Professional Documents

Culture Documents

DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015

Uploaded by

KamalVirkOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DFDFGD: THA - A318/A319/A320/ A321 Tail Number - MSN - FSN HS-TXP - 06254 - 015

Uploaded by

KamalVirkCopyright:

Available Formats

THA - A318/A319/A320/

A321

JOB CARD PACKAGE TITLE:

Tail Number - MSN -

dfdfgd

FSN

HS-TXP - 06254 - 015

Reference Title DocType

Clean the Engine Gas Path for Performance

72-00-00-100-010-A AMM

Improvement (Water only)

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 1 of 1

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

** ON A/C FSN ALL

TASK 72-00-00-100-010-A

Clean the Engine Gas Path for Performance Improvement (Water only)

FIN: 1000EM1 1000EM2

WARNING: BE CAREFUL WHEN YOU USE CONSUMABLE MATERIALS. OBEY THE MATERIAL

MANUFACTURER'S INSTRUCTIONS AND YOUR LOCAL REGULATIONS.

CAUTION: DO NOT USE WATER TO WASH ENGINES WITH GAS PATHS THAT HAVE BEEN

EXPOSED TO DRY POWDER FIRE EXTINGUISHING AGENTS. THESE AGENTS ARE

NOT WATER SOLUBLE. IF YOU CLEAN WITH WATER, THESE MATERIALS WILL

BOND TO ENGINE PARTS.

CAUTION: TO PREVENT THE FORMATION OF ICE, MIX V01-007 OR V01-124 ALCOHOL WITH

THE WATER YOU USE TO DILUTE THE CLEANER IF THE AMBIENT TEMPERATURE

IS BELOW 40 DEG.F (4.4 DEG.C) TO 25 DEG.F (3.9 DEG.C). DO NOT WASH BELOW

TEMPERATURES OF 25 DEG.F (MINUS 3.9 DEG.C).

CAUTION: THE ENGINE EGT MUST BE BELOW 150 DEG.F (65.6 DEG.C) TO PREVENT ENGINE

DAMAGE.

1. Reason for the Job

To clean the engine gas path for performance improvements or to remove debris because of

birdstrike. It is recommended to use pure water only for the engine gas path cleaning.

NOTE: This task can contribute to fuel savings and take off EGT margin recovery.

2. Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR PLUG - BLANKING

No specific AR SAFETY CLIP - CIRCUIT BREAKER

No specific AR WARNING NOTICE(S)

No specific AR WATER SOURCE - GROUND

No specific Torque wrench: range to between 159 and 177 lbf.in

(1.80 and 2.00 m.daN)

No specific Torque wrench: range to between 283 and 310 lbf.in

(3.20 and 3.50 m.daN)

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 1 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

REFERENCE QTY DESIGNATION

IAE4J12031 1 RING - SPRAY

IAE4J12034 1 TUBE-WATER WASH

B. Consumable Materials

REFERENCE DESIGNATION

V01-007 denatured ethyl alcohol

V01-124 Isopropyl Alcohol, Technical grade

V02-274 safety cable

No specific MIL-L-23699 oil

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

210 CKPT,FWD COMPT BHD TO FLT COMPT BULKHEAD

400 POWER PLANT, NACELLES AND PYLONS

FOR 1000EM1(ENGINE-1)

437AL, 438AR, 451AL,

452AR

FOR 1000EM2(ENGINE-2)

447AL, 448AR, 461AL,

462AR

D. Referenced Information

REFERENCE DESIGNATION

Ref. 12-13-79-610-010-A Drain the Engine Oil System

Ref. 12-13-79-610-011-A Check Oil Level and Replenish

Ref. 71-00-00-700-013-A Procedure to Dry Out the High Pressure Turbine After Oil

Contamination

Ref. 71-00-00-710-013-C Test No.11 : High Power Assurance Test

Ref. 71-00-00-710-018-A Discontinued Start, Restart and Shutdown Procedures

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 2 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

REFERENCE DESIGNATION

Ref. 71-00-00-710-043-A Normal Engine Automatic Start Procedure

Ref. 71-00-00-710-045-A Test No.1 : Dry Motor Leak Check

Ref. 71-00-00-710-047-A Normal Engine Manual Start Procedure

Ref. 71-13-00-010-010-A Opening of the Fan Cowls 437AL(447AL),438AR(448AR)

Ref. 71-13-00-410-010-A Closing of the Fan Cowls 437AL(447AL),438AR(448AR)

Ref. 75-32-41-000-010-A Removal of the Variable Stator Vane (VSV) Actuator

Ref. 75-32-41-400-010-A Installation of the Variable Stator Vane (VSV) Actuator

Ref. 75-32-41-400-010-A01 Installation of the Variable Stator Vane (VSV) Actuator (SBE

75-0122, Type G4000VSVA Series)

Ref. 77-21-43-350-801-A EGT Harness and Junction Box Dry-Out Procedure

Ref. 78-30-00-040-012-A Deactivation of the Thrust Reverser Hydraulic Control Unit

(HCU) for Ground Maintenance

Ref. 78-30-00-440-012-A Re-activation of the Thrust Reverser Hydraulic Control Unit

(HCU) after Ground Maintenance

Ref. 78-32-00-010-010-A Opening of the Thrust Reverser Halves

Ref. 78-32-00-410-010-A Closing of the Thrust Reverser Halves

Ref. Fig. P4.9 Air Tube Assembly

Ref. Fig. PS3 Sense Line Air Tube Assembly

Ref. Fig. Stage 12 (P3) Air Tube

Ref. Fig. Spray Ring, IAE 4J12031

Ref. Fig. Water Wash Tube, IAE 4J12034

Ref. Fig. Alcohol and Water Mixture Ratio

3. Job Set-up

SUBTASK 72-00-00-941-092-A

A. Safety Precautions

(1) On the center pedestal, on the ENG panel 115VU:

(a) Put a WARNING NOTICE(S) to tell persons not to start the engine.

(2) Make sure that the engine 1(2) shutdown occurred not less than five minutes before

you do this procedure.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 3 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

(3) On the overhead maintenance panel 50VU:

(a) Make sure that the ON legend of the ENG/FADEC GND PWR/1(2) pushbutton

switch is off.

(b) Put a WARNING NOTICE(S) to tell persons not to energize the FADEC 1(2).

SUBTASK 72-00-00-010-115-A

B. Open the fan cowls Ref. AMM TASK 71-13-00-010-010:

(1) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(2) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

SUBTASK 72-00-00-040-070-A

C. Deactivate the thrust reverser Hydraulic Control Unit (HCU) Ref. AMM TASK

78-30-00-040-012.

SUBTASK 72-00-00-010-116-A

D. Open the thrust reverser halves Ref. AMM TASK 78-32-00-010-010:

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

4. Procedure

SUBTASK 72-00-00-010-114-A

A. Set the cabin services bleed valves to the closed position.

(1) On the AIR COND panel 30VU, release the ENG 1(2) BLEED pushbutton switch.

(2) The OFF legend of this pushbutton switch comes on.

SUBTASK 72-00-00-020-053-A

B. Disconnect the following air tubes:

NOTE: Make sure that all the disconnected tubes are capped properly to prevent water/

Foreign Object Damage (FOD) intrusion.

(1) Disconnect the P4.9 air sense tube to the Electronic Engine Control (EEC) at the

fitting on the bottom of the turbine exhaust case. Install the PLUG - BLANKING on

the disconnected air tube end.

Ref. Fig. P4.9 Air Tube Assembly

(2) Disconnect the Pb (PS3) sensing air tube from the auto start probe. Install the PLUG

- BLANKING on the disconnected air tube end.

Ref. Fig. PS3 Sense Line Air Tube Assembly

PRE SBE 75-0081

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 4 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

(3) Disconnect the stage 12 (P3) make-up air valve muscle air tube from the off-take

tube before you do the core wash. Install the PLUG - BLANKING on the

disconnected air tube end.

Ref. Fig. Stage 12 (P3) Air Tube

END OF Pre SBE 75-0081

NOTE: The disconnection of the Variable Stator Vane (VSV) actuator and the

manual opening of the stator vanes are optional. An additional core wash

cycle can be done to compensate the core wash efficiency reduction due to

a closed VSV during the core wash.

(4) Disconnect the VSV control rod from the actuator and manually move the stator

vanes to the fully open position, and install the rig pin Ref. AMM TASK

75-32-41-000-010.

SUBTASK 72-00-00-420-057-A

CAUTION: WHEN YOU PUT THE SPRAY RING SEGMENTS THROUGH THE FAN

BLADES, MAKE SURE THAT THE SPRAY RING SEGMENTS DO NOT TOUCH

THE ENGINE PARTS THAT MOVE.

IF YOU DO NOT OBEY THIS INSTRUCTION, DAMAGE TO THE EQUIPMENT

CAN OCCUR.

C. Install the RING - SPRAY (IAE4J12031):

Ref. Fig. Spray Ring, IAE 4J12031

NOTE: This subtask is an alternative to subtask 72-00-00-420-073-A.

(1) Put each of the four spray ring segments (nozzle hole side to the rear) at the inlet of

the fan outlet inner vane assembly through the fan blades.

(2) Install a spray ring segment with a coupling that connects to the long hose around the

bottom of the fan outlet inner vane assembly.

(3) Install the clamp screws on the brackets of the spray rings through the fan blade.

Hang the hook of the clamp screw on the Low Pressure Compressor (LPC) outlet

guide vane.

(4) Tighten the eight wing nuts on the clamp screws by hand.

(5) Connect the couplings of the spray rings, then safety the spray ring assembly to the

fan outlet inner vane assembly with the clamp screws and the wing nuts. Adjust the

positions of the spray ring assembly as necessary.

(6) Connect one end of the long hose to the spray ring assembly and the other end to a

pressure pump for the WATER SOURCE - GROUND - 2.75 bar (40 psi) to 3.5 bar (51

psi).

(7) Safety the long hose to the common nozzle assembly with a clamp around the bottom

of the common nozzle.

SUBTASK 72-00-00-420-073-A

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 5 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

D. Install the TUBE-WATER WASH (IAE4J12034) as follows:

Ref. Fig. Water Wash Tube, IAE 4J12034

NOTE: This subtask is an alternative to Subtask 72-00-00-420-057-A.

(1) Put the two thicker wooden clamps on the front and aft sides of the No. 7 and No. 8

struts.

(2) Let the grooves in the clamps touch the strut edges and safety the clamps with the

two long bolts and wing nuts.

(3) Put the tube between the No. 7 and No. 8 struts from the rear in parallel to the engine

centerline, then let it go through between the fan exit guide vanes carefully so that the

tube does not touch the vanes.

(4) Set the square end of the tube to the aft clamps. Make sure that the front bent part of

the tube does not touch the trailing edges of the fan blades. If necessary, install the

spacer(s) between the aft clamps and the square end.

(5) Put the tube nozzle between the leading edges of the inlet guide vanes.

(6) Hold the tube with the thicker clamps and the thinner wooden clamps and safety them

with the four short bolts and wing nuts.

(7) Make sure again that the front bent part of the tube does not touch the trailing edges

of the fan blades, that the tube nozzle does not touch the inlet guide vanes and the

direction of the tube nozzle is at a correct angle.

(8) If necessary, use spacers to adjust the positions of the clamps and the angle of the

tube correctly.

(9) Safety the clamps tightly with the wing nuts.

(10) Connect a potable water or potable water/alcohol mix source with a pressure of 40 to

50 psi (275 to 345 kPa) to the tube.

SUBTASK 72-00-00-612-050-A

E. Add oil to the engine oil tank as necessary Ref. AMM TASK 12-13-79-610-011.

SUBTASK 72-00-00-865-050-A

F. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

FOR FIN 1000EM1(ENGINE-1)

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

FOR FIN 1000EM2(ENGINE-2)

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 6 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

PANEL DESIGNATION FIN LOCATION

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

SUBTASK 72-00-00-110-066-A

G. Clean the compressor:

(1) Prepare between 50 and 60 gallons (190 and 230 liters) of potable water or potable

water/alcohol mix.

NOTE: Volumes are given for reference only. It is permitted to use different

volumes.

(a) The water for the engine gaspath cleaning must agree with the local quality

specifications for potable water and with these quality specifications:

NOTE: When the local quality specifications for potable water and the quality

specifications that follow do not agree, the quality specifications that

follow are applicable.

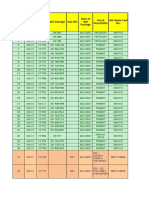

Table 1 - Potable Water Quality Specifications

PROPERTY PERMITTED LEVELS (ANALYSIS AT 75°F (24°C))

pH 6.0-10.0

Total dissolved solids 500 milligrams/liter maximum

Resistance or

conductivity:

Specific resistance 1800 ohm-centimeters minimum

Conductivity 550 microsimens/centimeter maximum

Chloride 250 milligrams/liter maximum

Fluoride 2.0 milligrams/liter maximum

(b) If the outside temperature is 41.9 deg.F (5.5 deg.C) or less, use water mixed

with denatured ethyl alcohol (Material Ref. V01-007) or Isopropyl Alcohol,

Technical grade (Material Ref. V01-124) at the applicable ratio to prevent icing.

Ref. Fig. Alcohol and Water Mixture Ratio

(2) Make sure that you do not operate the starter more than five minutes cumulative.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 7 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

CAUTION: DO NOT MOTOR THE ENGINE MORE THAN THE LIMIT OR YOU

CAN CAUSE DAMAGE TO THE STARTER (NOT CONTROLLED BY

THE EEC).

(a) Three cycles: Two cycles with a maximum duration of two minutes for each

cycle and one cycle maximum duration of one minute.

(b) Between the cycles, there must be a period of 15 seconds minimum when the

N2 speed is zero (0) rpm to allow for the starter rotor lubrication.

(c) After the three cycles, let the starter cool for 30 minutes before you try

motoring again.

(d) Do not engage the starter again with the engine motoring above 10 percent N2.

(3) Do the following water wash procedure:

(a) Motor the engine with the starter until a minimum of 14 percent N2 is reached

Ref. AMM TASK 71-00-00-710-045.

(b) While you continue to motor the engine at a minimum of 14 percent N2, spray

between 10 and 15 gallons (40 and 60 liters) of potable water or potable water/

alcohol mix in two minutes into the low pressure compressor.

(c) Stop motoring the engine, and let it soak for a minimum of 10 minutes.

(d) After a minimum soaking time of 10 minutes, motor the engine with the starter

until a minimum of 14 percent N2 is reached Ref. AMM TASK

71-00-00-710-045.

(e) While you continue to motor the engine at a minimum of 14 percent N2, spray

between 10 and 15 gallons (40 and 60 liters) of potable water or potable water/

alcohol mix in two minutes into the low pressure compressor.

(f) Stop motoring the engine, and let it soak for a minimum of 10 minutes.

(g) After a minimum soaking time of 10 minutes, dry motor the engine with the

starter at a minimum of 14 percent N2 Ref. AMM TASK 71-00-00-710-045.

(h) If necessary, do Para. (3) again. Make sure that you let the starter cool for 30

minutes before you try motoring again.

NOTE: If the wash fluid flow from the tail pipe is dirty, an added gaspath

wash will help. Multiple gaspath washes are allowed to get a better

or clear outflow.

SUBTASK 72-00-00-420-058-A

H. Connect the tubes and the VSV actuator:

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 8 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

WARNING: USE PROTECTIVE GOGGLES AND GLOVES WHEN YOU REMOVE OR

INSTALL LOCKWIRE. EACH TIME YOU CUT LOCKWIRE, REMOVE AND

DISCARD IT IMMEDIATELY. LOOSE LOCKWIRE CAN CUT YOU OR

MAKE YOU BLIND, AND/OR CAN CAUSE DAMAGE.

(1) Remove the PLUG - BLANKING and connect the P4.9 tube to the fitting at the

bottom of the turbine exhaust case and TORQUE the tube connector to between

159 and 177 lbf.in (1.80 and 2.00 m.daN):

(a) Safety with the safety cable (Material Ref. V02-274).

Ref. Fig. P4.9 Air Tube Assembly

(2) Remove the PLUG - BLANKING and connect the PB (PS3) sensing tube to the auto

start probe and TORQUE the tube connector to between 159 and 177 lbf.in (1.80

and 2.00 m.daN):

(a) Safety with the safety cable (Material Ref. V02-274).

Ref. Fig. PS3 Sense Line Air Tube Assembly

PRE SBE 75-0081

(3) Remove the PLUG - BLANKING and connect the stage 12 (P3) air tube to the off-

take tube and TORQUE the tube connector to between 283 and 310 lbf.in (3.20

and 3.50 m.daN):

(a) Safety with the safety cable (Material Ref. V02-274).

END OF PRE SBE 75-0081

(4) If the VSV actuator was disconnected before you do the rinsing, remove the rig pin,

move the stator vanes to the closed position and connect the VSV control rod to the

actuator Ref. AMM TASK 75-32-41-400-010.

(5) Remove the spray ring or the water wash tube.

SUBTASK 72-00-00-865-051-A

J. Remove the safety clip(s) and the tag(s) and close this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

49VU ENGINE/1 AND 2/IGN/SYS A 1JH A03

FOR FIN 1000EM1(ENGINE-1)

121VU ENGINE/IGN/ENG1/SYS B 3JH1 P41

121VU ENGINE/IGN/ENG1/SYS A BAT 2JH1 P39

FOR FIN 1000EM2(ENGINE-2)

121VU ENGINE/IGN/ENG2/SYS B 3JH2 P42

121VU ENGINE/IGN/ENG2/SYS A BAT 2JH2 P40

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 9 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

SUBTASK 72-00-00-100-051-A

K. Remove the moisture from the EGT harness and junction box Ref. AMM TASK

77-21-43-350-801.

5. Close-up

SUBTASK 72-00-00-410-115-A

A. Close the thrust reverser halves Ref. AMM TASK 78-32-00-410-010:

(1) FOR 1000EM1 (ENGINE-1)

451AL, 452AR

(2) FOR 1000EM2 (ENGINE-2)

461AL, 462AR.

SUBTASK 72-00-00-440-071-A

B. Activate the thrust reverser Hydraulic Control Unit (HCU) Ref. AMM TASK

78-30-00-440-012.

SUBTASK 72-00-00-410-117-A

C. Close Access

(1) Close the fan cowls Ref. AMM TASK 71-13-00-410-010:

(a) FOR 1000EM1 (ENGINE-1)

437AL, 438AR

(b) FOR 1000EM2 (ENGINE-2)

447AL, 448AR.

(2) Remove the WARNING NOTICE(S).

SUBTASK 72-00-00-700-050-A

D. Dry Out the High Pressure Turbine

(1) Do the dry out procedure for the HPT Ref. AMM TASK 71-00-00-700-013.

SUBTASK 72-00-00-710-053-A

E. Post High Pressure (HP) Compressor Wash and Oil Sampling

NOTE: IAE recommends to run the engine as soon as possible post HP compressor wash.

However, it is possible for the engine to sit up to 24 hours based on the water oil

content after the HP compressor wash, before the engine run.

NOTE: The test results from the water content of the oil must be available in 12 hours after

the core wash if no engine operation is scheduled in less than 12 hours.

(1) If the engine is sent back to service in less than 12 hours, no more action is required.

(2) If a high power assurance run Ref. AMM TASK 71-00-00-710-013 is done in less than

12 hours, no more action is necessary.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 10 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

(3) If the engine is not going back to service in less than 12 hours, do the following:

(a) Do a visual check of the engine oil tank sight glass for contamination.

1 Look at the oil through the oil tank sight glass. If the oil is emulsified (has

a white color), drain the engine oil system Ref. AMM TASK

12-13-79-610-010 and fill the system with new oil Ref. AMM TASK

12-13-79-610-011 immediately.

(b) If the visual check was satisfactory, do a check for water content of the oil as

follows.

1 Option 1:

a Take a sample of 4 oz (113.40 g) oil from the engine. The oil

sample must be taken for analysis as soon as possible but not

exceeding the 12 hours time interval.

b Do a Karl Fisher titration ASTMD-6304-04ae1 water analysis to

find the water content of the oil.

2 Option 2:

CAUTION: MAKE SURE THERE IS NO CONTAMINATION FROM

AN EXTERNAL WATER SOURCE. ONE DROP OF

WATER WILL CAUSE THE SAMPLE TO READ OVER

THE LIMITS.

a Use a new clear BOTTLE - SAMPLE to collect approximately a

0.0159 USgal (0.06 l) sample of oil for the thin film capacitive

polymer oil water content tester test. It is permissible to insert the

thin film capacitive polymer oil water content tester directly into the

main oil tank fill.

b Reinstall the main oil tank filler cap and make sure that it is

properly locked in position.

c For the thin film capacitive polymer oil water content tester, set the

thin film capacitive polymer oil water content tester to MIL-L-23699

oil.

d Stir the probe in the oil until the unit has reached the steady state

level of water concentration for 20 seconds. This normally takes at

least two minutes of stirring to complete.

(4) The results of the above tests in option 1 and 2 should be analyzed further as follows:

(a) If the water content is less than 1000 parts per million (ppm) by weight or by

volume, the engine can sit not more than a maximum of 24 hours before next

engine run-up.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 11 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

(b) If the water content is more than 1000 parts per million (ppm) by weight or by

volume, remove the water content from oil. Do the steps that follow:

1 Do the engine ground run to remove the water content from the oil.

a Start the engine Ref. AMM TASK 71-00-00-710-043 or Ref. AMM

TASK 71-00-00-710-047.

NOTE: Do not operate engine bleed before finishing the next

step, otherwise the air-conditioning system can become

contaminated.

NOTE: If the engine ground run at idle power is successful, a

further engine ground run will be required to functionally

check the air conditioning packs. This can be done at

operator convenience.

b Operate the engine at idle to bring the engine oil temperature to a

minimum of 220 deg.F (104.44 deg.C) for no less than 10 minutes

once the quoted oil temperature has been achieved.

c On AIR COND panel 30VU, push the ENG 1(2) BLEED pushbutton

switch to ON.

d Make sure that the OFF legend goes off when the engine bleed

system operates.

e Toggle the anti icing control valve ON/OFF by pressing the anti ice

selector switch ENG 1(2) from the flight deck overhead panel.

NOTE: The selector switch will have the ON indicator

illuminating in blue color.

f Keep the valve open (ON) while engine running in idle. Shut-off

valve (OFF) before the engine shutdown.

g Do an engine shutdown Ref. AMM TASK 71-00-00-710-018.

h If you do not get the minimum oil temperature, do one of the

procedures that follow:

Option 1: Do a high power assurance run immediately Ref. AMM

TASK 71-00-00-710-013. After successful completion of the high

power assurance run, no more action is necessary.

Option 2: Drain the engine oil system Ref. AMM TASK

12-13-79-610-010 and fill the system with new oil Ref. AMM TASK

12-13-79-610-011.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 12 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 13 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

Figure 72-00-00-991-21300-13-B (SHEET 1) - P4.9 Air Tube Assembly

** ON A/C FSN ALL

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 14 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

Figure 72-00-00-991-21400-13-B (SHEET 1) - PS3 Sense Line Air Tube Assembly

** ON A/C FSN ALL

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 15 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

Figure 72-00-00-991-28300-13-A (SHEET 1) - Stage 12 (P3) Air Tube

** ON A/C FSN ALL

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 16 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

A B

Figure 72-00-00-991-21500-13-A (SHEET 1) - Spray Ring, IAE 4J12031

** ON A/C FSN ALL

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 17 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

Figure 72-00-00-991-26000-13-A (SHEET 1) - Water Wash Tube, IAE 4J12034

** ON A/C FSN ALL

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 18 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

REV DATE: May

JOB CARD

01/2019

AMM - THA - A318/A319/A320/A321 TASK:

72-00-00-100-010-A

Tail Number - MSN - TITLE: 72-00-00-07 CONF 13

FSN: 72-00-00-100-010-A - Clean the Engine Gas Path for

HS-TXP - 06254 - 015 Performance Improvement (Water only)

MECH. INSP.

Figure 72-00-00-991-21200-13-A (SHEET 1) - Alcohol and Water Mixture Ratio

** ON A/C FSN ALL

*** END OF CARD ***

JCP Title: dfdfgd CERTIFICATE OF TASK / INSPECTION COMPLETION: Page 19 of 19

PRINT DATE: May 20/2019

CERTIFIES THAT THE TASK / INSPECTION HAS BEEN

COMPLETED TO THE REQUIRED STANDARD AND SUPPORTS

THE FINAL MAINTENANCE RELEASE / CERTIFICATE OF

RELEASE TO SERVICE

You might also like

- SB F2000ex - 386 R3Document20 pagesSB F2000ex - 386 R3Rudro Kumar100% (1)

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- 3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3Document357 pages3510A Model 377 Series PN 3510A377 CMM 25-25-69 (3510A377) Rev 3mikeNo ratings yet

- B737 Ch70 STD PracticesDocument21 pagesB737 Ch70 STD PracticesAhmed Abdoul ZaherNo ratings yet

- Development of Composite Fan SystemDocument5 pagesDevelopment of Composite Fan SystemnrNo ratings yet

- Gearbox SB NEODocument3 pagesGearbox SB NEOAnkit KaushikNo ratings yet

- Air Ion Counter PDFDocument4 pagesAir Ion Counter PDFRombang Rizky SihombingNo ratings yet

- Cosmetic Condition of Fan Exit Guide VanesDocument1 pageCosmetic Condition of Fan Exit Guide VanesRanjit ShawNo ratings yet

- Fuel AnalysisDocument15 pagesFuel Analysisomarzaboub1997No ratings yet

- Economic Analysis of Runway Rehabilitation AlternativesDocument26 pagesEconomic Analysis of Runway Rehabilitation AlternativesSameer SawantNo ratings yet

- ANAC SupplementDocument9 pagesANAC SupplementLysterNo ratings yet

- FE-V2500-1IA - Glossary of TermsDocument19 pagesFE-V2500-1IA - Glossary of TermsnegrotettNo ratings yet

- 8 Day Inspection Schedule Issue 12 Rev 00 (A320-232) PDFDocument22 pages8 Day Inspection Schedule Issue 12 Rev 00 (A320-232) PDFRoshith Krishnan100% (1)

- A323 EA07 VN 00278197 Last Minutes R00 PDFDocument12 pagesA323 EA07 VN 00278197 Last Minutes R00 PDFhợp trầnNo ratings yet

- Dy CHK - 400 2015 New 737 BOOK NG 00 103Document23 pagesDy CHK - 400 2015 New 737 BOOK NG 00 103Syed Salman UddinNo ratings yet

- CFM56-7B26 Engine Mini-PackDocument2 pagesCFM56-7B26 Engine Mini-PackAHAMEDNo ratings yet

- FAA 2012 0721 0009 - Attachment - 5Document119 pagesFAA 2012 0721 0009 - Attachment - 5CHIMONo ratings yet

- Goodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Document16 pagesGoodyear AMT MSC-PROPer Tire Spec 2012-001 Rev 1Muhammad Imran RosadinNo ratings yet

- Layover Inspection Schedule Issue 06Document17 pagesLayover Inspection Schedule Issue 06Pankaj Khondge100% (1)

- Aircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGDocument12 pagesAircraft Maintenance Manual: TASK 12 13 24 610 801 Servicing of The IDGCHIMONo ratings yet

- Service Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional InformationDocument11 pagesService Letter Atr42: TITLE: Time Limits Document - ATR42-200/-300/-320 - MLG and NLG Additional Informationa_sharafiehNo ratings yet

- Easa Pad 18-184 1Document4 pagesEasa Pad 18-184 1cf34No ratings yet

- PW11006-JM: LINE and Base MaintenanceDocument17 pagesPW11006-JM: LINE and Base MaintenanceGenaro RodriguezNo ratings yet

- Aircraft Anti-Icing SystemDocument3 pagesAircraft Anti-Icing SystemVejay RamNo ratings yet

- Ground Support Equipment Manuals Index CFM56 - CFM 2019Document4 pagesGround Support Equipment Manuals Index CFM56 - CFM 2019Ibnu AhmadNo ratings yet

- JCP TitleDocument14 pagesJCP Titlebilly100% (1)

- 57-49-23 Wing Leading Edge Access Panels PDFDocument24 pages57-49-23 Wing Leading Edge Access Panels PDFJheremy GilNo ratings yet

- Continuing Airworthiness Management Excedure (CAMOEDocument27 pagesContinuing Airworthiness Management Excedure (CAMOEDipendra SenNo ratings yet

- AtaDocument20 pagesAtaYousef AsmarNo ratings yet

- Fault Isolation ManualDocument11 pagesFault Isolation Manualmuchammad faruroziNo ratings yet

- Catalogue Nacelle Tooling A320neoDocument31 pagesCatalogue Nacelle Tooling A320neoPablo RestrepoNo ratings yet

- HPT Shroud and LPT NozzleDocument27 pagesHPT Shroud and LPT Nozzlekien Duy PhanNo ratings yet

- Brake Wear A320Document2 pagesBrake Wear A320Alfy Desanta Nasution100% (1)

- A318/A319/A320/A321: Service BulletinDocument54 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Exterior Inspection B737-800Document14 pagesExterior Inspection B737-800Me KeenNo ratings yet

- Basics of Aircraft Maintenance Reserve Development and ManagementDocument35 pagesBasics of Aircraft Maintenance Reserve Development and ManagementJuan LopezNo ratings yet

- Requirements for Air Operator Certificate RenewalDocument21 pagesRequirements for Air Operator Certificate RenewalHussainAhmedNo ratings yet

- HAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)Document2 pagesHAECO Job Applicant Declaration Form - FORM0W00086R01 - 202305 (AGUNG.P)tenhero92No ratings yet

- OMP Rev10Document289 pagesOMP Rev10Tenthup Wangchuk DorjiNo ratings yet

- ATA 06decoded PDFDocument52 pagesATA 06decoded PDFraiday840% (1)

- A330 Easa Tcds A.004 - Issue 50Document64 pagesA330 Easa Tcds A.004 - Issue 50Pablo CarmonaNo ratings yet

- AC 04006 Reliability CAAV A2009EDocument12 pagesAC 04006 Reliability CAAV A2009EThanh Hao LuongNo ratings yet

- On The Design and Structural Analysis o Fjet Engine Fan Blade StructuresDocument11 pagesOn The Design and Structural Analysis o Fjet Engine Fan Blade StructuresNico ScheggiaNo ratings yet

- Demo Systems PDL 30100 Manual Rev CDocument26 pagesDemo Systems PDL 30100 Manual Rev CEvandro Oliveira100% (1)

- Square Gasket PDFDocument2 pagesSquare Gasket PDFGoutam SahaNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument62 pagesA318/A319/A320/A321: Service BulletinPradeep K s100% (1)

- SVC A330Document9 pagesSVC A330Maria Amparo Corredor TorresNo ratings yet

- 737C1 FMC DatasheetDocument2 pages737C1 FMC DatasheetLebediyosAsnakeNo ratings yet

- B737-300F Aircraft Daily ChecklistDocument10 pagesB737-300F Aircraft Daily ChecklistUmer JavedNo ratings yet

- CRJ200.SRM (38) .SRM57 72 00 01Document6 pagesCRJ200.SRM (38) .SRM57 72 00 01Dzmitry KavaliouNo ratings yet

- Bonding, Grounding or EarthingDocument9 pagesBonding, Grounding or EarthingpannNo ratings yet

- 1A+2A+4A 11aug2007Document39 pages1A+2A+4A 11aug2007RaviSinghNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument23 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- CFM56 5B SB Rev 72-1092 TSN.00 N 20201210Document20 pagesCFM56 5B SB Rev 72-1092 TSN.00 N 20201210Irfan05No ratings yet

- 71 IAE Trouble ShootDocument22 pages71 IAE Trouble ShootMarc Covas MartorellNo ratings yet

- A 318Document213 pagesA 318Paul Dan PribacNo ratings yet

- All in One GE DataDocument3 pagesAll in One GE DataCh Ahmed MahmoodNo ratings yet

- The Grid 2: Blueprint for a New Computing InfrastructureFrom EverandThe Grid 2: Blueprint for a New Computing InfrastructureNo ratings yet

- Washing of The Engine Gas Path With Pure WaterDocument14 pagesWashing of The Engine Gas Path With Pure WaterridwansadelyNo ratings yet

- DGCA Module 11 June 2019 QuestionsDocument4 pagesDGCA Module 11 June 2019 QuestionsMC ManojNo ratings yet

- DGCA Module 11 June 2019 QuestionsDocument4 pagesDGCA Module 11 June 2019 QuestionsMC ManojNo ratings yet

- CWP 7880 2012 28 03 2019 Final OrderDocument2 pagesCWP 7880 2012 28 03 2019 Final OrderKamalVirkNo ratings yet

- v2500lm01r02 General PDFDocument28 pagesv2500lm01r02 General PDFKamalVirk100% (1)

- Abbreviations and Acronyms Guide for Aircraft MaintenanceDocument54 pagesAbbreviations and Acronyms Guide for Aircraft MaintenanceKamalVirkNo ratings yet

- Ezycolour Painting GuideDocument42 pagesEzycolour Painting GuideraghavavarmaNo ratings yet

- A320 - Documentation - Iss-03 - May 2016Document146 pagesA320 - Documentation - Iss-03 - May 2016KamalVirkNo ratings yet

- Car 66 PDFDocument155 pagesCar 66 PDFarjun vsNo ratings yet

- Systems ReviewDocument143 pagesSystems ReviewKamalVirk100% (2)

- TCASDocument39 pagesTCASKamalVirk100% (1)

- Aeroshell Book 5greases PDFDocument16 pagesAeroshell Book 5greases PDFAislanMendesNo ratings yet

- Procedures Day OneDocument244 pagesProcedures Day OneKamalVirk100% (2)

- VentilationDocument59 pagesVentilationKamalVirk100% (2)

- CVRDocument8 pagesCVRKamalVirkNo ratings yet

- Airbus A320 Flight Controls LawsDocument74 pagesAirbus A320 Flight Controls LawsMoHd MacKi0% (1)

- Gps Adirs Nav CBTDocument125 pagesGps Adirs Nav CBTKamalVirk100% (3)

- Three Oxygen Systems on A320 AircraftDocument17 pagesThree Oxygen Systems on A320 AircraftKamalVirkNo ratings yet

- Abnormal+Emergency ProceduresDocument71 pagesAbnormal+Emergency ProceduresSumit Chhillar100% (1)

- Mod 11A - CAR 66 (Modular) ExaminationDocument48 pagesMod 11A - CAR 66 (Modular) ExaminationamitNo ratings yet

- GPWS CBTDocument48 pagesGPWS CBTKamalVirk100% (1)

- A320 Fuel System OverviewDocument127 pagesA320 Fuel System OverviewKamalVirk100% (1)

- SPR For OctDocument780 pagesSPR For OctKamalVirkNo ratings yet

- Airbus Prologue ManualDocument98 pagesAirbus Prologue Manualdannyells_danielsNo ratings yet

- Avionics SmokeDocument64 pagesAvionics SmokeKamalVirkNo ratings yet

- GPWS CBTDocument48 pagesGPWS CBTKamalVirk100% (1)

- Hydraulics A320Document101 pagesHydraulics A320KamalVirk100% (6)

- Module 11A NewDocument437 pagesModule 11A NewMani RaoNo ratings yet

- Ca Form 19-06Document1 pageCa Form 19-06KamalVirk100% (2)

- CAR66 ELECTRONIC INSTRUMENT SYSTEMSDocument42 pagesCAR66 ELECTRONIC INSTRUMENT SYSTEMSanilmathew244No ratings yet

- Pipesim Model Management Program: For Reservoir, Production, and Process ModelingDocument2 pagesPipesim Model Management Program: For Reservoir, Production, and Process ModelingMauricio AlvaradoNo ratings yet

- Schottky DiodeDocument5 pagesSchottky Diodeilg1No ratings yet

- Format RAB SUHU DAN TEMPERATUR RUANGANDocument18 pagesFormat RAB SUHU DAN TEMPERATUR RUANGANmeliana314No ratings yet

- Awk Quick GuideDocument42 pagesAwk Quick GuideMurat TanırNo ratings yet

- E16 8 2Document4 pagesE16 8 2Branko FerenčakNo ratings yet

- High Performance Techniques For Microsoft SQL Server PDFDocument307 pagesHigh Performance Techniques For Microsoft SQL Server PDFmaghnus100% (1)

- Power Max India PVT LTD Extra Work Done at VMW Shed WorksDocument4 pagesPower Max India PVT LTD Extra Work Done at VMW Shed WorksparthaNo ratings yet

- Reso Course PlannerDocument2 pagesReso Course PlannerSnehasishGhosh100% (1)

- Lab 2 ECADocument7 pagesLab 2 ECAAizan AhmedNo ratings yet

- CE 205 - Analyzing Hydrographs and Deriving Unit HydrographsDocument17 pagesCE 205 - Analyzing Hydrographs and Deriving Unit HydrographsUmange RanasingheNo ratings yet

- GPT 7000L User: Manual'Document26 pagesGPT 7000L User: Manual'Adel Abo AdamNo ratings yet

- Lesson Plan 18 (Final)Document3 pagesLesson Plan 18 (Final)ryan agustianNo ratings yet

- Welcome To Cosc 3101/ Internet Programming: Five Cookies and Session Management in PHPDocument18 pagesWelcome To Cosc 3101/ Internet Programming: Five Cookies and Session Management in PHPSerkalem NegusseNo ratings yet

- PI ControllerDocument5 pagesPI Controllerdanuega1No ratings yet

- 19Ma2Icmat Module 5 - Elementary Numerical MethodsDocument4 pages19Ma2Icmat Module 5 - Elementary Numerical Methods1DS19CH011 Jashwanth C RNo ratings yet

- Serial Number AutoCAD 2014Document5 pagesSerial Number AutoCAD 2014Punith Ky67% (9)

- Command Line Basics - Everything CurlDocument2 pagesCommand Line Basics - Everything Curlnot hereNo ratings yet

- Problem 13.3Document2 pagesProblem 13.3kannyNo ratings yet

- TR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3Document3 pagesTR01B - Muhammad Aditya Prana Yoga - Analisa Listrik Chapter8.3AzeedNo ratings yet

- 5-Unsymmetrical Fault AnalysisDocument5 pages5-Unsymmetrical Fault Analysisvirenpandya0% (1)

- CG-SR SL Mechanical Drawing Ver1.40Document28 pagesCG-SR SL Mechanical Drawing Ver1.40Jose Cardoso100% (1)

- CT-1 (Paper-1) - 09-Aug-15Document63 pagesCT-1 (Paper-1) - 09-Aug-15HhjNo ratings yet

- A B C D Supply I1 1 2 3 4 Deman D I1Document7 pagesA B C D Supply I1 1 2 3 4 Deman D I1Shaurya DewanNo ratings yet

- Fluid Mechanics Chapter on Mechanical Energy and EfficiencyDocument43 pagesFluid Mechanics Chapter on Mechanical Energy and EfficiencyShazrel IzlanNo ratings yet

- Parsing Techniques and Grammars for Compiler DesignDocument102 pagesParsing Techniques and Grammars for Compiler DesignRajakumaran MohanNo ratings yet

- S4M Service ManualDocument522 pagesS4M Service ManualRafał Krzysztof Kowalski100% (1)

- (Advances in Cryogenic Engineering 37) Takayuki Kishi, Mizuo Kudo, Hiromasa Iisaka (Auth.), R. W. Fast (Eds.) - Advances in Cryogenic Engineering-Springer US (1991)Document729 pages(Advances in Cryogenic Engineering 37) Takayuki Kishi, Mizuo Kudo, Hiromasa Iisaka (Auth.), R. W. Fast (Eds.) - Advances in Cryogenic Engineering-Springer US (1991)ksvvijNo ratings yet

- Physics For Entertainment Volume 1 (Yakov Perelman)Document211 pagesPhysics For Entertainment Volume 1 (Yakov Perelman)snath7800No ratings yet

- Compression Test/ Group 1/ Material & Science Eng'GDocument6 pagesCompression Test/ Group 1/ Material & Science Eng'GNiaz KilamNo ratings yet