Professional Documents

Culture Documents

Aggregate

Uploaded by

Rayhan CreationCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aggregate

Uploaded by

Rayhan CreationCopyright:

Available Formats

Characteristic of aggregate- strength, particle shape, specific gravity, Compressive strength abram’s law- log F = log A- log B, where F is

bulk density, voids, porosity, moisture content and bulking. strength, compressive strength, A1 & B1 is constant x is w/c ratio by weight

particle shape, specific gravity, bulk density, voids, porosity, moisture

content and bulking. strength, particle shape, specific gravity, bulk Classification of concrete- based on cementing materials: lime

density, voids, porosity, moisture content and bulking. concrete, gypsum and cement concrete. Based on density: super heavy

(over 2500 kg/m3), dense (1800-2500 kg/m3), light weight (500–1800

Testing of aggregate-Particle size distribution T, Flakiness index and kg/m3) and extra light weight concrete (below 500 kg/m3), Based on

elongation index T, Deleterious materials and organic impurities test, place of casting- pre-cast and cast in situ.

Specific gravity and water absorption test, bulk density and void test,

Advantages of Concrete over other Materials of construction- it can

bulking T, crushing value test(ACV), ten per cent fines test, Aggregate be manufactured to desired strength and durability with economy, It

Impact Vale test(AIV), Aggregate abrasion Value test (AAV) can be cast to any desired shape, Maintenance cost of concrete

structures is almost negligible, concrete does not deteriorate

Types of preservations- Oil type preservatives, Organic solvent appreciably with age.

preservatives, Acetic anhydride treatment, Water soluble preservatives

are odorless organic or inorganic salts and are adopted for inside Slump Degree of Use for which concrete is suitable

locations only. value inch workability

0-1 Very low Precast and vibrated concrete works in roads and

piles (vibrated by power operated machine)

1-2 low Road works (vibrated by hand operated machine),

Mass concrete in foundation (without vibration),

lightly reinforced section (with vibration)

2-4 Medium Slabs (manually compacted), Normal reinforced

concrete (manually compacted), Heavily

reinforced sections (with vibration)

High For sections with congested reinforcement (Not

normally suitable for vibration)

Test of timber- Static bending strength test, Shear strength – parallel

and perpendicular to the grain, Tensile strength - parallel and

perpendicular to the grain, Impact bending strength, Compressive

strength test - parallel and perpendicular to the grain.

Functions of aggregate in concrete- The aggregate get the volume of

the concrete, around the surface of which the binding materials adheres

in the form of thin film. In the theory of voids in the fine aggregate is Concrete Mix design- (i)complies with the specifications of structural

filled up with binding materials. Finally, the binding materials ass the strength laid down, which is usually stated in terms of the compressive

name implies, Bind the individual units of the soil mass with the help strength of standard test specimens, (ii)complies with the durability

of water. requirements to resist the environment in which the structure will serve

its functional life, (iii) be capable of being mixed, transported,

Functions of water in concrete- water serves for: To wet the surface compacted as efficiently as possible without undue labor, (iv) and

of aggregates to develop the adhesion because the cement paste adhere lastly, but not least, be as economical as possible.

quickly and satisfactory to the wet surface of the aggregates than to dry

surface. To prepare a plastic mixture of various ingredients and to

impart workability to concrete to facilitate placing in the desired

position. Water in also needed for the hydration of the cementing

materials to set and harden during the period of curing.

Stages of concrete production- Batching or measurement of materials,

Mixing, Transporting, Placing, Compacting, Curing, Finishing

Methods of transporting- Mortar pan, Wheel barrow, Chute,

Damper, Bucket and ropeway, Belt conveyor, Skip and hoist, Pumping

Methods of curing- Water curing, Steam curing, Curing with infra-

red radiation, Electrical curing, Chemical curing

Concrete mix Design requirements- grade of concrete, Type of

concrete, Type and size of aggregate, Nominal maximum size

aggregate, Maximum/minimum cement content (kg/m3), Type of

mixing and curing water, Maximum free water-cement ratio by weight,

Degree of workability of concrete, Air content, Type of admixture

used, Maximum/ minimum density of concrete, Maximum/minimum

temperature of fresh concrete.

Factors defanging the choice of mix proportions- Compressive

strength, workability, Durability, Type size and grading of aggregates,

Aggregate cement ratio.

You might also like

- Geometry in Real LifeDocument21 pagesGeometry in Real LifeRayhan CreationNo ratings yet

- Orca Share Media1573382578128Document69 pagesOrca Share Media1573382578128Rayhan CreationNo ratings yet

- Fluid StaticsDocument75 pagesFluid StaticsRayhan CreationNo ratings yet

- Bernoulli's TheoremDocument5 pagesBernoulli's TheoremRayhan CreationNo ratings yet

- Department of Civil Engineering Course Outline of Semester: Fall 2019Document2 pagesDepartment of Civil Engineering Course Outline of Semester: Fall 2019Rayhan CreationNo ratings yet

- Column, Beam and SlabDocument31 pagesColumn, Beam and SlabRayhan CreationNo ratings yet

- Assignment: A.K.M NazimuddinDocument1 pageAssignment: A.K.M NazimuddinRayhan CreationNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Principles of Green Building DesignDocument36 pagesPrinciples of Green Building DesignJude Maala OnanadNo ratings yet

- Determination of Relative Density or Density Index of Cohesionless Soil (Is-2720-Part-15)Document16 pagesDetermination of Relative Density or Density Index of Cohesionless Soil (Is-2720-Part-15)Raj BakhtaniNo ratings yet

- 3098 Lamberts Channel Glass SolarDocument3 pages3098 Lamberts Channel Glass SolarIlinca MituNo ratings yet

- Conwood Eco-Friendly Building MaterialsDocument33 pagesConwood Eco-Friendly Building MaterialsIal LubisNo ratings yet

- B2a ElDocument5 pagesB2a ElBALAKRISHNANNo ratings yet

- Enerpac Fittings CatalogDocument1 pageEnerpac Fittings CatalogTitanplyNo ratings yet

- Plywood Types and ApplicationDocument3 pagesPlywood Types and ApplicationVibhor AgrawalNo ratings yet

- SeminarDocument24 pagesSeminarJyothishkumar MNo ratings yet

- Building Systems Exam Guide - Architecture Exam - NCARBDocument23 pagesBuilding Systems Exam Guide - Architecture Exam - NCARBiamarrNo ratings yet

- Insulation Thickness Chart PDFDocument9 pagesInsulation Thickness Chart PDFPartha Pratim GhoshNo ratings yet

- Handbook To BC1 2012Document11 pagesHandbook To BC1 2012Lau Kim HwaNo ratings yet

- NanoGrout CFGDocument3 pagesNanoGrout CFGimzee25100% (2)

- How To Classify Walls in A BuildingDocument2 pagesHow To Classify Walls in A BuildingsuryakantameNo ratings yet

- Adjustable Louver Grill Volume ControlDocument1 pageAdjustable Louver Grill Volume ControlmishtinilNo ratings yet

- Reference CardsDocument2 pagesReference CardsMansoorNo ratings yet

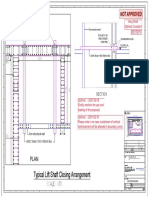

- Typical Lift Shaft Closing Arrangement SK-092Document1 pageTypical Lift Shaft Closing Arrangement SK-092ANUJ SHAHNo ratings yet

- Passive Solar Building Strategies for Nepalese CitiesDocument8 pagesPassive Solar Building Strategies for Nepalese CitiesAbhishek AcharyaNo ratings yet

- Ms - Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMs - Installation of Electric PVC Conduits and AccessoriesDuel TimeNo ratings yet

- Xe70 Series T6370/T6371: Fan-Coil Thermostats Fan Only ControlDocument4 pagesXe70 Series T6370/T6371: Fan-Coil Thermostats Fan Only ControlISMAEL ENRIQUE VALENCIA JURADONo ratings yet

- COMPRESSOR CROSS REFERENCE GUIDEDocument8 pagesCOMPRESSOR CROSS REFERENCE GUIDERidwan PramudyaNo ratings yet

- Class 1: Reinforced Concrete StructureDocument18 pagesClass 1: Reinforced Concrete StructureBaharulHussainNo ratings yet

- Bioconstruccion Eeuu MiamiDocument5 pagesBioconstruccion Eeuu MiamiArturo QRNo ratings yet

- JALBAA Literature Review - DocxfinDocument38 pagesJALBAA Literature Review - DocxfinSudha BistaNo ratings yet

- For FinolexDocument72 pagesFor FinolexKokila KokilaNo ratings yet

- Planilla ComparativaDocument29 pagesPlanilla ComparativaAnthony Luis Zevallos PortilloNo ratings yet

- Sr. No. - 19 Ward No - 18 Providing & Installing Electric Pole Near Bhagat Singh NagarDocument5 pagesSr. No. - 19 Ward No - 18 Providing & Installing Electric Pole Near Bhagat Singh Nagarnajuka ghodvindeNo ratings yet

- Costar 2K: Cementitious Waterproof MembraneDocument2 pagesCostar 2K: Cementitious Waterproof MembranePearl GbolahanNo ratings yet

- Students Project SchemeDocument9 pagesStudents Project SchemeAnonymous i3lI9MNo ratings yet

- Pier Cap PSC Multi StageDocument87 pagesPier Cap PSC Multi Stagesanyogitasawant5No ratings yet

- Construction On Flexible PavementDocument16 pagesConstruction On Flexible PavementABHAY SHRIVASTAVANo ratings yet