Professional Documents

Culture Documents

What plumbing designers need to know about valve materials and ratings

Uploaded by

Lloyd R. PonceOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What plumbing designers need to know about valve materials and ratings

Uploaded by

Lloyd R. PonceCopyright:

Available Formats

DESIGNER’S NOTEBOOK

BY JOSEPH V.

V MESSINA, CPD

What Plumbing Designers Need to Know

About Valves, Part 2

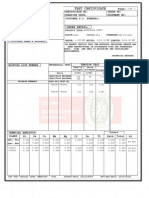

Part 1 of this series in the March/April shocks. Valv V es made of Figure 1 Valve components

2007 issue covered the functions of the ductile iron hav a e a higher

basic manually operated valves—gate, tensile strength and good

globe, angle, ball, butterfly,fl and check— k corrosion resistance.

which are used to start and stop the flow Steel valves are recom-

in a system, regulate flow, and prevent mended for temperatures

backflow. Part 2 will cover valve materi- as high as 450°F (232.2°C)

als, components, connections, working because of the wide vari-

pressures, and where to use what typ t e ofetyt of alloys in steel. They

valve. also are used in high-

Manufacturers must follow codes and pressure applications

standards when constructing valves. They and conditions that may a

are as follows: be too severe for iron or

• ASTM A 126: Sta t ndard r Specifi

i cation bronze bodies. Stainless

ffor Gra

ray Iron Cas

C tingngs for Valves,

s steel valves are av a ailable

F ang

Fl ngess, and Pipe Fit

F tingngs for an

ny in a wide variety t of alloys

valve constructed of iron and often are used for

• AWWA WA C500: Met M tal-Seated Gate pure water and other ser-

V lves for

Va f Water Supply l Service for vices requiring noncor-

gate valves for water and sewage sys- rosive materials. Seating

F cilitty Piping Systtems Handbook

tems surfaces, stems, and discs

• AWWA WA C504: Rubber- r Sealed Butterfl

rflyconstructed of stainless

V lves for rubber-seated ball valves

Va steel are suitable where

foreign materials in the

• MSS SP-67: Butterfl rfly Valves for but-

fluids handled could hav a e

terfly

fl valves

adverse effe ff cts.

Source: Fac

• MSS SP-80: Bronze Gate, e Globe,

e Angle

n e, V lves constructed of

Va

and Check Va V lves for bronze gate, thermoplastics are used

globe, angle, and check valves widely l to carry corrosive

VALVE MATERIALS fluids w ere conv

wh n en- are ava ailable. Generally, plastic valves

A valve may a be constructed of several tional valves are not suitable or other alloy are limited to a maximum temperature

types of materials, both metallic and non-

ty metals are very exp

x ensive. It is suggested of 250°F (121.1°C) and a maximum pres-

metallic. Metallic materials include brass, that thermoplastic valves can be used in sure of 150 pounds per square inch gauge

bronze, cast iron, malleable iron, ductile 85–90 percent of all utility t servi

v ces. (1,035 kilopascals). A ailable valve typ

Av t es

iron, steel, and stainless steel, and nonme- Many n differ

ff ent t

typ es of thermoplastic and their sizes are given in Ta

T ble 1.

tallic materials are ty l thermoplas- materials are used in the construction VALVE RATINGS

typically

tics. of valves, and all standard valve typ t es

Manufactures rate their valves in terms

Bronze and brass valves usually are of saturated steam pressure or pres-

limited to sizes 2 inches and smaller TTable 1 Thermoplastic materials and valve types sure of non-shock cold water, r oil, or

and are used for water services. Brass Valve Design g Materials Size Range

g , in. gas (WOG), or both. The rating appears

valves should not be used for operating Ball,, union design g PVC,CPV

, C,PP , P,PVDF

, ¼–4 on the body of the valve. A valve with

temperatures above 450°F (232.2°C), Ball,, compac p t design

g PVC,CPV

, C ½–3 the markings “125” and “200 WOG”

and bronze valves should be limited Ball,, multipor p t PVC,CPV

, C,PP , P,PVDF

, ½–3 will operate safely at a saturated steam

Diaphr

p agm g PVC,CPV

, C,PP , P,PVDF

, ½–10

to uses below 550°F (287.8°C). Cast pressure of 125 psi (861.3 kPa) or 200

Butterflyy PVC,CPV

, C,PP , P,PVDF

, 1½–24

iron valves commonly are used for Globe PVC,CPV

, C,PP , ½–4 psi (1,378 kPa) cold water, r oil, or gas.

water and steam up to 450°F (232.2°C). Gate PVC 1½–14 The plumbing designer should

A higher tensile strength iron can be Ball check PVC,CPV

, C,PP , P,PVDF

, 1–4 become familiar with these mark- k

used in larger sizes. Malleable iron Swingg check PVC,PP

, P,PVDF

, ¾–8 ings on valves and keep them in mind

valves are stronger, r stiffer

ff r, and more Labcock PVC ¼ during a construction inspection. If

durable than cast iron body valves and Foot PVC,CPV

, C,PP

, P,

,PVDF ½–4

Pressure relief PVC,CPV

, C,PP , ½–4 a valve ruptures, it can cause serious

hold much tighter pressure. This mate- Solenoid PVC,CPV

, C,PP , ½–1 damage and/or injury.

rial can withstand tough stresses and Source: Fac F cilitty Piping Systtems Handbook

24 Plumbing Systems & Design MAY/JUNE

A 2007 PSDMAGAZINE.ORG

Figure 3 Bonnet construction types

Source: Facility Piping Systems Handbook

VALVE COMPONENTS tems. When the hand

Figure 1 identifies every component wheel (which is non-

of a valve. The stem and bonnet are two rising) is turned, the

very important components to the valve stem rises as the yoke

because they are the only moving parts. bushing engages

The stem design is manufactured in four the stem threads.

A non-rising stem with inside screw

basic categories: rising stem with outside The threads are easy to lubricate; how-

(Figure 2c) is the valve to use when a

screw and yoke, rising stem with inside ever, care must be taken to not damage

requirement for minimum headroom for

screw, non-rising stem with inside screw, the exposed stem threads. When using a

operation exists. With this type of valve,

and sliding stem. rising stem valve, the plumbing designer

the stem does not rise, thus reducing

Stem Construction. The rising stem should make sure that sufficient clear-

packing wear. Because the threads are

with outside screw (Figure 2a) and the ance is available to allow a full opening of

inside the valve, heat, corrosion, erosion,

rising stem with outside screw and yoke the valve.

and solids can damage the stem threads

(Figure 2d) keep stem threads outside of The rising stem with inside screw

and cause excessive wear. Also, because

the valve, away from possible corrosives, (Figure 2b) is the most common stem

the stem does not rise when the hand

high temperatures, and solids in the line design in bronze gate valves. When this

wheel is turned, it is difficult to determine

that might damage the stem threads. valve is opened, both the hand wheel and

the disk position.

The rising stem with outside screw is stem rise, so the plumbing designer must

With the sliding stem (Figure 2e), the

ideal where the possibility of sticking is take caution to ensure enough clearance

operation of the stem is linear, straight

a hazard, such as in fire protection sys- for this valve to be fully opened.

up and down. There is a lever instead of

a hand wheel, and no threads are on the

Figure 2 Stem constructions

stem. The sliding stem is available on gate

and globe valves and is useful where quick

closing or opening of a valve is desired.

Bonnet Construction. When choos-

ing a valve, the bonnet should not be

overlooked. The bonnet provides a leak-

proof closure for the body of the valve.

The basic types of bonnet construction

include screwed union ring, screwed-in,

bolted, and welded designs (see Figure

3). The screwed union ring bonnet is used

where valves require frequent inspection

or cleaning. While ideal for smaller valves,

the screwed union ring bonnet is not prac-

tical for large-size valves. The screwed-in

bonnet is the simplest and least expen-

sive and usually is used on bronze gate,

globe, and angle valves. It also is recom-

mended where frequent dismantling is

not required. The bolted bonnet joint is

practical and commonly used for large-

size valves and for high-pressure applica-

tions. If the plumbing designer requires a

Source: Facility Piping Systems Handbook

leak-free body-to-bonnet joint, he should

specify a welded construction. The dis-

advantage of the welded bonnet is that

access to the trim parts is not available if

repairs are needed.

MAY/JUNE 2007 Plumbing Systems & Design 25

DESIGNER’S NOTEBOOK

END CONNECTIONS The flared end is commonly used on

Valves come with several different end valves and fittings for metal and plastic WORKING PRESSURE RATINGS BY

connections. They are screwed, welded, tubing up to 2 inches (50.8 millimeters) in

SERVICE

brazed, soldered, flared, and flanged diameter. The end of the tubing is flared, Hot and Cold Water Service

ends. and a ring nut is used to make a union- Gate Valves:

Screwed end connections are by far type joint. • 2 in. and smaller: Class 125, rated 125 psi SWP

the most widely used. This type of con- Flanged-end connections generally are (steam working pressure), 200 psi non-shock CWP

nection is found in brass, iron, steel, and used where screwed-end connections (cold working pressure)

alloy piping materials. It is suitable for are impractical because of cost, size, and • 2½ in. and larger: Class 125, rated 100 psi SWP,

all pressures but usually is confined to strength of joint. Large-diameter piping 150 psi non-shock CWP

small pipe sizes. usually requires a flanged-end connection. Ball Valves:

The welded-end connection is available Flanged ends also make assembly and dis- • 2 in. and smaller: Rated 150 psi SWP, 600 psi non-

only in steel valves and is used mainly mantling easier. When using flanged ends, shock CWP

for high-pressure and high-temperature it is important to match the facings. When Globe Valves:

services. The plumbing designer should bolting iron valves to forged steel flanges, • 2 in. and smaller: Class 125, rated 125 psi SWP,

specify welded-end connections only on the facing should be of the flat-face design 200 psi non-shock CWP

systems that do not require frequent dis- on both surfaces. • 2½ in. and larger: Class 125, rated 125 psi SWP,

mantling. There are two types of welded- See Table 2 for a general list of valves by 200 psi non-shock CWP

end materials: butt and socket welding. service type, and the sidebar for a break- Butterfly Valves:

Butt-welding valves and fittings come in down of valve working pressure ratings

• 2½ in. and larger: Rated 200 psi non-shock CWP

all sizes; socket-welding ends usually are by service. Valves are very important to

limited to sizes 2 inches and smaller. a plumbing system, and care should be Check Valves:

Brazed-end connections are available taken when selecting the right valve for • 2 in. and smaller: Class 125, rated 125 psi SWP,

on brass materials. The ends of such the application. Always verify the valve’s 200 psi non-shock CWP

materials are designed for use with braz- working pressure to ensure it can handle • 2½ in. and larger: Class 125, rated 125 psi SWP,

ing alloys to make the joint. While brazing the system pressure and material; make 200 psi non-shock CWP

is similar to solder joints, a brazed joint sure that the fluid being carried through Compressed-Air Service

can withstand higher temperatures. the system will not corrode the valve; and Ball Valves:

ensure that the valve material won’t have • 2 in. and smaller: Mainline valves shall be rated

Soldered joints are used with copper

150 psi SWP, 600 psi non-shock CWP

tubing for plumbing and heating lines. an effect on the fluid.

The joint is soldered by applying heat. Butterfly Valves:

RESOURCES • 2½ in. and larger: Rated 200 psi non-shock CWP

The solder flows into the joint between American Society of Plumbing Engi-

the tubing and the socket of the fitting or Check Valves:

neers Data Book, Volume 4: Plumbing • 2 in. and smaller: Class 125, rated 125 psi SWP,

valve by capillary action. Solder has a low Components and Equipment, Chapter 3, 200 psi non-shock CWP

melting point; thus, solder joints have “Valves.” • 2½ in. and larger: Class 125, rated 200 psi non-

limited use in high-temperature applica- Michael Frankel. Facility Piping Systems shock CWP

tions. Handbook. American Society of Plumb- Vacuum Service

ing Engineers. Ball Valves:

• 2 in. and smaller: Rated 150 psi SWP, 600 psi non-

shock CWP

Table 2 Valve selection by service type

Butterfly Valves:

Gate Ball Globe Butterfly Check • 2½ in. and larger: Rated 200 psi non-shock CWP

Service Valve Valve Valve Valve Valve

Hot and cold water • • • • • Medical Gas Service

Compressed air • • • Ball Valves:

Vacuum • • • 2 in. and smaller: Rated 150 psi SWP, 600 psi non-

Medical gas • shock CWP

Low-pressure steam • • • • • 2½ in. and larger: Rated 600 psi non-shock CWP

Medium-pressure steam • • • •

Low-pressure Steam

High-pressure steam • • •

Fire protection • (including service up to 125-psi saturated steam to

353°F [178°C])

Gate Valves:

• 2 in. and smaller: Class 125, rated 125 psi SWP,

200 psi non-shock CWP

• 2½ in. and larger: Class 125, rated 100 psi SWP,

150 psi non-shock CWP

26 Plumbing Systems & Design MAY/JUNE 2007 PSDMAGAZINE.ORG

JOSEPH V. MESSINA, CPD, is the discipline director

of plumbing engineering for CUH2A Inc., Architecture,

Engineering, Planning in Atlanta. He has more than

Ball Valves: 30 years experience specializing in plumbing and fire

• 2 in. and smaller: Rated 150 psi SWP, 600 psi non- protection design of instructional, research, and medical

shock CWP facilities. For more information or to comment on this

article, e-mail articles@psdmagazine.org.

Globe Valves:

• 2 in. and smaller: Class 125, rated 125 psi SWP,

200 psi non-shock CWP

STOP

• 2½ in. and larger: Class 125, rated 125 psi SWP,

200 psi non-shock CWP

Check Valves:

• 2 in. and smaller: Class 125, rated 125 psi SWP,

200 psi non-shock CWP

• 2½ in. and larger: Class 125, rated 125 psi SWP,

200 psi non-shock CWP

Medium-pressure Steam

(including up to 200-psi saturated steam to 391°F

[201°C])

Butterfly Valves:

• Not allowed in steam services unless stated as

acceptable for the application by the manufac-

Oil, Grease & Solids

turer

Gate Valves:

• 2 in. and smaller: Class 200, rated 200 psi SWP,

at the Source

400 psi non-shock CWP

• 2½ in. and larger: Class 250, rated 250 psi SWP,

500 psi non-shock CWP

Globe Valves:

• 2 in. and smaller: Class 200, rated 200 psi SWP,

400 psi non-shock CWP High Quality - Large Capacity

• 2½ in. and larger: Class 250, rated 250 psi SWP, Multi-Compartmented Interceptors

500 psi non-shock CWP

Check Valves: • Sized to comply with all National and

• 2 in. and smaller: Class 200, rated 200 psi SWP, Municipal Plumbing Codes.

400 psi non-shock CWP

• Designed to meet EPA and municipal

• 2½ in. and larger: Class 250, rated 250 psi SWP,

sewer pretreatment discharge limits for

500 psi non-shock CWP

fats, oils, grease, and solids.

High-pressure Steam Service

(including up to 300-psi saturated steam to 421°F Two Popular Styles for Sanitary

[216°C]) Sewer Protection: Available with:

Gate Valves: • Manways and Extensions

• 2 in. and smaller: Class 300, rated 300 psi SWP • Passive Grease Interceptors remove large • Traffic Bearing Covers

• 2½ in. and larger: Class 300, rated 300 psi SWP quantities of fats, oils, and grease (FOG), • Superior Corrosion Protection Systems

Globe Valves: and solids discharged from food service with 30 year limited warranty

• 2 in. and smaller: Class 300, rated 300 psi SWP facilities and large commercial and • Rugged Acid Resistant Linings

• 2½ in. and larger: Class 300, rated 300 psi SWP institutional kitchens. • Double-Wall Construction

• Stainless Steel Construction

Check Valves:

• Sand/Oil Interceptors separate sand, oil,

• 2 in. and smaller: Class 300, rated 300 psi SWP

and grease (hydrocarbons and other Features:

• 2½ in. and larger: Class 300, rated 300 psi SWP petroleum products) from automotive • Superior Quality and Workmanship

Fire Protection Systems repair, car washes, and other petroleum • Easy Installation and Maintenance

Gate Valves: and industrial facilities. • High Performance and Reliability

• 2 in. and smaller: Class 175 psi WWP (water work-

ing pressure) ,OWE�%NGINEERING 814-443-6800 • FAX 444-8662

• 2½ in. and larger: Class 175 psi WWP www.lowe-engineering.com staff@lowe-engineering.com

Circle 27 on your reader response card for product information.

MAY/JUNE 2007 Plumbing Systems & Design 27

You might also like

- Piping BasicDocument37 pagesPiping Basicaliyildizx17730100% (1)

- Piping FundamentalsDocument47 pagesPiping FundamentalsNguyễn Thanh TùngNo ratings yet

- Wo Glossary 2018Document8 pagesWo Glossary 2018Paulo Eduardo - Pro KnowledgeNo ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument11 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionNoushad P HamsaNo ratings yet

- Piping PresentationDocument144 pagesPiping PresentationSUNIL TVNo ratings yet

- ProductCatalog Cyrus Shank PSVDocument95 pagesProductCatalog Cyrus Shank PSVmramos4191No ratings yet

- Piping and Plumbing FittingDocument25 pagesPiping and Plumbing Fittingignatus lupapuloNo ratings yet

- CEU 228 Oct15 PDFDocument11 pagesCEU 228 Oct15 PDFMohamed AdelNo ratings yet

- DIVISION 15 - MechanicalDocument43 pagesDIVISION 15 - MechanicalLynette CabantingNo ratings yet

- Seriestvs 4000Document4 pagesSeriestvs 4000Jimit ShahNo ratings yet

- Valves: Continuing Education From The American Society of Plumbing EngineersDocument19 pagesValves: Continuing Education From The American Society of Plumbing Engineers185412No ratings yet

- Pneumatic Butterfly Valves Technical SpecificationDocument12 pagesPneumatic Butterfly Valves Technical SpecificationFactory FactoryNo ratings yet

- Lecture 8 Plumbing MaterialsDocument49 pagesLecture 8 Plumbing Materialspepito manalotoNo ratings yet

- Solenoid Valves Parker2Document27 pagesSolenoid Valves Parker2SREENATH S.SNo ratings yet

- Discussion 4 - Pipe FittingsDocument35 pagesDiscussion 4 - Pipe FittingsShan Troy Jamero IbarraNo ratings yet

- Piping I PDFDocument73 pagesPiping I PDFSyawaldi Bin KamaharuddinNo ratings yet

- KSB Valves - For - Water-Data PDFDocument16 pagesKSB Valves - For - Water-Data PDFPaul MaposaNo ratings yet

- Series 59 Full Port Ball ValveDocument4 pagesSeries 59 Full Port Ball Valvekyeong cheol leeNo ratings yet

- Vacuum Basics PDFDocument49 pagesVacuum Basics PDFhazbi2011No ratings yet

- Section 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionDocument5 pagesSection 15100 - Valves, Pipe Fittings, and Piping: Part 1 - General 1.1 Related Sections: 1.2 Scope of SectionAamir Abdul RahmanNo ratings yet

- Valves and Types of ValvesDocument10 pagesValves and Types of ValvesFarrukh ShahzadNo ratings yet

- 08 - SpeckDocument5 pages08 - SpeckSezer CetinNo ratings yet

- ValvesDocument22 pagesValvesimsarvesh05No ratings yet

- Lesson 2 - Plumbing Pipes and FittingsDocument39 pagesLesson 2 - Plumbing Pipes and FittingsNicholas Bonn SingNo ratings yet

- Underground Chilled Water System August 132014Document12 pagesUnderground Chilled Water System August 132014umair186No ratings yet

- Severn 3000 Series V1.1Document8 pagesSevern 3000 Series V1.1Thắng Trần QuangNo ratings yet

- Powell Valves - Handbook of Valve InformationDocument28 pagesPowell Valves - Handbook of Valve InformationdokundotNo ratings yet

- Check Valve Type NRVA: Data SheetDocument8 pagesCheck Valve Type NRVA: Data SheetleticiaNo ratings yet

- Standards For Pipe LineDocument57 pagesStandards For Pipe Linegopaltry33% (3)

- Samson Valve For High Temperature PDFDocument36 pagesSamson Valve For High Temperature PDFNARENDRA PATELNo ratings yet

- Flow Control Worcester ControlsDocument8 pagesFlow Control Worcester Controlsviller_lpNo ratings yet

- Head and Well RefDocument5 pagesHead and Well Refmehdi227No ratings yet

- High Nickel Alloy: Gate, Globe, Check, and Ball ValvesDocument4 pagesHigh Nickel Alloy: Gate, Globe, Check, and Ball ValvesshyamNo ratings yet

- Manifold PDFDocument32 pagesManifold PDFvivek_enggNo ratings yet

- Intro PipingDocument64 pagesIntro PipingAjay Kumar92% (12)

- SECTION 15110 Valves Part 1 - General 1.01 Related DocumentsDocument9 pagesSECTION 15110 Valves Part 1 - General 1.01 Related DocumentsMunir RasheedNo ratings yet

- The Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017Document7 pagesThe Royal Atlantis WSP Usa IBI Project No 38188 IFC - 22 March 2017MY PCNo ratings yet

- Piping and Plumbing FittingDocument21 pagesPiping and Plumbing FittingC.yrillNo ratings yet

- UTIL 2 MODULE 2 ReviewerDocument6 pagesUTIL 2 MODULE 2 ReviewerDonnalyn TizonNo ratings yet

- Pressure Relief Valves Standard Range: Safety DevicesDocument2 pagesPressure Relief Valves Standard Range: Safety DevicesPaweł HejmowskiNo ratings yet

- 2500 Valve BrochureDocument12 pages2500 Valve BrochureJurie_sk3608No ratings yet

- Valves Section SummaryDocument7 pagesValves Section SummarylightsonsNo ratings yet

- Valve End Connections, Screwed, Flanged, Socket-Weld, Butt-Weld, Capillary, Spigot PDFDocument2 pagesValve End Connections, Screwed, Flanged, Socket-Weld, Butt-Weld, Capillary, Spigot PDFjitendrakumarsahuNo ratings yet

- Firewater Piping Spec - DIDocument2 pagesFirewater Piping Spec - DIvaradarajNo ratings yet

- Install and maintain gate, globe valvesDocument4 pagesInstall and maintain gate, globe valvesModassir ZaheenNo ratings yet

- DPWH Standard Specification for ValvesDocument8 pagesDPWH Standard Specification for ValvesZA TarraNo ratings yet

- Apollo ValvesDocument16 pagesApollo Valvesvijuindia1111No ratings yet

- Tubing Clamps and Sealant PDFDocument1 pageTubing Clamps and Sealant PDFanon_454964186No ratings yet

- JPT Review Notes for Master Plumber Board Exam PrepDocument108 pagesJPT Review Notes for Master Plumber Board Exam Prepcajaro100% (1)

- We Control The Flow: Field Proven Valves Providing Years of Cost Effective, Efficient, Safe and Reliable ServiceDocument4 pagesWe Control The Flow: Field Proven Valves Providing Years of Cost Effective, Efficient, Safe and Reliable ServiceNguyen Anh TuanNo ratings yet

- Water Supplies Department: M-02-01 June 2016Document11 pagesWater Supplies Department: M-02-01 June 2016seeralan_1986No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesFrom EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesNo ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Sexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicFrom EverandSexton's Pocket-Book for Boiler-Makers and Steam Users: Comprising a Variety of Useful Information for Employer and Workmen, Government Inspectors, Board of Trade Surveyors, Engineers in Charge of Works and Ships, Foreman of Manufactories, and the General Steam-Using PublicNo ratings yet

- Winds Peed To Pressure ConversionDocument1 pageWinds Peed To Pressure ConversionLloyd R. PonceNo ratings yet

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- Planning Process 12 Step CLUPDocument10 pagesPlanning Process 12 Step CLUPLloyd R. Ponce100% (1)

- Calculating Fiber Loss and DistanceDocument4 pagesCalculating Fiber Loss and DistanceroomforsquaresNo ratings yet

- Concrete Expansion JointsDocument80 pagesConcrete Expansion JointsDiana Sekar Sari100% (1)

- TN 76Document6 pagesTN 76Lloyd R. Ponce100% (3)

- British Standard document reviewDocument23 pagesBritish Standard document reviewLloyd R. PonceNo ratings yet

- DIN 17155-1983, Creep Resistant Steel Plate and StripDocument16 pagesDIN 17155-1983, Creep Resistant Steel Plate and StripLloyd R. Ponce100% (1)

- BS 957-1-1941, Specification For Feeler Gauges PDFDocument14 pagesBS 957-1-1941, Specification For Feeler Gauges PDFLloyd R. PonceNo ratings yet

- DIN 17007-4-1963, Material Type NumberDocument9 pagesDIN 17007-4-1963, Material Type NumberLloyd R. PonceNo ratings yet

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraNo ratings yet

- Braided Hose Expansion JointDocument1 pageBraided Hose Expansion JointLloyd R. PonceNo ratings yet

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- TSSC 65 - 410Document1 pageTSSC 65 - 410Lloyd R. PonceNo ratings yet

- Directive 2006-42-CE - Machinery PDFDocument63 pagesDirective 2006-42-CE - Machinery PDFeng13No ratings yet

- FanEffectPPT2 PDFDocument41 pagesFanEffectPPT2 PDFJoel AlcantaraNo ratings yet

- Galvalume Rolling ShuttersDocument40 pagesGalvalume Rolling ShuttersLloyd R. PonceNo ratings yet

- CLASS NOTES Chap 10 1 Bond & AnchorageDocument13 pagesCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105No ratings yet

- Jet FansDocument15 pagesJet FansLloyd R. PonceNo ratings yet

- CrackDocument83 pagesCrackSeba Roskopf100% (1)

- Planning Mandates of Local GovernmentsDocument20 pagesPlanning Mandates of Local GovernmentsLloyd R. PonceNo ratings yet

- Fulltext01 Early Age ConcreteDocument18 pagesFulltext01 Early Age ConcreteLloyd R. PonceNo ratings yet

- A R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SDocument25 pagesA R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SLloyd R. PonceNo ratings yet

- Dow Corning 993 Product InfoDocument4 pagesDow Corning 993 Product InfoLloyd R. PonceNo ratings yet

- Filled Composite ColumnDocument1 pageFilled Composite ColumnLloyd R. PonceNo ratings yet

- EnP Ultimate Reviewer No. 2ADocument22 pagesEnP Ultimate Reviewer No. 2ALloyd R. Ponce0% (1)

- M-Bloc Type C SubmittalDocument2 pagesM-Bloc Type C SubmittalLloyd R. PonceNo ratings yet

- Finishing MaterialsDocument13 pagesFinishing MaterialsLloyd R. PonceNo ratings yet

- MTC AluminumDocument1 pageMTC AluminumLloyd R. PonceNo ratings yet

- Main products of furniture, building material and hardware companiesDocument116 pagesMain products of furniture, building material and hardware companiesAuras TechnologyNo ratings yet

- Campbell HausfeldDocument44 pagesCampbell HausfeldMireya Linares MoriNo ratings yet

- Process Industry Practices VesselsDocument54 pagesProcess Industry Practices VesselsAnonymous yCpjZF1rF100% (1)

- 7539 Rev E Air FiltrationDocument36 pages7539 Rev E Air Filtrationatia2kNo ratings yet

- Asme Section Ii A-2 Sa-961Document12 pagesAsme Section Ii A-2 Sa-961Anonymous GhPzn1xNo ratings yet

- Wrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDocument2 pagesWrapidbond™ FST: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDinesh PillaiNo ratings yet

- Gen TT Install InstructionsDocument25 pagesGen TT Install Instructionsspsperformance1No ratings yet

- SpearsDocument96 pagesSpearsatnkpr_vn9368No ratings yet

- BS 143Document4 pagesBS 143ramthecharm_46098467No ratings yet

- PVC Gravity Sewer PipeDocument1 pagePVC Gravity Sewer PipeDGWNo ratings yet

- Harrison Superduct Specifications 2015 PDFDocument12 pagesHarrison Superduct Specifications 2015 PDFJeoung MashitoNo ratings yet

- Tube-Mac Metric CatalogeDocument279 pagesTube-Mac Metric CatalogeTheAnonymousLugia100% (2)

- D-6041 Fiber Glass Hand-Layup PipesDocument7 pagesD-6041 Fiber Glass Hand-Layup Pipesmanuel.ape6263No ratings yet

- Valves and PipingDocument118 pagesValves and PipingMahdi Daly100% (1)

- Flanges - Standard Dim For Flanges Used in InvestaDocument2 pagesFlanges - Standard Dim For Flanges Used in InvestaBharat TailorNo ratings yet

- ASME BPE Plain End Weld v1.0Document13 pagesASME BPE Plain End Weld v1.0noodlehead675No ratings yet

- Din 11864 / Din 11853: Armaturenwerk Hötensleben GMBHDocument70 pagesDin 11864 / Din 11853: Armaturenwerk Hötensleben GMBHFrancisco Javier Zúñiga MontielNo ratings yet

- QP Technical Standard for Corrosion Monitoring SystemsDocument36 pagesQP Technical Standard for Corrosion Monitoring Systemssamynathan_bvsNo ratings yet

- Budget Recapitulation for Pipeline RelocationDocument4 pagesBudget Recapitulation for Pipeline RelocationSlamet SuntoroNo ratings yet

- 2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFDocument197 pages2021 PM 81805873-11 (L2z08524-Up) (September 2015) PDFGourish Bhandari100% (1)

- Shield Pipes Fittings PDFDocument36 pagesShield Pipes Fittings PDFilieoniciuc50% (2)

- THOMAS & BETTS Cable Tray CatalogueDocument24 pagesTHOMAS & BETTS Cable Tray CataloguemadhivananspNo ratings yet

- API-570-Inspection Checklist PDFDocument2 pagesAPI-570-Inspection Checklist PDFFred Moore100% (16)

- Cuña Neumatica Oil CountryDocument50 pagesCuña Neumatica Oil CountryGianna Frola100% (1)

- Pump & Pump Piping PresentationDocument55 pagesPump & Pump Piping PresentationEduard Gonzalo Rojas Cervantes100% (1)

- PW95 1Document440 pagesPW95 1marjan4386% (7)

- PDDATADocument646 pagesPDDATAClaudio SotoNo ratings yet

- Piping Class DatasheetDocument5 pagesPiping Class Datasheetcyno21100% (2)

- Flow of Incompressible Fluids in Conduits and ThinDocument81 pagesFlow of Incompressible Fluids in Conduits and Thinkruthi_dhoriaNo ratings yet