Professional Documents

Culture Documents

Xlub

Uploaded by

たましろ あきら0 ratings0% found this document useful (0 votes)

12 views2 pagesOriginal Title

xlub.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesXlub

Uploaded by

たましろ あきらCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Boundary Lubrication

Boundary lubrication in marine diesel engine bearings occurs during start

up and stopping, relatively slow speeds, high contact pressures, and with

less than perfectly smooth surfaces. As running conditions become more

severe such as with rough surfaces, and high contact pressures, wear

becomes a severe problem to the system.

With mineral oil, it is possible to create a lubricant that forms a surface film

over the surfaces, strongly adhering to the surface. These films are often

only one or two molecules thick but they can provide enough of a protection

to prevent metal to metal contact.

Boundary lubricating conditions occur when the lubricant film is

insufficient to prevent surface contact. This results in bearing wear and a

relatively high friction value.

Hydrodynamic Lubrication

Fluid film or hydrodynamic lubrication is the term given when a shaft

rotating in a bearing is supported by a layer or wedge of oil so that the shaft

is not in contact with the bearing material.

The principle which allows large loads to be supported by

similar to that which causes a car to aquaplane on a w

Aquaplaning occurs when water on the road accumulates

vehicle's tyres faster that the weight of your vehicle and the

of the tyre tread can push it out of the way. The water pressu

car to rise up and slide on top of a thin layer of water betwe

the road. Just like a car has to be travelling at a certa

aquaplaning will occur (this varies according to tyre con

surface but is generally about 55mph), a shaft must be rot

speed before hydrodynamic lubrication takes place.

Hydrodynamic lubrication was first researched by Osborne Reynolds (1842-

1912).When a lubricant was applied to a shaft and bearing, Reynolds found

that the rotating shaft pulled a converging wedge of lubricant between the

shaft and the bearing. He also noted that as the shaft gained velocity, the

liquid flowed between the two surfaces at a greater rate. This, because the

lubricant is viscous, produces a liquid pressure in the lubricant wedge that is

sufficient to keep the two surfaces separated. Under ideal conditions,

Reynolds showed that this liquid pressure was great enough to keep the two

bodies from having any contact and that the only friction is the system was

the viscous resistance of the lubricant.

The operation of hydrodynamic lubrication in journal bearings is illustrated

below. Before the rotation commences the shaft rests on the bearing

surface. When the rotation commences the shaft moves up the bore until an

equilibrium condition is reached when the shaft is supported on a wedge of

lubricant. The moving surfaces are then held apart by the pressure

generated within the fluid film. Journal bearings are designed such that at

normal operating conditions the continuously generated fluid pressure

supports the load with no contact between the bearing surfaces. This

operating condition is known as thick film lubrication and results in a very

low operating friction and extremely low bearing load

The rotating shaft drag

beneath it that develops

enough to support the sh

contact friction betwee

bearing

Viscosity of the lubricant is an important feature. The higher the viscosity,

the higher the friction between oil and shaft, but the thicker the

hydrodynamic film. However friction generates heat, which will reduce the

viscosity, the thickness of the film and may result in metal to metal contact.

Using an oil with a low initial viscosity will also result in a reduced oil film

thickness. We have to be very careful that the distance between the two

surfaces is greater than the largest surface defect. The distance between the

two surfaces decreases with higher loads on the bearing, less viscous fluids,

and lower speeds. Hydrodynamic lubrication is an excellent method of

lubrication since it is possible to achieve coefficients of friction as low as

0.001 (=0.001), and there is no wear between the moving parts. However

because the lubricant is heated by the frictional force and since viscosity is

temperature dependent, additives to decrease the viscosity's temperature

dependence are used. The oil of course is cooled before it is pumped back

through the engine.

You might also like

- Bearing LubricationDocument29 pagesBearing LubricationJameel Khan100% (1)

- Computational Methods For Platicity-SouzaDocument816 pagesComputational Methods For Platicity-SouzaMel Santos100% (7)

- Lubrication For Journal BearingDocument25 pagesLubrication For Journal BearingNguyễn Thanh SơnNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Tensile Strength of Mass Concrete 913-938 PDFDocument28 pagesTensile Strength of Mass Concrete 913-938 PDFchutton681No ratings yet

- Understanding proper lubrication from a bearing's perspectiveDocument22 pagesUnderstanding proper lubrication from a bearing's perspectiveengrsurifNo ratings yet

- Journal BearingDocument30 pagesJournal BearingAravind LakhanNo ratings yet

- Industrial Lubrication and TribologyDocument16 pagesIndustrial Lubrication and TribologyBonifacio Bagual JrNo ratings yet

- Lubrication TrainingDocument49 pagesLubrication TrainingzeruNo ratings yet

- Hydrodynamic or Full Fluid Film LubricationDocument59 pagesHydrodynamic or Full Fluid Film LubricationAbhishek Singh ChauhanNo ratings yet

- Oil and Gas Artificial Fluid Lifting TechniquesFrom EverandOil and Gas Artificial Fluid Lifting TechniquesRating: 5 out of 5 stars5/5 (1)

- Hydrostatic Lubrication RegimesDocument24 pagesHydrostatic Lubrication RegimesSharat ChandraNo ratings yet

- ASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingDocument186 pagesASTM STP1385 Durability 2000 Accelerated and Outdoor Weathering TestingKYAW SOENo ratings yet

- Thermal Analysis of Albendazole Investigated by HSM, DSC and FTIRDocument8 pagesThermal Analysis of Albendazole Investigated by HSM, DSC and FTIRElvina iskandarNo ratings yet

- Lubrication in Diesel Engines - Fluid Film Vs Boundary LubricationDocument3 pagesLubrication in Diesel Engines - Fluid Film Vs Boundary LubricationmavericksailorNo ratings yet

- Lubricants and Types of LubricantsDocument38 pagesLubricants and Types of Lubricantsumesh jaiswalNo ratings yet

- DTSDocument12 pagesDTSMartin SudhanNo ratings yet

- EHL PrincipleDocument2 pagesEHL PrincipleAnonymous alQXB11EgQNo ratings yet

- Fluid Bearing - WikipediaDocument8 pagesFluid Bearing - Wikipediaslam12125No ratings yet

- Journal Bearing Lubrication Modes: Thick Film vs Thin FilmDocument4 pagesJournal Bearing Lubrication Modes: Thick Film vs Thin FilmGovindNo ratings yet

- Unit I DTS - Journal BearingDocument19 pagesUnit I DTS - Journal BearingsathiaNo ratings yet

- BEARINGS MODULE LECTURE ON SLIDING CONTACT & HYDRODYNAMIC LUBRICATIONDocument17 pagesBEARINGS MODULE LECTURE ON SLIDING CONTACT & HYDRODYNAMIC LUBRICATIONSamuel JohnNo ratings yet

- Hydrodynamic Lubrication AssignmentDocument7 pagesHydrodynamic Lubrication AssignmentHARISH JANGRANo ratings yet

- Fluid BearingDocument3 pagesFluid Bearingyousafsappal795No ratings yet

- Load Capacity For Fitted Bearings of Hydrodynamic Lubrication Under Low and High Rotation NumberDocument10 pagesLoad Capacity For Fitted Bearings of Hydrodynamic Lubrication Under Low and High Rotation NumberMohammad MiyanNo ratings yet

- Plain Bearing ReportDocument15 pagesPlain Bearing Reportpresident fishrollNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument23 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsdawit melkamuNo ratings yet

- Tyre Construction Shock Absorber Aqua Planning: Finsen Resky SembiringDocument16 pagesTyre Construction Shock Absorber Aqua Planning: Finsen Resky SembiringThyra TalithaNo ratings yet

- "Starved Lubrication in Ehd Contacts": Mr. Sachin A. MoreDocument7 pages"Starved Lubrication in Ehd Contacts": Mr. Sachin A. MoreSACHIN A. MORENo ratings yet

- Bearings Course NotesDocument3 pagesBearings Course NotesEr Rajesh BuraNo ratings yet

- Marine Diesel Engine Lubrication Technologies ExplainedDocument3 pagesMarine Diesel Engine Lubrication Technologies ExplainedmavericksailorNo ratings yet

- 01 - Basic Module - Fundamentals of Lubrication - FilterDocument34 pages01 - Basic Module - Fundamentals of Lubrication - FilterJack PranNo ratings yet

- Elastohydrodynamic FILMDocument1 pageElastohydrodynamic FILMhegdemahesh1No ratings yet

- Hydrostatic & Hydrodynamic Bearing: Name:Kalani Mitesh H. Machine Tool EnggDocument12 pagesHydrostatic & Hydrodynamic Bearing: Name:Kalani Mitesh H. Machine Tool EnggMitesh KalaniNo ratings yet

- Lubrication Regimes ExplainedDocument9 pagesLubrication Regimes ExplainedSounak SasmalNo ratings yet

- Marine Bearings and Hydrodynamic LubricationDocument34 pagesMarine Bearings and Hydrodynamic LubricationThomas O'brien-bardenNo ratings yet

- Lubrication and Lubricants: Understanding Friction Reduction TechniquesDocument21 pagesLubrication and Lubricants: Understanding Friction Reduction TechniquesnishthaNo ratings yet

- Fluid Film Lubrication RegimesDocument10 pagesFluid Film Lubrication Regimesanhntran4850No ratings yet

- Experiment No - 5: AIM: To Study Various Types of Lubricating Systems. Theory: LubricationDocument3 pagesExperiment No - 5: AIM: To Study Various Types of Lubricating Systems. Theory: LubricationParas KumbalwarNo ratings yet

- Project 2Document56 pagesProject 2Parth ShahNo ratings yet

- Gears TheoryDocument23 pagesGears TheoryNAVEEN H V MENo ratings yet

- Lubrication techniques reduce wear between moving surfacesDocument3 pagesLubrication techniques reduce wear between moving surfacesThomas George AlumkalNo ratings yet

- Elasto-Hydrodynamic Lubrication: Table 4.11: Effect of Pressure On Relative Viscosity ThickeningDocument4 pagesElasto-Hydrodynamic Lubrication: Table 4.11: Effect of Pressure On Relative Viscosity ThickeningSheensky V. SalasaNo ratings yet

- WINSEM2017-18 - MEE2009 - TH - GDN109 - VL2017185003149 - Reference Material I - 6.lubricationDocument58 pagesWINSEM2017-18 - MEE2009 - TH - GDN109 - VL2017185003149 - Reference Material I - 6.lubricationUTKARSH SHARMANo ratings yet

- BearingsDocument4 pagesBearingsPraveen Kumar100% (1)

- Principles of Hydrodynamic Lubrication: Fig. 1-2 Fig. 1-3Document27 pagesPrinciples of Hydrodynamic Lubrication: Fig. 1-2 Fig. 1-3gao379No ratings yet

- Squeeze Film BearingDocument6 pagesSqueeze Film Bearingsuresh krishnaNo ratings yet

- NITA Chemistry Department Lubricants NotesDocument11 pagesNITA Chemistry Department Lubricants Notesnikunj chauhanNo ratings yet

- NO GMO's, and Will Not Upset Anyone's Precious FEELINGSDocument19 pagesNO GMO's, and Will Not Upset Anyone's Precious FEELINGSjameel babooramNo ratings yet

- BearingDocument23 pagesBearingAhmed Gad100% (1)

- Lubrication System in AutomobileDocument14 pagesLubrication System in AutomobileAshish Kumar BhaskarNo ratings yet

- Classification of LubricantsDocument3 pagesClassification of LubricantsSebastián RolexNo ratings yet

- BearingsDocument33 pagesBearingsRavishanker BaligaNo ratings yet

- Bearings and Their ApplicationDocument4 pagesBearings and Their ApplicationAkarsh AdiNo ratings yet

- 03 Lubricants PDFDocument21 pages03 Lubricants PDFrenz pepaNo ratings yet

- ME 308 Machine Elements Ii: Journal BearingsDocument70 pagesME 308 Machine Elements Ii: Journal BearingsxxxNo ratings yet

- FrictionDocument9 pagesFrictionjarvis007No ratings yet

- Lecture 13 & 14Document26 pagesLecture 13 & 14farah nazNo ratings yet

- bearingDocument41 pagesbearinghaymanotNo ratings yet

- Hydrodynamic Lubrication: Theory and DefinitionDocument10 pagesHydrodynamic Lubrication: Theory and DefinitionJohn Jhay CanlasNo ratings yet

- Introduction to Tribology - The Science of Interacting SurfacesDocument48 pagesIntroduction to Tribology - The Science of Interacting SurfacesManoj K VNo ratings yet

- Tribology: Module4: Lubricants & LubricationDocument5 pagesTribology: Module4: Lubricants & LubricationAkankshya MishraNo ratings yet

- Principles OF LubricationDocument46 pagesPrinciples OF LubricationMurugan GaneshNo ratings yet

- Hydrodynamic LubricationDocument14 pagesHydrodynamic Lubricationrsinha06089411No ratings yet

- Notas PDFDocument2 pagesNotas PDFたましろ あきらNo ratings yet

- 2Document1 page2たましろ あきらNo ratings yet

- Internal Combustion EnginesDocument2 pagesInternal Combustion Enginesたましろ あきらNo ratings yet

- Exploring SeaDocument6 pagesExploring Seaたましろ あきらNo ratings yet

- Internal Combustion EnginesDocument2 pagesInternal Combustion Enginesたましろ あきらNo ratings yet

- GUINESDocument1 pageGUINESたましろ あきらNo ratings yet

- Lecture NotesDocument1 pageLecture Notesたましろ あきらNo ratings yet

- A First Course in Linear Algebra PDFDocument424 pagesA First Course in Linear Algebra PDFShelvin Naidu100% (1)

- The Synchronus Rotor Instability Phenomenon - Morton Effect PDFDocument9 pagesThe Synchronus Rotor Instability Phenomenon - Morton Effect PDFabdullah buttNo ratings yet

- Soil Testing Procedures For Calcareous SoilsDocument5 pagesSoil Testing Procedures For Calcareous SoilsDoThanhTungNo ratings yet

- MarriageDocument3 pagesMarriageAstrologerAnjaanNo ratings yet

- Comparing Masses of Reactants and ProductsDocument4 pagesComparing Masses of Reactants and ProductsDaniel TriumbariNo ratings yet

- Make a castable lab test mixDocument16 pagesMake a castable lab test mixthaituan237No ratings yet

- TFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionDocument1 pageTFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionrajkumarfNo ratings yet

- A2 Nuclear Models LiqDrop FermiGasDocument19 pagesA2 Nuclear Models LiqDrop FermiGasAbdul RehmanNo ratings yet

- Mechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownDocument1 pageMechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownkprasannanNo ratings yet

- 9702 w04 QP 4Document16 pages9702 w04 QP 4api-3706826No ratings yet

- Analytical Chemistry & Numerical MCQ Test 3 - Makox MCQsDocument5 pagesAnalytical Chemistry & Numerical MCQ Test 3 - Makox MCQsنونه الحنونةNo ratings yet

- Cyclotron: A Brief GuideDocument11 pagesCyclotron: A Brief GuideasishNo ratings yet

- Feasibility of Manufacturing Silt Curtains in IndiaDocument3 pagesFeasibility of Manufacturing Silt Curtains in IndiaarvindkaushikNo ratings yet

- Ewald SphereDocument57 pagesEwald SphereMohammad Rameez0% (1)

- Temperature Regulator With Two Temperature SensorsDocument2 pagesTemperature Regulator With Two Temperature SensorsSandi AslanNo ratings yet

- Astm A82 1979Document6 pagesAstm A82 1979yoki_triwahyudiNo ratings yet

- SOFTENING POINTDocument8 pagesSOFTENING POINTSusi MulyaniNo ratings yet

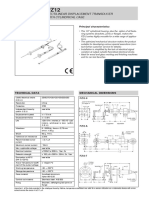

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- Marking Scheme Physics Trial SPM SBP 2016 Paper 3Document6 pagesMarking Scheme Physics Trial SPM SBP 2016 Paper 3Anonymous UypCttWNo ratings yet

- Comparison of Design of Steel Roof Truss Using IS 875 and SP 38Document3 pagesComparison of Design of Steel Roof Truss Using IS 875 and SP 38anbugobiNo ratings yet

- M.Prasad Naidu MSC Medical Biochemistry, PH.D Research ScholarDocument31 pagesM.Prasad Naidu MSC Medical Biochemistry, PH.D Research ScholarDr. M. Prasad NaiduNo ratings yet

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDocument14 pagesThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloNo ratings yet

- Spectrophotometric Determination of The Equilibrium Constant of A ReactionDocument5 pagesSpectrophotometric Determination of The Equilibrium Constant of A Reactionnarras11100% (1)

- Inline Desilter ManualDocument18 pagesInline Desilter ManualdesaviniciusNo ratings yet

- 4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFDocument500 pages4th International Conference On Thermal Equipment, Renewable Energy and Rural Development PDFMittapalli SaikiranNo ratings yet

- Metalic AsDocument16 pagesMetalic AsKarencita Genesis LapibaNo ratings yet