Professional Documents

Culture Documents

Panels Erection at Station: Ehs Risk Assessment

Uploaded by

Rohit SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Panels Erection at Station: Ehs Risk Assessment

Uploaded by

Rohit SinghCopyright:

Available Formats

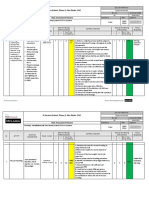

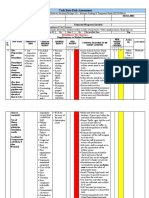

EHS RISK ASSESSMENT

Ref : HMRP - 08 B Rev 00

Project : Hyderabad Metro Rail

Client : Hyderabad Metro Rail limited

Independent Engineer : Louis Berger Consulting Pvt. Ltd

Concessionaire : L&T Metro Rail Hyderabad Limited

Contractor : L&T Construction PT&D IC (POWER SUPPLY & SCADA PROJECT)

Activity considered : PANELS ERECTION @ STATION Date: 13.05.14

Severity rating

Hazard / Environment Aspect

Probability

Risk / Residual

Existing control

rating

Sl.no Activity Source / Imapct Additional Control measures Risk / Action by

Possible People at measures

Situation level Impact

outcome risk

/ Act

1) Making the access road

1) Making the access

sufficient enough width at

clear without any

culverts etc

undulations

2) Taking LC, if in presence of

Transportatio 2) Making the access

Access / Electrocut Public, overhead power lines

n (Trailor / rigid enough Site

undulatio ion, driver & 3) Abiding the site safety rules of

crane (compacted) to Engineer /

1 ns / public Topple, hit Workmen 4 5 High speed limitations etc Low

entering into withstand the load P&M

interferen & fall in the 4) Driver is medically fit w.r.t to

site / onto 3) Making the access Engineer

ce etc hazards trailor etc eye & physique (eye test)

road) clear without any

5) All the workmen should be

powerlines existence

screened & trained etc

4) Vehicle having all

6) Vehicle to be guided by traffic

statutory documents

marshal / signal man in traffic

1) Ensure to have good

1) Making the access

communication while reversing

clear without any

of the vehicle

undulations

2) Vehicle to be guided by

2) Making the access

Public, flagman in traffic

Turnings, rigid enough Site

Vehicle / Topple, driver & 3) Ensure to have chock blocks to

Public (compacted) to Engineer /

2 crane on to fall, hit to Workmen 3 4 High arrest the freeflow Low

interferen withstand the load P&M

position public etc working 4) Vehicle parking area to be

ce etc 3) Crane to have all Engineer

near etc barricated (isolated from public /

statutory documents &

traffic interference)

all safety requirements

5) Outriggers to be extend fully

as per format HMRP -

with base plates

15A Rev 00

6) No additional packages to be

kept beneath the outriggers

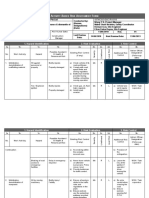

1) Ensure to reach to heights

using ladder or suitable means

wooden

Arrangement Workmen 2) Remove the nails or bend

package 1) Using of all tools

s (slinging )for nail prick, involved 3) Slinging to be in the center ( Site

3 nails, tackes having 3rd party 3 3 Medium Low

lifting of fall etc in the tiltation should not be allowed) enginner

lengthier test certificates

panles work etc 4) Tagline to be put

panels etc

5) Use only monthly certified

tools

1) Prior to work obtain lifting

plan & permit

2) Workmen should not be

present in the trailor while lifting

panels (probability of stuckin

hazards)

3) No one should not stand

beneath the lifting load

4) Should have tagline & tagline

Failure of 1) Using of all tools to be handled by standing min of

Injury to

tools Workmen tackes having 3rd party 3mtr distance

workmen,

tackles, involved test certificates 5) Only one signalman to Site

Lifting of public,

4 obstructio in it, near 2) The driver to be 4 5 High communicate Low Incharge /

panels material

ns, public by public competent enough with 6) Operator should have clear Engineer

damage

interferen etc valid license & with eye visibility of destination point &

etc

ce etc test signal man

7) Operator should not have any

distractions

8) Should not work in the vicinity

of OH electrical lines (if so take

LC) 9) Crane

to be guided at the back with a

helper (for movement)

10) The working zone to be

cordoned off

1) The persons who are pulling

(receiving ) the load to have edge

height protection or fullbody harness

work, 2) Lifting load should not get

edge Fall of Workmen struck with any obstructions Site

Receiving of

5 protection workmen involved 3 5 High 3) The load should not be catch Low Engineer /

the load

, etc in it & pulled on top Incharge

obstructio 4) No loose materials or ledger

ns pipes to be in the working area

(probability of slip, trip & roll

hazards)

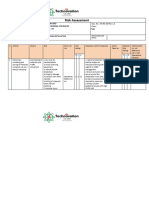

Injury to

1) Slings & web-slings to be

De-slinging workmen, Site

Materials Workmen secured to crane hook &

(webslings to public, Engineer

6 slip & fall involved 3 3 medium descend down Low

descend material &

etc in it 2) Materials should not be

down) damage Incharge

thrown down

etc

1) While using of crowbar / pipe

nail prick, for paking removal - workmen

Eye

wooden should not stand infront / behind

damage, Workmen 1) Fullfledge PPE of Site

Removing of chop 2) All the removed materials to

7 nail prick involved Helmet, Safety shoe, 3 4 medium Low Engineer /

the packings pieces kept a side & with removal of

injuries in it goggles etc Incharge

into eye protrudes

etc

etc 3) While removing of packing no

one should stand nearby

PM / CM EHSO

You might also like

- EHS Risk Assessment for DG Unloading and ErectionDocument3 pagesEHS Risk Assessment for DG Unloading and ErectionRohit SinghNo ratings yet

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- Back FillingDocument1 pageBack FillingRohit SinghNo ratings yet

- Res HirarcDocument15 pagesRes HirarcSawLaiBoyanNo ratings yet

- HIRA - Pier ConstructionDocument8 pagesHIRA - Pier ConstructionMMRDACA07 SAFETYNo ratings yet

- Risk Assessment For Installation of Ducts and AccessoriesDocument17 pagesRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan82% (11)

- Pump Installation Risk AssessmentDocument17 pagesPump Installation Risk AssessmentAnandu Ashokan75% (8)

- Risk Assessment For Cable TrayDocument11 pagesRisk Assessment For Cable Traynellaika puspa dewiNo ratings yet

- GrindingDocument1 pageGrindingRohit SinghNo ratings yet

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment of Installation of Chilled Water PipesDocument20 pagesRisk Assessment of Installation of Chilled Water PipesJomy JohnyNo ratings yet

- Plant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingDocument11 pagesPlant and Traffic Movement: L S Risk Score Risk Rating L S Risk Score Risk RatingRAMANo ratings yet

- Risk Assessment For Installation of Drainage PipesDocument17 pagesRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For MEP Services in P6 Existing ParkingDocument16 pagesRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- SiteDocument4 pagesSiteFILE 1131No ratings yet

- Risk Assessment Record Activity: Installation ofDocument17 pagesRisk Assessment Record Activity: Installation ofvasanth pugazhendhi0% (1)

- Risk Assessment For Installation of Air Handling UnitsDocument19 pagesRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Jsa For Cable Laying & TermnationDocument7 pagesJsa For Cable Laying & Termnationsakthi venkat0% (1)

- Risk Assessment of Installation of Chilled Water PipesDocument19 pagesRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment - CableDocument6 pagesRisk Assessment - Cablemohamad hafiz0% (2)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDocument11 pagesRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- RISK ASSESSMENT Installation and Testing of Access Control SystemDocument11 pagesRISK ASSESSMENT Installation and Testing of Access Control SystemAnandu Ashokan100% (3)

- Civil WorkDocument10 pagesCivil WorkNisanth ThulasidasNo ratings yet

- Risk Assessment Form for Lift Modernisation WorkDocument12 pagesRisk Assessment Form for Lift Modernisation Workeric chenNo ratings yet

- Risk Assessment For Laying of Pipes TextDocument3 pagesRisk Assessment For Laying of Pipes TextBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Risk Assessment For CABLE TRAYDocument11 pagesRisk Assessment For CABLE TRAYAnandu Ashokan86% (14)

- For CABLE TRAY AssessmentDocument10 pagesFor CABLE TRAY AssessmentIliyanPetrovNo ratings yet

- Scaffolding Erection and DismantlingDocument14 pagesScaffolding Erection and DismantlingDylan GreyNo ratings yet

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDocument12 pagesRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Cooling TowersDocument19 pagesRisk Assessment For Installation of Cooling TowersVlad Karo100% (1)

- PPR Installation & Pressure Testing RADocument19 pagesPPR Installation & Pressure Testing RAJomy JohnyNo ratings yet

- 310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Document5 pages310C22011 - RA - Refurbishment of Tank T-201 - For - Site Mobilization For TK 201 - SNOC Format - Rev.01 - 02Vinay MishraNo ratings yet

- Air Conditioning and Mechanical Ventilation System (ACMV Electrical Works)Document5 pagesAir Conditioning and Mechanical Ventilation System (ACMV Electrical Works)haidil abd hamidNo ratings yet

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDocument15 pagesRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment For PAS InstallationDocument18 pagesRisk Assessment For PAS Installationjide.atolagbe3737No ratings yet

- HEYTDocument17 pagesHEYTMariam BakariNo ratings yet

- ExcavationDocument73 pagesExcavationZien Mahmoud Ahmad0% (1)

- RADocument2 pagesRAalisheeraz0302No ratings yet

- 002 SWMS - Soil Back FillingDocument10 pages002 SWMS - Soil Back Fillingsasi kumarNo ratings yet

- IM-08-B EHS Risk Assessment DC WorkDocument4 pagesIM-08-B EHS Risk Assessment DC WorkAndrés PacompíaNo ratings yet

- Risk Assessment For Installation of HVAC Duct and AccessoriesDocument15 pagesRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- JSA - Undergound MappingDocument2 pagesJSA - Undergound Mappingshamierrul shahliNo ratings yet

- Sample Risk Assessment ProjectDocument2 pagesSample Risk Assessment Projectusman sNo ratings yet

- HIRA, TCS-ACP Sheet FixingDocument2 pagesHIRA, TCS-ACP Sheet FixingGowtham Kishore75% (4)

- Project Falcon Earthing Risk AssessmentDocument16 pagesProject Falcon Earthing Risk Assessmentfaizan khan50% (2)

- EHS Risk Assessment for Hyderabad Metro Rail Project ActivitiesDocument2 pagesEHS Risk Assessment for Hyderabad Metro Rail Project ActivitiesRohit Singh92% (12)

- Risk-Assessment Ducts & AccessoriesDocument13 pagesRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNo ratings yet

- Risk Assessment For Excavation & BackfillingDocument4 pagesRisk Assessment For Excavation & Backfillingkeshav chaturvediNo ratings yet

- Risk Assessment For MT Works in Port Road - DammamDocument4 pagesRisk Assessment For MT Works in Port Road - DammamRenatoNo ratings yet

- De-Com - For Existing 8 12 Inch - Pipeline - TRA1Document6 pagesDe-Com - For Existing 8 12 Inch - Pipeline - TRA1Darius DsouzaNo ratings yet

- TRA For Blasting and PaintingDocument6 pagesTRA For Blasting and Paintingrizvidawar220No ratings yet

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- 08 Cable Termination Risk AssessmentDocument2 pages08 Cable Termination Risk AssessmentBaranidaranRavi72% (18)

- TA-Road WorksDocument7 pagesTA-Road WorksShannon MooreNo ratings yet

- Demolition Risk AssessmentsDocument9 pagesDemolition Risk Assessmentssamar0% (1)

- Risk Assessment For Pressure TestingDocument13 pagesRisk Assessment For Pressure TestingAnandu Ashokan75% (4)

- Risk Assessment For Installation of HVAC Systems (RA34)Document19 pagesRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- 1 RA 1410 Demolition & Site ClearanceDocument11 pages1 RA 1410 Demolition & Site ClearanceMuhammad Shahid Iqbal100% (5)

- Site Ehs RulesDocument1 pageSite Ehs RulesRohit SinghNo ratings yet

- Overhead Crane Safety TrainingDocument71 pagesOverhead Crane Safety TrainingGovarthanan Gopalan100% (8)

- HelloDocument78 pagesHelloRohit SinghNo ratings yet

- Medical Tieup LetterDocument1 pageMedical Tieup LetterRohit SinghNo ratings yet

- Why Workers Fail To Report Hazards & InjuriesDocument4 pagesWhy Workers Fail To Report Hazards & InjuriesRohit SinghNo ratings yet

- The Motor Vehicles (Amendment) Bill, 2019Document5 pagesThe Motor Vehicles (Amendment) Bill, 2019Rohit SinghNo ratings yet

- The Motor Vehicles (Amendment) Bill, 2019: Bill No. 154-C of 2019Document45 pagesThe Motor Vehicles (Amendment) Bill, 2019: Bill No. 154-C of 2019PintuSarangiNo ratings yet

- SafetyDocument2 pagesSafetyRohit SinghNo ratings yet

- BOCW Act RequirementsDocument11 pagesBOCW Act RequirementsRohit SinghNo ratings yet

- IMS 9001/14001/45001 Requirements ComparisonDocument1 pageIMS 9001/14001/45001 Requirements ComparisonCentauri Business Group Inc.95% (20)

- Maintaining Solar PV SystemsDocument44 pagesMaintaining Solar PV SystemsSuresh KumarNo ratings yet

- Safety SpectaclesDocument1 pageSafety SpectaclesRohit SinghNo ratings yet

- Safety 2Document3 pagesSafety 2Rohit SinghNo ratings yet

- Safety Spectacles PDFDocument1 pageSafety Spectacles PDFRohit SinghNo ratings yet

- S.No Description of Work Action PlanDocument3 pagesS.No Description of Work Action PlanRohit SinghNo ratings yet

- EHS PlanDocument37 pagesEHS PlanVishal TiwariNo ratings yet

- Conveyor SafetyDocument2 pagesConveyor SafetyRohit SinghNo ratings yet

- Tool Box Talk - Requirements of Machine GuardingDocument1 pageTool Box Talk - Requirements of Machine GuardingRohit SinghNo ratings yet

- Week Topic: Seismology and The Earth's Deep InteriorDocument49 pagesWeek Topic: Seismology and The Earth's Deep InteriorRohit SinghNo ratings yet

- Blood Borne PathogensDocument29 pagesBlood Borne PathogensRohit SinghNo ratings yet

- How to Calculate the Heat Index and Stay Safe in High HumidityDocument1 pageHow to Calculate the Heat Index and Stay Safe in High HumidityRohit SinghNo ratings yet

- Prevent Hypothermia and Frostbite with Proper Cold Weather Clothing P2Document1 pagePrevent Hypothermia and Frostbite with Proper Cold Weather Clothing P2Rohit SinghNo ratings yet

- Preventing Hypothermia and FrostbiteDocument1 pagePreventing Hypothermia and FrostbiteRohit SinghNo ratings yet

- Motor Vehicle Act9279Document52 pagesMotor Vehicle Act9279dineshvhavalNo ratings yet

- Blasting Regulations: Regulatory Requirements For Blasting OperationsDocument14 pagesBlasting Regulations: Regulatory Requirements For Blasting OperationsRohit SinghNo ratings yet

- Running Nip Point OperationDocument1 pageRunning Nip Point OperationRohit SinghNo ratings yet

- TBT-Heat Disorders - DehydrationDocument2 pagesTBT-Heat Disorders - DehydrationRohit SinghNo ratings yet

- TBT-Heat Disorders - Heat ExhaustionDocument1 pageTBT-Heat Disorders - Heat ExhaustionRohit SinghNo ratings yet

- Snow RemovalDocument1 pageSnow RemovalRohit SinghNo ratings yet

- Feeding The Ejection MethodsDocument1 pageFeeding The Ejection MethodsRohit SinghNo ratings yet

- Systems Engineering Guidebook - Isbn 9780692091807Document95 pagesSystems Engineering Guidebook - Isbn 9780692091807Anthony MaidaNo ratings yet

- Turnaround Management in An Oil Refinery: ArticleDocument27 pagesTurnaround Management in An Oil Refinery: Articleasif rashid khanNo ratings yet

- Ipc2022-86870 - Management System Enabled Esg PerformanceDocument10 pagesIpc2022-86870 - Management System Enabled Esg PerformanceOswaldo MontenegroNo ratings yet

- Guideline On Good Pharmacovigilance Practices (GVP)Document60 pagesGuideline On Good Pharmacovigilance Practices (GVP)SandraCenovicNo ratings yet

- Impact Natural Disasters Manmade Hazards Computer Engineering DiplomaDocument8 pagesImpact Natural Disasters Manmade Hazards Computer Engineering DiplomaOmkar ManthenaNo ratings yet

- Un Gge Report 2013 EngDocument13 pagesUn Gge Report 2013 EngJulian VillarrealNo ratings yet

- Banking Strategies and Risk ManagementDocument4 pagesBanking Strategies and Risk ManagementFred DuhagaNo ratings yet

- Effects of External Uncertainties and Power On Opportunism in Supply Chains Evidence From ChinaDocument15 pagesEffects of External Uncertainties and Power On Opportunism in Supply Chains Evidence From Chinaivlachos@gmail.comNo ratings yet

- Creative Writing1 Elements and Kinds of GenreDocument3 pagesCreative Writing1 Elements and Kinds of GenreKevin Dela CalzadaNo ratings yet

- Project Risk Management: Shwetang Panchal Sigma Institute of Management StudiesDocument40 pagesProject Risk Management: Shwetang Panchal Sigma Institute of Management StudiesShwetang Panchal100% (1)

- Blackrock Sustainable Investing ResilienceDocument28 pagesBlackrock Sustainable Investing Resiliencemuun yayoNo ratings yet

- Internal Audit MidtermDocument17 pagesInternal Audit MidtermInho Shin0% (1)

- Risk Management Plan TemplateDocument6 pagesRisk Management Plan TemplateDibyendu KarmakarNo ratings yet

- B 3 Summary TableDocument1 pageB 3 Summary Tablecarlosito_lauraNo ratings yet

- Fanuc 10T Operational HandbookDocument112 pagesFanuc 10T Operational HandbookMilojica KarterNo ratings yet

- CISA Lecture Domain 1Document118 pagesCISA Lecture Domain 1Gerald D Archer0% (1)

- Handbook On Design and Operation of Flexible PipesDocument712 pagesHandbook On Design and Operation of Flexible PipesKarine FreitasNo ratings yet

- Financial Management - Midterm Exam - 1st DraftDocument5 pagesFinancial Management - Midterm Exam - 1st DraftRenalyn Paras100% (2)

- HSE Audits & InspectionsDocument38 pagesHSE Audits & InspectionsZain Ali KidwaiNo ratings yet

- The Management of Health and Safety at Work Regulations 1999Document18 pagesThe Management of Health and Safety at Work Regulations 1999om prakashNo ratings yet

- Fire AwarenessDocument1 pageFire AwarenessNick LatumboNo ratings yet

- DHJR022011 1Document7 pagesDHJR022011 1David HanlonNo ratings yet

- Who Urban Pests Health Significance PDFDocument292 pagesWho Urban Pests Health Significance PDFDavidNo ratings yet

- Apply to Become a Popular Investor on eToroDocument14 pagesApply to Become a Popular Investor on eToroandreea921No ratings yet

- Risk Appetite Guidance Note v1.0 FINALDocument18 pagesRisk Appetite Guidance Note v1.0 FINALStefanos DiamantisNo ratings yet

- SAEP-14 Project ProposalDocument53 pagesSAEP-14 Project ProposalRaad AbwiniNo ratings yet

- IPMVP Core ConceptsDocument28 pagesIPMVP Core ConceptsWaleed A. Shreim100% (1)

- Effect of Online Social Networking On Employee Productivity: Peer Reviewed ArticleDocument16 pagesEffect of Online Social Networking On Employee Productivity: Peer Reviewed ArticleproftechitspecialistNo ratings yet

- Lifting Risk AssessmentDocument5 pagesLifting Risk AssessmentimranNo ratings yet

- Appendix3 KPMG Blockchain PaperDocument151 pagesAppendix3 KPMG Blockchain PaperrashadgamarNo ratings yet