Professional Documents

Culture Documents

ASTM A672 Welded Pipe Standard PDF

Uploaded by

umeshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTM A672 Welded Pipe Standard PDF

Uploaded by

umeshCopyright:

Available Formats

Designation: A672/A672M − 09

Standard Specification for

Electric-Fusion-Welded Steel Pipe for High-Pressure Service

at Moderate Temperatures1

This standard is issued under the fixed designation A672/A672M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 41 normalized and tempered, see 5.3.3 9 none

42 normalized and tempered, see 5.3.3 9 8.3

1.1 This specification2 covers steel pipe: electric-fusion- 43 normalized and tempered, see 5.3.3 none 8.3

welded with filler metal added, fabricated from pressure-vessel 50 quenched and tempered, see 5.3.4 none none

quality plate of any of several analyses and strength levels and 51 quenched and tempered, see 5.3.4 9 none

52 quenched and tempered, see 5.3.4 9 8.3

suitable for high-pressure service at moderate temperatures. 53 quenched and tempered, see 5.3.4 none 8.3

Heat treatment may or may not be required to attain the desired

NOTE 1—Selection of materials should be made with attention to

properties or to comply with applicable code requirements. temperature of service. For such guidance, Specification A20/A20M may

Supplementary requirements are provided for use when addi- be consulted.

tional testing or examination is desired. 1.4 The values stated in either SI units or inch-pound units

1.2 The specification nominally covers pipe 16 in. [400 are to be regarded separately as standard. Within the text, the

mm] in outside diameter or larger with wall thicknesses up to SI units are shown in brackets. The values stated in each

3 in. [75 mm], inclusive. Pipe having other dimensions may be system may not be exact equivalents; therefore, each system

furnished provided it complies with all other requirements of shall be used independently of the other. Combining values

this specification. from the two systems may result in non-conformance with the

1.3 Several grades and classes of pipe are provided. standard. The inch-pound units shall apply unless the “M”

1.3.1 Grade designates the type of plate used. designation of this specification is specified in the order.

1.3.2 Class designates the type of heat treatment performed 2. Referenced Documents

during manufacture of the pipe, whether the weld is radio-

graphically examined, and whether the pipe has been pressure 2.1 ASTM Standards:3

tested as listed in 1.3.3. A20/A20M Specification for General Requirements for Steel

1.3.3 Class designations are as follows (Note 1): Plates for Pressure Vessels

A370 Test Methods and Definitions for Mechanical Testing

Radiography, Pressure Test,

Class Heat Treatment on Pipe see Section see Section of Steel Products

A435/A435M Specification for Straight-Beam Ultrasonic

10 none none none

11 none 9 none

Examination of Steel Plates

12 none 9 8.3 A530/A530M Specification for General Requirements for

13 none none 8.3 Specialized Carbon and Alloy Steel Pipe

20 stress relieved, see 5.3.1 none none

21 stress relieved, see 5.3.1 9 none

A577/A577M Specification for Ultrasonic Angle-Beam Ex-

22 stress relieved, see 5.3.1 9 8.3 amination of Steel Plates

23 stress relieved, see 5.3.1 none 8.3 A578/A578M Specification for Straight-Beam Ultrasonic

30 normalized, see 5.3.2 none none

31 normalized, see 5.3.2 9 none

Examination of Rolled Steel Plates for Special Applica-

32 normalized, see 5.3.2 9 8.3 tions

33 normalized, see 5.3.2 none 8.3 E109 Method for Dry Powder Magnetic Particle Inspection;

40 normalized and tempered, see 5.3.3 none none

Replaced by E 709 (Withdrawn 1981)4

E138 Method for Wet Magnetic Particle Inspection; Re-

placed by E 709 (Withdrawn 1981)4

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

3

A01.09 on Carbon Steel Tubular Products. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2009. Published November 2009. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1972. Last previous edition approved in 2008 as A672 – 08. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A0672_A0672M-09. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications see related Specifi- The last approved version of this historical standard is referenced on

cation SA-672 in Section II of that Code. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A672/A672M − 09

E110 Test Method for Indentation Hardness of Metallic 4.1.9 Supplementary requirements, if any, (refer to S1

Materials by Portable Hardness Testers through S14).

E165 Practice for Liquid Penetrant Examination for General

Industry 5. Materials and Manufacture

E709 Guide for Magnetic Particle Testing

2.1.1 Plate Steel Specifications (Table 1) 5.1 Materials—The steel plate material shall conform to the

A202/A202M Specification for Pressure Vessel Plates, Alloy requirements of the applicable plate specification for pipe

Steel, Chromium-Manganese-Silicon (Withdrawn 2004)4 grade ordered as listed in Table 1.

A204/A204M Specification for Pressure Vessel Plates, Alloy 5.2 Welding:

Steel, Molybdenum

5.2.1 The joints shall be double-welded, full-penetration

A285/A285M Specification for Pressure Vessel Plates, Car-

bon Steel, Low- and Intermediate-Tensile Strength welds made in accordance with procedures and by welders or

A299/A299M Specification for Pressure Vessel Plates, Car- welding operators qualified in accordance with the ASME

bon Steel, Manganese-Silicon Boiler and Pressure Vessel Code, Section IX.

A302/A302M Specification for Pressure Vessel Plates, Alloy 5.2.2 The welds shall be made either manually or automati-

Steel, Manganese-Molybdenum and Manganese- cally by an electric process involving the deposition of filler

Molybdenum-Nickel metal.

A515/A515M Specification for Pressure Vessel Plates, Car- 5.2.3 The welded joint shall have positive reinforcement at

bon Steel, for Intermediate- and Higher-Temperature Ser- the center of each side of the weld, but not more than 1⁄8 in. [3

vice mm]. This reinforcement may be removed at the manufactur-

A516/A516M Specification for Pressure Vessel Plates, Car- er’s option or by agreement between the manufacturer and

bon Steel, for Moderate- and Lower-Temperature Service purchaser. The contour of the reinforcement shall be smooth,

A533/A533M Specification for Pressure Vessel Plates, Alloy and the deposited metal shall be fused smoothly and uniformly

Steel, Quenched and Tempered, Manganese-Molybdenum into the plate surface.

and Manganese-Molybdenum-Nickel

5.2.4 When radiographic examination in accordance with

A537/A537M Specification for Pressure Vessel Plates, Heat-

Treated, Carbon-Manganese-Silicon Steel 9.1 is to be used, the weld reinforcement shall be governed by

the more restrictive provisions of UW–51 of Section VIII of

2.2 ASME Boiler and Pressure Vessel Code:5 the ASME Boiler and Pressure Vessel Code instead of 5.2.3 of

Section II, Material Specifications this specification.

Section III, Nuclear Vessels

Section VIII, Unfired Pressure Vessels 5.3 Heat Treatment—All classes other than 10, 11, 12 and

Section IX, Welding Qualifications 13 shall be heat treated in furnace controlled to 6 25 °F [15

°C] and equipped with a recording pyrometer so that heating

3. Terminology records are available. Heat treating after forming and welding

3.1 Definitions of Terms Specific to This Standard: shall be to one of the following:

3.1.1 A lot shall consist of 200 ft [60 m] or fraction thereof 5.3.1 Classes 20, 21, 22, and 23 pipe shall be uniformly

of pipe from the same heat of steel. heated within the post-weld heat-treatment temperature range

3.1.2 The description of a lot may be further restricted by indicated in Table 2 for a minimum of 1 h/in. [0.4 hr/cm] of

use of Supplementary Requirement S14. thickness or 1 h, whichever is greater.

5.3.2 Classes 30, 31, 32, and 33 pipe shall be uniformly

4. Ordering Information heated to a temperature in the austenitizing range and not

4.1 The inquiry and order for material under this specifica- exceeding the maximum normalizing temperature indicated in

tion should include the following information: Table 2 and subsequently cooled in air at room temperature.

4.1.1 Quantity (feet, metres, or number of lengths), 5.3.3 Classes 40, 41, 42, and 43 pipe shall be normalized in

4.1.2 Name of material (steel pipe, electric-fusionwelded), accordance with 5.3.2. After normalizing, the pipe shall be

4.1.3 Specification number, reheated to the tempering temperature indicated in Table 2 as a

4.1.4 Grade and class designations (see 1.3), minimum and held at temperature for a minimum of 1⁄2 h/in.

4.1.5 Size (inside or outside diameter, nominal or minimum [0.2 hr/cm] of thickness or 1⁄2 h, whichever is greater, and air

wall thickness), cooled.

4.1.6 Length (specific or random),

4.1.7 End finish (11.4), 5.3.4 Classes 50, 51, 52, and 53 pipe shall be uniformly

4.1.8 Purchase options, if any (see 5.2.3, 11.3, 14.1 and heated to a temperature in the austenitizing range, and not

Sections 16, 20.1, 21, 22 of Specification A530/A530M), and exceeding the maximum quenching temperature indicated in

Table 2 and subsequently quenched in water or oil. After

quenching the pipe shall be reheated to the tempering tempera-

5

ture indicated in Table 2 as a minimum and held at temperature

Available from American Society of Mechanical Engineers (ASME), ASME

International Headquarters, Three Park Ave., New York, NY 10016-5990, http:// for a minimum of 1⁄2 h/in. [0.2 hr/cm] of thickness or 1⁄2 h,

www.asme.org. whichever is greater, and air cooled.

Copyright by ASTM Int'l (all rights reserved); 2

A672/A672M − 09

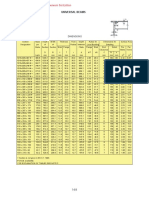

TABLE 1 Plate Specification 8. Mechanical Properties

ASTM Specification

Pipe Grade Type of Steel 8.1 Tension Test:

No. Grade

A 45 plain carbon A285/A285M A 8.1.1 Requirements—Transverse tensile properties of the

A 50 plain carbon A285/A285M B welded joint shall meet the minimum requirements for ultimate

A 55 plain carbon A285/A285M C tensile strength of the specified plate material. In addition for

B 60 plain carbon, killed A515/A515M 60 Grades Dxx, Hxx, Jxx, and Nxx in Classes 3x, 4x, and 5x

B 65 plain carbon, killed A515/A515M 65 transverse tensile properties of the base plate, shall be deter-

B 70 plain carbon, killed A515/A515M 70

mined on specimens cut from the heat-treated pipe. These

C 55 plain carbon, killed, fine grain A516/A516M 55 properties shall meet the mechanical test requirements of the

C 60 plain carbon, killed, fine grain A516/A516M 60 plate specification.

C 65 plain carbon, killed, fine grain A516/A516M 65

C 70 plain carbon, killed, fine grain A516/A516M 70 8.1.2 Number of Tests—One test specimen shall be made to

represent each lot of finished pipe.

D 70 manganese-silicon— A537/A537M 1

normalized 8.1.3 Test Specimen Location and Orientation—The test

D80 manganese-silicon—Q&TA A537/A537M 2 specimens shall be taken transverse to the weld at the end of

H 75 manganese-molybdenum— A302/A302M A

the finished pipe and may be flattened cold before final

normalized machining to size.

H 80 manganese-molybdenum— A302/A302M B, C or D

normalized

8.1.4 Test Method—The test specimen shall be made in

accordance with QW-150 in Section IX of the ASME Boiler

J 80 manganese-molybdenum— A533/A533M Cl-1B and Pressure Vessel Code. The test specimen shall be tested at

Q&TA

J 90 manganese-molybdenum— A533/A533M Cl-2B

room temperature in accordance with Test Methods and Defi-

Q&TA nitions A370.

J 100 manganese-molybdenum— A533/A533M Cl-3B

Q&TA 8.2 Transverse-Guided-Weld-Bend Tests:

K 75 chromium-manganese-silicon A202/A202M A

8.2.1 Requirements—The bend test shall be acceptable if no

K 85 chromium-manganese-silicon A202/A202M B cracks or other defects exceeding 1⁄8 in. [3 mm] in any

direction are present in the weld metal or between the weld and

L 65 molybdenum A204/A204M A

L 70 molybdenum A204/A204M B the base metal after bending. Cracks that originate along the

L 75 molybdenum A204/A204M C edges of the specimen during testing, and that are less than

1⁄4 in. [6 mm] measured in any direction shall not be

N 75 manganese-silicon A299/A299M ...

A

considered.

Q&T = quenched and tempered.

B

Any grade may be furnished. 8.2.2 Number of Tests—One test (two specimens) shall be

made to represent each lot of finished pipe.

8.2.3 Test Specimen Location and Orientation—Two bend

test specimens shall be taken transverse to the weld at the end

6. General Requirements

of the finished pipe. As an alternative by agreement between

6.1 Material furnished to this specification shall conform to the purchaser and the manufacturer, the test specimens may be

the applicable requirements of the current edition of Specifi- taken from a test plate of the same material as the pipe, the test

cation A530/A530M unless otherwise provided herein. plate being attached to the end of the cylinder and welded as a

prolongation of the pipe longitudinal seam.

7. Chemical Composition

8.2.4 Test Method—The test requirements of Test Methods

7.1 Product Analysis of Plate—The pipe manufacturer shall and Definitions A370, paragraph A2.5.1.7 shall be met. For

make an analysis of each mill heat of plate material. The wall thickness over 3⁄8 in. [10 mm] but less than 3

⁄ in. [19

product analysis so determined shall meet the requirements of mm] side-bend tests may be made instead of the face and

the plate specification to which the material was ordered. root-bend tests. For wall thicknesses 3⁄4 in. [19 mm] and over

7.2 Product Analysis of Weld—The pipe manufacturer shall both specimens shall be subjected to the side-bend test.

make an analysis of the finished deposited weld material from

8.3 Pressure Test—Classes X2 and X3 pipe shall be tested in

each 500 ft [150 m] or fraction thereof. Analysis shall conform

accordance with Specification A530/A530M, Section 20.

to the welding procedure for deposited weld metal.

7.3 Analysis may be taken from the mechanical test speci- 9. Radiographic Examination

mens. The results of the analyses shall be reported to the

purchaser. 9.1 The full length of each weld of Classes X1 and X2 shall

be radiographically examined in accordance with and meet the

7.4 If the analysis of one of the tests specified in 7.1 or 7.2

requirements of the ASME Boiler and Pressure Vessel Code,

does not conform to the requirements specified, analyses shall

Section VIII, paragraph UW–51.

be made on additional pipes of double the original number

from the same lot, each of which shall conform to the 9.2 Radiographic examination may be performed prior to

requirements specified. Nonconforming pipe shall be rejected. heat treatment.

Copyright by ASTM Int'l (all rights reserved); 3

A672/A672M − 09

TABLE 2 Heat Treatment ParametersA

Quenching Tem- Tempering

Normalizing Tem-

Specification and Post-Weld Heat-Treat perature, max, Temperature, min,

Pipe GradeB perature, max,

GradeC Temperature Range, °F (°C) °F (°C) °F (°C)

°F (°C)

A 45 A 285A 1100–1250 [590–680] 1700 [925] ... ...

A 50 A 285B 1100–1250 [590–680] 1700 [925] ... ...

A 55 A 285C 1100–1250 [590–680] 1700 [925] ... ...

B 60 A515-60 1100–1250 [590–680] 1750 [950] ... ...

B 65 A515-65 1100–1250 [590–680] 1750 [950] ... ...

B 70 A515-70 1100–1250 [590–680] 1750 [950] ... ...

C 55 A516-55 1100–1250 [590–680] 1700 [925] 1650 [900] 1200 [650]

C 60 A516-60 1100–1250 [590–680] 1700 [925] 1650 [900] 1200 [650]

C 65 A516-65 1100–1250 [590–680] 1700 [925] 1650 [900] 1200 [650]

C 70 A516-70 1100–1250 [590–680] 1700 [925] 1650 [900] 1200 [650]

D 70 A537-1 1100–1250 [590–680] 1700 [925] ... ...

D 80 A537-2 1100–1250 [590–680] ... 1650 [900] 1200 [650]

H 75 A 302-A 1100–1250 [590–680] 1800 [980] ... 1100 [590]

H 80 A 302-B, C or D 1100–1250 [590–680] 1800 [980] ... 1100 [590]

J 80 A 533-C11C 1100–1250 [590–680] ... 1800 [980] 1100 [590]

J 90 A 533-C12C 1100–1250 [590–680] ... 1800 [980] 1100 [590]

J 100 A 533-C13C 1100–1250 [590–680] ... 1800 [980] 1100 [590]

K 75 A 202A 1100–1200 [590–650] ... ... ...

K 85 A 202B 1100–1200 [590–650] ... ... ...

L 65 A 204A 1100–1200 (590–650) ... ... ...

L 70 A 204B 1100–1200 (590–650) ... ... ...

L 75 A 204C 1100–1200 (590–650) ... ... ...

N 75 A299 1100–1200 [590–650] 1700 [925] ... ...

A

Where ellipses (...) appear in this table, there is no requirement.

B

Numbers indicate minimum tensile strength in ksi.

C

Any grade may be used.

10. Rework by radiography in accordance with the methods and the

10.1 Elimination of Surface Imperfections—Unacceptable acceptance standards of Section 9.

surface imperfections shall be removed by grinding or machin- 10.2.6 The repair surface shall be blended uniformly into

ing. The remaining thickness of the section shall be no less than the surrounding base metal surface and examined and accepted

the minimum specified in Section 11. The depression after in accordance with Section S6 or S8.

grinding or machining shall be blended uniformly into the 10.3 Repair of Weld Metal Defects by Welding:

surrounding surface. 10.3.1 The manufacturer may repair weld metal defects if he

10.2 Repair of Base Metal Defects by Welding: meets the requirements of 10.2.3, 10.2.4, 10.3.2, 10.3.3, and

10.2.1 The manufacturer may repair, by welding, base metal 10.4.

where defects have been removed, provided the depth of the 10.3.2 The defects shall be removed by suitable mechanical

repair cavity as prepared for welding does not exceed 1⁄3 of the or thermal cutting or gouging methods and the repair cavity

nominal thickness and the requirements of 10.2.2-10.2.6 are examined and accepted in accordance with Sections S7 or S9.

met. Base metal defects in excess of these may be repaired with 10.3.3 The weld repair shall be blended uniformly into the

proper approval of the customer. surrounding metal surfaces and examined and accepted in

10.2.2 The defect shall be removed by suitable mechanical accordance with 9.1 and Sections S7 or S9.

or thermal cutting or gouging methods and the cavity prepared 10.4 Retest—Each length of repaired pipe of a class requir-

for repair welding. ing a pressure test shall be hydrostatically tested following

10.2.3 The welding procedure and welders or welding repair.

operators are to be qualified in accordance with Section IX of 11. Dimensions, Mass and Permissible Variations

the ASME Boiler and Pressure Vessel Code.

10.2.4 The full length of the repaired pipe shall be heat 11.1 The wall thickness and weight for welded pipe fur-

treated after repair in accordance with the requirements of the nished to this specification shall be governed by the require-

pipe class specified. ments of the specification to which the manufacturer ordered

10.2.5 Each repair weld of a defect where the cavity, the plate.

prepared for welding, has a depth exceeding the lesser of 3⁄8 in. 11.2 Permissible variations in dimensions at any point in a

[10 mm] or 10 % of the nominal thickness shall be examined length of pipe shall not exceed the following:

Copyright by ASTM Int'l (all rights reserved); 4

A672/A672M − 09

11.2.1 Outside Diameter—Based on circumferential mea- 12. Workmanship, Finish, and Appearance

surement 6 0.5 % of the specified outside diameter.

12.1 The finished pipe shall be free of injurious defects and

11.2.2 Out-of-Roundness—Difference between major and

minor outside diameters, 1 %. shall have a workmanlike finish. This requirement is to mean

11.2.3 Alignment—Using a 10-ft [3-m] straightedge placed the same as the identical requirement that appears in Specifi-

so that both ends are in contact with the pipe, 1⁄8 in. [3 mm]. cation A20/A20M with respect to steel plate surface finish.

11.2.4 Thickness—The minimum wall thickness at any point

in the pipe shall not be more than 0.01 in. [0.3 mm] under the 13. Product Marking

specified nominal thickness. 13.1 In addition to the marking provision of Specification

11.3 Circumferential welded joints of the same quality as A530/A530M, class marking in accordance with 1.3.3 shall

the longitudinal joints shall be permitted by agreement between follow the grade marking; for example, C 70–10.

the manufacturer and the purchaser.

13.2 Bar Coding—In addition to the requirements in 13.1,

11.4 Lengths with unmachined ends shall be within −0, +1⁄2 bar coding is acceptable as a supplemental identification

in. [−0, +13 mm] of that specified. Lengths with machined method. The purchaser may specify in the order a specific bar

ends shall be as agreed upon between the manufacturer and the coding system to be used.

purchaser.

SUPPLEMENTARY REQUIREMENTS

One or more of the following supplementary requirements shall be applied only when specified by

the purchaser in the inquiry, contract, or order. Details of these supplementary requirements shall be

agreed upon in writing by the manufacturer and purchaser. Supplementary requirements shall in no

way negate any requirement of the specification itself.

S1. Tension and Bend Tests S3. Hardness Test

S1.1 Tension tests in accordance with 8.1 and bend tests in S3.1 Hardness measurements in accordance with Test Meth-

accordance with 8.2 shall be made on specimens representing ods and Definitions A370 or Test Method E110 shall be made

each length of pipe. across the welded joint at both ends of each length of pipe. The

maximum acceptable hardness shall be as agreed upon between

S2. Charpy V-Notch Test (For pipe with nominal wall the manufacturer and the purchaser.

thickness of 1⁄2 in. [13 mm] and greater)

S4. Product Analysis

S2.1 Requirements —The acceptable test energies shall be

S4.1 Product analyses in accordance with 7.1 shall be made

as shown in Table A1.15 of Specification A20/A20M for the

on each 500 ft [150 m] of pipe or fraction thereof or

applicable plate specification unless otherwise stated in the

alternatively, on each length of pipe as designated in the order.

order. As an alternative, the test temperature may be 10 °F [−12

°C]. S5. Metallography

S2.2 Number of Specimens—Each test shall consist of at

S5.1 The manufacturer shall furnish one photomicrograph

least three specimens.

to show the microstructure of 100× magnification of the weld

S2.2.1 One base-metal test shall be made from one pipe metal or base metal of the pipe in the as-finished condition. The

length per heat, per heat-treat charge, and per nominal wall purchaser shall state in the order: the material, base metal or

thickness. For pipe from Classes 10, 11, 12, and 13, one base weld, and the number and locations of tests to be made. This

metal test shall be made per heat per size and per wall test is for information only.

thickness.

S2.2.2 One weld-metal and one heat-affected zone (HAZ) S6. Magnetic Particle Examination of Base Metal

metal test shall be made in accordance with NB 4335 of S6.1 All accessible surfaces of the pipe shall be examined in

Section III of the ASME Boiler and Pressure Vessel Code. accordance with Methods E109 or E138. Accessible is defined

S2.3 Test Specimen Location and Orientation: as: All outside surfaces, all inside surfaces of pipe 24 in. [600

S2.3.1 Base-metal specimens of stress-relieved, normalized, mm] in diameter and greater, and inside surfaces of pipe less

and normalized and tempered pipe shall be taken in accordance than 24 in. [600 mm] in diameter for a distance of one pipe

with the provisions for tension specimens in the body of this diameter from the ends.

specification. S6.2 Acceptance Standards—The following relevant indi-

S2.3.2 Base-metal specimens of quenched and tempered cations are unacceptable:

pipe shall be taken in accordance with the provisions of NB S6.2.1 Any linear indications greater than 1⁄16 in. [1 mm]

2225 of Section III of the ASME Boiler and Pressure Vessel long for materials less than 5⁄8 in. [16 mm] thick; greater than

Code. 1⁄8 in. [3 mm] long for materials 5⁄8 in. [16 mm] thick to under

Copyright by ASTM Int'l (all rights reserved); 5

A672/A672M − 09

2 in. [50 mm] thick; and greater than 3⁄16 in. [5 mm] long for S11. Straight Beam Ultrasonic Examination of Flat

materials 2 in. [50 mm] thick or greater. Plate—UT 2

S6.2.2 Rounded indications with dimensions greater than 1⁄8

in. [3 mm] for thicknesses less than 5⁄8 in. [16 mm] and greater S11.1 The plate shall be examined in accordance with

than 3⁄16 in. [5 mm] for thicknesses 5⁄8 in. [16 mm] and greater. Specification A578/A578M except that 100 % of one surface

S6.2.3 Four or more indications in any line separated by 1⁄16 shall be scanned and the acceptance criteria shall be as follows:

in. [1 mm] or less edge-to-edge. S11.2 Any area, where one or more discontinuities produce

S6.2.4 Ten or more indications in any 6 in.2 [39 cm2] of a continuous total loss of back reflection accompanied by

surface with the major dimension of this area not to exceed 6 continuous indications on the same plane that cannot be

in. [150 mm] when it is taken in the most unfavorable encompassed within a circle whose diameter is 3 in. [75 mm]

orientation relative to the indications being evaluated. or 1⁄2 of the plate thickness, whichever is greater, is unaccept-

S7. Magnetic Particle Examination of Weld Metal able. In addition, two or more discontinuities on the same plane

and having the same characteristics but smaller than described

S7.1 All accessible weld shall be examined in accordance above shall be unacceptable unless separated by a minimum

with Practice E709. Accessible is defined as: All outside

distance equal to the largest diameter of the larger discontinuity

surfaces, all inside surfaces of pipe less than 24 in. [600 mm]

or unless they may be collectively encompassed by the circle

in diameter for a distance of one pipe diameter from the ends.

described above.

S7.2 Acceptance Criteria—The following relevant indica-

tions are unacceptable:

S7.2.1 Any cracks and linear indications. S12. Angle-Beam Ultrasonic Examination (Plate Less than

S7.2.2 Rounded indications with dimensions greater than 2 in. [50 mm)] Thick)—UT 3

3⁄16 in. [5 mm].

S12.1 The plate shall be examined in accordance with

S7.2.3 Four or more indications in any line separated 1⁄16 in. Specification A577/A577M except that the calibration notch

[1 mm] or less edge-to-edge. shall be V-shaped and the acceptance criteria shall be as

S7.2.4 Ten or more indications in any 6 in.2 [39 cm2] of follows: Any area showing one or more reflectors producing

surface with the major dimension of this area not to exceed 6 indications whose amplitude exceeds that of the calibration

in. [150 mm] when it is taken in the most unfavorable

notch is unacceptable.

orientation relative to the indications being evaluated.

S8. Liquid Penetrant Examination of Base Metal S13. Repair Welding

S8.1 All accessible surfaces of the pipe shall be examined in S13.1 Repair of base metal defects by welding shall be done

accordance with Test Method E165. Accessible is as defined in only with customer approval.

S6.1.

S8.2 The acceptance criteria shall be in accordance with S14. Description of Term

S6.2.

S14.1 lot—all pipe of the same mill heat of plate material

S9. Liquid Penetrant Examination of Weld Metal

and wall thickness (within 61⁄4 in. [6 mm]) heat treated in one

S9.1 All accessible surfaces of the pipe shall be examined in furnace charge. For pipe that is not heat treated or that is heat

accordance with Test Method E165. Accessible is as defined in treated in a continuous furnace, a lot shall consist of each 200

S7.1 ft [60 m] or fraction thereof of all pipe of the same mill heat of

S9.2 The acceptance criteria shall be in accordance with plate material and wall thickness (within 61⁄4 in. [6 mm]),

S7.2

subjected to the same heat treatment. For pipe heat treated in a

S10. Straight Beam Ultrasonic Examination of Flat batch-type furnace that is automatically controlled within a 50

Plate—UT 1 °F [30 °C] range and is equipped with recording pyrometers so

S10.1 The plate shall be examined and accepted in accor- that heating records are available, a lot shall be defined the

dance with Specification A435/A435M except that 100 % of same as for continuous furnaces.

one surface shall be scanned by moving the search unit in

parallel paths with not less than 10 % overlap.

Copyright by ASTM Int'l (all rights reserved); 6

A672/A672M − 09

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this specification since the last issue,

A672 – 08, that may impact the use of this specification. (Approved October 1, 2009)

(1) Revised the standard as a dual units specification.

Committee A01 has identified the location of selected changes to this specification since the last issue,

A672 – 06, that may impact the use of this specification. (Approved May 1, 2008)

(1) Removed B 55 from Table 1 and Table 2.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 7

You might also like

- Secrets of A Super HackerDocument243 pagesSecrets of A Super HackerLeLiberte86% (7)

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Astm A352Document5 pagesAstm A352depeche1modeNo ratings yet

- Maxwell-Betti Reciprocal TheoremDocument1 pageMaxwell-Betti Reciprocal TheoremTalha MahmoodNo ratings yet

- ASME - B16.5 - Interpretation To ASME B16.5Document24 pagesASME - B16.5 - Interpretation To ASME B16.5Aristya Ed Geins100% (1)

- Astm A572Document4 pagesAstm A572charles4667% (3)

- Astm A403Document7 pagesAstm A403mtpiping2572100% (1)

- Astm A350Document8 pagesAstm A350nse mcx100% (1)

- Asme B18.2.2-2015Document39 pagesAsme B18.2.2-2015DmitriyNo ratings yet

- Ac 036630 001Document1 pageAc 036630 001navaronefraNo ratings yet

- 16 Astm - A350-A350mDocument10 pages16 Astm - A350-A350mFYNo ratings yet

- Astm A960-00Document9 pagesAstm A960-00Asad Bin Ala Qatari100% (2)

- Mesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Document17 pagesMesc Spe 77-100 Oct 2012 Ball Valve To Bs 5351Dwayne YiiNo ratings yet

- Difference ASTM A106 and A333 Grade 6.Document2 pagesDifference ASTM A106 and A333 Grade 6.Qaisir MehmoodNo ratings yet

- 90203-1036DEB - Arc Welding Operation Manual (E Series) PDFDocument270 pages90203-1036DEB - Arc Welding Operation Manual (E Series) PDFumeshNo ratings yet

- 90203-1036DEB - Arc Welding Operation Manual (E Series) PDFDocument270 pages90203-1036DEB - Arc Welding Operation Manual (E Series) PDFumeshNo ratings yet

- Sa 479Document12 pagesSa 479singaravelan narayanasamyNo ratings yet

- Case 2864 9Cr–1Mo–VDocument1 pageCase 2864 9Cr–1Mo–VAlevj Db100% (1)

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature ServiceDocument8 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Moderate and High Temperature Servicesharon blushteinNo ratings yet

- Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalDocument7 pagesFerritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded With Addition of Filler MetalSameh AminNo ratings yet

- Astm A312 PDFDocument12 pagesAstm A312 PDFGustavo Freitas100% (1)

- Asme B36.10 2004Document26 pagesAsme B36.10 2004rogersampaiocosta60% (5)

- Astm A420a420m-16Document6 pagesAstm A420a420m-16arcadiosco100% (1)

- Astm A403-A403m-2022Document10 pagesAstm A403-A403m-2022CarlosNo ratings yet

- En 10025 1 PDFDocument34 pagesEn 10025 1 PDFumeshNo ratings yet

- Astm B446 - 2003 - 2008Document5 pagesAstm B446 - 2003 - 2008isaque300984No ratings yet

- b16 47Document65 pagesb16 47Gustavo FamaNo ratings yet

- Asme B36.19M-2004 PDFDocument14 pagesAsme B36.19M-2004 PDFUlises Montao100% (1)

- ASME B31.1 vs B31.3 Code ComparisonDocument1 pageASME B31.1 vs B31.3 Code ComparisonKhurramNo ratings yet

- Asme 36.19Document18 pagesAsme 36.19shakeelahmadjsr100% (1)

- A694 16Document4 pagesA694 16Esteban CastellanoNo ratings yet

- Part 01 - Review of EN ISO 9606-1Document26 pagesPart 01 - Review of EN ISO 9606-1Turbo Snail RNo ratings yet

- Astm A694Document3 pagesAstm A694Muhammad Awais0% (1)

- Astm A216-98Document3 pagesAstm A216-98panap25100% (1)

- Iso 8501Document4 pagesIso 8501cisar0007100% (2)

- Astm A795 - A795m - 13Document7 pagesAstm A795 - A795m - 13alejandroNo ratings yet

- Poster Weldingpositions enDocument1 pagePoster Weldingpositions enslowmosquitoNo ratings yet

- Polymers Unit Exploring Key ConceptsDocument23 pagesPolymers Unit Exploring Key ConceptsderbewalebelNo ratings yet

- General Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt AlloysDocument4 pagesGeneral Requirements For Chemical Check Analysis Limits For Nickel, Nickel Alloys and Cobalt Alloysanurag yadavNo ratings yet

- DIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsDocument15 pagesDIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsKovács Zsolt100% (1)

- DIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsDocument15 pagesDIN EN10278 1999 Dimensions and Tolerances of Bright Steel ProductsKovács Zsolt100% (1)

- A358/a358m 12Document8 pagesA358/a358m 12Maria Ivana100% (1)

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samyNo ratings yet

- JIS Standard ValveDocument8 pagesJIS Standard ValveJong JavaNo ratings yet

- ASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedDocument33 pagesASME ANSI B16.11 Forged Fittings Socket Welding and ThreadedpaulamuisesNo ratings yet

- Wrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForDocument10 pagesWrought Austenitic Stainless Steel Piping Fittings: Standard Specification ForMatheus Ferreira SilvaNo ratings yet

- Fundamentals of Geometric Dimensioning and Tolerancing AnswersDocument15 pagesFundamentals of Geometric Dimensioning and Tolerancing Answersram_10850% (2)

- Astm A312Document12 pagesAstm A312Ruth Sarai YañezNo ratings yet

- Astm A999 A999m 13Document11 pagesAstm A999 A999m 13islamakthamNo ratings yet

- Astm A-192Document2 pagesAstm A-192LoriGalbanusNo ratings yet

- Anodes in Cooling Water Exchangers PDFDocument12 pagesAnodes in Cooling Water Exchangers PDFcbrittaivNo ratings yet

- Astm A653Document9 pagesAstm A653MEPNo ratings yet

- MSS SP 95Document16 pagesMSS SP 95JUAN DAVID GOMEZ PATIÑONo ratings yet

- BS EN 10048 Tolerances PDFDocument24 pagesBS EN 10048 Tolerances PDFShaikh Mohd QaisarNo ratings yet

- BS EN 10048 Tolerances PDFDocument24 pagesBS EN 10048 Tolerances PDFShaikh Mohd QaisarNo ratings yet

- En 10168 Inspection InformationDocument12 pagesEn 10168 Inspection InformationStefano Squadrani100% (2)

- Asme B 18.2.2Document41 pagesAsme B 18.2.2Luis MontoyaNo ratings yet

- BS en 10021-2006Document20 pagesBS en 10021-2006anjanamurthy20060% (1)

- Astm-A707 CS As LTS PDFDocument5 pagesAstm-A707 CS As LTS PDFGoutam Kumar DebNo ratings yet

- Astm 672Document7 pagesAstm 672Ecruz Cruz LNo ratings yet

- Astm A671 2020Document7 pagesAstm A671 2020امينNo ratings yet

- Asme Section II A Sa-105 Sa-105mDocument6 pagesAsme Section II A Sa-105 Sa-105mAnonymous GhPzn1xNo ratings yet

- JISG3459Document39 pagesJISG3459Son-Tuan PhamNo ratings yet

- Electric-Fusion-Welded Steel Pipe For Atmospheric and Lower TemperaturesDocument7 pagesElectric-Fusion-Welded Steel Pipe For Atmospheric and Lower Temperaturesrgi178No ratings yet

- 24 Astm A815Document8 pages24 Astm A815FYNo ratings yet

- A494Document7 pagesA494Prakash MakadiaNo ratings yet

- SB - 622 PDFDocument10 pagesSB - 622 PDFSamir ChaudharyNo ratings yet

- Malleable Specifications StandardsDocument4 pagesMalleable Specifications StandardsSusan Sue Berrospi Merino100% (1)

- Astm A 450Document10 pagesAstm A 450Telmo VianaNo ratings yet

- Astm A494 - A494m - 13Document7 pagesAstm A494 - A494m - 13raul100% (1)

- Specification For Carbon Steel Forgings For Piping ApplicationsDocument10 pagesSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezNo ratings yet

- Pressure-Reducing Valves For Water Systems, ShipboardDocument10 pagesPressure-Reducing Valves For Water Systems, Shipboardreza amiriniaNo ratings yet

- A 516 - A 516M - 17Document4 pagesA 516 - A 516M - 17picottNo ratings yet

- ASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesDocument5 pagesASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesYaser Mohamed AbasNo ratings yet

- 6-79-0016 Rev 1Document11 pages6-79-0016 Rev 1abhishek100% (1)

- 20 Astm A672 A672m-2014Document7 pages20 Astm A672 A672m-2014FYNo ratings yet

- Sa 672Document7 pagesSa 672lalitaliNo ratings yet

- Astm A385 PDFDocument8 pagesAstm A385 PDFRaja Rao BoleNo ratings yet

- Astm A787 PDFDocument6 pagesAstm A787 PDFumeshNo ratings yet

- A312 A312M 16 Standard Speci PDFDocument13 pagesA312 A312M 16 Standard Speci PDFSuthan Murugesan RajeswariNo ratings yet

- TDS Zinga En-2018Document6 pagesTDS Zinga En-2018IMJ J100% (1)

- A312 A312M 16 Standard Speci PDFDocument13 pagesA312 A312M 16 Standard Speci PDFSuthan Murugesan RajeswariNo ratings yet

- Brake Dynamometer Development For Drexel University Fsae Race TeamDocument22 pagesBrake Dynamometer Development For Drexel University Fsae Race TeamgustavoNo ratings yet

- QA8000 - Fabrication Standards Instruction Manual PDFDocument102 pagesQA8000 - Fabrication Standards Instruction Manual PDFphalguna bnNo ratings yet

- 3 CSWIP-3 1-BrouchureDocument4 pages3 CSWIP-3 1-BrouchureRAKESH RANJANNo ratings yet

- Beams & Hooks CalculationDocument11 pagesBeams & Hooks CalculationLaurentiu MacloadNo ratings yet

- Minimum Requirements For The Education, Examination and QualificationDocument34 pagesMinimum Requirements For The Education, Examination and QualificationАнтон ХруцкийNo ratings yet

- Graduate Application GuideDocument7 pagesGraduate Application GuideSainath ReddyNo ratings yet

- Lincoln GMAW Welding GuideDocument96 pagesLincoln GMAW Welding GuideМич БјукенонNo ratings yet

- Natrosol HEC Grade All Grades June 2018Document2 pagesNatrosol HEC Grade All Grades June 2018Hai PhongNo ratings yet

- Field Test and Numerical Analysis of Offshore Laterally Loaded Pile in Multilayered SoilsDocument16 pagesField Test and Numerical Analysis of Offshore Laterally Loaded Pile in Multilayered SoilsDoThanhTungNo ratings yet

- Astm 434Document3 pagesAstm 434Fabián MartínezNo ratings yet

- Ernesto GuadesDocument11 pagesErnesto GuadesAliNo ratings yet

- P201: Handbook of Structural Steelwork 3rd Edition: Universal BeamsDocument44 pagesP201: Handbook of Structural Steelwork 3rd Edition: Universal Beamsmbhanusagar.keynesNo ratings yet

- Basic Semiconductor TheoryDocument224 pagesBasic Semiconductor TheoryJackie JonesNo ratings yet

- Wevo Folder Produkte Wevopur en Screen 230313Document4 pagesWevo Folder Produkte Wevopur en Screen 230313jason KlangNo ratings yet

- ASTM F1962 Design Values - PE Pipe Parameters - Soil ParametersDocument2 pagesASTM F1962 Design Values - PE Pipe Parameters - Soil Parametersjua666n100% (1)

- Theoretical Expectation of Strip Thickness in Planar Flow Casting ProcessDocument6 pagesTheoretical Expectation of Strip Thickness in Planar Flow Casting Processsohrabi64No ratings yet

- 2 D MaterialsDocument16 pages2 D Materialsisimone7No ratings yet

- Effects of Recycling On The Microstructure and The Mechanical Properties of Isotactic PolypropyleneDocument7 pagesEffects of Recycling On The Microstructure and The Mechanical Properties of Isotactic PolypropyleneOumaima BenNo ratings yet

- Staad Pro Tutorial.Document79 pagesStaad Pro Tutorial.ArushiBiswasNo ratings yet

- Entry Exam - PhD Chemical EngineeringDocument5 pagesEntry Exam - PhD Chemical Engineeringhiba thamirNo ratings yet

- 2SC2078 SpecsDocument3 pages2SC2078 Specsgerler jhony hernandez rodriguezNo ratings yet

- Week 5 General Properties of MaterialsDocument3 pagesWeek 5 General Properties of MaterialsSamantha NamzugNo ratings yet

- Mru DiodeDocument18 pagesMru DiodeShanmuganathan ShanNo ratings yet

- Capacitive Voltage: TransformersDocument6 pagesCapacitive Voltage: TransformersDaniloNo ratings yet

- MFL68439704 1 LJ48V 55ub8200-ShDocument106 pagesMFL68439704 1 LJ48V 55ub8200-Shluciano casoNo ratings yet

- Gibbs-Thomson Effect Melting Point DepressionDocument4 pagesGibbs-Thomson Effect Melting Point Depressionaditya2053100% (1)

- Electricity Discoveries That Changed Our LivesDocument17 pagesElectricity Discoveries That Changed Our Livesyolanda álvarez del viejoNo ratings yet

- adhesive used in storage battery systemDocument24 pagesadhesive used in storage battery systemjasonguo901No ratings yet

- Letters To Nature: Low-Temperature Processing of Baroplastics' by Pressure-Induced FlowDocument5 pagesLetters To Nature: Low-Temperature Processing of Baroplastics' by Pressure-Induced Flowfrox123No ratings yet

- MasstransfernotesallDocument19 pagesMasstransfernotesallapi-354955216No ratings yet

- Journal IJEP Format SentDocument12 pagesJournal IJEP Format SentSoumyadip GhoshNo ratings yet

- Heat Treatment Types for Improving Metal PropertiesDocument29 pagesHeat Treatment Types for Improving Metal PropertiesPratheep AddrinNo ratings yet

- 364 - CE8402 Strength of Materials II (SOM 2) - Question BankDocument19 pages364 - CE8402 Strength of Materials II (SOM 2) - Question BankPRASANTHNo ratings yet

- Review of The Performance of High Strength Steels Used OffshoreDocument130 pagesReview of The Performance of High Strength Steels Used OffshoreElias Kapa100% (1)

- Laboratory Tests On Compensation Grouting, The Influence of Grout BleedingDocument6 pagesLaboratory Tests On Compensation Grouting, The Influence of Grout BleedingChristian SchembriNo ratings yet

- Model Set Up For MSC Nastran Embedded Fatigue (NEF) : Physics On ScreenDocument4 pagesModel Set Up For MSC Nastran Embedded Fatigue (NEF) : Physics On ScreenTiep Tran QuangNo ratings yet