Professional Documents

Culture Documents

LNK364PN

Uploaded by

Jose BenavidesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LNK364PN

Uploaded by

Jose BenavidesCopyright:

Available Formats

DI-133 Design Idea

®

LinkSwitch-XT

Non-Isolated Induction Cooktop Auxiliary Supply

Application Device Power Output Input Voltage Output Voltage Topology

Induction Cooktop LNK364PN 5.9 W 185 – 265 VAC 5 V, 100 mA / 18 V, Flyback

300 mA

Design Highlights A high-voltage current source within U1 feeds current into bypass

• Low cost, low component count solution: only 17 parts capacitor C3, during the MOSFET off-time. Capacitor C3

• Both outputs exhibit good cross regulation develops the operating voltage for the IC and supplies the normal

• <130 mW no-load power consumption at 265 VAC operating current to the chip.

• Meets CEC active mode efficiency with good margin

Due to the phasing of T1’s windings and the locations and orienta-

Operation tions of the output diodes (D4 and D5), no secondary current flows

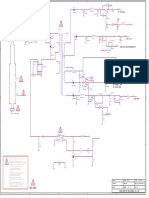

The non-isolated flyback converter shown in Figure 1 was while the MOSFET is on and current is flowing through the primary

designed around a member of the LinkSwitch-XT IC family, the winding of T1. Once the integrated controller within U1 switches off

LNK364PN (U1). Its dual outputs (5 V for the display and 18 V for the MOSFET, the voltages across the windings of T1 reverse, D4

the fan and IGBT control circuit) can provide up to 5.9 W of power and D5 are forward biased, and secondary winding current flows

at the lowest input line voltage (185 VAC). into output capacitors C4 and C5.

Since the cooktop has conducted EMI filtering for the induction Resistor divider R3 and R4 sense the 5 V output. The controller

heating converter, this auxiliary supply requires no fuse or filter within U1 uses the current into the FEEDBACK (FB) pin to control

components. Diode D1 half-wave rectifies the AC input and MOSFET switching and regulate the 5 V output. The turns ratio

capacitor C1 filters it to produce the high-voltage DC bus that between the 5 V and the 18 V windings provides adequate

feeds transformer T1. An RCD clamp (C2, D3, R1 and R2) across regulation of the 18 V output. An LC post filter (L1 and C6) on the

the primary winding of T1 limits the amplitude of the leakage- 5 V output attenuates the switching ripple to <100 mV pk-pk.

inductance voltage spike that occurs each time the integrated

power MOSFET within U1 switches off.

L T1 +18 V, 300 mA

2 8

D1 R1 C2 D4

1N4007 120 kΩ 1 nF UF4002 C4

1 kV 100 μF

3 6

25 V L1

6.8 μH +5 V, 100 mA

7

R2

100 Ω

C5 C6

100 μF 100 μF

10 V 10 V

5

RTN

D3

C1 1N4007

185-265 4.7 μF EE16 D5

VAC 400 V

UF4002

R4

16 kΩ

LinkSwitch-XT 1/8 W

U1

D

FB LNK364PN

BP

R3

S

10 kΩ

C3 1/8 W

100 nF

N 50 V

PI-4573-010208

Figure 1. LinkSwitch-XT, 5.9 W Induction Cooktop, Auxiliary Power Supply.

www.powerint.com January 2008

Key Design Points • Select the values of R3 and R4 so that when the 5 V output is in

• Wind T1 for the lowest leakage inductance by choosing wire regulation, there is 1.63 V on the FB pin, with a current of 49 μA

gauge sizes that completely fill each winding layer. flowing into the FB pin. Higher ohmic values for R3 and R4 will

• The PI Xls spreadsheet tool can be used to modify this supply not improve efficiency and may degrade regulation accuracy.

to allow operation over the universal AC input voltage range • Feedback resistor R4 must be connected before the LC post

(85 – 265 VAC). (L1 and C6) filter in order to avoid groups of enabled and

disabled switching cycles from occurring.

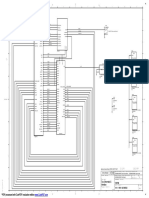

130

PI-4583-021407

Loading 5 V Output 18 V Output

No-Load Input Power (mW)

100% on 5 V and

120 4.94 18.14

100% on 18 V

100% on 5 V and

110 5.01 19.46

10% on 18 V

10% on 5 V and

100 5.08 17.99

100% on 18 V

10% on 5 V and

5.14 18.51

90 10% on 18 V

Table 1. Output Cross Regulation at 265 VAC.

80

70

Transformer Parameters

185 205 225 245 265

EE16 NC-2H or equivalent,

Input Voltage (VAC) Core Material

gapped for ALG of 63 nH/t²

Figure 2. No-Load Input Power vs. Line Voltage.

Bobbin EE16, 8 pin

Primary: 200T, 36 AWG, tape

73 Secondary: 5 V:, 11T, 29 AWG triple

PI-4584-021407

Winding Details insulated, tape

Secondary: 18 V: 26T, 30 AWG triple

insulated, tape

Primary Inductance 2.77 mH, ±10%

Efficiency (%)

72

Primary Resonant 500 kHz (minimum)

Frequency

Full Load Leakage

Inductance 111 μH (maximum)

71

Table 2. Transformer Parameters. (AWG = American Wire Gauge,

TIW = Triple Insulated Wire)

70

185 205 225 245 265

Input Voltage (V)

Figure 3. Efficiency vs. Input Voltage at Full Load.

Power Integrations Power Integrations reserves the right to make changes to its products at any time to improve reliability or manufacturability. Power

5245 Hellyer Avenue Integrations does not assume any liability arising from the use of any device or circuit described herein. POWER INTEGRATIONS

San Jose, CA 95138, USA. MAKES NO WARRANTY HEREIN AND SPECIFICALLY DISCLAIMS ALL WARRANTIES INCLUDING, WITHOUT LIMITATION, THE IMPLIED

Main: +1 408-414-9200 WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF THIRD PARTY RIGHTS.

Customer Service The products and applications illustrated herein (transformer construction and circuits external to the products) may be covered by

Phone: +1-408-414-9665 one or more U.S. and foreign patents or potentially by pending U.S. and foreign patent applications assigned to Power Integrations.

Fax: +1-408-414-9765 A complete list of Power Integrations' patents may be found at www.powerint.com. Power Integrations grants

Email: usasales@powerint.com its customers a license under certain patent rights as set forth at http://www.powerint.com/ip.htm.

The PI logo, TOPSwitch, TinySwitch, LinkSwitch, DPA-Switch, PeakSwitch, EcoSmart, Clampless, E-Shield, Filterfuse, StackFET,

On the Web PI Expert and PI FACTS are trademarks of Power Integrations, Inc. Other trademarks are property of their respective companies.

www.powerint.com ©2007, Power Integrations, Inc.

B

1/08 DI-133

You might also like

- D 1875 LM 1875 Nte 7143Document2 pagesD 1875 LM 1875 Nte 7143ANTONIO PEREZNo ratings yet

- Manual de Servicio TV Toshiba 20ar20 - 30Document32 pagesManual de Servicio TV Toshiba 20ar20 - 30Antonio José Montaña Pérez de Cristo100% (1)

- Circuito de Controle Do Display TV Samsung Ln-26A330J: (PLACA T-CON V260-B1-C04)Document2 pagesCircuito de Controle Do Display TV Samsung Ln-26A330J: (PLACA T-CON V260-B1-C04)ELECTRONICA J Y CENTRO ELECTRONICO100% (2)

- Color TV Horizontal Deflection Output Applications: Data SheetDocument4 pagesColor TV Horizontal Deflection Output Applications: Data SheetJesus Wladimir RondonNo ratings yet

- Xr-A670 370Document78 pagesXr-A670 370pepitito22No ratings yet

- Manual Control Remoto GDRC-400T (Ingles)Document9 pagesManual Control Remoto GDRC-400T (Ingles)Alexandro Conde MartínezNo ratings yet

- Service Manual: ModelsDocument92 pagesService Manual: ModelscocolisoteNo ratings yet

- A Aiwa Service Manual CD MechanismDocument22 pagesA Aiwa Service Manual CD MechanismcobrabrNo ratings yet

- Semiconductor KIA7019AP/AF/AT KIA7045AP/AF/AT: Technical DataDocument4 pagesSemiconductor KIA7019AP/AF/AT KIA7045AP/AF/AT: Technical DatajesadNo ratings yet

- LG 32LN520BDocument43 pagesLG 32LN520Bboroda2410100% (6)

- LG Color Monitor Service ManualDocument39 pagesLG Color Monitor Service ManualJose Fco. Aleman ArriagaNo ratings yet

- Pioneer Sx-4, 5, 6, 7 SMDocument14 pagesPioneer Sx-4, 5, 6, 7 SMvali dNo ratings yet

- BSC25-0217G - Aa26-00305a PDFDocument2 pagesBSC25-0217G - Aa26-00305a PDFReneNo ratings yet

- TV Philco Pfs2980Document30 pagesTV Philco Pfs2980Mario Cesar RuizNo ratings yet

- Panasonic TH-42PV60E GP9DE Chassie Service ManualDocument217 pagesPanasonic TH-42PV60E GP9DE Chassie Service ManualWims280100% (3)

- Noblex: SERVICE MANUAL Colour TelevisionDocument29 pagesNoblex: SERVICE MANUAL Colour Televisionjose4445No ratings yet

- Mainboard 35022968Document14 pagesMainboard 35022968Manuel GarciaNo ratings yet

- Manual Service LN40C550J1RDocument86 pagesManual Service LN40C550J1RAngel Luciano Ramon GomezNo ratings yet

- General Description Product Summary: Bvdss Rdson IDDocument4 pagesGeneral Description Product Summary: Bvdss Rdson IDDavid BarriosNo ratings yet

- Current Mode LED Driver: General Description FeaturesDocument1 pageCurrent Mode LED Driver: General Description FeaturesEnrique LandraNo ratings yet

- Vestel 17MB55-IDTVDocument83 pagesVestel 17MB55-IDTVVinilNo ratings yet

- Sony STR-De635 Ver 1.1Document58 pagesSony STR-De635 Ver 1.1rumendm100% (1)

- Enhancement Mode N-Channel Power MOSFET: OSG65R900xTFDocument10 pagesEnhancement Mode N-Channel Power MOSFET: OSG65R900xTFCube7 Geronimo100% (1)

- Diagrama Fonte DeltaDocument7 pagesDiagrama Fonte DeltacesarNo ratings yet

- Hisense Rsag7.820.1569ver.e Psu PDFDocument1 pageHisense Rsag7.820.1569ver.e Psu PDFJesus Almanzar SantosNo ratings yet

- Network diagram optimization guideDocument8 pagesNetwork diagram optimization guideLeudin Russo PedrozaNo ratings yet

- Chassis 40-2918T6-MAE1X Manual de Servicio PDFDocument47 pagesChassis 40-2918T6-MAE1X Manual de Servicio PDFDaniel AvecillaNo ratings yet

- Skyworth 5M67BDocument19 pagesSkyworth 5M67BAlb TvledNo ratings yet

- Philips 40PFL4707 (F7 F8) Ba21p6f0102 CH PL12 3Document75 pagesPhilips 40PFL4707 (F7 F8) Ba21p6f0102 CH PL12 3jesus100% (4)

- 68w TransistorDocument5 pages68w TransistorTahar BenacherineNo ratings yet

- Bn44-00703a L48s1-Esm Pslf121s06aDocument3 pagesBn44-00703a L48s1-Esm Pslf121s06aSaulvcr64 PorleyNo ratings yet

- Ap 3502 em Regulador DCDC s1005Document11 pagesAp 3502 em Regulador DCDC s1005gerson evandro hanauerNo ratings yet

- DTQ 20v1ssDocument48 pagesDTQ 20v1sselectronika806067% (3)

- Csy 1281 AerDocument3 pagesCsy 1281 AerMelgarejo GustavoNo ratings yet

- Led TV: Service ManualDocument53 pagesLed TV: Service ManualMauricio PérezNo ratings yet

- 1629339I Dtvla FunDocument15 pages1629339I Dtvla FunJuan Carlos100% (2)

- 8823CPNG5VA4Document1 page8823CPNG5VA4Carlo BriceñoNo ratings yet

- TDA7296 70V - 60W DMOS Audio AmplifierDocument13 pagesTDA7296 70V - 60W DMOS Audio AmplifierGokayAkayNo ratings yet

- Aiwa 3Cd-Player 4ZG-1 Service ManualDocument24 pagesAiwa 3Cd-Player 4ZG-1 Service ManualMaria Aparecida AlmeidaNo ratings yet

- SYLVANIA W6413tc - SMDocument46 pagesSYLVANIA W6413tc - SMdreamyson1983100% (1)

- Sanyo DVD-9408 Reproductor DVD DiagramaDocument44 pagesSanyo DVD-9408 Reproductor DVD DiagramaJuan Sebastián Ledesma100% (1)

- JVC KW Avx738 Manual de UsuarioDocument147 pagesJVC KW Avx738 Manual de UsuariofrancisibaNo ratings yet

- Bd9397efv e PDFDocument30 pagesBd9397efv e PDFshafiuddin7326No ratings yet

- Ms39Ca TCL Design - V1.2: Last SavedDocument8 pagesMs39Ca TCL Design - V1.2: Last Savedبوند بوندNo ratings yet

- Panasonic SA-AK960 Mini ComboDocument121 pagesPanasonic SA-AK960 Mini Comboppstone100% (3)

- Di-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating ControlDocument2 pagesDi-123 Design Idea Tinyswitch-Iii: 9.65 W, Dual Output Power Supply For Residential Heating Controlahmed chaouki ChamiNo ratings yet

- Application Note An-45 Linkswitch-Cv Family: Design GuideDocument18 pagesApplication Note An-45 Linkswitch-Cv Family: Design Guidebharath prabhuNo ratings yet

- Slyt 391Document5 pagesSlyt 391deedeeNo ratings yet

- Di 124Document2 pagesDi 124shreyNo ratings yet

- Di-198 Design Idea Linkswitch-Cv: Wide Range DVD Player Multiple Output Power Supply Without Need For OptocouplerDocument2 pagesDi-198 Design Idea Linkswitch-Cv: Wide Range DVD Player Multiple Output Power Supply Without Need For OptocouplerAllyfranhy Nunes AlvesNo ratings yet

- Di-91 Design Idea Tinyswitch-Iii: 12 W Universal Input CV AdapterDocument2 pagesDi-91 Design Idea Tinyswitch-Iii: 12 W Universal Input CV Adapterahmed chaouki ChamiNo ratings yet

- TNY278PNDocument4 pagesTNY278PNJose BenavidesNo ratings yet

- Di146 0Document2 pagesDi146 0amitNo ratings yet

- DatasheetDocument2 pagesDatasheetRyanz Nayrz100% (1)

- Data Sheet: Stereo Cassette Head Preamplifier and EqualizerDocument16 pagesData Sheet: Stereo Cassette Head Preamplifier and EqualizerahmedNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithDinh TucNo ratings yet

- Topswitch: Designing Multiple Output Flyback Power Supplies WithDocument24 pagesTopswitch: Designing Multiple Output Flyback Power Supplies WithHải TrầnNo ratings yet

- Skilling DocumentDocument10 pagesSkilling DocumentMLM TELUGU GAMERSNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Document6 pagesPioneer Plasma Top10 Repair Tips pdp-433cmx 434 4300 4304 4310 4314hd 4330 4340 502mx 505hd 504 5004 5014 5030 5031 5040 Pro-800 810 910 1000 1010 1110Daniboy1994No ratings yet

- Design Example Report: TitleDocument19 pagesDesign Example Report: TitleJose BenavidesNo ratings yet

- Induction Cooktop: Cooking PerformanceDocument2 pagesInduction Cooktop: Cooking PerformanceJose BenavidesNo ratings yet

- NT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListDocument22 pagesNT-R60 Plus SAMSUNG Laptop - Notebook 06. Electrical Part ListJose BenavidesNo ratings yet

- Printed circuit boards main/crt componentsDocument1 pagePrinted circuit boards main/crt componentsJose BenavidesNo ratings yet

- TNY268PNDocument2 pagesTNY268PNJose BenavidesNo ratings yet

- How to print large block diagrams in sectionsDocument2 pagesHow to print large block diagrams in sectionsJose BenavidesNo ratings yet

- Di-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionDocument8 pagesDi-117 Design Idea Tinyswitch-Iii: 15 W, 12 V Adapter With 100 MW No-Load ConsumptionJose BenavidesNo ratings yet

- Bluetooth antenna connector padsDocument1 pageBluetooth antenna connector padsJose BenavidesNo ratings yet

- Sony Play Station 2 Laser Calibration Using OscilloscopeDocument10 pagesSony Play Station 2 Laser Calibration Using OscilloscopeH3liax100% (1)

- The Ultimate DVD Region Hack Guide Book LIBROS de DVDDocument143 pagesThe Ultimate DVD Region Hack Guide Book LIBROS de DVDlondon335No ratings yet

- TNY264PNDocument6 pagesTNY264PNJose Benavides100% (1)

- Design Example Report: TitleDocument63 pagesDesign Example Report: TitleJose BenavidesNo ratings yet

- TNY277PNDocument2 pagesTNY277PNJose BenavidesNo ratings yet

- Di-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterDocument4 pagesDi-18 Design Idea Linkswitch: Low Cost 2.75 W CV/CC Charger or AdapterJose Benavides100% (1)

- China 17-Lcd-power-Inverter Oz9938 Top245 SCHDocument2 pagesChina 17-Lcd-power-Inverter Oz9938 Top245 SCHRicardo Chaman ChavezNo ratings yet

- TNY278PNDocument4 pagesTNY278PNJose BenavidesNo ratings yet

- TOP261LNDocument50 pagesTOP261LNJose BenavidesNo ratings yet

- LNK362 PDFDocument16 pagesLNK362 PDFJose BenavidesNo ratings yet

- LNK302P Der-92Document14 pagesLNK302P Der-92Jose BenavidesNo ratings yet

- TOP258PNDocument46 pagesTOP258PNJose BenavidesNo ratings yet

- Di-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerDocument2 pagesDi-143 Design Idea Topswitch-Hx: High Effi Ciency Inkjet Power Supply Provides Up To 80 Watts of Peak PowerJose BenavidesNo ratings yet

- Design Example Report: Title Specification Application Author Document Number Date RevisionDocument40 pagesDesign Example Report: Title Specification Application Author Document Number Date RevisionJose Benavides100% (1)

- TOP233YDocument24 pagesTOP233YJose BenavidesNo ratings yet

- TOP244PDocument112 pagesTOP244PJose BenavidesNo ratings yet

- TOP257ENDocument34 pagesTOP257ENJose BenavidesNo ratings yet

- Top259en PDFDocument2 pagesTop259en PDFJose BenavidesNo ratings yet

- TOP250YNDocument38 pagesTOP250YNJose BenavidesNo ratings yet

- Datasheet B985Document4 pagesDatasheet B985Jose BenavidesNo ratings yet

- Tutorial 1Document3 pagesTutorial 1dfsdsdfsdfsdfsdfsdNo ratings yet

- Spartan Family of One-Time Programmable Configuration Proms (Xc17S00)Document9 pagesSpartan Family of One-Time Programmable Configuration Proms (Xc17S00)saikumarNo ratings yet

- Anil ResumeDocument2 pagesAnil ResumeNaushad AlamNo ratings yet

- AM Generation Circuit DesignDocument132 pagesAM Generation Circuit DesignShashank Kna Hna Hs100% (2)

- Service Manual: MX-J570V MX-J680VDocument112 pagesService Manual: MX-J570V MX-J680VEnzo PalliniNo ratings yet

- AR100, AR120, AR150, AR160, AR200, AR1200, AR2200, AR3200, and AR3600 Hardware Installation and Maintenance Guide PDFDocument222 pagesAR100, AR120, AR150, AR160, AR200, AR1200, AR2200, AR3200, and AR3600 Hardware Installation and Maintenance Guide PDFmmarrioNo ratings yet

- Subaru Forester SF SUPPLEMENTAL RESTRAINT SYSTEMDocument82 pagesSubaru Forester SF SUPPLEMENTAL RESTRAINT SYSTEMjonekzawNo ratings yet

- BMXP342020H: Product DatasheetDocument3 pagesBMXP342020H: Product Datasheetمحمد امين التشغيل الآليNo ratings yet

- Encoder,,decoder, Mux, DemuxDocument19 pagesEncoder,,decoder, Mux, Demuxruthika ruthiNo ratings yet

- Contoh Kisi-Isi SoalDocument1 pageContoh Kisi-Isi SoalsuhaeniNo ratings yet

- MSP 430 FR 5739Document118 pagesMSP 430 FR 5739nwnwasdNo ratings yet

- Low Band Receiving AntennasDocument50 pagesLow Band Receiving AntennasDavid Bohorquez RamosNo ratings yet

- Numerical Analysis of Nonlinear Pulse Propagation in Optical Fiber (35Document107 pagesNumerical Analysis of Nonlinear Pulse Propagation in Optical Fiber (35MuhammadMazidNo ratings yet

- Raspberry Pi - Boards (Elinux)Document16 pagesRaspberry Pi - Boards (Elinux)sher123No ratings yet

- MODEL NO.: LTN154X3-L01: TO Date:: May. 9, 2007Document30 pagesMODEL NO.: LTN154X3-L01: TO Date:: May. 9, 2007Holly TjilatjapNo ratings yet

- Cuestionario 8Document2 pagesCuestionario 8Holleey100% (1)

- GCSE OCR 1.1 Von Neumann ArchitectureDocument62 pagesGCSE OCR 1.1 Von Neumann ArchitectureMichael O’LearyNo ratings yet

- Mediatek Mt7688 Spi Slave Programming Guide: 1.0 Release Date: 10 May 2017Document16 pagesMediatek Mt7688 Spi Slave Programming Guide: 1.0 Release Date: 10 May 2017asfasfasfasfNo ratings yet

- Fichas Técnicas Equipos Multifuncionales GELA 2Document1 pageFichas Técnicas Equipos Multifuncionales GELA 2hmr810104No ratings yet

- Automatic Voltage Control SystemsDocument33 pagesAutomatic Voltage Control SystemsNaveen Reddy100% (2)

- AXIpremium X HC BLK 120 cell solar module with 15 year warrantyDocument2 pagesAXIpremium X HC BLK 120 cell solar module with 15 year warrantyatılay demirezerNo ratings yet

- Hardware Installation Guide: D-Link™ DGS-3100 SERIES Gigabit Stackable Managed SwitchDocument74 pagesHardware Installation Guide: D-Link™ DGS-3100 SERIES Gigabit Stackable Managed SwitchAlfred PskNo ratings yet

- Computer Hardware Worksheet / Quiz: Make Sure That The Worksheet Is Saved Into The Network Drive Folder For CreditDocument2 pagesComputer Hardware Worksheet / Quiz: Make Sure That The Worksheet Is Saved Into The Network Drive Folder For CreditRaimundo LimaNo ratings yet

- E18365 2 11 13 - Eds8000 PDFDocument2 pagesE18365 2 11 13 - Eds8000 PDFezeizabarrenaNo ratings yet

- Power ElexDocument38 pagesPower ElexTin PelingonNo ratings yet

- E1BERTesterXG2138 PDFDocument3 pagesE1BERTesterXG2138 PDFRicardo Ledessma KortijoNo ratings yet

- AccuverDocument2 pagesAccuverZiya2009No ratings yet

- Ericsson 3GDocument3 pagesEricsson 3GMarkNo ratings yet

- Information Technology Fundamentals IT 100Document3 pagesInformation Technology Fundamentals IT 100Mashelet ValleNo ratings yet

- LNL 1300 Series 3 - SRIMDocument2 pagesLNL 1300 Series 3 - SRIMIan CaseyNo ratings yet