Professional Documents

Culture Documents

AppGuide - EnhancedTT MasterCam 2017

Uploaded by

eltklasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AppGuide - EnhancedTT MasterCam 2017

Uploaded by

eltklasCopyright:

Available Formats

MP APPLICATION GUIDES

Working with enhanced tool

tables

revision date: April 30, 2016

Contents

1. Introduction ...........................................................................................................................1

2. Implementing enhanced tool table processing in your post .............................2

A. Information that is available to ptooltable$ .............................................................4

Getting operation parameters from inside ptooltable$ .....................................9

Getting NCI data from inside ptooltable$ ............................................................9

B. Using the tt_ variables in any postblock ..................................................................9

C. Information that is available to puidlist$ ................................................................11

3. Using the t_list function ..................................................................................................12

4. Migrating an existing post to use the new tool tables .......................................15

MP Application Guide—Working with enhanced tool tables

Copyright © 2016 CNC Software, Inc.—All rights reserved

Terms of Use—Use of this document is subject to the Mastercam End User License Agreement.

A copy of the Mastercam End User License Agreement is included with the Mastercam product package.

The Mastercam End User License Agreement can also be found at: http://www.mastercam.com/en-us/Company-Info/Legal/LicenseAgreement/

rev. April 30, 2016 INTRODUCTION 1

1. Introduction Contents

Before Mastercam 2017, MP relied on an extensive set of pre-processing routines to

facilitate tool table processing. This process was characterized by the following

components:

Initializing the tooltable$ variable to 1 or 3 enable pre-processing.

Pre-reading the NCI file as a separate process before the normal NCI processing.

Implementing the pwrtt$ postblock for as the starting point for your tool table

logic.

Implementing the pwrttparam$ postblock to get operation parameters during

the pre-read process.

Beginning in Mastercam 2017, MP has access to a completely new set of routines that

allow access to tool table information while completely bypassing the traditional pre-

read process. This results in a much more efficient post and much simpler interaction

between the post and the NCI file. The new process is characterized by the following

components:

New x_tooltable$ variable to initiate tool table processing. This is called from

within a postblock at the point where you wish to begin processing your tool

table.

Elimination of the NCI pre-read process.

New predefined postblock ptooltable$ as the starting point for tool table logic,

replacing pwrtt$.

Use of opinfo function for additional operation parameters (plus fprm/

fprmtbl), replacing pwrttparam$.

New function, t_list, gives you easy expanded access to complete tool list

information (including probes) at any time.

New set of predefined variables, beginning with tt_. These are populated by the

new tool table routines so that you can keep those values separate from NCI

variables. For example, tt_gcode$ is populated by the tool table routines, while

gcode$ is populated by the NCI processing.

This guide is divided into the following sections:

Implementing enhanced tool table processing in your post . . . . . . . . . . . page 2

Using the t_list function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Migrating an existing post to use the new tool tables . . . . . . . . . . . . . . . page 15

NOTE: The enhanced tool table routines are designed to complement the new

parameter access routines, as described in the Working with tool and operation

parameters application guide. However, they are separate concepts and either can

be used independently of the other.

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 2

2. Implementingenhancedtooltable Contents

processing in your post

The new tool table routines are triggered by the x_tooltable$ variable and command

word. Use x_tooltable$ instead of the tooltable$ variable that has been traditionally

used in Mastercam posts.

IMPORTANT: If you choose to use x_tooltable$, tooltable$ should not be used

anywhere in your post.

x_tooltable$ has two main applications:

When it is set to –1 or –2, it will trigger calls to the puidlist$ postblock. This

postblock will be executed for each 20600 line (–1)or 20601 line (–2) in the NCI.

You can use this to build lists of all the component IDs or axis combo IDs.

When it is set to 0 or higher, it will trigger calls to the ptooltable$ postblock.

This postblock is run for each toolpath operation—in other words, each

operation that creates an 1000/1001/1002 line in the NCI file.

You are free to combine both uses in the same post so that you process both puidlist$

and ptooltable$; all you need to do is assign a new value to x_tooltable$, and then

call it again.

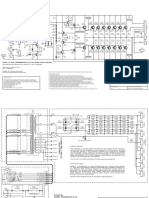

The table below details each mode for x_tooltable$.

Table 1: x_tooltable$ processing modes

Value Processing routine

–2 Call puidlist$ for each 20601 entry (axis combination)

–1 Call puidlist$ for each 20600 entry (component)

0 Call ptooltable$ for current operation only (defined by current op_id$ value).

(This is the default value.)

1 Call ptooltable$ for each operation in the operation list.

2 Call ptooltable$ for each operation in the operation list whose type matches

posttype$ value.

Follow this general outline:

Set x_tooltable$ to the desired mode by initializing it to a value from Table 1.

Implement puidlist$ or ptooltable$ as appropriate for your intended

application.

At the point in your post where you want processing to begin, place

x_tooltable$ on a line by itself as a command. This can be in any postblock,

but pheader$ is a common location for a typical tool table.

You can either initialize x_tooltable$ to a value in the header area of your post, or

assign a value to it inside a postblock before it is called.

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 3

Typically x_tooltable$ will be set to 1 for normal tool table processing; however note

the following values for special applications:

value 0—call ptooltable$ for single operation only.

value 2—filter mill/lathe operations for use in mill/turn posts. Contents

You can call x_tooltable$ from anywhere in your post to initiate tool table processing

and execute the ptooltable$ postblock. Note that if you do this from a postblock after

MP has begun processing the NCI file, there is no impact at all on the NCI processing:

MP’s internal “pointer” will remain exactly where it was when you called x_tooltable$,

since the new tool table routines do not rely on reading the NCI file.

Note also that even though you can call x_tooltable$ before the NCI file is read, if you

want to output tool table records to your NC file, you still must wait until the NC file has

been opened. For example, you cannot write tool table output from pprep$. For most

tool table applications, pheader$ is the most practical choice.

Example

Implementing enhanced tool table processing

The following code shows how the new tool table routines might be implemented in

a typical Mill post. The tool table routines are called directly from pheader$,

immediately after it has output several header lines to the NC file.

Notice that the ptooltable$ postblock uses the new tt_ variables, instead of the

normal NCI variables (see next section). The normal NCI variables have not been set

(since the NCI has not yet been processed), so the tt_ variables are used.

This example also references the tldia$ value, which is a traditional NCI variable.

Since the NCI has not yet been read, the post gets the 1013 line from a parameter

table. The next section discusses this in more detail.

fprmtbl 101 5 # Operation - tool table

1013 sparameter$

10010 xy_stock

10068 z_stock

15346 comp_type

20001 strtool$

pheader$ # Call before start of file

"%", e$

"(DATE=DD-MM-YY - ", date$, ")", e$

"(MCX FILE - ", *smcpath$, *smcname$, *smcext$, ")", e$

"(NC FILE - ", *spathnc$, *snamenc$, *sextnc$, ")", e$

"(MATERIAL - ", *stck_matl$, ")", e$

x_tooltable$ = 1 # Process all operations in order

x_tooltable$ # Call the tooltable

ptooltable$ # Tooltable output

if tool_info > 1 & tt_count$ = 1,

[

# Copy prefix string

s_t_pre_tt = s_t_pre$, s_d_pre_tt = s_d_pre$,

s_h_pre_tt = s_h_pre$

# Get the data from parameter lookup

result = fprm (101, 0, 0)

# Tool diameter from 1013 string

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 4

tldia$ = rparsngl (sparameter$, 2)

# Output tool table line

"(", *tt_tool$, sdelimiter, pstrtool, sdelimiter, *tt_tlngno$

if tt_drlcycle$ = –1, # No stock with drill Contents

[

if comp_type > 0 & comp_type < 4,

[

sdelimiter, tt_offset$, sdelimiter, *scomp_type,

sdelimiter, *tldia$

]

if xy_stock <> 0 | z_stock <> 0,

[

sdelimiter, *xy_stock, sdelimiter, *z_stock

]

]

")", e$

]

A. Information that is available to ptooltable$

To support the enhanced tool table processing routines, a new class of data objects has

been created. Legacy tool table processing (in other words, tooltable processing triggered

by the tooltable$ variable) relied on NCI variables that were populated during the NCI

pre-read. Since the enhanced tool table routines do not use the NCI pre-read, the

traditional NCI variables are not available, so new data objects have been created that

can be used instead.

The enhanced tool table processing has access to a set of 106 data objects, as listed in

Table 2 on page 5. While some of these are still only for internal use, most of them have

been exposed to the post writer through new predefined variables whose names begin

with tt_. Most of these correspond to traditional NCI variables; the difference is that the

tt_ variables are set from the new tool table routines, while the traditional variables are

set from reading the NCI data.

Having the two sets of values in different sets of variables means that you do not need to

worry about the tool table data overwriting the NCI data, and vice versa. Any of the

variables in Table 2 can be used freely in the ptooltable$ postblock.

If you do need access to one of the new data objects for which a predefined variable has

not been created—for example, one of the misc ints or reals—you can use the opinfo

function to get it. Use a statement of the following form

var = opinfo(n, 0)

where var is the name of a numeric variable to store the value, and n is the number from

the table below. For example, to get the value of misc integer 4, use a statement like this:

my_mi4 = opinfo(33, 0)

See the Working with tool and operation parameters application guide to learn more.

Table 2 lists all of the 106 possible settings. Not all of them are useful. They have been

exposed to the post writer as a group, but some of them are only relevant to MP’s internal

processing, as noted below.

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 5

Many of the tt_ variables listed below have enumerated lists of values; in most cases

(with a couple of exceptions), these will be the same as the regular MP variable. All the

values can be found in the MP reference documentation; they are not duplicated here.

Table 2: Variables for use with enhanced tool table processing Contents

Value for Variable name

Description

opinfo queries (if any)

1 Operation ID tt_op_id$

2 Xform operation ID tt_xform_op_id$

3 (internal use only)

4 (internal use only)

5 Stream ID tt_stream$

6 Post type tt_posttype$

7 Toolpath operation code tt_tool_op$

8 Axis combo tt_axiscombo$

9 (internal use only)

10 (internal use only)

11 (internal use only)

12 pointer to tool plane view matrix (1014 data); can be

useful with opmatrix function.

13 pointer to WCS view matrix (1027 data); can be useful

with opmatrix function.

14 Coordinate of max motion extent (X)

15 Coordinate of max motion extent (Y)

16 Coordinate of max motion extent (Z)

17 Coordinate of min motion extent (X)

18 Coordinate of min motion extent (Y)

19 Coordinate of min motion extent (Z)

20 Value of misc real 1

21 Value of misc real 2

22 Value of misc real 3

23 Value of misc real 4

24 Value of misc real 5

25 Value of misc real 6

26 Value of misc real 7

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 6

Table 2: Variables for use with enhanced tool table processing

Value for Variable name

Description

opinfo queries (if any)

Contents

27 Value of misc real 8

28 Value of misc real 9

29 Value of misc real 10

30 Value of misc int 1

31 Value of misc int 2

32 Value of misc int 3

33 Value of misc int 4

34 Value of misc int 5

35 Value of misc int 6

36 Value of misc int 7

37 Value of misc int 8

38 Value of misc int 9

39 Value of misc int 10

40 Current cutting plane tt_plane$

41 (internal use only)

42 Cutter compensation code tt_cc_pos$

43 Program number tt_progno$

44 Gcode for previous tool change prv_tt_gcode$

45 (internal use only)

46 (internal use only)

47 Tool number tt_tool$

48 Tool station number tt_tool_station$

49 Offset tt_offset$

50 Length offset tt_tlngno$

51 Indicates whether this tool is the first tool, last tool, or tt_state$

neither.

52 If the tool is used multiple times, indicates which tt_count$

instance is this operation.

53 Work offset tt_workoffs$

54 Spindle direction tt_spndl_dir$

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 7

Table 2: Variables for use with enhanced tool table processing

Value for Variable name

Description

opinfo queries (if any)

Contents

55 Is CSS active? tt_css_actv$

56 Type of rotary conversion tt_rot_conv$

57 Axis of rotation tt_rot_axis$

58 Rotary axis substitution direction tt_axis_subs_dir$

59 Rotary axis vector (X coordinate)

60 Rotary axis vector (Y coordinate)

61 Rotary axis vector (Z coordinate)

62 Diameter for axis substitution tt_axis_subs_dia$

63 Transform subprogram flag

64 Drill cycle tt_drlcycle$

65 (internal use only)

66 (internal use only)

67 Planes collection ttplane$

68 The type of rotary selection made in the Rotary Axis tt_rotary_type$

dialog box.

69 Rotary axis orientation in terms of the current tool plane tt_rotary_axis$

70 Speed tt_speed$

71 Home position (X coordinate)

72 Home position (Y coordinate)

73 Home position (Z coordinate)

74 (internal use only)

75 (internal use only)

76 (internal use only)

77 (internal use only)

78 (internal use only)

79 (internal use only)

80 Lathe canned cycle type

81 Flag to indicate if this is a finish profile

82 Coordinate of cycle start (X)

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 8

Table 2: Variables for use with enhanced tool table processing

Value for Variable name

Description

opinfo queries (if any)

Contents

83 Coordinate of cycle start (Y)

84 Coordinate of cycle start (Z)

85 Coordinate of cycle end (X)

86 Coordinate of cycle end (Y)

87 Coordinate of cycle end (Z)

88 Cycle direction vector (X)

89 Cycle direction vector (Y)

90 Cycle direction vector (Z)

91 Force toolchange flag

92 Validated tool change Gcode tt_gcode$

93 Probe active flag

94 Probe NCI flag

95 Feed rate tt_fr_pos$

96 Is IPR active? tt_ipr_actv$

97 The sequence number of this operation within the overall

sequence of operations. This is defined as operations that

have an NCI 1000/1001/1002 line.

98 The sequence number of this operation within the overall

sequence of operations as determined by list of NCI 999

lines. This is broader than setting 97, since some

operations (such as probing) have an NCI 999 line but not

a 1000/1001/1002 line.

99 The number of this operation within the set of operations

that have the same operation ID.

100 The total number of operations that have the same

operation ID as this operation.

101 Flag indicating if this operation has a tool change

102 Does this op use rotary axis substitution? tt_axis_subs$

103 Spindle number tt_spindle_no$

104 Turret number tt_lturret$

105 Nesting operation ID tt_nesting_op_id$

106 (internal use only)

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 9

Getting operation parameters from inside ptooltable$

In addition to the data objects in Table 2, the ptooltable$ postblock can access

operation parameters. Use either of these techniques:

Contents

Define parameter tables, then populate them with fprm statements in

ptooltable$.

Use the opinfo function to query them directly. Using the opinfo function also

lets you get parameters for previous/next operations.

Similar to opinfo, use the mdinfo, cdinfo, or groupinfo functions to get

parameters from the machine definition, control definition, or machine group.

See Implementing enhanced tool table processing on page 3 for a example of this.

See the Working with tool and operation parameters application guide for complete

information about using these functions.

Getting NCI data from inside ptooltable$

If the data that you need for your tool table is not available as one of the data objects in

Table 2, you can use the opinfo function to directly access tool change NCI lines. The

opinfo function will typically return an entire line of NCI parameters as a single string

which would need to be parsed with rparsngl to extract the desired value. For example:

ptooltable$ # Tooltable output

# Tool diameter from 1013 string

tldia$ = rparsngl (opinfo(1013, 0), 2)

Recall that you can use opinfo in this way to access NCI lines numbered 950 and higher,

including the NCI 20000+ lines that are encapsulated in the tool change NCI block.

See the Working with tool and operation parameters application guide for complete

information and more examples.

B. Using the tt_ variables in any postblock

Technically, the tt_ variables can be used in any other postblock in your post, not just

ptooltable$— even though, for most practical purposes, the traditional NCI variables

are the more appropriate choice. It is important to understand that the values of the tt_

variables will not be automatically set by MP outside of the ptooltable$ postblock.

However, MP gives you several techniques for populating their values outside of the

ptooltable$ postblock and ensuring that they have meaningful values relative to the

operation that MP is currently processing.

The most important tool for doing this is the opchng function. This function is

introduced in Mastercam 2017. Use it to update the tt_ enhanced tool table variables

anywhere in your post outside of the ptooltable$ postblock. You can use the opchng

function to update the tt_ variables to any operation in the operation list, not just the

current one.

Importantly, the opchng function will also update the previous values of the tt_

variables ( prv_tt_ ) to the tt_ values for the previous operation. So if you use opchng

function more than once, please understand that the prv_tt_ values will behave

differently than you might expect.

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 10

The general form of the function is

return = opchng( n )

where

Contents

return is a numeric variable to store the success/fail code.

–2 = no values could be obtained.

–1 = the prv_tt_ values could not be obtained.

0 = the tt_ values could not be obtained.

1 = both sets of values were obtained successfully.

n indicates the operation for which you want to populate the tt_ variables. Use 0 to

specify the current operation; any other value (positive or negative) is interpreted as

an offset from this. For example, a value of 2 would look ahead two operations,

while –1 would indicate the previous operation.

When opchng updates the prv_tt_ variables, these will automatically be relative to

whatever operation you select. For example, if you use opchng( 3 ) to get values

for three operations ahead, the prv_tt_ variables will be set to the values for two

operations ahead.

As an alternative to opchng, if you are using the opinfo function to access the enhanced

tool table data, you can update the tt_ values at the same time with opinfo. Use the

optional third argument in the opinfo function to do this. Set the 100s digit to 1 to

populate the tt_ variables. For example:

next_misc_int = opinfo(33, 1, 100)

In this example, opinfo will update all of the enhanced tool table data to values from the

next operation in the list, and then capture parameter 33 (the value of misc integer 4)

from that operation.

Working with enhanced tool tables

rev. April 30, 2016 IMPLEMENTING ENHANCED TOOL TABLE PROCESSING IN YOUR POST 11

C. Information that is available to puidlist$

The puidlist$ postblock is used to cycle through the 20600 NCI entries for individual Contents

components (x_tooltable$ = –1) or the the 20601 NCI entries for axis combinations

(x_tooltable$ = –2). As a convenience, the following variables are automatically

populated from each 20600/20601 entry as puidlist$ is being executed:

Table 3: Information available to puidlist$

Variable/string …is set to: Position on the 20600/20601 line

prmcode$ the numeric entity ID of the component or Param #1

axis combination

sparameter$ the string ID of the component or axis Param #1

combination

suser_label$ the name of the component or axis 20600: param #5

combination 20601: param #4

Recall that parameters 3 & 4 on the 20600 line are the absolute and incremental axis

labels for the component. If you need these strings inside the puidlist$ postblock, you

can get them easily with the uidinfo function:

puidlist$

s_abs_label = uidinfo(1, prmcode$)

s_inc_label = uidinfo(2, prmcode$)

See the Working with tool and operation parameters application guide for complete

information about the uidinfo function. Note also that suser_label$ is a new string

introduced in Mastercam 2017.

Working with enhanced tool tables

rev. April 30, 2016 USING THE T_LIST FUNCTION 12

3. Using the t_list function Contents

Beginning with Mastercam 2017, MP includes new routines that make it easier for you to

access information about the tools used in your part program. This includes a redesigned

tool list. The new tool list includes the following features:

It includes probes in addition to standard tools.

It is built and maintained outside of the NCI pre-read processes that have

traditionally been the source of tool information, so you can access it anywhere

in your post independently of which operation is currently being processed.

A new function, called t_list( ), has been introduced which lets you access the tool

list. You can use t_list( ) to query regular tools, probes, or both, whichever is

appropriate for your application.

MP builds the new tool list automatically when you initiate posting. Because it is

independent of the NCI pre-read process, you don’t need to rely on the pwrtt$ postblock

to access it. This makes the t_list( ) function an ideal complement to the new tool

table techniques described in the earlier sections of this document.

The general form of the function is:

return = t_list(mode, status, index)

where:

return = a numeric variable to store the return value. For most of the function

modes this is the number of a specific tool or probe, but see Table 4 for a complete

list.

mode = the function state (0–16) that tells MP exactly what you are searching for.

These are described in Table 4 below.

status = a coded value that provides additional context about the value that is

returned. This is a “license plate” value where each digit describes a specific

property. These are described in Table 5 below.

index = the position within the tool list of the selected tool or probe. This gets used

in two ways:

When you call t_list( ), in most function modes this will determine where

in the tool list to begin searching.

When t_list( ) returns, this will be set to the position of the tool or probe

that has been found.

For all function modes, index is optional. Its value is set just prior to the

ptlchng1002$ postblock call. If you do not include index, the search will begin by

default with the operation that is currently being processed by the NCI. If you are

calling the t_list( ) function before the NCI has begun processing (for example,

in pheader$), MP will simply start at the beginning of the tool list.

Working with enhanced tool tables

rev. April 30, 2016 USING THE T_LIST FUNCTION 13

Table 4: t_list function states

Function How ‘index’ is used: How ‘index’ is used: Contents

Return value

state when function is called when function returns

0 The tool number of the first tool Start position for search. The value of index will be set

or probe. to the postion of the tool or

probe.

1 The tool number of the first Start position for search. The value of index will be set

standard tool (in other words, to the postion of the tool.

not a probe).

2 The number of the first probe. Start position for search. The value of index will be set

to the postion of the probe.

3 The tool number of the next tool The next tool or probe after The value of index will be set

or probe. the index value. to the postion of the tool or

probe.

4 The tool number of the next The next tool after the index The value of index will be set

standard tool (in other words, value. to the postion of the tool.

not a probe).

5 The number of the next probe. The next probe after the index The value of index will be set

value. to the postion of the probe.

6 The number of the tool or probe The next tool change after the The value of index will be set

referenced in the next change. index value. to the postion of the tool or

probe.

7 The number of the tool The next tool change after the The value of index will be set

referenced in the next standard index value. to the postion of the tool.

(non-probe) tool change.

8 The number of the next probe. The next tool change after the The value of index will be set

index value. to the postion of the probe.

9 The tool number of the last tool Start position for search. The value of index will be set

or probe in the tool list. to the postion of the tool or

probe.

10 The tool number of the last Start position for search. The value of index will be set

standard tool (in other words, to the postion of the tool.

not a probe).

11 The number of the last probe. Start position for search. The value of index will be set

to the postion of the probe.

12 The total number of tools and Not used. Unchanged.

probes in the tool list.

13 The total number of standard Not used. Unchanged.

(non-probe) tools in the tool list.

14 The total number probes in the Not used. Unchanged.

tool list.

15 The index position in the tool list Not used. Unchanged.

of the tool used in the operation

that is currently being

processed from the NCI file.

16 The status code (see Table 5) The index position to query. If Unchanged.

of the tool at the referenced not present, MP will query the

index position. current tool.

Working with enhanced tool tables

rev. April 30, 2016 USING THE T_LIST FUNCTION 14

The following table describes the status codes that are set by the t_list( )

function. Note that values 0 through –3 are not “license plate” values, but are

ordinary integers; you can implement simple logic in your post to test for these

error states before trying to evaluate the other values.

Contents

Table 5: codes for “status” digits

Value of “status” What it means

–3 Error scanning the tool list; the beginning of the list was overrun.

–2 Error scanning the tool list; the end of the list was overrun.

–1 Error scanning the tool list; no tool/probe was found.

0 A tool or probe number was returned successfully, but no other information.

nnnnn1 The returned tool number was the first in the list.

nnnnn2 The returned tool number was the first of its type (standard tool or probe) in

the list.

nnnn1n Only non-probing tool changes were scanned.

nnnn2n Tool changes including probing were scanned.

nnn1nn The tool change for the returned tool number was the last in the list.

nnn2nn The tool change for the returned tool number was the last of its type (standard

tool or probe) in the list.

nn1nnn The returned tool number was the last in the list.

nn2nnn The returned tool number was the last of its type (standard tool or probe) in the

list.

1nnnnn The returned tool number is a probe.

Working with enhanced tool tables

rev. April 30, 2016 MIGRATING AN EXISTING POST TO USE THE NEW TOOL TABLES 15

4. Migrating an existing post to use Contents

the new tool tables

Follow this general outline for converting an existing post to the new tool table routines.

1. In the section of your post where you initialize your variables, find and remove

the line that initializes tooltable$.

2. Find the location in your post where you wish to begin writing the tool table.

a. Set x_tooltable$ to the desired processing mode.

b. Place it on a line by itself inside a postblock to initiate tool table processing.

x_tooltable$ = 1 # Select normal tool table mode

x_tooltable$ # Begin processing

3. Find the pwrtt$ postblock and migrate the logic to ptooltable$.

Much of the processing logic inside pwrtt$ will most likely still be applicable

to ptooltable$.

In many of the standard posts from CNC Software, pwrtt$ calls a user-

defined postblock named ptooltable. Typically, the logic inside the user-

defined ptooltable can simply be moved to ptooltable$, or you can

rename ptooltable to another user-defined postblock name.

4. Inside the pwrtt$ postblock—and all postblocks that it calls—find all references

to NCI variables and replace them with either:

References to the new tt_ variables from Table 2 on page 5.

Calls to opinfo to get the data from the proper NCI lines.

5. Remove pwrtt$.

6. Search for the pwrttparam$ postblock.

Rewrite the parameter calls to use the opinfo function (or mdinfo/cdinfo/

groupinfo, as appropriate).

Typically you can just move the logic to ptooltable$. Or, you can rename

pwrttparam$ as a user-defined postblock, and call it from ptooltable$.

7. Remove pwrttparam$.

8. Find any instances in the post where tooltable$ is used as a command word.

Typically, these can simply be changed to x_tooltable$. Otherwise, they

should be removed—no references to tooltable$ should be in the post.

As a best practice, always explicitly set x_tooltable$ to the desired mode

before calling it.

9. Test your post thoroughly!

IMPORTANT: Always make a backup copy of your post before making edits!

Working with enhanced tool tables

You might also like

- Pickoff Pull Cutoff Application Guide in MasterCamDocument20 pagesPickoff Pull Cutoff Application Guide in MasterCameltklasNo ratings yet

- 103 Changes To The MP PostDocument12 pages103 Changes To The MP Postxuanphuong2710No ratings yet

- 102 Intro To MP Post Proc PDFDocument26 pages102 Intro To MP Post Proc PDFKen LeeNo ratings yet

- 107 PostblocksDocument28 pages107 Postblocksxuanphuong2710100% (1)

- 306 NCI FileDocument81 pages306 NCI FileHoang LamNo ratings yet

- MCAMX6 PostDebuggerUG NoRestrictionDocument72 pagesMCAMX6 PostDebuggerUG NoRestrictionlvf51004No ratings yet

- Version 9 MP Post Processor Online Reference GuideDocument1 pageVersion 9 MP Post Processor Online Reference GuideHoang LamNo ratings yet

- Mastercam X7 NCI Parameter RefDocument465 pagesMastercam X7 NCI Parameter Refmarkoskitp75% (8)

- 302 PostblocksDocument206 pages302 PostblocksHoang LamNo ratings yet

- Mastercam PostDocument8 pagesMastercam PostwcwtnuiNo ratings yet

- Mastercam 2017 NCI Reference GuideDocument146 pagesMastercam 2017 NCI Reference GuideeltklasNo ratings yet

- How Subprograms Work: Subprograms in Mastercam Mill and LatheDocument16 pagesHow Subprograms Work: Subprograms in Mastercam Mill and LatheHoang LamNo ratings yet

- McamX3 Post Parameter RefDocument416 pagesMcamX3 Post Parameter Refabsalon_jarvNo ratings yet

- Edit numbered questions and tool comments in CNC postDocument3 pagesEdit numbered questions and tool comments in CNC postEd lHighNo ratings yet

- MP Online Reference 2018Document1,935 pagesMP Online Reference 2018HungTranNo ratings yet

- MPBinX Guide Reference Mastercam 2017Document12 pagesMPBinX Guide Reference Mastercam 2017eltklas100% (1)

- 103 Changes To The MP Post PDFDocument12 pages103 Changes To The MP Post PDFKen LeeNo ratings yet

- SAMPLE Mastercam X9 Multiaxis Professional CoursewareDocument33 pagesSAMPLE Mastercam X9 Multiaxis Professional CoursewareEduardo Aleman Reyna100% (1)

- 5 Axis Generic PostDocument68 pages5 Axis Generic Postwidya90% (10)

- Intro To The MP Post GuideDocument14 pagesIntro To The MP Post GuideanilkpNo ratings yet

- Mastercam Graphics Functions GuideDocument6 pagesMastercam Graphics Functions GuideMinh PhươngNo ratings yet

- 101 Intro To The MP Post GuideDocument12 pages101 Intro To The MP Post Guiderpanther040% (1)

- Getting Started With Mill-TurnDocument158 pagesGetting Started With Mill-TurnDiogenes CardosoNo ratings yet

- Sample X5 Mill Level 1 Training Tutorial MetricDocument98 pagesSample X5 Mill Level 1 Training Tutorial MetricMario TrevinoNo ratings yet

- MCAMX2 AdvMultiaxisTutorialDocument130 pagesMCAMX2 AdvMultiaxisTutorialTranhoaTranhoaNo ratings yet

- Vericut Help PDFDocument2,147 pagesVericut Help PDFNam Lê67% (3)

- Changes to MP Post Processor Reference GuideDocument86 pagesChanges to MP Post Processor Reference GuideMinh PhươngNo ratings yet

- Multi Axis Lesson 7Document34 pagesMulti Axis Lesson 7Truonglana100% (1)

- Mastercam 2017 Mill Advanced Training Tutorial SAMPLE PDFDocument36 pagesMastercam 2017 Mill Advanced Training Tutorial SAMPLE PDFsekhon875115No ratings yet

- Sample - Mastercam X5 Advanced Multiaxis Training TutorialDocument65 pagesSample - Mastercam X5 Advanced Multiaxis Training Tutorialtuanvn76100% (6)

- 5 Axis Lesson 2 SampleDocument20 pages5 Axis Lesson 2 SampledizorientedNo ratings yet

- MCAMX2 AdvMultiaxisTutorialDocument130 pagesMCAMX2 AdvMultiaxisTutorialAaron Winter100% (1)

- Convert A Mill Post To A Router X9 MasterCamDocument9 pagesConvert A Mill Post To A Router X9 MasterCameltklasNo ratings yet

- Post Processor ReferenceDocument437 pagesPost Processor Referencennn765100% (1)

- 307 Parameter InformationDocument293 pages307 Parameter InformationHoang LamNo ratings yet

- Mastercam C-Axis Tutorial6Document55 pagesMastercam C-Axis Tutorial6xuanphuong27100% (1)

- V9.1 Lathe Tutorial Change Pages (Inch)Document39 pagesV9.1 Lathe Tutorial Change Pages (Inch)Andrew TNo ratings yet

- Mastercam - Post-Processor Tutorial 1Document40 pagesMastercam - Post-Processor Tutorial 1Edson Sawada100% (1)

- Mastercam 2017 Handbook Volume 2 SAMPLEDocument29 pagesMastercam 2017 Handbook Volume 2 SAMPLEsekhon875115100% (1)

- Q&A Manual Guide 16i 18i 21iDocument23 pagesQ&A Manual Guide 16i 18i 21ivrpatel1No ratings yet

- Mill Tutorial Inch V9.1 SP2 Changes (Inch)Document107 pagesMill Tutorial Inch V9.1 SP2 Changes (Inch)Andrew TNo ratings yet

- Post Text - Misc ValuesDocument21 pagesPost Text - Misc ValuesPhanba LanNo ratings yet

- SAMPLE Mastercam X9 Mill Essentials Training Tutorial METRICDocument52 pagesSAMPLE Mastercam X9 Mill Essentials Training Tutorial METRICvlad_bj_86224467% (3)

- Mastercam2020 MultiaxisAdvanced TrainingTutorial SAMPLEDocument43 pagesMastercam2020 MultiaxisAdvanced TrainingTutorial SAMPLENguyen Van LyNo ratings yet

- CAMplete TruePath - MasterCAM - Using MasterCAM To Export Cycle 262Document4 pagesCAMplete TruePath - MasterCAM - Using MasterCAM To Export Cycle 262MX100No ratings yet

- 3 Axis Surface MachiningDocument512 pages3 Axis Surface MachiningagrbovicNo ratings yet

- MastercamX7 Intro To Multiaxis Bai 2Document38 pagesMastercamX7 Intro To Multiaxis Bai 2MastercamToolpathNo ratings yet

- MCAMX2 Art TutorialDocument350 pagesMCAMX2 Art Tutorialcadcamshop100% (1)

- CMU 15-445 Buffer Pool ProjectDocument1 pageCMU 15-445 Buffer Pool ProjectalucardchaNo ratings yet

- RapidResponse Solution Design & Authoring StandardsDocument17 pagesRapidResponse Solution Design & Authoring StandardsSAP TRGNo ratings yet

- Abinitio-FaqsDocument14 pagesAbinitio-Faqsinderjeetkumar singh100% (1)

- Module 2 AdsDocument60 pagesModule 2 AdsLavena gee BolusoNo ratings yet

- MP Ref Guide - Vol 1 PDFDocument211 pagesMP Ref Guide - Vol 1 PDFeltklas100% (1)

- MPBinX Guide Reference Mastercam 2017Document12 pagesMPBinX Guide Reference Mastercam 2017eltklas100% (1)

- Working With Tool and Operation Parameters: MP Application GuidesDocument69 pagesWorking With Tool and Operation Parameters: MP Application GuideseltklasNo ratings yet

- Convert A Mill Post To A Router X9 MasterCamDocument9 pagesConvert A Mill Post To A Router X9 MasterCameltklasNo ratings yet

- MP Ref Guide - Vol 1 PDFDocument211 pagesMP Ref Guide - Vol 1 PDFeltklas100% (1)

- MP Debugger User Guide PDFDocument72 pagesMP Debugger User Guide PDFeltklasNo ratings yet

- Working in Mastercam With MD & CDDocument44 pagesWorking in Mastercam With MD & CDeltklasNo ratings yet

- Replacing A Post in MD-CD in MastercamDocument6 pagesReplacing A Post in MD-CD in MastercameltklasNo ratings yet

- Mastercam 2017 NCI Reference GuideDocument146 pagesMastercam 2017 NCI Reference GuideeltklasNo ratings yet

- Calculo de LevasDocument69 pagesCalculo de LevaseltklasNo ratings yet

- Masters of Science Fiction and Fantasy Art - A Collection of The Most Inspiring Science Fiction, Fantasy, and Gaming Illustrators in The World-Rockport Publishers (2011)Document225 pagesMasters of Science Fiction and Fantasy Art - A Collection of The Most Inspiring Science Fiction, Fantasy, and Gaming Illustrators in The World-Rockport Publishers (2011)filipef100% (3)

- Funds Management Integration with Asset AccountingDocument5 pagesFunds Management Integration with Asset AccountingKathiresan NagarajanNo ratings yet

- Querying The Schema's Using Xspath in XML Language: T. Vamsi Vardhan Reddy, D.V. Subbaiah. M.Tech, (PH.D)Document5 pagesQuerying The Schema's Using Xspath in XML Language: T. Vamsi Vardhan Reddy, D.V. Subbaiah. M.Tech, (PH.D)IOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Yacht Devices NMEA 2000 Wi-Fi GatewayDocument44 pagesYacht Devices NMEA 2000 Wi-Fi GatewayAlexander GorlachNo ratings yet

- CH-SIK-COAX-02 SpecificationDocument5 pagesCH-SIK-COAX-02 SpecificationDuong NathanNo ratings yet

- 1770 KF2Document8 pages1770 KF2Chuy HernandezNo ratings yet

- Join Beldex at The World Blockchain SummitDocument2 pagesJoin Beldex at The World Blockchain SummitBeldexNo ratings yet

- CHRMP Generative AI Sept 2023 1Document19 pagesCHRMP Generative AI Sept 2023 1shajmalikNo ratings yet

- SOP SampleDocument2 pagesSOP SampleMohit Tandon75% (4)

- It Lecture 2Document23 pagesIt Lecture 2Muhammad Ali MasoodNo ratings yet

- SynopsisDocument12 pagesSynopsisTony HobbsNo ratings yet

- Course Syllabus Data Structures and AlgorithmDocument11 pagesCourse Syllabus Data Structures and AlgorithmCarl GloriosoNo ratings yet

- 07 - ESOL Entry 2 Unit 7Document20 pages07 - ESOL Entry 2 Unit 7Wayne100% (1)

- Jaguar XJS Help by Kirby PalmDocument201 pagesJaguar XJS Help by Kirby Palmrexgary100% (5)

- Build Apps On SAP BTPDocument13 pagesBuild Apps On SAP BTPtecsafinaNo ratings yet

- Document 2005035Document2 pagesDocument 2005035Joseph LeeNo ratings yet

- Operation Manual 4350 Paper CutterDocument44 pagesOperation Manual 4350 Paper CutterWhitaker BrothersNo ratings yet

- Librosa - Audio and Music Signal Analysis in Python SCIPY 2015Document7 pagesLibrosa - Audio and Music Signal Analysis in Python SCIPY 2015Kate ZenNo ratings yet

- 1.2 Cmri 1010Document2 pages1.2 Cmri 1010biglingambigNo ratings yet

- Matrix 1.4 - Dos-V (Implememting Vas With Dynamic Output Sinking)Document4 pagesMatrix 1.4 - Dos-V (Implememting Vas With Dynamic Output Sinking)អំភ្លី សំលេងNo ratings yet

- Reply To RFI 004 - BIM Related QueriesDocument7 pagesReply To RFI 004 - BIM Related QueriesSuresh DNo ratings yet

- CCTVDocument3 pagesCCTVJoan Cristy Cornista LastrillaNo ratings yet

- VirtualHost Examples - Apache HTTP ServerDocument9 pagesVirtualHost Examples - Apache HTTP ServerSaitejaTallapellyNo ratings yet

- TERADATA Basic TABLE SCRIPTSDocument7 pagesTERADATA Basic TABLE SCRIPTSJaya SankarNo ratings yet

- l1 Sep IntroductionDocument6 pagesl1 Sep IntroductionFact HubNo ratings yet

- Part of Bluetooth BookDocument41 pagesPart of Bluetooth Bookmeroka2000100% (1)

- MC 10205801 9999Document2 pagesMC 10205801 9999Si Thu LwinNo ratings yet

- (FE) Hax GuiDocument5 pages(FE) Hax GuiSogeki LeeNo ratings yet

- The Ultimate Scalper Course ManualDocument248 pagesThe Ultimate Scalper Course ManualAspirant100% (5)

- DX DiagDocument13 pagesDX DiagSpinnersPeterNo ratings yet