Professional Documents

Culture Documents

Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability

Uploaded by

AlexTLS0 ratings0% found this document useful (0 votes)

20 views3 pagesAirworthiness Directive

Original Title

EASA_AD_CF-2019-17_1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAirworthiness Directive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

20 views3 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability

Uploaded by

AlexTLSAirworthiness Directive

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

TP 7245E

1 of 3

AD Number: CF-2019-17

AIRWORTHINESS DIRECTIVE

This Airworthiness Directive (AD) is issued pursuant to Canadian Aviation Regulation (CAR) 521.427.

No person shall conduct a take-off or permit a take-off to be conducted in an aircraft that is in their legal

custody and control, unless the requirements of CAR 605.84 pertaining to ADs are met. Standard 625 -

Aircraft Equipment and Maintenance Standards Appendix H provides information concerning alternative

means of compliance (AMOC) to ADs.

Number: Effective Date:

CF-2019-17 22 May 2019

ATA: Type Certificate:

32 A-131

Subject:

Landing Gear – Main Landing Gear - Corrosion

Applicability:

Bombardier Inc. aeroplanes:

Model CL-600-2C10, serial numbers 10002 and subsequent,

Model CL-600-2D15 and CL-600-2D24, serial number 15001 and subsequent,

Model CL-600-2E25, serial numbers 19001 and subsequent.

Compliance:

As indicated below, unless already accomplished.

Background:

In-service reports and design review show that there is a possibility that corrosion exists on the main

landing gear (MLG) outer cylinder at the interface with the gland nut on the shock strut installation and on

the forward and aft trunnion pins in the MLG dressed shock strut assembly. Additionally, it is possible that

a quality escape may have resulted in some MLG outer cylinders having an inappropriate coating

application introduced at the gland nut thread relief groove and chamfer areas. Finally, it is possible that

some trunnion pins may have had the corrosion inhibiting compound removed inadvertently during

maintenance. Undetected corrosion on the trunnion pins or at the gland nut outer cylinder interface could

result in a MLG collapse.

This AD mandates the inspection, rectification, and modification of the appropriate MLG components in

order to mitigate the risk of MLG collapse.

Corrective Actions:

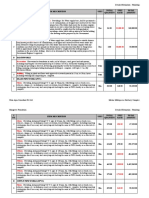

Part I - Applicable to CL-600-2C10 aeroplane model:

Perform a detailed visual inspection and rectification of the MLG outer cylinder assemblies and MLG

dressed shock strut assemblies with part numbers and serial numbers listed in the effectivity table for CL-

600-2C10 in Section 1.A.(1) in accordance with Section 2 Accomplishment Instructions, Part A –

Corrosion protection on the outer cylinder of BA SB 670BA-32-024, Revision C, dated 11 February 2015,

or later revisions approved by the Chief, Continuing Airworthiness, Transport Canada, using the following

schedule:

A. For assemblies that have accumulated 12 500 hours air time or less, and have been in service for six

years or less from their entry-into-service or last overhaul date: within 6500 hours air time or 3 years,

whichever occurs first, from the effective date of this AD; or

B. For assemblies that have accumulated more than 12 500 hours air time, or have been in service for

more than six years from its entry-into-service or last overhaul date: within 3500 hours air time or 2

years, whichever occurs first, from the effective date of this AD.

CF-2019-17 2 of 3

Incorporation of Section 2, Part A of the Accomplishment Instructions of BA SB 670BA-32-024 Revision

B, dated 19 December 2012, meets the requirements of Part I of this AD.

Part II - Applicable to CL-600-2D15 and CL-600-2D24 aeroplane models:

Perform a detailed visual inspection and rectification of the MLG dressed shock strut assemblies with part

numbers and serial numbers listed in the effectivity table for CL-600-2D15 and CL-600-2D24 in Section

1.A.(1) in accordance with Section 2 Accomplishment Instructions, Part B – Inspection of the outer

cylinder of BA SB 670BA-32-024, Revision C, dated 11 February 2015, or later revisions approved by the

Chief, Continuing Airworthiness, Transport Canada, using the following schedule:

A. For assemblies that have accumulated 12 500 hours air time or less, and have been in service six

years or less from its entry-into-service or last overhaul date: within 6500 hours air time or 3 years,

whichever occurs first, from the effective date of this AD; or

B. For assemblies that have accumulated more than 12 500 hours air time, or have been in service for

more than six years, from its entry-into-service or last overhaul date: within 3500 hours air time or 2

years, whichever occurs first, from the effective date of this AD.

Incorporation of Section 2, Part B of the Accomplishment Instructions of BA SB 670BA-32-024, Revision

B, dated 19 December 2012, meets the requirements of Part II of this AD.

Performing Aircraft Maintenance Manual (AMM) Task 32-11-10-960-802, Revision 40, dated 25 March

2012, or later approved revisions, meets the requirements of Part II of this AD.

Part III - Applicable to all aeroplane models:

Within 6500 hours air time or 3 years, whichever occurs first, from the effective date of this AD, perform a

detailed visual inspection and rectification of the MLG outer cylinder assemblies with part numbers and

serial numbers listed in Section 1.A. Effectivity, in accordance with the Accomplishment Instructions of BA

SB 670BA-32-052, dated 9 February 2015, or later revisions approved by the Chief, Continuing

Airworthiness, Transport Canada.

Part IV - Applicable to all aeroplane models:

Perform a detailed visual inspection and rectification or rework of the MLG forward and aft trunnion pins

with part numbers and serial numbers listed in Section 1.A. Effectivity, in accordance with the

Accomplishment Instructions of BA SB 670BA-32-034, Revision B, dated 21 December 2018, or later

revisions approved by the Chief, Continuing Airworthiness, Transport Canada, using the following

schedule:

A. For trunnion pins and grease adapters that have not had Goodrich SB 49101-32-47 (any revision)

incorporated:

i. For trunnion pins that have accumulated 10 000 hours air time or less, and have been in service

five years or less from its entry-into-service or last overhaul date: within 6500 hours air time or 3

years, whichever occurs first, from the effective date of this AD; or

ii. For trunnion pins that have accumulated more than 10 000 hours air time, and have been in

service for more than five years from its entry-into-service or last overhaul date: within 3000 hours

air time or 2 years, whichever occurs first, from the effective date of this AD.

B. For trunnion pins that have had Goodrich SB 49101-32-47 (any revision) incorporated, within 6500

hours air time or 3 years, whichever occurs first, from the effective date of this AD.

Note: The underlying corrective action is applicable to aft and forward trunnion pin part numbers (P/N)

49101-9/-11/-13 reworked from P/N 49101-1/-5/-7 in accordance with Goodrich SB 49101-32-47 (any

revision). The underlying corrective action is not applicable to aft and forward trunnion pin P/N

49101-9/-11/-13 installed as original equipment or purchased from Goodrich Landing Gear.

Incorporation of the Accomplishment Instructions of BA SB 670BA-32-034, Revision A, dated 17 August

2012, meets the requirements of Part IV of this AD.

Incorporation of the Accomplishment Instructions of BA SB 670BA-32-034 Initial Issue, dated 29 February

2012, meets the requirements of Part IV of this AD.

Part V - Applicable to all aeroplane models with forward and aft trunnion pin P/N 49101-9, 49101-

11, and 49101-13, maintained in accordance with the following maintenance instructions:

A. AMM Task 32-11-05-400-801 A01 (Installation of the MLG Shock-Strut Assembly), with a revision

date of 20 March 2010 or earlier; or

CF-2019-17 3 of 3

B. AMM Task 32-11-05-400-801 A02 (Installation of the MLG Shock-Strut Assembly), with a revision

date of 20 December 2010 or earlier; or

C. AMM Task 32-11-05-400-804 A01 (Installation of the MLG Shock-Strut Assembly – Forward Trunnion

Pin), with a revision date of 20 March 2011 or earlier; and/or, as applicable,

D. AMM Task 32-11-05-400-805 A01 (Installation of the MLG Shock-Strut Assembly – Aft Trunnion Pin),

with a revision date of 20 March 2011 or earlier.

Note: The underlying corrective action is not applicable to aft and forward trunnion pin P/N

49101-9/-11/-13 reworked from P/N 49101-1/-5/-7 in accordance with Goodrich SB 49101-32-47 (any

revision). The underlying corrective action is applicable to aft and forward trunnion pin P/N

49101-9/-11/-13 installed as original equipment or purchased from Goodrich Landing Gear.

Within 6500 hours air time or 3 years, whichever occurs first, from the effective date of this AD, perform a

detailed visual inspection and rectification of the MLG forward and aft trunnion pins in accordance with

the Accomplishment Instructions of BA SB 670BA-32-039, dated 29 February 2012, or later revisions

approved by the Chief, Continuing Airworthiness, Transport Canada.

Performing AMM Task 32-11-05-400-801 A01 Revision 38, dated 25 March 2012, or later approved

revisions, meets the requirements of Part V of this AD.

Performing AMM Task 32-11-05-400-801 A02 Revision 38, dated 25 March 2012, or later approved

revisions, meets the requirements of Part V of this AD.

Performing AMM Task 32-11-05-400-804 A01 Revision 37, dated 25 November 2011, or later approved

revisions, satisfies the Accomplishment Instructions found at paragraph 2.B.(1) of BA SB 670BA-32-039,

dated 29 February 2012.

Performing AMM Task 32-11-05-400-805 A01 Revision 37, dated 25 November 2011, or later approved

revisions, satisfies the Accomplishment Instructions found at paragraph 2.B.(2) of BA SB 670BA-32-039,

dated 29 February 2012.

Authorization:

For the Minister of Transport,

ORIGINAL SIGNED BY

Rémy Knoerr

Chief, Continuing Airworthiness

Issued on May 8 2019

Contact:

Marie-Claude Cardinal, Continuing Airworthiness, Ottawa, telephone 1-888-663-3639, facsimile

613-996-9178 or e-mail AD-CN@tc.gc.ca or any Transport Canada Centre.

You might also like

- Easa Ad CF-2021-33 1Document3 pagesEasa Ad CF-2021-33 1Talha stajNo ratings yet

- Easa Ad CF-2023-03 1Document2 pagesEasa Ad CF-2023-03 1RawiNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityBahadorNo ratings yet

- Easa Ad CF-2014-45 1Document3 pagesEasa Ad CF-2014-45 1Karol KrzysztoszekNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability: Compliance: BackgroundDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Applicability: Compliance: BackgroundKarol KrzysztoszekNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Revision: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Revision: ApplicabilityFares HarbiNo ratings yet

- Easa Ad CF-2018-03 1Document2 pagesEasa Ad CF-2018-03 1cf34No ratings yet

- Easa Ad CF-2019-07 1Document2 pagesEasa Ad CF-2019-07 1Heiko Oliva LiberjenNo ratings yet

- Easa Ad CF-2018-27 1Document2 pagesEasa Ad CF-2018-27 1Heiko Oliva LiberjenNo ratings yet

- Easa Ad CF-2023-19 1Document2 pagesEasa Ad CF-2023-19 1RawiNo ratings yet

- Easa Airworthiness Directive: AD No.: 2015-0133Document10 pagesEasa Airworthiness Directive: AD No.: 2015-0133Rajiv RimalNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Revision: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Revision: ApplicabilityBahadorNo ratings yet

- Airworthiness Directive: Civil Aviation AuthorityDocument5 pagesAirworthiness Directive: Civil Aviation AuthoritySzilárd Zeőke -SzőkeNo ratings yet

- Easa Ad CF-2022-13R1 1 PDFDocument3 pagesEasa Ad CF-2022-13R1 1 PDFBahadorNo ratings yet

- Blanik l13 - Gfa Ad-369Document11 pagesBlanik l13 - Gfa Ad-369mersoigNo ratings yet

- CFM56-7B SB 72-1033R01Document34 pagesCFM56-7B SB 72-1033R01Rahmat Mameth WintoloajiNo ratings yet

- Easa Ad CF-2023-50R1 1Document3 pagesEasa Ad CF-2023-50R1 1ctmmodernNo ratings yet

- Easa Ad CF-2013-11R1 2Document2 pagesEasa Ad CF-2013-11R1 2Heiko Oliva LiberjenNo ratings yet

- Easa Airwothiness DirectiveDocument2 pagesEasa Airwothiness DirectiveAlexTLSNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityRAMON CALDERONNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDharmendra Sumitra UpadhyayNo ratings yet

- Easa Ad CF-2021-51R1 1Document3 pagesEasa Ad CF-2021-51R1 1Heiko Oliva LiberjenNo ratings yet

- Easa Ad CF-2022-54 1Document2 pagesEasa Ad CF-2022-54 1PeteNo ratings yet

- 601 0617 Rev03Document17 pages601 0617 Rev03Madhan GanesanNo ratings yet

- Easa Ad CF-2021-29 1Document2 pagesEasa Ad CF-2021-29 1BahadorNo ratings yet

- FAA 2018 1039 0003 - Attachment - 1Document40 pagesFAA 2018 1039 0003 - Attachment - 1Luisbatista WachinNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: SubjectDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subjectcf34No ratings yet

- SB95 3B PDFDocument3 pagesSB95 3B PDFdzakub50% (2)

- F2Document4 pagesF2cypNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityBahadorNo ratings yet

- Easa Ad CF-2002-39R1 1Document3 pagesEasa Ad CF-2002-39R1 1cf34No ratings yet

- Airworthiness Directive: Civil Aviation AuthorityDocument2 pagesAirworthiness Directive: Civil Aviation AuthoritySzilárd Zeőke -SzőkeNo ratings yet

- Easa Ad CF-2023-28 1 PDFDocument2 pagesEasa Ad CF-2023-28 1 PDFBahadorNo ratings yet

- Airworthiness Directive: 2017-04-11 The Boeing Company: Amendment 39-18806 Docket No. FAA-2016-5468Document4 pagesAirworthiness Directive: 2017-04-11 The Boeing Company: Amendment 39-18806 Docket No. FAA-2016-5468Carlos VarrentiNo ratings yet

- Tcca Ad CF-2017-24Document3 pagesTcca Ad CF-2017-24syedumarahmed52No ratings yet

- Asb - 212 10 140Document12 pagesAsb - 212 10 140smartasss100% (1)

- Easa Ad CF-2017-20 1Document2 pagesEasa Ad CF-2017-20 1danna valentina benavides cetinaNo ratings yet

- Ad 2008 08 10Document9 pagesAd 2008 08 10bnolascoNo ratings yet

- MC 8 Mod 08 AD 91-15-04Document4 pagesMC 8 Mod 08 AD 91-15-04bhanu pratap lodhiNo ratings yet

- Airworthiness Directive Schedule: Aeroplanes Hawker Beechcraft Corporation C90A, C90Gt and C90Gti 27 May 2010Document17 pagesAirworthiness Directive Schedule: Aeroplanes Hawker Beechcraft Corporation C90A, C90Gt and C90Gti 27 May 2010midun100% (1)

- Airworthiness Directive: Civil Aviation AuthorityDocument4 pagesAirworthiness Directive: Civil Aviation AuthoritySzilárd Zeőke -SzőkeNo ratings yet

- Cf34-8e 72-A0221Document8 pagesCf34-8e 72-A0221Stephen Hyde100% (1)

- Brazilian Airworthiness Directive: Agência Nacional de Aviação Civil - BrazilDocument3 pagesBrazilian Airworthiness Directive: Agência Nacional de Aviação Civil - Brazils mNo ratings yet

- Easa Ad BR-2022-09-01 1Document3 pagesEasa Ad BR-2022-09-01 1Jaydip SinghNo ratings yet

- Engine Inspection - "Mr. C. Gonzalez Class": "Airworthiness Directives" Assignment Study Questions 1-11Document6 pagesEngine Inspection - "Mr. C. Gonzalez Class": "Airworthiness Directives" Assignment Study Questions 1-11Luis AlonsoNo ratings yet

- Airworthiness Directive: Transport Transports Canada Canada CF-2007-20R2 6 February 2009Document3 pagesAirworthiness Directive: Transport Transports Canada Canada CF-2007-20R2 6 February 2009Karol KrzysztoszekNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityBahadorNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document5 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Muhammad Amirul Amirul EmptyNo ratings yet

- Tugas AD 2009-26-4 (Kelompok 4)Document3 pagesTugas AD 2009-26-4 (Kelompok 4)vegi pujiantoNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityDocument3 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: Replacement: ApplicabilityluisNo ratings yet

- Airworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityDocument2 pagesAirworthiness Directive: Number: Ata: Effective Date: Type Certificate: Subject: ApplicabilityFahad JavaidNo ratings yet

- 99 10 12Document11 pages99 10 12bnolascoNo ratings yet

- FAA 2007 28413 0045 - Attachment - 2Document17 pagesFAA 2007 28413 0045 - Attachment - 2dyinganaldestroyer1No ratings yet

- CFM SB 72-1033Document30 pagesCFM SB 72-1033Mohammad AkhterNo ratings yet

- Easa Ad CF-2023-71 1Document2 pagesEasa Ad CF-2023-71 1RawiNo ratings yet

- SL 455Document3 pagesSL 455Aeronca ChampNo ratings yet

- Airworthiness Directive: Civil Aviation AuthorityDocument3 pagesAirworthiness Directive: Civil Aviation AuthorityCarlos VarrentiNo ratings yet

- 48 57Document7 pages48 57turboshaftNo ratings yet

- Service Bulletin: TitleDocument12 pagesService Bulletin: TitleLuis EnriqueNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- Easa Pad 19-070 1 PDFDocument3 pagesEasa Pad 19-070 1 PDFAlexTLSNo ratings yet

- Easa Ad 2019-0084 1Document4 pagesEasa Ad 2019-0084 1AlexTLSNo ratings yet

- EASA Emergency Airworthiness DirectiveDocument4 pagesEASA Emergency Airworthiness DirectiveWHAS11 NewsNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)AlexTLSNo ratings yet

- Airworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)Document3 pagesAirworthiness Directive: Design Approval Holder's Name: Type/Model Designation(s)AlexTLSNo ratings yet

- Explanatory Statement For Absence of AD DocumentDocument1 pageExplanatory Statement For Absence of AD DocumentAlexTLSNo ratings yet

- Explanatory Statement For Absence of AD DocumentDocument1 pageExplanatory Statement For Absence of AD DocumentAlexTLSNo ratings yet

- Easa Ad 2019-0100 1Document3 pagesEasa Ad 2019-0100 1AlexTLSNo ratings yet

- Easa Airwothiness DirectiveDocument2 pagesEasa Airwothiness DirectiveAlexTLSNo ratings yet

- Notification of A Proposal To Issue An Airworthiness DirectiveDocument3 pagesNotification of A Proposal To Issue An Airworthiness DirectiveAlexTLSNo ratings yet

- Easa Ad 2019-0099 1Document4 pagesEasa Ad 2019-0099 1AlexTLSNo ratings yet

- Easa Pad 19-081 1Document4 pagesEasa Pad 19-081 1AlexTLSNo ratings yet

- Easa Ad 2019-0104 1Document3 pagesEasa Ad 2019-0104 1AlexTLSNo ratings yet

- Presentation On Plant LayoutDocument20 pagesPresentation On Plant LayoutSahil NayyarNo ratings yet

- HP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisDocument5 pagesHP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisFernandoDiasNo ratings yet

- Appointment - Letter GaganDocument10 pagesAppointment - Letter GaganAjay choudharyNo ratings yet

- Part - A (Short Answer Questions) : S. No. Questions Bloom's Taxonomy Level Course OutcomeDocument11 pagesPart - A (Short Answer Questions) : S. No. Questions Bloom's Taxonomy Level Course OutcomeDevendra BhavsarNo ratings yet

- CIMICDocument228 pagesCIMICKehinde Olaoluwa100% (1)

- Surveillance of Healthcare-Associated Infections in Indonesian HospitalsDocument12 pagesSurveillance of Healthcare-Associated Infections in Indonesian HospitalsRidha MardiyaniNo ratings yet

- 5d814c4d6437b300fd0e227a - Scorch Product Sheet 512GB PDFDocument1 page5d814c4d6437b300fd0e227a - Scorch Product Sheet 512GB PDFBobby B. BrownNo ratings yet

- Star - 6 ManualDocument100 pagesStar - 6 ManualOskarNo ratings yet

- Java Programming Unit5 Notes PDFDocument110 pagesJava Programming Unit5 Notes PDFVishnu VardhanNo ratings yet

- Satisfaction Attributes and Satisfaction of Customers: The Case of Korean Restaurants in BataanDocument10 pagesSatisfaction Attributes and Satisfaction of Customers: The Case of Korean Restaurants in BataanMaraNo ratings yet

- 03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019Document52 pages03 Marine Multispecies Hatchery Complex Plumbing Detailed BOQ - 23.10.2019samir bendreNo ratings yet

- CPWA Code MCQDocument43 pagesCPWA Code MCQSamrat Mukherjee100% (3)

- Intel L515 - User - GuLidarDocument20 pagesIntel L515 - User - GuLidarRich ManNo ratings yet

- MC1413 D PDFDocument8 pagesMC1413 D PDFAnonymous oyUAtpKNo ratings yet

- To. Whom It May Concern: Available Mentioned Position in IndonesiaDocument8 pagesTo. Whom It May Concern: Available Mentioned Position in IndonesiaGreen Sustain EnergyNo ratings yet

- LCD Television Service Manual: Chassis MTK8222 Product TypeDocument46 pagesLCD Television Service Manual: Chassis MTK8222 Product TypetvdenNo ratings yet

- Moon Chae-Won - AsianWiki - 1606832167285Document6 pagesMoon Chae-Won - AsianWiki - 1606832167285CESHNo ratings yet

- Disaster Management in Schools: Status ReportDocument28 pagesDisaster Management in Schools: Status ReportRamalingam VaradarajuluNo ratings yet

- AccreditationDocument6 pagesAccreditationmyra delos santosNo ratings yet

- Questionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewDocument2 pagesQuestionnaire Exercise: Deals Desk Analyst Please Answer Below Questions and Email Your Responses Before First Technical Round of InterviewAbhinav SahaniNo ratings yet

- Nammcesa 000010 PDFDocument1,543 pagesNammcesa 000010 PDFBasel Osama RaafatNo ratings yet

- Program 7Document6 pagesProgram 7Khushi GuptaNo ratings yet

- Feasibility Report, Modhumoti, Rev. - April-.2015-1Document19 pagesFeasibility Report, Modhumoti, Rev. - April-.2015-1Jahangir RaselNo ratings yet

- BA5411 ProjectGuidelines - 2020 PDFDocument46 pagesBA5411 ProjectGuidelines - 2020 PDFMonisha ReddyNo ratings yet

- Income Tax Banggawan Chapter 10Document18 pagesIncome Tax Banggawan Chapter 10Earth Pirapat100% (5)

- Marketing Theory and PracticesDocument4 pagesMarketing Theory and PracticesSarthak RastogiNo ratings yet

- Determination of Molecular Radius of Glycerol Molecule by Using R SoftwareDocument5 pagesDetermination of Molecular Radius of Glycerol Molecule by Using R SoftwareGustavo Dos SantosNo ratings yet

- Retdem CathDocument17 pagesRetdem CathShane Aileen AngelesNo ratings yet

- 1.SITXWHS003 Student Assessment Tasks 1Document58 pages1.SITXWHS003 Student Assessment Tasks 1Yashaswi GhimireNo ratings yet

- Fss Operators: Benchmarks & Performance ReviewDocument7 pagesFss Operators: Benchmarks & Performance ReviewhasanmuskaanNo ratings yet