Professional Documents

Culture Documents

Effects of Refining On Chemical and Physical Properties of Palm Oil Products

Uploaded by

ifiokOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effects of Refining On Chemical and Physical Properties of Palm Oil Products

Uploaded by

ifiokCopyright:

Available Formats

1116

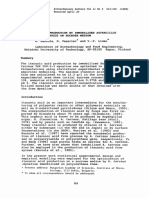

Effects of Refining on Chemical and Physical Properties of Palm Oil

Products

W . L Slew" a n d Yassln M o h a m m a d

Palm 011 Research Institute of Malaysia, P.O. Box 10620, Kuala Lupur, Malaysia

S o m e c h e m i c a l c h a n g e s in t h e c o m p o s i t i o n a n d physi- Oxidative c h a n g e s t h a t o c c u r d u r i n g bleaching a n d

cal p r o p e r t i e s o f p a l m oil p r o d u c t s are d i s c u s s e d . T h e d e g u m m i n g were e v a l u a t e d on 21 s a m p l e s of c r u d e a n d

e f f e c t s o f b l e a c h i n g and d e o d o r i z a t i o n o n o x i d a t i v e refined p a l m oil p r o d u c t s . L a b o r a t o r y refining was per-

properties and possible isomerization and interester- f o r m e d on c r u d e p a l m oil using different e a r t h s at varying

i f i c a t i o n o f t h e fatty a c i d s w e r e i n d i c a t e d f r o m labora- dosages. The c o n j u g a t e d dienes a n d trienes were meas-

tory refining experiments. Investigation of commer- ured. These were also c a r r i e d o u t on v a r i o u s quality c r u d e

cial s a m p l e s o f r e f i n e d p a l m oil p r o d u c t s s h o w e d t h a t otis.

t h e c o n j u g a t e d d i e n e s a n d t r i e n e s f o r m e d are min- Analysis offatty acid methyl esters (FAME). The f a t t y

imal, i n d i c a t i n g t h e u s e o f g o o d quality r a w m a t e r i a l s acid c o m p o s i t i o n s of the oils w e r e analyzed as methyl

and mild p r o c e s s i n g c o n d i t i o n s . Very little i s o m e r i z a - e s t e r s which were p r e p a r e d by a r a p i d method; 0.05 g of

l i o n o c c u r r e d in c o m m e r c i a l r e f i n e d p r o d u c t s as indi- s a m p l e was dissolved in one ml of n - h e x a n e in a screw-

c a t e d from t h e level o f t r a n s acids, and c h a n g e s in t h e c a p p e d vial. Then, 0.05 ml of 1 M s o d i u m m e t h o x i d e was

POP to PPO t r i g l y c e r i d e s d u e to p o s s i b l e i n t e r e s t e r i f l - a d d e d . The m i x t u r e was s h a k e n vigorously for five

c a t i o n w e r e i n s i g n i f i c a n t . C h a n g e s in p h y s i c a l proper- s e c o n d s and then allowed to s e t t l e before the h e x a n e

t i e s w e r e i n e v i t a b l e d u e to t h e r e m o v a l o f free fatty layer was p i p e t t e d for gas liquid c h r o m a t o g r a p h i c (GLC)

a c i d s and d i g l y c e r i d e s a n d to m i n o r i m p u r i t i e s . analysis.

t r a n s Ac/ds. FAMEs p r e p a r e d w e r e analyzed on a 6-m •

3-mm i.d. glass c o l u m n of 15% OV 275 on a 100-120 mesh

Oils are refined to remove u n d e s i r a b l e m a t e r i a l s such as C h r o m o s o r b P AW-DMCS (Supelco Inc., Bellefonte, Penn-

color bodies, o x i d a t i v e c o m p o n e n t s , gums, m e t a l c o n t a m - sylvania). The c o l u m n t e m p e r a t u r e was set isothermally

i n a n t s a n d volatiles. Palm oil is refined by physical pro- at 220~ a n d the injector t e m p e r a t u r e was at 270~ The

cesses a n d involves d e g u m m i n g a n d bleaching followed c a r r i e r gas flow r a t e ( n i t r o g e n ) was set at 10 cm3/min.

by d e o d o r i z a t i o n . During d e g u m m i n g a n d bleaching, Analyses were c a r r i e d o u t on a Perkin Elmer Sigma 2 Gas

p h o s p h o r i c acid a n d a c t i v a t e d clay a r e d o s e d at t e m p e r - chromatograph.

a t u r e s of90-105~ Deodorization o c c u r s at 240-2800(:; for A s t a n d a r d p a l m oil which h a d been c a l i b r a t e d against

p e r i o d s ranging from .5 to 2 hr. In physical refining, it is a Nu Chek 20 A r e f e r e n c e m i x t u r e was used for the deter-

i m p o r t a n t to e n s u r e t h a t mild c o n d i t i o n s a r e used in m i n a t i o n of r e s p o n s e factors for t h e v a r i o u s FAME. trans

o r d e r to avoid d e l e t e r i o u s effects on oil c o m p o s i t i o n a n d 18:1 FAME was assigned a r e s p o n s e f a c t o r similar to t h a t

properties. for cis 18:1 FAME, a n d trans, trans 18:2 a n d cis trans 18:2

The p r e s e n t p a p e r aims a t providing some i n f o r m a t i o n were assigned the r e s p o n s e f a c t o r s for c/s, c/s 18:2 methyl

on t h e possible changes t h a t m a y o c c u r to the chemical esters.

a n d physical p r o p e r t i e s of p a l m oil u n d e r different refin- Triglyceride analysis by carbon number. A Perkin

ing conditions. Elmer Sigma 1 Gas c h r o m a t o g r a p h was used. Five per-

c e n t solutions of t h e s a m p l e s in c h l o r o f o r m were pre-

MATERIALS AND METHODS p a r e d for analyses. The glass c o l u m n used was 46 cm x 3

m m i.d. c o n t a i n i n g 3% OV-I on 100-120 Gas Chrom Q. The

C r u d e p a l m olein, p a l m m i d - f r a c t i o n , c r u d e p a l m oils of c a r r i e r gas was nitrogen at a flow r a t e of 60-80 ml/min.

v a r y i n g quality, a n d s e t s of c r u d e a n d r e f i n e d p a l m oil D e t e c t o r a n d injector t e m p e r a t u r e s of 370~ were used.

p r o d u c t s w e r e u s e d for t h e e x p e r i m e n t s . The column was p r o g r a m m e d from 280 to 345~

Laboratory refining. A b o u t 500 g of c r u d e p a l m olein with initial a n d holding times at t h e s t a r t i n g a n d final

and palm mid-fraction samples were d e g u m m e d with t e m p e r a t u r e s set at t h r e e min each. Response factors

0.1% of p h o s p h o r i c a c i d at 90 ~ for 10 min. Tonsil were d e t e r m i n e d using a s t a n d a r d p a l m oil reference pre-

O p t i m u m F F b l e a c h i n g e a r t h (0.5 g) was a d d e d , a n d t h e

viously c a l i b r a t e d a g a i n s t a m i x t u r e of p u r e s a t u r a t e d

oil w a s s t i r r e d v i g o r o u s l y for 15 min at 95~ The oil w a s

triglycerides.

f i l t e r e d twice t h r o u g h W h a t m a n No. 1 filter p a p e r on a

Fatty acid at the 2-position. A semi microlipolysis

B u c h n e r filter funnel. D e o d o r i z a t i o n w a s c a r r i e d o u t at

m e t h o d was used. Triglycerides were o b t a i n e d from a

d i f f e r e n t t e m p e r a t u r e s r a n g i n g f r o m 220-280~ for

c o l u m n c h r o m a t o g r a p h y m e t h o d (2). The triglycerides

p e r i o d s r a n g i n g f r o m 1 to 4 hr.

(40-60 mg) were melted, dissolved in a few d r o p s of

A n a l y s e s of trans f a t t y acids, f a t t y a c i d c o m p o s i t i o n ,

b u t a n o l in a t e s t t u b e (19 x 2 c m ) a n d p l a c e d in a w a t e r

t r i g l y c e r i d e c o m p o s i t i o n a n d f a t t y acid at t h e 2-

b a t h m a i n t a i n e d at 40~ Buffer (1.2 M NH4CL/NHaOH.

p o s i t i o n of t h e g l y c e r i d e w e r e p e r f o r m e d on t h e r e f i n e d

pH 8.5, 2 ml), c a l c i u m chloride solution (22%, 0.2 ml)

samples. These samples were refined under severe

a n d bile salts (25%, 0.10 ml) w e r e a d d e d . The m i x t u r e

c o n d i t i o n s to d e t e r m i n e t h e p o s s i b l e c h a n g e s t h a t m a y

was s t i r r e d slowly by a m a g n e t i c s t i r r e r until an

occur.

emulsion was obtained. P a n c r e a t i c lipase (50 mg, pre-

viously w a s h e d with e t h e r ) w a s t h e n a d d e d a n d the

r e a c t i o n m i x t u r e was s t i r r e d vigorously for 10 rain. The

enzymes were i n a c t i v a t e d by a d d i n g hydrochloric acid

*To whom correspondence should be addressed. (5 M): w a t e r (1:1, v/v, 1 ml). The h y d r o l y s a t e was

JAOCS, Vol. 66, no. 7 (July 1989)

1117

PROPERTIES OF PALM OIL PRODUCTS

TABLE 1

E f f e c t s of P r o c e s s i n g on Fatty Acid C o m p o s i t i o n of P a l m Mid F r a c t i o n s and Palm Olein

Sample Deodorization Fatty Acid Composition (%)

Temp Time

(~ (hr) 14:0 16:0 18:0 18:1t 18:1c 18:2ct 18:2cc 18:3 20:0 Other

Crude olcin 0.9 40.2 4.2 41.7 11.1 0.3 0.3 1.0

Refined olein 220 1 0.9 40.5 4.2 41.2 11.0 0.3 0.4 1.0

R e f n e d olein 260 2 1.0 40.5 4.3 41.5 0.3 10.7 0.1 0.3 1.2

Refined olein 280 4 1.0 41.1 4.4 0.4 41.0 1.7 8.4 0.2 0.4 0.8

Crude PMF a 1.0 46.8 4.4 38.2 8.3 0.2 0.3 0.8

Refined PMF 220 1 0.9 47.0 4.3 38.0 0.1 8.0 0.2 ().'] 0.9

Refined PMF 260 2 1.0 46.6 4.5 38.5 8.3 0.1 0.3 0.7

Refined PMF 280 4 1.0 47.7 4.4 0.2 37.0 1.3 6.6 0.1 0.4 0.8

~Palm mid fraction.

TABLE 2

E f f e c t s of P r o c e s s i n g on Triglyceride C o m p o s i t i o n of Palm Mid Fraction and Palm

Oleins

Sample Deodorization Triglyceride Composition (%)

Temp Time

(~ (h!') C46 C48 (!50 (J,5'2 (.',54 C56

Crude olein 0.2 2,2 41.8 45.2 10.2 0.2

Refned olein 220 1 0.2 2.3 41.5 45.3 10.2 0.'3

Refined olein 260 2 0.2 2.7 41.2 44.9 10.6 0.'3

Refined olein 280 4 0.5 5.5 36.,1 43.9 13.2 0.2

()rude PMF ~ 0.3 3.0 54.9 35.1 6.2 0.2

Refined PMF 220 1 0.4 3.1 54.2 35.1 6.7 0.2

Refined PMF 260 2 0.4 3.4 53.2 35.5 7.1 0.2

Refined PMF 28(1 4 0.5 4.9 50.0 36.4 7.3 0.3

9~Palm mid fraction.

held at the measuring temperatures for 30 min prior to

e x t r a c t e d w i t h e t h e r ( 2 • 10 m l ) , w a s h e d w i t h w a t e r the reading of signals.

(2 • 10 m l ) , d r i e d o v e r a n h y d r o u s s o d i u m s u l p h a t e a n d

Cl(md point. C l o u d p o i n t is t h e t e m p e r a t u r e a t w h i c h

concentrated under a stream of nitrogen. a c l o u d o f c r y s t a l s is i n d u c e d in t h e s a m p l e c a u s e d b y

The monoglyceride fraction was separated by prepar- t h e f i r s t s t a g e o f c r y s t a l l i z a t i o n . I t is d e f i n e d a s t h e

ative TLC (20 • 20 cm 2 plates coated with 0.75 mm temperature at which the thermometer in t h e s a m p l e

s i l i c a gel). T h e c h r o m a t o g r a m s w e r e d e v e l o p e d in h e x - no longer appears visible, under the conditions of the

ant:ether:formic acid (V/V 50:50:1). The 2-monoglycer-

test. Cloud points of palm oleins were performed

ides were recovered with ether and transesterified. a c c o r d i n g t h e A O C S O f f i c i a l M e t h o d C.c 6 - 2 5 ( 4 ) .

Conjugated dienes a n d tri~.mes. T h e s e w e r e m e a s u r e d

according to PORIM test methods (3) at 233 and 269

n m in a H P 8 4 5 0 A LW-Vis s p e c t o p h o t o m e t e r . A b o u t 0.12

RESULTS AND DISCUSSION

g o f oil in i s o - o c t a n e in a 2 5 - m l v o l u m e t r i c f l a s k w a s

prepared. The absorbances at 233, 269 and 446 nm Fatty a c i d a n d t r i g l y c e r i d e composition. Table 1 shows

were measured against a reference (pure iso-octane) tile fatty acid composition of palm oleins and palm mid-

and corrected for cuvette error at these wavelengths. A fractions. Significant changes were observed only when

correction factor was made to account for the carotene the samples were subjected to 280~ for a four-hour

absorbance. deodorization period, trans Fatty acids were absent in

Solid f a t c(mtent (SFC) m e a s u r e m e ~ t by nuclear the crude and refined samples deodorized at 220 and

magnetic res(mance (NMR). A N e w p o r t M a r k I I I A N M R 260 C for one and two hr respectively. Small amounts of

with temperature controller was used. The instrument 1 8 : l t r a n s a n d 18:2 cis t r a n s w e r e d e t e c t a b l e u n d e r

w a s s e t a t g a t e w i d t h = 1% G: R.F. = 4 5 A, A.F. g a i n = 3 7 5 conditions of 280~ for four hr. One and one-half and

u n i t a n d i n t e g r a t i o n t i m e = 3 2 sec. S a m p l e w e i g h t w a s 2.1% o f t o t a l t r a n s a c i d s w e r e o b s e r v e d i n t h e p a l m o l e i n

c a . 1.5 g, a n d t r i o l e i n w a s u s e d ms r e f e r e n c e . P a r a l l e l and palm mid-fractions. The conditions were more

tempering procedure was used. A number of tubes of extreme than those used in a c t u a l commercial

each sample were required but only one tube was held p r o c e s s e s . N o t m o r e t h a n 0.6% o f t o t a l t r a n s a c i d s w e r e

at each of the measuring temperatures. The sample was r e p o r t e d in c o m m e r c i a l r e f i n e d p a l m oil p r o d u c t s ( 5 ) .

m e l t e d a t 70~ f o r 3 0 m i n , c h i l l e d a t 0~ f o r 9 0 m i n a n d These oils were subjected to deodorization conditions

JAOCS, Vol. 66, no. 7 (July 1989)

1118

W.L. SIEW AND YASSIN MOHAMMAD

TABLE 3 of 260-2750C for 0.75-1.5 hr. Rossell et al. (6) r e p o r t e d u p

to 10% trans acids in s o y b e a n oil w h e n r e f i n e d at 280~ for

E f f e c t s o f R e f i n i n g o n t h e F a t t y A c i d C o m p o s i t i o n (%) a t t h e o n e hr, while t h o s e r e f i n e d a t 2400C for two h r s h o w e d a

2-Position of the Glyceride

trans acid c o n t e n t of 2.3%. S i m i l a r f i n d i n g s w e r e r e p o r t e d

by A c k m a n et al. (7) on t h e d e t e c t i o n of artefacts,

Samples C14 CI6 C18 C18:1 C18:2 identified as c/s-9, trans-12, c/s-15 a n d trans-9, c/s-12,

Crude palm oil 0.5 14.5 1.9 63.4 19.8 c/s-15 i s o m e r s of linolenic acid. Some 0.7 to 2.6% of these

Degummed 0.5 15.3 1.7 62.8 19.6 acids w e r e f o u n d in r a p e s e e d vegetable oils f r o m t h e retail

bleached oil

Refined oil 0.5 16.7 1.9 62.4 18.5 market.

The t r i g l y c e r i d e c o m p o s i t i o n in Table 2 shows t h a t

Crude palm olein 0.5 8.3 1.3 68.6 21.4

Degummed 0.4 8.2 1.3 68.8 21.0 i n t e r m o l e c u l a r r e a r r a n g e m e n t of f a t t y acid c a n be

bleached olein o b s e r v e d only in s a m p l e s s u b j e c t e d to d r a s t i c refining

Refined olein 0.4 9.5 1.3 67.4 21.5 c o n d i t i o n s . Typically, little o r n o c h a n g e is observed in

c o m m e r c i a l l y r e f i n e d oils (8).

TABLE 4

Effects of Processing on Physical Properties of Palm Oils and Oleins

Solid fat content

Sample 5~ 10~ 15~ 20~ 25~ 30~ 35~ 400C Cloud point (~

(mean)

Crude palm oil 60.8 49.6 34.7 22.5 13.5 9.2 6.6 4.0

Neutralized palm 64.9 54.2 38.2 26.1 15.2 9.8 6.7 4.3

oil

Refined palm oil 62.2 50.3 35.2 23.2 13.7 8.5 5.8 3.5

Crude palm olein 49.6 33.6 12.6 3.2 10.4

Neutralized palm 55.4 40.3 20.4 5.3 8.1

olein

Refined palm 51.1 37.0 19.2 5.9 8.8

nlein

50

Interesterification may occur during deodor~ation,

45 84 r e s u l t i n g in a n i n c r e a s e in t h e s a t u r a t e d f a t t y acids at the

2 - p o s i t i o n of the glycerid.e (Table 3). A l t h o u g h t h e r e

a p p e a r s to be a slight i n c r e a s e in t h e p a l m i t i c acid

40

c o n t e n t of 1-2%, the i n c r e a s e m a y n o t be c o n s i d e r e d

s i g n i f i c a n t as c r u d e p a l m oil h a s a p a l m i t i c acid c o n t e n t

35 at the 2 - p o s i t i o n of 14.4 to 18.1% ( r a n g e of 7 s a m p l e s

studied).

The effect of t i m e a n d t e m p e r a t u r e o n t h e POP:PPO

30-

ratio of p a l m oil was d i s c u s s e d by Williams (9). The

c h a n g e in t h e r a t i o was s i g n i f i c a n t if t h e oil was s u b j e c t e d

25- to t e m p e r a t u r e s of above 270~ for long r e s i d e n c e times.

o Special c a r e t a k e n d u r i n g t h e r e f i n i n g p r o c e s s c a n mini-

mize t h e c h a n g e in t h e s y m m e t r i c a l triglyceride c o n t e n t

20

(POP) to t h e u n s y m m e t r i c a l triglyceride (PPO).

Physical properties of palm oil. In r e m o v i n g i m p u r i -

ties, i.e., free f a t t y acids a n d diglycerides, r e f i n i n g results

\

o 15

in c h a n g e s in t h e physical p r o p e r t i e s of t h e oil. These

i:

I differences a r e o b s e r v e d in t h e oils (Table 4). Tan et al. (8)

r e p o r t e d i n c r e a s e d v a l u e s in solid fat c o n t e n t in refined

p a l m oils c o m p a r e d to c r u d e oils a t t h e lower t e m p e r a -

t u r e r a n g e (5-20~

The overall i n c r e a s e in solid fat c o n t e n t in r e f i n e d oils is

d e p e n d e n t o n d e o d o r i z a t i o n c o n d i t i o n s . F i g u r e 1 shows

0

10 15 20 25 30 35 40 t h e effect of r e f i n i n g c o n d i t i o n s on solid fat c o n t e n t of

p a l m olein. The tailing o b s e r v e d in p a l m olein s u b j e c t e d to

TEMPERATURE ~ 2800C for f o u r h r is highly s i g n i f i c a n t a n d w o u l d affect the

F I G . 1. E f f e c t o f p r o c e s s i n g o n s o l i d f a t c o n t e n t o f p a l m o l e i n s ,

oil's c r y s t a l l i z a t i o n behavior. A l t h o u g h c l o u d p o i n t s of

, c r u d e p a l m o l e i n , .......... , r e f i n e d o l e i n , d e o d o r i z a t i o n p a l m oleins are g e n e r a l l y r e d u c e d d u r i n g refining, the

250~ 2 hr; .......... , r e f i n e d o l e i n , d e o d o r i z a t i o n 280~ 4 hr. tailing effect p r o d u c e d by i n t e r e s t e r i f i c a t i o n of the fatty

JAOCS, Vol. 66, no. 7 (July 1989)

1119

PROPERTIES OF PALM OIL PRODUC'I,'S

TABLE 5 a c i d s a t h i g h t e m p e r a t u r e s w o u l d r e s u l t in e a r l y c r y s t a l -

lization of palm olein on storage.

Conjugated D i e n e s and Trienes o f Bleached Oils (150"C for .5 hr) O x i d a t i v e c h a n g e s . D u r i n g b l e a c h i n g o f v e g e t a b l e oils,

c o l o r p i g m e n t s a n d o t h e r i m p u r i t i e s a r e a d s o r b e d . In oils

Dosage of bleaching earths (%) containing PUFAs, conjugated dienes, trienes and

0 0.5 1.0 1.5 2.0 tetraenes are formed.

E 21~ 1.76 1.52 1.67 1.,90 2.42 T h e f o r m a t i o n o f t h e c o n j u g a t e d d i e n e s a n d t r i e n e s in

E ~9 0.22 0.77 0.7:3 0.70 0.60 p a l m oil is s h o w n in T a b l e s 5 a n d 6. T h e a m o u n t o f

c o n j u g a t e d d i e n e s m e a s u r a b l e a t 233 n m d e p e n d e d o n

the dosage of [)leaching earths used, more being formed

with higher earth dosage. A reduction was observed when

TABLE 6

l o w e a r t h d o s a g e o f 1% a n d b e l o w w a s u s e d . T h i s w a s d u e

Effect o f Refining on Conjugated D i e n e s and Trienes of Various to c o n j u g a t e d h y d r o p e r o x i d e s b e i n g b r o k e n d o w n d u r i n g

Quality Crude Oils bleaching. Dehydration of hydroxy compounds may

o c c u r (1 l ) e s p e c i a l l y w i t h h i g h e a r t h d o s a g e s a n d l o n g e r

Z ~ii;, Z ~;ii, b l e a c h i n g t i m e r e s u l t i n g in h i g h e r a m o u n t s o f d i e n e s

Samples Crude Bleached Refined Crude Bleached Refined formed.

Good 1.05 0.90 1.46 0.19 0.29 0.19 A n i n c r e a s e in c o n j u g a t e d t r i e n e s w a s o b s e r v e d d u r i n g

Average 1.76 1.30 1.60 (1.21 9.90 0.81 b l e a c h i n g , w h i c h d e p e n d e d o n t h e q u a l i t y o f t h e c r u d e oil.

Oxidized 4.88 2.41 2.79 0.70 2.85 2.51 The effect of earth dosage was minimal. The amount of

t r i e n e s in oils r e f i n e d f r o m o x i d i z e d c r u d e m a t e r i a l w a s

13 t i m e s t h a t f o r m e d in oils r e f i n e d f r o m g o o d q u a l i t y

c r u d e oils. S o m e of t h e c o n j u g a t e d t r i e n e s a r e r e m o v e d

TABLE 7

later, during deodorization.

Conjugated D i e n e s in Commercial Refined Palm Oil Products T h e f o r m a t i o n o f c o n j u g a t e d d i e n e s a n d t r i e n e s in

c o m m e r c i a l r e f i n e d p a l m oil p r o d u c t s is m i n i m a l ( T a b l e s

Sample Mean ~ Min Max 7 a n d 8), i n d i c a t i n g t h e u s e o f g o o d q u a l i t y c r u d e oils a s

raw feedstock and mild processing conditions.

Crude palm oil 1.8 1.2 2.7

Degummcd bleached pahn oil 1.4 1.1 1.7

Refined l)alm oil 1.9 1.5 2.2 ACKNOWLEDGMENT

Crude l)ahn olein 2.1 1.5 2.9

Degummed I)leached olein 1.5 1.2 1.9 The authors thank the director general of POI{IM for i)ermission to

Refined pahn olein 2.0 1.2 2.6 publish this paper and the analyti(.al staff for technical assistance.

Crude palm stearin 1.7 1.4 2.4

Degummed bleached stearin 1.5 1.2 1.7 REFERENCES

Refined palm stearin 1.6 1.9 2.0

1. I)oroanne, C., J.P. Wathele! and M. Sever[n, Rev. Ft. Corps (~ras

~'t~a.sed on a total of 21 samples. 22:5(,)(.) ( 1975 ).

2. Christie, W.W., Lipid Analysis, Pergamon Press, 1973.

:3. PORIM Test Methods, Palm Oil Research Inslitute of Malaysia,

TABLE 8 K uala Lump ur, Malaysia, 1988, Test P 2.15.

4. Qf.f~;al and Tentative Metlu)~Ls qf the American Oil Chemists'

,~x~iety, edited by R.C. Walker, AOCS, Champaign, IL, 1984,

Conjugated Trienes in Commercial Refined Palm Oil Products

Method Ce 6 25.

5. Tan, B.K., Y.A. Tan and S.tl. Ong, PORIM PO (54) Restricted

Sample Mean" Min Max ( 198:1 ).

Crud 9 palm oil 0.3 0.2 0.6 6. Rossell, 3.B., S.P. Kochar and I.M. Jawad, I~rfmeedings of the

Degummed bleached palm oil 0.7 0.3 1.0 ,~cemd American S~ybean Assotgation Symposium (m Soy

Refined palm oil 0.5 0.'3 0.8 bean Processing, ASA, Antwerp, 1981.

7. Aekman, R.G., S.N. lh)oper and D.L. Hooper, J. Ant. Oil C~tt~n.

Crude palm olein 1).3 9.2 0.4 ,~:. 51:42 ( 1974 ).

Degummed bleached olein 0.9 0.5 1.5 8. Tan, B.K., and F.C.}t. Oh, PORIM Technology ISSN 0217-0257,

Refined palm olein 9.7 0.4 1.0 No. 4 (1981).

9. Willems. M.G.A., J. Am. Oil Clu~,m. , ~ . 62:454 (1985).

Crude palm stearin 0.4 0.2 0.7 10. Mitchell, J.lt., and tI.R. KraybilI,J. Am. Clumt Stx~. 6&988 (1942).

I)egummed bleached stearin 0.7 0.5 1.0 11. Hadorn, II., and K. Zurcher, Travau:r dv CTzimie Alimentaire et

Refined palm stearin 0.5 0.3 0.7 d 'Hygieme 57:189 (1966).

~Based on a total of 21 samples.

[ R e c e i v e d A u g u s t 1, 1988; a c c e p t e d O c t o b e r 21, 1988]

[J55331

JAOCS, Vol. 66, no. 7 (July fl989)

You might also like

- Avocado OilDocument6 pagesAvocado OilgicacmNo ratings yet

- Bitter Test Olive OilDocument2 pagesBitter Test Olive OilSlaw Ben AissaNo ratings yet

- Fritsch 1971Document2 pagesFritsch 1971oscarNo ratings yet

- 1986 Transesterification Kinetics of Soybean OilDocument6 pages1986 Transesterification Kinetics of Soybean OilAlberto Hernández CruzNo ratings yet

- Cromatografia FTIRDocument7 pagesCromatografia FTIRJorge EsquerreNo ratings yet

- Bearing Steel 52100Document10 pagesBearing Steel 52100Dan PascuNo ratings yet

- Ashworth 1970Document6 pagesAshworth 1970antonio leonNo ratings yet

- Interactoin of Enhanced Oil Recovery Surfactant With Model Crude Oil Surfactant PDFDocument8 pagesInteractoin of Enhanced Oil Recovery Surfactant With Model Crude Oil Surfactant PDFRaemora Zaith IthinNo ratings yet

- 25 - 4 - San Francisco - 08-80 - 0264Document6 pages25 - 4 - San Francisco - 08-80 - 0264Trinh GiaNo ratings yet

- Material Safety Data Sheet: Muriate of PotashDocument7 pagesMaterial Safety Data Sheet: Muriate of PotashChrist Akmel RatuNo ratings yet

- An Investigation of Waxes Isolated From Heavy Oils Produced From Northwest Asphalt Ridge Tar SandsDocument21 pagesAn Investigation of Waxes Isolated From Heavy Oils Produced From Northwest Asphalt Ridge Tar SandsMa JamieNo ratings yet

- 23 - 3 - Miami Beach - 09-78 - 0160Document8 pages23 - 3 - Miami Beach - 09-78 - 0160lam2289No ratings yet

- International Federation of Fruit Juice Froducers I.FJ.U.-Analyses No. 31 (Characterization by Thin-Layer Chromatography On Cellulose)Document7 pagesInternational Federation of Fruit Juice Froducers I.FJ.U.-Analyses No. 31 (Characterization by Thin-Layer Chromatography On Cellulose)ivannamilanesi-1No ratings yet

- Effect Oxygen Compounds Addition O N The Hydrocracking of AlkylpbenolsDocument4 pagesEffect Oxygen Compounds Addition O N The Hydrocracking of AlkylpbenolsShakir AbbasNo ratings yet

- Spectrophotometric and Fluorimetric Methods for Determining Nicotinamide-Adenine DinucleotidesDocument28 pagesSpectrophotometric and Fluorimetric Methods for Determining Nicotinamide-Adenine DinucleotidesYovi AviantoNo ratings yet

- 23 - 4 - Miami Beach - 09-78 - 0072Document9 pages23 - 4 - Miami Beach - 09-78 - 0072adrian2009-2020No ratings yet

- Paper BOP 2Document2 pagesPaper BOP 2Della EfrianNo ratings yet

- Olefin Sulfonate Based Systems : Studies On The Stability of Kathon - Cg/Icp Mjcrobicide in AlphaDocument7 pagesOlefin Sulfonate Based Systems : Studies On The Stability of Kathon - Cg/Icp Mjcrobicide in AlphaShivon LamNo ratings yet

- Ali 1983Document32 pagesAli 1983Andres Rengifo BotinaNo ratings yet

- Physical Chemistry and Its Biological ApplicationsFrom EverandPhysical Chemistry and Its Biological ApplicationsRating: 3 out of 5 stars3/5 (1)

- (Received April 1988 Revision 26 Sept. 1988) : Minerals Engineering, Vol. 2, No. 2, Pp. 217-227, 1989Document11 pages(Received April 1988 Revision 26 Sept. 1988) : Minerals Engineering, Vol. 2, No. 2, Pp. 217-227, 1989alinoriNo ratings yet

- 32 - 3 - New Orleans - 08-87 - 0255Document5 pages32 - 3 - New Orleans - 08-87 - 0255Abdul AzizNo ratings yet

- 1Document185 pages1امیرحسین محمدیNo ratings yet

- Determination of Mono-And Diglycerides by Capillary Gas ChromatographyDocument10 pagesDetermination of Mono-And Diglycerides by Capillary Gas ChromatographyJuliette GaviriaNo ratings yet

- Low FrictionDocument1 pageLow Frictionkannanmech87No ratings yet

- Vol24 2 PDFDocument378 pagesVol24 2 PDFAnonymous 3XvNuVNo ratings yet

- 21 Breuling Alfermann Reinhard 1985Document4 pages21 Breuling Alfermann Reinhard 1985nurul9535No ratings yet

- Thyme On ButterDocument4 pagesThyme On ButterBekele TilahunNo ratings yet

- Design of Pillars in Shrinkage StopingDocument13 pagesDesign of Pillars in Shrinkage StopingManuel QuirozNo ratings yet

- Emulsifier Esters AnalysisDocument13 pagesEmulsifier Esters AnalysisAnalitica DiransaNo ratings yet

- Polishes, Coatings and SealersDocument30 pagesPolishes, Coatings and SealersIdkaNo ratings yet

- Mass Culture of Spirulina Using Low-Cost NutrientsDocument5 pagesMass Culture of Spirulina Using Low-Cost NutrientsemadhsobhyNo ratings yet

- Johnv. Elackay, Gleiss.: Apo2ChDocument7 pagesJohnv. Elackay, Gleiss.: Apo2ChagyaaNo ratings yet

- Argonne and Amoco collaborate on ceramic membranes for clean fuel productionDocument1 pageArgonne and Amoco collaborate on ceramic membranes for clean fuel productionAditya RahmatNo ratings yet

- Steam ReformerDocument16 pagesSteam Reformersatishchemeng100% (5)

- Best Method Analysis of Ethanol UV and GC MethodDocument4 pagesBest Method Analysis of Ethanol UV and GC MethodMahit RajanNo ratings yet

- BF02642758 1Document9 pagesBF02642758 1Edgar LopezNo ratings yet

- Estimating Methane Content of Bituminous Coalbeds From AdsorptionDocument26 pagesEstimating Methane Content of Bituminous Coalbeds From AdsorptionAdhitya KuswantoroNo ratings yet

- 1977 Calorimetric Studies of 7000 Series Aluminum Alloys - I. Matrix Precipitate Characterization of 7075Document7 pages1977 Calorimetric Studies of 7000 Series Aluminum Alloys - I. Matrix Precipitate Characterization of 7075yhgrinmNo ratings yet

- Printing Ink and Overprint VarnishDocument137 pagesPrinting Ink and Overprint VarnishSutopo100% (2)

- Olo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelsDocument4 pagesOlo + I: Effect OF Hydrostatic Extrusion ON Properties OF Trip SteelspabusaoNo ratings yet

- Physical Properties of Palm OilDocument9 pagesPhysical Properties of Palm OilIman Pujitrianto100% (1)

- International Journal of Mine Water - © International Mine Water Association 2006 - WWW - IMWA.infoDocument13 pagesInternational Journal of Mine Water - © International Mine Water Association 2006 - WWW - IMWA.infoGIANCARLONo ratings yet

- Literatura i kvalitet kajmakaDocument4 pagesLiteratura i kvalitet kajmakaDragan Fića FilipovićNo ratings yet

- Effect of Microstructure on Crack Growth in Nickel AlloysDocument2 pagesEffect of Microstructure on Crack Growth in Nickel AlloysEnary SalernoNo ratings yet

- Chemistry, The University, Leyden (NetDocument4 pagesChemistry, The University, Leyden (NetCristhian ParedesNo ratings yet

- Sni 02-2803-2000Document15 pagesSni 02-2803-2000fahriansyah105No ratings yet

- A SIMPLE FAT EXTRACTION TUBE Butt 1915Document2 pagesA SIMPLE FAT EXTRACTION TUBE Butt 1915ManoleteNo ratings yet

- Wet Limestone Grinding for Flue Gas DesulfurizationDocument10 pagesWet Limestone Grinding for Flue Gas DesulfurizationLevent ErgunNo ratings yet

- AcknowledgementsDocument98 pagesAcknowledgementsShreyansh PanchalNo ratings yet

- Itaconic Acid Production by Immobilized Aspergillus Terreus On Sucrose MediumDocument6 pagesItaconic Acid Production by Immobilized Aspergillus Terreus On Sucrose Mediumxinyi zhangNo ratings yet

- 1937-Art of CombustionDocument7 pages1937-Art of CombustionKrozeNo ratings yet

- Ammonium NitrateDocument4 pagesAmmonium NitrateSteve WanNo ratings yet

- Butadiene PproductionDocument5 pagesButadiene PproductionYoteshYadavNo ratings yet

- The Effect of Added Solvents On Soy Oil Lutein Adsorption by Suicic AcidDocument4 pagesThe Effect of Added Solvents On Soy Oil Lutein Adsorption by Suicic AcidEndah AyuningtyasNo ratings yet

- GeologyDocument5 pagesGeologyAmna Nashit100% (1)

- Published With PermissionDocument30 pagesPublished With Permissionvinod kumarNo ratings yet

- A High Risk Energy Boom Sweeps Across North America (Yale)Document10 pagesA High Risk Energy Boom Sweeps Across North America (Yale)SchaliegasNo ratings yet

- Anon 2Document18 pagesAnon 2ifiokNo ratings yet

- Chapter One 1.0 1.1. Background of The StudyDocument3 pagesChapter One 1.0 1.1. Background of The StudyifiokNo ratings yet

- ZeoliDocument11 pagesZeoliifiokNo ratings yet

- Template For Research ProjectDocument18 pagesTemplate For Research ProjectifiokNo ratings yet

- Biodiesel Production From Palm Kernel Oil Using CalciumDocument28 pagesBiodiesel Production From Palm Kernel Oil Using CalciumifiokNo ratings yet

- Bleaching Effect On Palm OilDocument239 pagesBleaching Effect On Palm Oilde eagle100% (6)

- AnonDocument26 pagesAnonifiokNo ratings yet

- 2multicomponent Distillation CalculationsDocument1 page2multicomponent Distillation CalculationsifiokNo ratings yet

- Stocks PDFDocument4 pagesStocks PDFifiokNo ratings yet

- CHE518 Introduction To Polymer Engineering and ProcessingDocument3 pagesCHE518 Introduction To Polymer Engineering and ProcessingifiokNo ratings yet

- Auwal Paint2 Power PointDocument24 pagesAuwal Paint2 Power PointifiokNo ratings yet

- Investing in BondsDocument6 pagesInvesting in BondsNicolloNo ratings yet

- EarningsDocument18 pagesEarningsArun KumarNo ratings yet

- Engine Oil and Oil in General Can Be Made From Several MaterialsDocument5 pagesEngine Oil and Oil in General Can Be Made From Several MaterialsifiokNo ratings yet

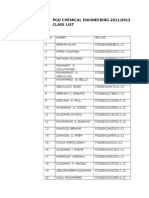

- PGD Chemical Engineering 2011/2012 Class ListDocument2 pagesPGD Chemical Engineering 2011/2012 Class ListifiokNo ratings yet

- Lecture - 3 - Heat and The First Law Example ProblemsDocument22 pagesLecture - 3 - Heat and The First Law Example ProblemsifiokNo ratings yet

- CHE 414 Principles of Plant Design I Part 2Document30 pagesCHE 414 Principles of Plant Design I Part 2ifiokNo ratings yet

- CHE 414 Principles of Plant Design I Part 4ADocument58 pagesCHE 414 Principles of Plant Design I Part 4AifiokNo ratings yet

- Alkenes and Alkynes I. Addition Reactions: Chapter EightDocument68 pagesAlkenes and Alkynes I. Addition Reactions: Chapter EightifiokNo ratings yet

- CHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTDocument4 pagesCHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTCharles BaileyNo ratings yet

- Week 4Document45 pagesWeek 4Iwuoha Maxrofuzo ChibuezeNo ratings yet

- Self Evaluation Skills: Dayo OdukoyaDocument17 pagesSelf Evaluation Skills: Dayo OdukoyaifiokNo ratings yet

- Time Management by Owoeye S.TDocument10 pagesTime Management by Owoeye S.TifiokNo ratings yet

- Schematic Diagram: Water WaterDocument5 pagesSchematic Diagram: Water WaterifiokNo ratings yet

- Corrosion Class Coating SlideDocument27 pagesCorrosion Class Coating SlideIwuoha Maxrofuzo ChibuezeNo ratings yet

- EDS411 - Entrepreneurial Marketing777777777777777Document26 pagesEDS411 - Entrepreneurial Marketing777777777777777ifiokNo ratings yet

- Che 414 Process Design e NoteDocument114 pagesChe 414 Process Design e Noteifiok100% (1)

- CHE 414 Principles of Plant Design I Part 5BDocument35 pagesCHE 414 Principles of Plant Design I Part 5BifiokNo ratings yet

- CHE 414 Part 1Document87 pagesCHE 414 Part 1ifiokNo ratings yet

- Veritrade Resumen UPC - (Pcmemama) US E 20220628172031Document36 pagesVeritrade Resumen UPC - (Pcmemama) US E 20220628172031Juan MartinaNo ratings yet

- Ahotu JDocument82 pagesAhotu JyemiNo ratings yet

- Guide to Assessing Integrity of Aging PipelinesDocument21 pagesGuide to Assessing Integrity of Aging PipelinesAmritesh Pandey100% (3)

- M. Mohamed Musthafa - T. Ashok Kumar - T. Mohanraj - R. Chandramouli 2018Document6 pagesM. Mohamed Musthafa - T. Ashok Kumar - T. Mohanraj - R. Chandramouli 2018Steve CardenasNo ratings yet

- Liquid Gold Petroleum's Performance and SuccessesDocument2 pagesLiquid Gold Petroleum's Performance and SuccessesShubham DawleNo ratings yet

- Gajendra Singh (ONGC Training Report)Document55 pagesGajendra Singh (ONGC Training Report)Gajju12567% (6)

- Selective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsDocument10 pagesSelective Adsorption For Removal of Nitrogen Compounds From Liquid HC Streams Over Carbon - and Alumina - Based AdsorbentsJohnSmithNo ratings yet

- Introduction To Exploration Geophysics With Recent Advances: April 2018Document34 pagesIntroduction To Exploration Geophysics With Recent Advances: April 2018MithunNo ratings yet

- Nigerian-Oil-And-Gas-Update-Quarterly-Newsletter - Edition-2021Document3 pagesNigerian-Oil-And-Gas-Update-Quarterly-Newsletter - Edition-2021cyrilNo ratings yet

- Formation Bou DabbousDocument8 pagesFormation Bou DabboushajlaouiNo ratings yet

- Eco7 Case NotesDocument6 pagesEco7 Case NotesValerie Bodden KlugeNo ratings yet

- Screw PumpDocument4 pagesScrew Pumpnastranfan100% (2)

- Latent Heat QueriesDocument20 pagesLatent Heat QueriesYeditha Satyanarayana MurthyNo ratings yet

- General 03 15Document71 pagesGeneral 03 15GloryoneNo ratings yet

- 4410 - Section E - Technical PDFDocument45 pages4410 - Section E - Technical PDFArnaldo BenitezNo ratings yet

- EnppiDocument49 pagesEnppiMostafa SharafNo ratings yet

- Plastics and The EnvironmentDocument783 pagesPlastics and The EnvironmentBerlin Anand100% (4)

- (Magazine) Hydrocarbon Processing 01 2014Document103 pages(Magazine) Hydrocarbon Processing 01 2014Huy Văn ĐoànNo ratings yet

- 11-12 NOGEPA NewsletterDocument5 pages11-12 NOGEPA Newsletterjahehe2000No ratings yet

- Cases For IntegrationDocument3 pagesCases For IntegrationWainaina Githii100% (1)

- HCR Reprting Guidance Issue 2 Technical PresentationDocument20 pagesHCR Reprting Guidance Issue 2 Technical Presentationdiegofc7No ratings yet

- The Idiots' Guide To Highways MaintenanceDocument24 pagesThe Idiots' Guide To Highways Maintenancemp SinghNo ratings yet

- Three Day Course 2 BDocument143 pagesThree Day Course 2 BDanang AbimanyuNo ratings yet

- IGS Technical ProgramDocument15 pagesIGS Technical ProgramSalma AzizahNo ratings yet

- Peca 20110430Document112 pagesPeca 20110430kennym8No ratings yet

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument3 pagesMaintenance Interval Schedule: Operation and Maintenance ManualsxturboNo ratings yet

- Chapter (Non-Refereed) : Biological Recording of Changes in British WildlifeDocument14 pagesChapter (Non-Refereed) : Biological Recording of Changes in British WildlifeﺭﺍﺑﻌﺔﺍﻟﺒﺼﺮﻱNo ratings yet

- Marpol SECADocument3 pagesMarpol SECAAnonymous XtvvG80zuNo ratings yet

- Deregulation of Essential CommoditiesDocument130 pagesDeregulation of Essential CommoditiesRajagopal RaoNo ratings yet