Professional Documents

Culture Documents

Serpentin Apodaca

Uploaded by

Impulsora DemaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Serpentin Apodaca

Uploaded by

Impulsora DemaCopyright:

Available Formats

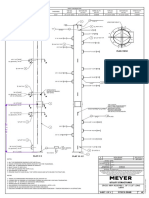

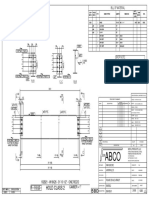

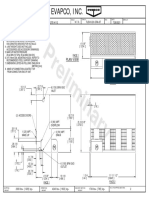

UNIT DWG.

#

ATC-1046E SLAW2412-DD

TITLE

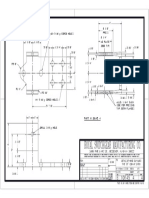

STEEL SUPPORT CONFIGURATION EVAPCO, INC. SCALE

N.T.S.

DRAWN BY

JLG

11'-11 3/4"

3651

1'-0"

5" 305 5"

127 127 1 5/8" 1 5/8"

13/16" 5'-7/8" 5'-7/8" 41 41

21 9 1/4" 1546 1546

9 1/4"

Pr

233 233 13/16" 13/16"

21 21

C/L OF UNIT LOAD

11'-8 3/8"

el UNIT

im

3566

MOUNTING HOLE

C/L OF MOUNTING HOLES UNIT OUTLINE 6 3/4"

171

1'-0" MIN.

(24)O 3/4" [19mm] 305

MOUNTING HOLES

in

CENTER ARRANGEMENT

24'-1 1/8"

7344

6 3/4"

ar

171

C/L OF UNIT LOAD

1 5/8"

y

11'-8 3/8" 41

3566

C/L OF MOUNTING HOLES 13/16"

21

UNIT

MOUNTING HOLE

TYPICAL END VIEW

13/16"

21 PLAN VIEW

NOTES: 6. THE FACTORY RECOMMENDED STEEL SUPPORT CONFIGURATION IS SHOWN.

1. BEAMS SHOULD BE SIZED IN ACCORDANCE WITH ACCEPTED STRUCTURAL PRACTICES. CONSULT THE FACTORY FOR ALTERNATE SUPPORT CONFIGURATIONS.

MAXIMUM DEFLECTION OF BEAM UNDER UNIT TO BE 1/360 OF UNIT LENGTH NOT TO EXCEED 1/2" [13mm]. 7. UNIT SHOULD BE POSITIONED ON STEEL SUCH THAT THE ANCHORING HARDWARE FULLY

2. DEFLECTION MAY BE CALCULATED BY USING 55% OF THE OPERATING WEIGHT AS PENETRATES THE BEAM'S FLANGE AND CLEARS THE BEAM'S WEB.

A UNIFORM LOAD ON EACH BEAM. SEE CERTIFIED PRINT FOR OPERATING WEIGHT. 8. FOR ALL MULTIPLE CELL UNITS, OPERATING WEIGHT OF EACH CELL IS

3. SUPPORT BEAMS AND ANCHOR HARDWARE ARE TO BE FURNISHED BY OTHERS. FOUND BY DIVIDING TOTAL OPERATING WEIGHT BY THE NUMBER OF CELLS.

ANCHOR HARDWARE TO BE ASTM A325 5/8" [16mm] BOLT OR EQUIVALENT. 9. WHEN VIBRATION ISOLATION IS REQUIRED, THE VIBRATION ISOLATORS ( BY OTHERS)

4. BEAMS MUST BE LOCATED UNDER THE FULL LENGTH OF THE PAN SECTION. MUST BE LOCATED UNDER THE SUPPORTING STEEL BEAMS AND NOT BETWEEN THE SUPPORTING

5. SUPPORTING BEAM SURFACE MUST BE LEVEL. DO NOT LEVEL THE UNIT BY STEEL BEAMS AND THE UNIT.

PLACING SHIMS BETWEEN THE UNIT MOUNTING FLANGE AND THE SUPPORTING BEAM. 10.THE CENTER BEAM SHOULD HAVE A MINIMUM WIDTH OF 12" [305mm]

11. DIMENSIONS LISTED AS FOLLOWS: ENGLISH FT-IN

[METRIC] [mm]

You might also like

- Plantilla HT24 Ansi-2013Document4 pagesPlantilla HT24 Ansi-2013servicio5No ratings yet

- Tank Drawings Example PDFDocument2 pagesTank Drawings Example PDFMiguel OrhlNo ratings yet

- Cross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4Document4 pagesCross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4raulNo ratings yet

- Customer Po Number Pump Tag Number Pump Serial No.: MABRE 10 X 12 X 18 WPV-R FLUSH PLAN 11/13 1403-A-FLUSH 1:10 A3Document3 pagesCustomer Po Number Pump Tag Number Pump Serial No.: MABRE 10 X 12 X 18 WPV-R FLUSH PLAN 11/13 1403-A-FLUSH 1:10 A3Israel Gibran Cañas RodriguezNo ratings yet

- J. H. Fletcher & Co.: B251 Bench DrillDocument1 pageJ. H. Fletcher & Co.: B251 Bench DrilljiaozhongxingNo ratings yet

- Short coupled shaft installation drawingDocument1 pageShort coupled shaft installation drawingJorge Calcaneo MartinezNo ratings yet

- Dressor-Galion Motor Grader Transmission Service ManualDocument44 pagesDressor-Galion Motor Grader Transmission Service ManualMonty100% (1)

- SCM55 Dakota Bodies line body for utility truckDocument26 pagesSCM55 Dakota Bodies line body for utility truckVinod YbNo ratings yet

- Produced by An Autodesk Educational Product: Ground Floor Slab Reinf - Plan For Arun DalhousieDocument1 pageProduced by An Autodesk Educational Product: Ground Floor Slab Reinf - Plan For Arun DalhousieAjay VermaNo ratings yet

- C Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Document2 pagesC Brand FX Body Company, INC. 2012 F-73-00-04 Rev:03Alan TrejoNo ratings yet

- BILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSDocument1 pageBILL OF MATERIALS FOR STEEL BEAM AND CONNECTIONSai ambaraNo ratings yet

- Bill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"Document1 pageBill of Material: 102B6 - W18X40 - 43'-1" - ONE REQ'D Camber 2"ai ambaraNo ratings yet

- Homes - NVR - Drawings - 1 1Document1 pageHomes - NVR - Drawings - 1 1j3ark0No ratings yet

- Hold Class 2: Bill of MaterialDocument1 pageHold Class 2: Bill of Materialai ambaraNo ratings yet

- BILL OF MATERIALS FOR BEAM 102B21Document1 pageBILL OF MATERIALS FOR BEAM 102B21ai ambaraNo ratings yet

- Ammo Can Rack PlanDocument6 pagesAmmo Can Rack Plane3ertrtrNo ratings yet

- Top Drive Warrior 3527H14HRDocument1 pageTop Drive Warrior 3527H14HRRicardo PrietoNo ratings yet

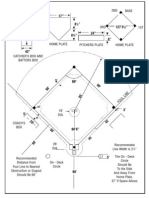

- Engineering Standards: Plan ViewDocument1 pageEngineering Standards: Plan ViewsawNo ratings yet

- BERENDSEN - CylinderCatalogueDocument32 pagesBERENDSEN - CylinderCatalogueKitana HandaNo ratings yet

- Top Drive Warrior Model 110H70Document1 pageTop Drive Warrior Model 110H70Ricardo PrietoNo ratings yet

- Top Drive 250H14 dimensionsDocument1 pageTop Drive 250H14 dimensionsRicardo PrietoNo ratings yet

- Greeneville TN Chick-Fi-La RenderingsDocument1 pageGreeneville TN Chick-Fi-La RenderingsAnonymous ROc32R1gNo ratings yet

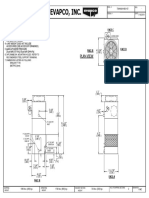

- Evapco, Inc.: Plan ViewDocument1 pageEvapco, Inc.: Plan ViewTheVictor VSNo ratings yet

- MSV-2 Storm Valve DrawingDocument4 pagesMSV-2 Storm Valve DrawingEdwin DamasenaNo ratings yet

- BILL OF MATERIAL STRUCTURAL STEEL LISTDocument1 pageBILL OF MATERIAL STRUCTURAL STEEL LISTai ambaraNo ratings yet

- p1sm - 665 - Center CenterDocument1 pagep1sm - 665 - Center Centerapi-299328817No ratings yet

- ColumnDocument1 pageColumnxmsasmzwofjqvqbwsdNo ratings yet

- NFHS Baseball Field MeasurementsDocument1 pageNFHS Baseball Field Measurementsbeach_lover_1970No ratings yet

- Continuous Cleat Coping Product DetailDocument2 pagesContinuous Cleat Coping Product DetailIrinel CopacinschiNo ratings yet

- 911PLNPF00 P01Document1 page911PLNPF00 P01Copy PueblaNo ratings yet

- Counter shaft box assembly parts listDocument1 pageCounter shaft box assembly parts listCampel SilvaNo ratings yet

- EVAPCO cooling tower technical drawingDocument1 pageEVAPCO cooling tower technical drawingDiego RodriguezNo ratings yet

- Grove Rough Terrain Cranes Spec 9879beDocument21 pagesGrove Rough Terrain Cranes Spec 9879beItzhak SchwartzmanNo ratings yet

- RMQLP-4120-H10 (Assembly)Document3 pagesRMQLP-4120-H10 (Assembly)Debabrata SahaNo ratings yet

- Engineering Standards: Plan ViewDocument1 pageEngineering Standards: Plan ViewsawNo ratings yet

- Drawing MX40S666 With CoverDocument1 pageDrawing MX40S666 With CoverAlonso Patricio Herrera GuzmanNo ratings yet

- Dyna Flo Fh2 2 Cajon Ag (Cp02) ModelDocument1 pageDyna Flo Fh2 2 Cajon Ag (Cp02) ModelHernan RomeroNo ratings yet

- Ground FLR VRF Pipe SizeDocument1 pageGround FLR VRF Pipe SizeAbdullah.N FAAliNo ratings yet

- Manual Grúa GroveDocument22 pagesManual Grúa GroveQanttum Sport Club100% (1)

- DYNA FLO - FH1-1-AG (CP10) - ModelDocument1 pageDYNA FLO - FH1-1-AG (CP10) - ModelHernan RomeroNo ratings yet

- Control Loop 9Document19 pagesControl Loop 9nmulyonoNo ratings yet

- Small Change Big Difference: Joy Industrial Co., LTDDocument20 pagesSmall Change Big Difference: Joy Industrial Co., LTDcip2009No ratings yet

- Transmision RTLO 14618ADocument2 pagesTransmision RTLO 14618ATractopartes IntertipNo ratings yet

- Model 3500 Multi-Pin PDFDocument3 pagesModel 3500 Multi-Pin PDFAlejandro ZanellaNo ratings yet

- Certified: 3/23/2021 Garrett BinnsDocument1 pageCertified: 3/23/2021 Garrett Binnsjose luis rios guerraNo ratings yet

- Galvanised steel top cap with M16 clearance holeDocument7 pagesGalvanised steel top cap with M16 clearance holeSGQNo ratings yet

- Rev 2 Suitcase - Piping (6 Pack)Document2 pagesRev 2 Suitcase - Piping (6 Pack)Oscar CarrascoNo ratings yet

- 18-052 E70101e 1 PDFDocument1 page18-052 E70101e 1 PDFCursed SquadNo ratings yet

- BOP S RIG 15Document1 pageBOP S RIG 15rig 15No ratings yet

- ITD1007L ITD1007R: in The Ditch Towing ProductsDocument2 pagesITD1007L ITD1007R: in The Ditch Towing ProductsGruasRubensNo ratings yet

- 1 Gauge Bracket Support Conduit Support 2 3 4 5 6: Tank WallDocument1 page1 Gauge Bracket Support Conduit Support 2 3 4 5 6: Tank Wallaravind grandhiNo ratings yet

- Tadano Rough Terrain Cranes Spec 4657c5Document20 pagesTadano Rough Terrain Cranes Spec 4657c5salman alfariziNo ratings yet

- Royal Switchgear Manufacturing Co.: PART # 10645-4Document1 pageRoyal Switchgear Manufacturing Co.: PART # 10645-4sagar ramaniNo ratings yet

- K-30 - 8.02.4 Oil SeparatorDocument1 pageK-30 - 8.02.4 Oil SeparatorAlexsandro TorezinNo ratings yet

- 911PLNPF00 P00Document1 page911PLNPF00 P00Copy PueblaNo ratings yet

- Grove Model Tm9120 - 120 Ton Capacity: Transportation Specs - Hydraulic Truck CranesDocument2 pagesGrove Model Tm9120 - 120 Ton Capacity: Transportation Specs - Hydraulic Truck CranesLudovic LandemaineNo ratings yet

- Ford 2Document148 pagesFord 2luong khanhbanhNo ratings yet

- 4 3/4Document1 page4 3/4Andres Lds PteNo ratings yet

- IQ3 dimensional data sheetDocument3 pagesIQ3 dimensional data sheetKarthik EvilordNo ratings yet

- The Corvette: A Nathaniel Drinkwater NovelFrom EverandThe Corvette: A Nathaniel Drinkwater NovelRating: 4.5 out of 5 stars4.5/5 (14)

- Turbo Air 3000 PDFDocument186 pagesTurbo Air 3000 PDFImpulsora DemaNo ratings yet

- 12FOS and 22FOS Series: Multi-Cartridge Filter HousingsDocument2 pages12FOS and 22FOS Series: Multi-Cartridge Filter HousingsImpulsora DemaNo ratings yet

- Untitled DrawingDocument1 pageUntitled DrawingImpulsora DemaNo ratings yet

- Centrifugal Compressor HandbookDocument186 pagesCentrifugal Compressor HandbookHalil İbrahim Küplü100% (1)

- SystemSpecification PVC-U Metric 2015 en PDFDocument24 pagesSystemSpecification PVC-U Metric 2015 en PDFpablo mendoza ibarraNo ratings yet

- Solvent Cement Jointing of PVC-U Fittings d250 - 400Document1 pageSolvent Cement Jointing of PVC-U Fittings d250 - 400pablo mendoza ibarraNo ratings yet

- Slaw0911 de PDFDocument1 pageSlaw0911 de PDFImpulsora DemaNo ratings yet

- EK Series PDFDocument8 pagesEK Series PDFImpulsora DemaNo ratings yet

- WB3241210 DRC ST PDFDocument1 pageWB3241210 DRC ST PDFImpulsora DemaNo ratings yet

- Lovejoy Hydraulics: Water-Oil CoolersDocument32 pagesLovejoy Hydraulics: Water-Oil CoolersImpulsora DemaNo ratings yet

- Mini ChillerDocument19 pagesMini ChillerJose MeraNo ratings yet

- WB3241210 DRC STDocument1 pageWB3241210 DRC STImpulsora DemaNo ratings yet

- WB3241210 DRC STDocument1 pageWB3241210 DRC STImpulsora DemaNo ratings yet

- Evapco Evaporative Condenser Engineering Manual 1 1 PDFDocument32 pagesEvapco Evaporative Condenser Engineering Manual 1 1 PDFImpulsora DemaNo ratings yet

- WB3241210 DRC STDocument1 pageWB3241210 DRC STImpulsora DemaNo ratings yet

- Demineralised Water Tank-ModelDocument1 pageDemineralised Water Tank-ModelImpulsora DemaNo ratings yet

- Solvent Cement Jointing of PVC-U Fittings d250 - 400Document1 pageSolvent Cement Jointing of PVC-U Fittings d250 - 400pablo mendoza ibarraNo ratings yet

- Ubc 2015 May Sharpe JillianDocument65 pagesUbc 2015 May Sharpe JillianherzogNo ratings yet

- Case Study On Maruti 800Document4 pagesCase Study On Maruti 800Nizar MesaniNo ratings yet

- Philosophy of Disciple Making PaperDocument5 pagesPhilosophy of Disciple Making Paperapi-665038631No ratings yet

- Osprey, Men-At-Arms #008 The Black Watch (1971) (-) OCR 8.12Document48 pagesOsprey, Men-At-Arms #008 The Black Watch (1971) (-) OCR 8.12mancini100% (4)

- User Manual - Numrolgy SoftwareDocument14 pagesUser Manual - Numrolgy SoftwareComputershastriNoproblem0% (1)

- ZJJ 3Document23 pagesZJJ 3jananiwimukthiNo ratings yet

- Unit 01 Family Life Lesson 1 Getting Started - 2Document39 pagesUnit 01 Family Life Lesson 1 Getting Started - 2Minh Đức NghiêmNo ratings yet

- Types of Ego?Document2 pagesTypes of Ego?S.UdhayakumarNo ratings yet

- Njhs Application EssayDocument4 pagesNjhs Application Essaycjawrknbf100% (2)

- James and Robson 2014 UAVDocument8 pagesJames and Robson 2014 UAVAdriRGNo ratings yet

- 2009 GCSE PE SpecificationsDocument225 pages2009 GCSE PE SpecificationsAdstasticNo ratings yet

- Unit Test Nervous System 14.1Document4 pagesUnit Test Nervous System 14.1ArnelNo ratings yet

- Prperman 2016 14 3 (Spec. 14Document8 pagesPrperman 2016 14 3 (Spec. 14celia rifaNo ratings yet

- Vernacular Architecture: Bhunga Houses, GujaratDocument12 pagesVernacular Architecture: Bhunga Houses, GujaratArjun GuptaNo ratings yet

- 2018 Diesel TOYOTA Jun11Document90 pages2018 Diesel TOYOTA Jun11eko sulistyo75% (4)

- Differentiation SS2Document88 pagesDifferentiation SS2merezemenike272No ratings yet

- Solution Aid-Chapter 01Document21 pagesSolution Aid-Chapter 01Vishal ChintapalliNo ratings yet

- Chapter 1 Critical Thin...Document7 pagesChapter 1 Critical Thin...sameh06No ratings yet

- Ra 11223 PDFDocument34 pagesRa 11223 PDFNica SalazarNo ratings yet

- Understanding The Self Metacognitive Reading Report 1Document2 pagesUnderstanding The Self Metacognitive Reading Report 1Ako Lang toNo ratings yet

- 1 API 653 Exam Mar 2015 MemoryDocument12 pages1 API 653 Exam Mar 2015 MemorymajidNo ratings yet

- Compabloc Manual NewestDocument36 pagesCompabloc Manual NewestAnonymous nw5AXJqjdNo ratings yet

- Fancy YarnsDocument7 pagesFancy Yarnsiriarn100% (1)

- Cls A310 Operations ManualDocument23 pagesCls A310 Operations ManualAntonio Ahijado Mendieta100% (2)

- PMMC ExperimentDocument2 pagesPMMC ExperimentShyam ShankarNo ratings yet

- Physics MCQ Solid State PhysicsDocument15 pagesPhysics MCQ Solid State PhysicsRams Chander88% (25)

- Albert PikeDocument6 pagesAlbert Pikeapi-302575383No ratings yet

- Event ReportDocument2 pagesEvent Reportakshitdaharwal997No ratings yet

- Defender 90 110 Workshop Manual 5 WiringDocument112 pagesDefender 90 110 Workshop Manual 5 WiringChris Woodhouse50% (2)

- Berger Paints (India) Limited 21 QuarterUpdateDocument7 pagesBerger Paints (India) Limited 21 QuarterUpdatevikasaggarwal01No ratings yet