR & Chemical Reactions!rudey18No ratings yet

- Important SeminarsDocument1 pageImportant Seminarsrudey18No ratings yet

- Repair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat ExchangerDocument8 pagesRepair of Tube-Tubesheet Weld Cracks in A Cracked Gas/Steam Heat Exchangermontie3No ratings yet

- BMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)Document2 pagesBMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)YeisonNo ratings yet

- Models - Mph.pid ControlDocument14 pagesModels - Mph.pid ControlArunkumar SeshadriNo ratings yet

- Bezmasleni Kompresori Za Pet Industriata Siad PDFDocument8 pagesBezmasleni Kompresori Za Pet Industriata Siad PDFplasticos_jfm6580No ratings yet

- NEF Coupling Catalog English 20061201Document48 pagesNEF Coupling Catalog English 20061201Aryo WicaksonoNo ratings yet

- Greenstar 25Si/30Si: User Instructions & Customer Care GuideDocument20 pagesGreenstar 25Si/30Si: User Instructions & Customer Care GuideJBNo ratings yet

- Connection HCS PDFDocument25 pagesConnection HCS PDFPranay UpadhyayNo ratings yet

- PACCAR MX Engine Reference Sheet PDFDocument2 pagesPACCAR MX Engine Reference Sheet PDFMalique ChamauneNo ratings yet

- The Extended Rayleigh-Ritz Method For An Analysis of Nonlinear VibrationsDocument7 pagesThe Extended Rayleigh-Ritz Method For An Analysis of Nonlinear VibrationsGuilherme NagaeNo ratings yet

- Climate Control PDFDocument80 pagesClimate Control PDFArivup PavalanNo ratings yet

- A Review of Pipeline Defect Assessment Manual (PDAM) ProjectDocument6 pagesA Review of Pipeline Defect Assessment Manual (PDAM) ProjectOs SanchezNo ratings yet

- Stainless Steel Float Level Switch and Mechanical Float Switch for Tank Level MonitoringDocument1 pageStainless Steel Float Level Switch and Mechanical Float Switch for Tank Level MonitoringErick Nacor ArevaloNo ratings yet

- Tecflex 400 Series Flexible DuctingDocument6 pagesTecflex 400 Series Flexible DuctingEN LeedNo ratings yet

- CAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Document34 pagesCAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Jonathan Carlson100% (4)

- Catalog Ecodan - ATW - 2017 PDFDocument32 pagesCatalog Ecodan - ATW - 2017 PDFDamian OvidiuNo ratings yet

- Driving Without Wheels, Flying Without WingsDocument18 pagesDriving Without Wheels, Flying Without Wingsaditya_kumar_me100% (1)

- ITT CONTROLS Barton Chart Recorders 202e User Manual 1Document52 pagesITT CONTROLS Barton Chart Recorders 202e User Manual 1Edbaac BANo ratings yet

- Ed FTV-B PDFDocument32 pagesEd FTV-B PDFChâu Văn KhánhNo ratings yet

- Honda Gs390 Owners Manual (Powerwasher)Document60 pagesHonda Gs390 Owners Manual (Powerwasher)Nate SpaydNo ratings yet

- Fracturing Engineering Manual - 4243456 - 02Document903 pagesFracturing Engineering Manual - 4243456 - 02Pablo Antezana100% (2)

- GNL 06 PDFDocument4 pagesGNL 06 PDFAnuj AsatiNo ratings yet

- Tabela TROUBLESHOOTING FT 2010Document14 pagesTabela TROUBLESHOOTING FT 2010Lucas TavaresNo ratings yet

- Emoving and Installing TurbochargerDocument7 pagesEmoving and Installing TurbochargerDamir MiholićNo ratings yet

- Ies 1997 - II ScanDocument21 pagesIes 1997 - II ScanK.v.SinghNo ratings yet

- TM 9 2320 363 24PDocument1,164 pagesTM 9 2320 363 24PAdvocateNo ratings yet

- Models 69NT40-511-300 To 309, 69NT40-511-311 To 399Document117 pagesModels 69NT40-511-300 To 309, 69NT40-511-311 To 399cloviskrelling100% (2)

- MAB 103B-24 - Parts - 2011Document60 pagesMAB 103B-24 - Parts - 2011Centrifugal SeparatorNo ratings yet

- Acom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFDocument16 pagesAcom85 - 4 High Temperature Behaviour of The Austenitic SS UNS S30815 (253 MA) & Weldments PDFpipedown456No ratings yet

- FLUID MECHANICS I COURSE OVERVIEWDocument14 pagesFLUID MECHANICS I COURSE OVERVIEWOyedotun TundeNo ratings yet

- Structural Analysis 1 (SA1) - Civil Engineering 2nd Year Notes Notes, Books, Ebook PDF DownloadDocument85 pagesStructural Analysis 1 (SA1) - Civil Engineering 2nd Year Notes Notes, Books, Ebook PDF DownloadVinnie Singh100% (2)