Professional Documents

Culture Documents

308 - Mapegrout t40 - GB PDF

Uploaded by

Sonu PathakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

308 - Mapegrout t40 - GB PDF

Uploaded by

Sonu PathakCopyright:

Available Formats

ut EN 1504-3

gro 4 0

pe T

Ma

Medium strength

(40 MPa), fibre

reinforced, thixotropic

grout for repairing

concrete

WHERE TO USE must be cured under damp conditions in order to

Repair of degraded vertical or horizontal concrete guarantee that the product’s expansive properties develop

surfaces with mortar possessing medium mechanical completely and correctly. However, it is not very easy to

performance characteristics. guarantee that these conditions are created on site.

Therefore, to guarantee that the expansive properties of

Some application examples Mapegrout T40 take place when drying in the open air,

• Repair of degraded concrete surfaces, corners of 0.25% of Mapecure SRA, a special additive which has

pillars and beams, balconies damaged by rusted the property of reducing both plastic and hydraulic

reinforcing bars. shrinkage, may be used to great advantage by adding

• Repairs to diaphragms and tunnels. it to the mix.

• Concrete linings for canals and hydraulic projects. Mapecure SRA has a very important role to play, in

• Reconstruction of concrete coverings of reinforcing guaranteeing better curing of mortar. Also, when mixed

bars. with Mapegrout T40, it may be considered a

• Repair of surface irregularities including exposed technologically advanced system, in that the additive

aggregate, joints between new and old concrete, has the capacity of slowing down evaporation of the

holes in formwork concrete, protruding steel, etc. water and of promoting the development of hydration

• Filling of rigid joints. reactions.

Mapecure SRA behaves like an internal curing agent

TECHNICAL CHARACTERISTICS and, thanks to its interaction with some of the main

Mapegrout T40 is a premixed powdered mortar components which make up the cement, it helps to

composed of cement, graded aggregates and special

reduce shrinkage by between 20% and 50% compared

additives manufactured from a formula developed in the

with the standard values of the product without the

MAPEI Research Laboratories.

When mixed with water Mapegrout T40 forms an easy additive. This will obviously lead to a lower incidence of

to apply thixotropic mortar that can be applied without cracking phenomena.

slumping even in substantial thicknesses on vertical Mapegrout T40 meets the requirements defined by

surfaces without formwork. EN 1504-9 (“Products and systems for the protection

When fully cured, Mapegrout T40: and repair of concrete structures - Definitions,

• has moderate flexural and compressive strength; requirements, quality control and evaluation of

• has a modulus of elasticity, thermal expansion conformity - General principles for the use of products

coefficient and permeability coefficient similar to that and systems”) and the minimum requirements claimed

of medium quality concrete; by EN 1504-3 (“Structural and non structural repair”)

• is waterproof; for structural mortars of class R3.

• has excellent adhesion to existing concrete surfaces

provided they are saturated with water and reinforcing RECOMMENDATIONS

bars are first treated with Mapefer or Mapefer 1K. • Do not use Mapegrout T40 to repair structures

If Mapegrout T40 is prepared by only adding water, it subject to high compressive loads, high impact or

[sche3] 308_mapegrout t40_gb (29.05.2009 - 3ª Bozza/Ciano/PDF)

rout0 abrasion: use Mapegrout Thixotropic or

Mapegrout T60 instead.

APPLICATION LITRES OF WATER

per 25-kg BAG

peg T4 • Do not use Mapegrout T40 when the

material has to be pumped over long Trowel from 3.8 to 4.0

Ma distances or in the case of large pumping

heads (use Mapegrout Easy Flow).

• Do not use Mapegrout T40 on smooth

Spray from 3.9 to 4.1

• Start the mixer and slowly add the

concrete surfaces. Roughen the surface Mapegrout T40 to the water in a

thoroughly and add reinforcing if necessary. continuous flow.

• Do not use Mapegrout T40 for anchoring • If improved open-air curing of the mortar

(use Mapefill or Mapefill R). is required, add Mapecure SRA at the

• Do not pour Mapegrout T40 for pumping end of the mixing phase at a dosage of

into formwork (use Mapegrout Hi-flow). 0.25% in weight of the mortar (0.25 kg

• Do not add cement or admixtures to every 100 kg of Mapegrout T40).

Mapegrout T40. • Mix for 1 to 2 minutes, then make sure

• Do not add water once the mix has begun the mix is well blended. Scrape any

to set. unblended powder from the bottom and

• Do not use Mapegrout T40 at temperatures the sides of the mixer. Mix again for another

lower than +5°C. 2 to 3 minutes.

• Do not use Mapegrout T40 if the bag has • Either a cement mixer or a drill equipped

been damaged or already opened. with a mixing attachment may be used,

according to the amount of material to be

HOW TO USE prepared. Mixing must be carried out at

Substrate preparation low speeds, to avoid air being entrapped

• Remove degraded and loose concrete until in the mix.

the substrate is solid, resistant and rough. • Avoid mixing manually unless absolutely

Any previous repair work that is no longer necessary. If so, mix small amounts at a

thoroughly bonded must also be removed. time for at least 5 to 6 minutes until a

• Sandblast the concrete and the reinforcing completely homogeneous paste is

bars until they are free of dirt, rust, cement obtained.

Degraded building laitance, grease, oil, varnish or old paint. Keep in mind that mixing by hand requires

façade in need of • Saturate the substrate with water. Before a larger amount of water. This adversely

repair repairing with Mapegrout T40, wait until affects several of the mortar’s characteristics,

the excess water has evaporated. To including mechanical strength, shrinkage,

facilitate the elimination of free water, use impermeability, etc.

compressed air if needed. Mapegrout T40 remains workable for

approximately 1 hour at +20°C.

Preparing the mortar The expansion of Mapegrout T40 is

• Pour into the mixer the amount of water calculated to compensate for plastic

needed to obtain the consistency required shrinkage. For it to be effective, the substrate

for the application. needs to be adequately reinforced with

rebars or forms.

Applying Mapegrout T40 without formwork

in thicknesses of more than 2 cm should be

done only after reinforcing and roughening

the surface of the concrete, taking care to

cover the reinforcement with a layer at least

2 cm thick.

Lower thicknesses can be applied without

reinforcing as long as the substrate has been

substantially roughened to counter the

expansion.

The expansion phase ends during the first

days of curing.

Application procedure

The mortar can be applied with a trowel or

spray without formwork even on vertical

surfaces or ceilings in maximum thicknesses

of 30 to 35 mm per layer.

Mapegrout T40 can also be spray applied,

using Turbosol or Putzmeister type

equipment, excluding continuous mixing

machines. Reinforcing bars must be

previously treated with Mapefer or

Mapefer 1K before applying the

Mapegrout T40.

Where necessary, apply a second layer of

Mapegrout T40 before the previous layer has

finished setting (within 4 hours at +23°C).

The complete repair cycle calls for smoothing

with Monofinish, Mapefinish, Planitop 100

or Mapelastic, and then painting with

Elastocolor Paint.

Precautions to be taken during and

after application

• Only use sacks of Mapegrout T40 which

have been stored on their original pallets

Spray application of and covered and stored in a dry place.

Mapegrout T40

TECHNICAL DATA (typical values)

PRODUCT IDENTIFICATION

Class according to EN 1504-3: R3

Type: PCC

Consistency: powder

Colour: grey

Maximum aggregate size (mm): 2.5

Bulk density (kg/m3): 1,250

Dry solids content (%): 100

Chloride ions content - minimum requirements ≤ 0.05% -

≤ 0.05

according to EN 1015-17 (%):

Storage: 12 months in original packaging in a dry place

Finishing of

Mapegrout T40

Hazard classification according to CE Directive 1999/45: irritant.

Before using refer to the “Safety instructions for

preparation and application” paragraph and the

information on the packaging and Safety Data Sheet

Customs class: 3824 50 90

APPLICATION DATA (at +20°C - 50% R.H.)

Colour of mix: grey

Mixing ratio: 100 parts of Mapegrout T40 with 15.5-16.5 parts water

(approx. 3.8-4.1 l per 25 kg sack)

Consistency of the mix: thixotropic

Density of the mix (kg/m3): 2,200

pH of the mix: > 12.5

Application temperature range: from +5°C to +35°C

Pot life of the mix: about 1 h Reparing a balcony

with Mapegrout T40

FINAL PERFORMANCES (16% mixing water)

Test Minimum requirements according Product

Performance characteristic

method to EN 1504-3 for R3 class mortar performance

> 8 (after 1 day)

Compressive strength (MPa): EN 12190 > 25 (after 28 gg) > 30 (after 7 days)

> 40 (after 28 days)

> 2.0 (after 1 day)

Flexural strength (MPa): EN 196/1 none > 5.5 (after 7 days)

> 7.0 (after 28 days)

Compressive modulus of elasticity (GPa): EN 13412 > 15 (after 28 days) 25 (after 28 days)

Bond strength to concrete (MC 0.40

type substrate water/concrete ratio = 0.40) EN 1542 > 1.5 (after 28 days) > 2 (after 28 days)

according to EN 1766 (MPa):

Capillary absorption (kg/m2•h0,5): EN 13057 < 0.5 < 0.20

Thermal compatibility measured as bonding

according to EN 1542 (MPa):

– freeze-thaw cycles with deicing salts: EN 13687/1 > 1.5 (after 50 cycles) > 1.5

– storm cycle: EN 13687/2 > 1.5 (after 30 cycles) > 1.5

– dry thermal cycle: EN 13687/4 > 1.5 (after 30 cycles) > 1.5

Reaction to fire: Euroclass value declared by manufacturer A1

rout0 • In warm weather do not expose the material

to direct sunlight. Use cold water to prepare

PACKAGING

25 kg bags.

peg T4 the mix. Store in a cool place.

• At low temperatures, prepare the mix with STORAGE

Ma water heated to approx. +20°C.

After applying Mapegrout T40, we

recommend that it is cured carefully,

12 months, if stored in a dry, sheltered place.

Manufactured in compliance with the

regulations of the 2003/53/EC Directive.

(GB) A.G. BETA

especially in hot or windy weather, to avoid

the water evaporating too quickly and

causing the formation of surface cracks due SAFETY INSTRUCTIONS FOR

to plastic shrinkage. Spray water on the PREPARATION AND INSTALLATION

surface 8-12 hours after applying the mortar, Contains cement that, when in contact with

and repeat the operation (every 3-4 hours) for sweat or other body fluids, produces an

at least the first 48 hours. As an alternative, irritant alkaline reaction and a sensitising

after tamping the mortar, spread on a layer of reaction in those who are subject to such a

either Mapecure E anti-evaporation complaint.

treatment in watery emulsion with a It is highly recommended to use gloves and

low-pressure pump, Mapecure S eye protection.

solvent-based curing film for mortar and For further information refer to the Safety

concrete or Elastocolor Primer Data Ssheet.

solvent-based, high-penetration primer for

absorbent substrates and curing agent for PRODUCT FOR PROFESSIONAL USE.

repair mortar. Mapecure E and Mapecure S,

as with all the best quality products in the WARNING

same category which are currently available Although the technical details and

on the market, impede bonding of successive recommendations contained in this data

dressing layers. Therefore, if a smoothing sheet correspond to the best of our

layer or paint is to be applied later, they must knowledge and experience, all the above

be completely removed by sandblasting. If information must, in every case be taken as

Elastocolor Primer is used as an anti- merely indicative and subject to confirmation

evaporation treatment, on the other hand, a after long-term practical applications; for this

final protective layer of Elastocolor Paint or reason, anyone who intends to use the

Any reproduction of texts, photos and illustrations published

product must ensure beforehand that it is

Elastocolor Rasante may be applied directly

suitable for the envisaged application. In

on the treated surface without having to

here is prohibited and subject to prosecution

every case, the user alone is fully responsible

remove it. for any consequences deriving from the use

of the product.

Cleaning

Mortar that has not yet hardened can be

removed from tools with water.

After setting, cleaning is very difficult and can All relevant references for

only be done mechanically. the product are available

upon request and from

CONSUMPTION www.mapei.com

Approx. 18.5 kg/m2 per cm of thickness.

308-5-2009

BUILDING THE FUTURE

You might also like

- Mapegroutt 60Document4 pagesMapegroutt 60폴로 쥰 차No ratings yet

- Mapegrout Thixotropic 2016Document4 pagesMapegrout Thixotropic 2016Yudi KurniawanNo ratings yet

- Mapei PlanitopDocument4 pagesMapei PlanitopÖzgün BıçakNo ratings yet

- Technical Data SheetDocument5 pagesTechnical Data SheetPEng. Tech. Alvince KoreroNo ratings yet

- 1 Mapegroutgunite GBDocument4 pages1 Mapegroutgunite GByaw shuNo ratings yet

- 517 Ultratop GB PDFDocument6 pages517 Ultratop GB PDFSzaboNo ratings yet

- Mastertop TC 405 W PDFDocument3 pagesMastertop TC 405 W PDFFrancois-No ratings yet

- Patchroc RSPDocument46 pagesPatchroc RSPvietpineNo ratings yet

- Mastertop 410: High Performance Nonmetallic Aggregate Surface HardenerDocument2 pagesMastertop 410: High Performance Nonmetallic Aggregate Surface Hardenercandra_sugiantoNo ratings yet

- 4006 Ultratopliving GB PDFDocument4 pages4006 Ultratopliving GB PDFSzaboNo ratings yet

- Planitop G40 SPDocument4 pagesPlanitop G40 SPChee Soon LeeNo ratings yet

- 22 6138-Mapefloorsystem35f-GbDocument4 pages22 6138-Mapefloorsystem35f-GbDarmaji Tejo SukmonoNo ratings yet

- Basf Masteremaco t288 TdsDocument2 pagesBasf Masteremaco t288 TdsharsoNo ratings yet

- 389 Planigrout310 GBDocument4 pages389 Planigrout310 GBAndres MedinaNo ratings yet

- 299 Mapefillr GBDocument4 pages299 Mapefillr GBsteNo ratings yet

- Masteremaco - S - 5400 (Emaco Nanocrete r4)Document4 pagesMasteremaco - S - 5400 (Emaco Nanocrete r4)Bhanuka SamarakoonNo ratings yet

- Purtop EasyDocument4 pagesPurtop EasypankajmandloiNo ratings yet

- MasterEmaco - S 348 v2Document2 pagesMasterEmaco - S 348 v2Umeshchandra PatilNo ratings yet

- Mapefill 318 - 1137-11-2014Document4 pagesMapefill 318 - 1137-11-2014Iqbal Muhammad100% (1)

- 1 00701 Planicrete enDocument6 pages1 00701 Planicrete enaungpyaeNo ratings yet

- Mapelastic Foundation: Pe Las Tic Un Da Tio NDocument4 pagesMapelastic Foundation: Pe Las Tic Un Da Tio NAdam LimNo ratings yet

- Basf Masterflow 980 TdsDocument4 pagesBasf Masterflow 980 Tdschopdekar1969_890124No ratings yet

- Mapefill MC 06Document4 pagesMapefill MC 06Yudi KurniawanNo ratings yet

- Tds - Emaco r301Document2 pagesTds - Emaco r301Venkata Rao0% (1)

- Masterflow 980 Tds PDFDocument4 pagesMasterflow 980 Tds PDFAdamo Absalome MulocheNo ratings yet

- Emaco Nanocrete R3 - PDS - ASEAN - 241110Document3 pagesEmaco Nanocrete R3 - PDS - ASEAN - 241110Andri AjaNo ratings yet

- Masterflow: Cementitious High Strength Non-Shrink Precision GroutDocument3 pagesMasterflow: Cementitious High Strength Non-Shrink Precision GroutAydın VarolNo ratings yet

- Tds - Mapefloor Epoxy Terrazo System GDocument4 pagesTds - Mapefloor Epoxy Terrazo System GDarmaji Tejo SukmonoNo ratings yet

- BASF MasterEmaco S488Document2 pagesBASF MasterEmaco S488HJNo ratings yet

- MasterEmaco - S 348 v1Document2 pagesMasterEmaco - S 348 v1vahab_shaik0% (1)

- MasterEmaco - T288 - Asean - v1.0616. BR PDFDocument2 pagesMasterEmaco - T288 - Asean - v1.0616. BR PDFMuhammad Fadhil ImansyahNo ratings yet

- Masterflex 801 Asean 0509Document2 pagesMasterflex 801 Asean 0509Andri AjaNo ratings yet

- FloArm Screed Eco Ver7Document4 pagesFloArm Screed Eco Ver7imsNo ratings yet

- Mastertile 30: Highly Polymer Modified Grey Coloured Cementitious Tile AdhesiveDocument3 pagesMastertile 30: Highly Polymer Modified Grey Coloured Cementitious Tile AdhesiveChaitanya IdateNo ratings yet

- Masteremaco - S 348 v2Document2 pagesMasteremaco - S 348 v2shahzadNo ratings yet

- Mastertop 1740m 12-04Document3 pagesMastertop 1740m 12-04djrote4No ratings yet

- Masterflow 160A: Aluminium Free Expanding Grout FluidifierDocument2 pagesMasterflow 160A: Aluminium Free Expanding Grout Fluidifiermonu yadav100% (2)

- Mapei Topcem - Fast Drying, Shrinkage Controlled ScreedDocument4 pagesMapei Topcem - Fast Drying, Shrinkage Controlled ScreedΘανάσης ΓεωργακόπουλοςNo ratings yet

- Estogrout MP70 PremixDocument2 pagesEstogrout MP70 PremixElias Jaya PerkasaNo ratings yet

- Mastertop 20M 12-04Document2 pagesMastertop 20M 12-04djrote4No ratings yet

- Mapei Hi-Flow B2Document4 pagesMapei Hi-Flow B2Avinash PrajapatiNo ratings yet

- Patchroc RSPDocument4 pagesPatchroc RSPBalasubramanian Ananth100% (1)

- Masterflow 980 TdsDocument4 pagesMasterflow 980 Tdszhangjinlin132No ratings yet

- Masteremaco S 5410 Ci Tds PDFDocument3 pagesMasteremaco S 5410 Ci Tds PDFSolomon AhimbisibweNo ratings yet

- LATICRETE® Xtrabond FSA 336: Thin-Set AdhesiveDocument4 pagesLATICRETE® Xtrabond FSA 336: Thin-Set AdhesiveChaitanya IdateNo ratings yet

- 12 1tapecreteDocument2 pages12 1tapecreteelephantynose100% (1)

- Masteremaco S 488: Structural Repair MortarDocument3 pagesMasteremaco S 488: Structural Repair MortarKhan ShahzebNo ratings yet

- Masteremaco S 348Document2 pagesMasteremaco S 348shahzadNo ratings yet

- Masteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortarDocument2 pagesMasteremaco S 348: Dual Shrinkage Compensated, Trowelable Fibre Reinforced Thixotropic Repair MortardepakmunirajNo ratings yet

- Basf Mastertop 430 TdsDocument3 pagesBasf Mastertop 430 TdsPanruti S SathiyavendhanNo ratings yet

- Basf Masterroc Sa160 TdsDocument3 pagesBasf Masterroc Sa160 TdsProboNo ratings yet

- Fosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutDocument2 pagesFosroc Conbextra EP40: Free Flowing, Epoxy Resin GroutVincent JavateNo ratings yet

- Mastertop 1240 Tds PDFDocument3 pagesMastertop 1240 Tds PDFSolomon AhimbisibweNo ratings yet

- Mastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayDocument3 pagesMastertop 538: Industrial Grade Self-Smoothing Cementitious Floor OverlayAbi SomutNo ratings yet

- 404 Dr. Fixit Fevimate TG Tile GroutingDocument3 pages404 Dr. Fixit Fevimate TG Tile GroutingJoseph EzekielNo ratings yet

- MasterTop 430Document32 pagesMasterTop 430Ahmad ElghazolyNo ratings yet

- Masterflow 9400: Ultra-High Strength, Cement Based Grout For Onshore Wind Turbine InstallationsDocument4 pagesMasterflow 9400: Ultra-High Strength, Cement Based Grout For Onshore Wind Turbine InstallationsThanhNguyenPhuongNo ratings yet

- Tec 303 HFG: Highly Fluid Post-Tensioning GroutDocument2 pagesTec 303 HFG: Highly Fluid Post-Tensioning Groutmanikandan4strlNo ratings yet

- Araco Hardtop - 2018Document2 pagesAraco Hardtop - 2018Aman Engineering100% (1)

- How To Calculate The Lux Level in A RoomDocument21 pagesHow To Calculate The Lux Level in A RoomSonu Pathak100% (1)

- Scott B. Stock Market Investing For Beginner... (4 Books in 1) 2021Document345 pagesScott B. Stock Market Investing For Beginner... (4 Books in 1) 2021Sonu Pathak100% (1)

- Drk ProfileDocument84 pagesDrk ProfileSonu PathakNo ratings yet

- Greensphere Autonomy 24 Hrs Integrated Solar Street LightDocument18 pagesGreensphere Autonomy 24 Hrs Integrated Solar Street LightSonu PathakNo ratings yet

- Municipal Administration and Water Supply Department Maraimalai Nagar Municipality Contract No. /2020 Notice InvitingDocument74 pagesMunicipal Administration and Water Supply Department Maraimalai Nagar Municipality Contract No. /2020 Notice InvitingSonu PathakNo ratings yet

- Analysis of Market Characteristi Cs and Promoti On Strategy of Rooftop PVDocument103 pagesAnalysis of Market Characteristi Cs and Promoti On Strategy of Rooftop PVSonu PathakNo ratings yet

- Price List 24.08.2020Document4 pagesPrice List 24.08.2020Sonu PathakNo ratings yet

- Aster Vibe Street LightDocument2 pagesAster Vibe Street LightSonu PathakNo ratings yet

- The Illumination Pundit... : WWW - Spanco.bizDocument4 pagesThe Illumination Pundit... : WWW - Spanco.bizSonu PathakNo ratings yet

- Clean Solar Energy: The Impact of Nanoscale Science On Solar Energy ProductionDocument24 pagesClean Solar Energy: The Impact of Nanoscale Science On Solar Energy ProductionSonu PathakNo ratings yet

- 12w Solar Street Light SystemDocument8 pages12w Solar Street Light SystemSonu PathakNo ratings yet

- 1629357267616resume NageshDocument2 pages1629357267616resume NageshSonu PathakNo ratings yet

- Media Planning & Optimization Case Study: National Life Insurance BrandDocument1 pageMedia Planning & Optimization Case Study: National Life Insurance BrandSonu PathakNo ratings yet

- Pur Top 600: Top 600 Pu Rto p6 00Document4 pagesPur Top 600: Top 600 Pu Rto p6 00Sonu PathakNo ratings yet

- Salary Slip NarenderDocument77 pagesSalary Slip NarenderSonu PathakNo ratings yet

- Marriage Biodata Format 7Document2 pagesMarriage Biodata Format 7Sonu PathakNo ratings yet

- F3ltd-Payroll With Payslip FormatDocument6 pagesF3ltd-Payroll With Payslip FormatSonu PathakNo ratings yet

- 411 Idrostop GBDocument4 pages411 Idrostop GBSonu PathakNo ratings yet

- LetterDocument9 pagesLetterSonu PathakNo ratings yet

- Material DetailsDocument1 pageMaterial DetailsSonu PathakNo ratings yet

- CaseStudy Merkle DisplayDocument1 pageCaseStudy Merkle DisplaySonu PathakNo ratings yet

- C V (Updated)Document4 pagesC V (Updated)Sonu PathakNo ratings yet

- Asst. Manager - Events Marketing and Organizing: February 2010 - Present (3 Years 9 Months) Vasant Kunj, DelhiDocument1 pageAsst. Manager - Events Marketing and Organizing: February 2010 - Present (3 Years 9 Months) Vasant Kunj, DelhiSonu PathakNo ratings yet

- Project Report On Birla Sun LifeDocument62 pagesProject Report On Birla Sun Lifeeshaneeraj94% (34)

- MCN401 Industrial Safety EngineeringDocument10 pagesMCN401 Industrial Safety EngineeringVilayil jestinNo ratings yet

- Session 5&6 - Process - Layout PlanningDocument47 pagesSession 5&6 - Process - Layout PlanningKartikay GoswamiNo ratings yet

- Ambience LightingDocument340 pagesAmbience Lightingdambe22No ratings yet

- Elvax® 460 PDFDocument2 pagesElvax® 460 PDFXuân Giang NguyễnNo ratings yet

- Innovative Use of Paper Industry Waste (Hypo Sludge) in Pervious Concrete - DR - Jayeshkumar Pitroda - Academia - EduDocument12 pagesInnovative Use of Paper Industry Waste (Hypo Sludge) in Pervious Concrete - DR - Jayeshkumar Pitroda - Academia - EduRahul Singh PariharNo ratings yet

- Human Powered ForkliftDocument3 pagesHuman Powered ForkliftVinay MuleyNo ratings yet

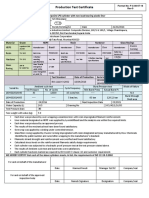

- Production Test CertificateDocument2 pagesProduction Test CertificateSolomon MacwanNo ratings yet

- Mechanical Specifications For Fiberbond ProductDocument8 pagesMechanical Specifications For Fiberbond ProducthasnizaNo ratings yet

- Translucent Concrete As A Housing Material AlternativeDocument12 pagesTranslucent Concrete As A Housing Material AlternativePurchiaNo ratings yet

- Design Equations For FRP Structural BeamsDocument40 pagesDesign Equations For FRP Structural BeamsAmol Gole100% (1)

- MATLAB Code For Flexural Design of RDocument6 pagesMATLAB Code For Flexural Design of Rselina100% (1)

- Summer Internship Report: Presented by - Abhishek Singh 2017 MBA 01Document22 pagesSummer Internship Report: Presented by - Abhishek Singh 2017 MBA 01lucky rajNo ratings yet

- Haryanto 2021 IOP Conf. Ser. Mater. Sci. Eng. 1096 012026Document13 pagesHaryanto 2021 IOP Conf. Ser. Mater. Sci. Eng. 1096 012026ravindra andukuriNo ratings yet

- Coeficiente de RozamientoDocument2 pagesCoeficiente de RozamientoThomasNo ratings yet

- ASTM Welding Procedures A36 To A930Document22 pagesASTM Welding Procedures A36 To A930Israel Mojica MNo ratings yet

- AluminumDocument7 pagesAluminumcollenedesilvaNo ratings yet

- Technical Data Sheet: Akepox 5010, 5010 Gel Mix, 5010 Single MixDocument3 pagesTechnical Data Sheet: Akepox 5010, 5010 Gel Mix, 5010 Single MixstarigradNo ratings yet

- Furse CEMDocument1 pageFurse CEMEjaz AhamedNo ratings yet

- Pop A Plug MaterialDocument2 pagesPop A Plug MaterialHijau Auliya Keramat Al-qadiryNo ratings yet

- Q QFN Nylqefqmid (1) Q FQFDocument99 pagesQ QFN Nylqefqmid (1) Q FQFKeviin CruzNo ratings yet

- Makrolon UV: Solid Polycarbonate SheetDocument2 pagesMakrolon UV: Solid Polycarbonate SheetKIMIKA Industrial CorporationNo ratings yet

- Aisi Cfsd86Document4 pagesAisi Cfsd86Mahaveer Janapala100% (1)

- Class Exercises-Activity Based CostingDocument2 pagesClass Exercises-Activity Based CostingPrachi YadavNo ratings yet

- Lifting Plan Chassing Catalist Cooler RFCC CilacapDocument30 pagesLifting Plan Chassing Catalist Cooler RFCC CilacapGunawan100% (1)

- Rr411809 Light Metals and AlloysDocument4 pagesRr411809 Light Metals and AlloysSRINIVASA RAO GANTANo ratings yet

- Finite Element Analysis PDFDocument5 pagesFinite Element Analysis PDFchetan c patilNo ratings yet

- Metallurgy Fundamentals Brandt PDFDocument301 pagesMetallurgy Fundamentals Brandt PDFSantiago Cordova Alva100% (2)

- Practical Data HandbookDocument120 pagesPractical Data Handbookjtamminga100% (18)

- Truck Technical DrawingsDocument14 pagesTruck Technical Drawingsapi-305087646No ratings yet

- 3-24-4 Vibracast Refractory LiningDocument38 pages3-24-4 Vibracast Refractory LiningPierre Ramirez100% (1)