Professional Documents

Culture Documents

Aci 318-08 RC-SL-001 PDF

Uploaded by

Luis Ariel B. MorilloOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aci 318-08 RC-SL-001 PDF

Uploaded by

Luis Ariel B. MorilloCopyright:

Available Formats

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 2

EXAMPLE ACI 318-08 RC-SL-001

Slab Flexural Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab flexural design in SAFE

A one-way, simple-span slab supported by walls on two opposite edges is

modeled using SAFE. The slab is 6 inches thick and spans 12 feet between walls.

To ensure one-way action, Poisson’s ratio is taken to be zero. The slab is

modeled using thin plate elements. The walls are modeled as line supports

without rotational stiffnesses and with very large vertical stiffness (1 × 1020

k-in). The computational model uses a finite element mesh, automatically

generated by SAFE. The maximum element size is specified to be 24 inches. To

obtain factored moments and flexural reinforcement in a design strip, one one-

foot-wide strip is defined in the X-direction on the slab, as shown in Figure 1.

Simply

Simply

12 ft span supported

supported

edge at wall

edge at wall

Free edge

Y 1ft design strip

X Free edge

Figure 1 Plan View of One-Way Slab

One dead load case (DL80) and one live load case (LL100) with uniformly

distributed surface loads of magnitudes 80 and 100 psf, respectively, are defined

in the model. A load combination (COMB100) is defined using the ACI 318-08

load combination factors, 1.2 for dead loads and 1.6 for live loads. The model is

analyzed for both load cases and the load combination.

The slab moment on a strip of unit width is computed analytically. The total

factored strip moments are compared with the SAFE results. After completing

the analysis, design is performed in accordance with ACI 318-08 using SAFE

and also by hand computation. Table 1 shows the comparison of the moments

and design reinforcements computed using the two methods.

EXAMPLE ACI 318-08 RC-SL-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 2

GEOMETRY, PROPERTIES AND LOADING

Thickness T, h = 6 in

Depth of tensile reinf. dc = 1 in

Effective depth d = 5 in

Clear span ln, l1 = 144 in

Concrete strength fc = 4,000 psi

Yield strength of steel fy = 60,000 psi

Concrete unit weight wc = 0 pcf

Modulus of elasticity Ec = 3,600 ksi

Modulus of elasticity Es = 29,000 ksi

Poisson’s ratio ν = 0

Dead load wd = 80 psf

Live load wl = 100 psf

TECHNICAL FEATURES OF SAFE TESTED

¾ Calculation of flexural reinforcement

¾ Application of minimum flexural reinforcement

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments in the design

strip with the moments obtained by the hand computation method. Table 1 also

shows the comparison of the design reinforcements.

Table 1 Comparison of Design Moments and Reinforcements

Reinforcement Area (sq-in)

Load Moment

Level Method (k-in) As+

SAFE 55.220 0.213

Medium

Calculated 55.296 0.211

A +s ,min = 0.1296 sq-in

COMPUTER FILE: ACI 318-08 RC-SL-001.FDB

CONCLUSION

The SAFE results show an acceptable comparison with the independent results.

EXAMPLE ACI 318-08 RC-SL-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 2

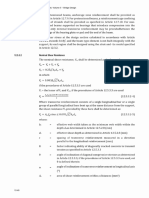

HAND CALCULATION

The following quantities are computed for the load combination:

ϕ = 0.9

b = 12 in

As,min = 0.0018bh = 0.1296 sq-in

⎛ f c′ − 4000 ⎞

β1 = 0.85 − 0.05 ⎜ ⎟ = 0.85

⎝ 1000 ⎠

0.003

cmax = d = 1.875 in

0.003 + 0.005

amax = β1cmax = 1.59375 in

For the load combination, w and Mu are calculated as follows:

w = (1.2wd + 1.6wt) b / 144

wl12

Mu =

8

As = min[As,min, (4/3) As,required] = min[0.1296, (4/3)2.11] = 0.1296 sq-in

COMB100

wd = 80 psf

wt = 100 psf

w = 21.33 lb/in

Mu = 55.296 k-in

The depth of the compression block is given by:

2 Mu

a = d − d2 − = 0.3108 in < amax

0.85 f c'ϕ b

The area of tensile steel reinforcement is then given by:

Mu

As = = 0.2114 sq-in > As,min

⎛ a⎞

ϕ fy ⎜ d − ⎟

⎝ 2⎠

As = 0.2114 sq-in

EXAMPLE ACI 318-08 RC-SL-001 - 3

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- MetallurgyDocument9 pagesMetallurgyRj SakthiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A3 14 (SC) 01 (B)Document184 pagesA3 14 (SC) 01 (B)bpd21No ratings yet

- Literature Review of Coconut Coir in Polymer CompositesDocument17 pagesLiterature Review of Coconut Coir in Polymer CompositesFaruq Luqman60% (5)

- ACI - Crack CalculationsDocument3 pagesACI - Crack CalculationsLuis Ariel B. MorilloNo ratings yet

- ACI 224R - 90 Control of Cracking in ConcreteDocument43 pagesACI 224R - 90 Control of Cracking in ConcreteRobert Stachera100% (5)

- Polymers Unit Exploring Key ConceptsDocument23 pagesPolymers Unit Exploring Key ConceptsderbewalebelNo ratings yet

- Tbi 2017Document148 pagesTbi 2017Aie Bantugan100% (1)

- Seepage Through Soils PDFDocument133 pagesSeepage Through Soils PDFLuis Ariel B. MorilloNo ratings yet

- Seepage Through Soils PDFDocument133 pagesSeepage Through Soils PDFLuis Ariel B. MorilloNo ratings yet

- Physics Bernoulis Theorem Project CBSE Class 12Document21 pagesPhysics Bernoulis Theorem Project CBSE Class 12Faaiz100% (3)

- Clark1976 PDFDocument10 pagesClark1976 PDFLuis Ariel B. MorilloNo ratings yet

- Wu, Chi-San Handbook of Size Exclusion Chromatography and Related Techniques Revised and ExpandedDocument697 pagesWu, Chi-San Handbook of Size Exclusion Chromatography and Related Techniques Revised and ExpandedIoana Ruxandra AroşculeseiNo ratings yet

- Retrofit Measures For Superstructures, Bearing and Seats - FHA PDFDocument52 pagesRetrofit Measures For Superstructures, Bearing and Seats - FHA PDFLuis Ariel B. MorilloNo ratings yet

- PHL Grid Code 2016edition (ResolutionNo22Seriesof2016) PDFDocument180 pagesPHL Grid Code 2016edition (ResolutionNo22Seriesof2016) PDFJerry MateoNo ratings yet

- Rapid Repair Design of Temporary Support Systems For Bridges Damaged by EquakeDocument19 pagesRapid Repair Design of Temporary Support Systems For Bridges Damaged by EquakeLuis Ariel B. MorilloNo ratings yet

- QTMR Pavement Rehabilitation Manual 2012-04Document381 pagesQTMR Pavement Rehabilitation Manual 2012-04Jean PajueloNo ratings yet

- PP - Bridge NonLinear Analysis - Updated PDFDocument129 pagesPP - Bridge NonLinear Analysis - Updated PDFLuis Ariel B. MorilloNo ratings yet

- Field Inspection ManualDocument74 pagesField Inspection ManualLuis Ariel B. MorilloNo ratings yet

- CE297 Discussion Questions - ACME MedicalDocument3 pagesCE297 Discussion Questions - ACME MedicalLuis Ariel B. Morillo100% (1)

- Field Inspection ManualDocument74 pagesField Inspection ManualLuis Ariel B. MorilloNo ratings yet

- ISSEP. Grutas SpectralAccelerationComparison - ISSEPpdfDocument31 pagesISSEP. Grutas SpectralAccelerationComparison - ISSEPpdfLuis Ariel B. MorilloNo ratings yet

- Design of A Pre-Stressed Bridge GirderDocument37 pagesDesign of A Pre-Stressed Bridge GirderLuis Ariel B. MorilloNo ratings yet

- Ce 259 11819 #08 Response SpectraDocument11 pagesCe 259 11819 #08 Response SpectraLuis Ariel B. MorilloNo ratings yet

- PHL Grid Code 2016edition (ResolutionNo22Seriesof2016) PDFDocument180 pagesPHL Grid Code 2016edition (ResolutionNo22Seriesof2016) PDFJerry MateoNo ratings yet

- 1930 Cyclopean SpecDocument4 pages1930 Cyclopean SpecLuis Ariel B. MorilloNo ratings yet

- SlabsDocument55 pagesSlabsYoussef AliNo ratings yet

- Elastomeric Bearing Pad PropertiesDocument1 pageElastomeric Bearing Pad PropertiesLuis Ariel B. MorilloNo ratings yet

- Shear CapacityDocument7 pagesShear CapacityLuis Ariel B. MorilloNo ratings yet

- ACI 350-06 ErrataDocument7 pagesACI 350-06 ErrataLuis Ariel B. MorilloNo ratings yet

- Bridge Design Manual 3rd Edition OverviewDocument43 pagesBridge Design Manual 3rd Edition OverviewSahil ChaudharyNo ratings yet

- Numerical Evaluation of Dynamic ResponseDocument20 pagesNumerical Evaluation of Dynamic Responsemacynthia26No ratings yet

- General Physics 2 Current and ResistanceDocument24 pagesGeneral Physics 2 Current and ResistanceCassandra Mae Bauit PascuaNo ratings yet

- Exam 1 Sp23Document11 pagesExam 1 Sp23Mike TederNo ratings yet

- Discover How Piezoelectric Materials Generate Electricity from MovementDocument9 pagesDiscover How Piezoelectric Materials Generate Electricity from MovementMahmudul HasanNo ratings yet

- C6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - CONNECTION DIAGRAMSDocument6 pagesC6.6 ENGINE - GENERATOR SET Operation & Maintenance Manuals - CONNECTION DIAGRAMSsuperteffyNo ratings yet

- Spring: Ali Attamimi Jurusan Teknik Mesin FTIDocument26 pagesSpring: Ali Attamimi Jurusan Teknik Mesin FTIKomeng KomengNo ratings yet

- High Voltage Lab Report 1Document5 pagesHigh Voltage Lab Report 1testNo ratings yet

- Line Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKDocument3 pagesLine Item 18 To 24 # Datasheet - 8F, 12F, 24F, 48F, 96F, 144F, 288F D MTA SS PE BKSadiqNo ratings yet

- +2 Phy Complete Material E.MDocument320 pages+2 Phy Complete Material E.MAjayNo ratings yet

- Micromeritics-Part 2Document18 pagesMicromeritics-Part 2SafwanNo ratings yet

- CMT 405 - Distillation PDFDocument72 pagesCMT 405 - Distillation PDFMuhammad Azri HaziqNo ratings yet

- ESR and NMRDocument20 pagesESR and NMRUmang SoniNo ratings yet

- Direct Current Machines + Summarised NotesDocument21 pagesDirect Current Machines + Summarised NotesElisha NissiNo ratings yet

- PENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDocument5 pagesPENGARUH SUDUT POTONG DAN KECAMATAN POTONG TERHADAP MESIN BUBUTDonnie Hafiz Prasetya RitongaNo ratings yet

- MECE 2334 Final ExamDocument9 pagesMECE 2334 Final Examdroblesb91No ratings yet

- MECH 390 - PRACTICE 1 - FALL 2011Document5 pagesMECH 390 - PRACTICE 1 - FALL 2011Abeer AlnaqbiNo ratings yet

- Non-Destructive Testing Methods GuideDocument24 pagesNon-Destructive Testing Methods GuideakalNo ratings yet

- Thermodynamic Relation IntroDocument4 pagesThermodynamic Relation IntromahendranNo ratings yet

- Enhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDocument4 pagesEnhanced Sintering, Microstructure Evolution and Mechanical Properties of 316LDaniel SolesNo ratings yet

- IEEE STD 100-96 - DictionaryDocument1,287 pagesIEEE STD 100-96 - DictionaryHERNANDEZ FLORES EMMANUEL oNo ratings yet

- Power System - Ii Lab Manual (EE-328) Vi Semester Electrical EngineeringDocument22 pagesPower System - Ii Lab Manual (EE-328) Vi Semester Electrical EngineeringRahul DuttaNo ratings yet

- Wevo Folder Produkte Wevopur en Screen 230313Document4 pagesWevo Folder Produkte Wevopur en Screen 230313jason KlangNo ratings yet

- 10th Class Physics Guess Paper 2023Document24 pages10th Class Physics Guess Paper 2023Farhatullah MuhammadNo ratings yet

- Perrys Chemical Engineering Handbook-Halaman-132-134 PDFDocument3 pagesPerrys Chemical Engineering Handbook-Halaman-132-134 PDFJuana HizkiaNo ratings yet