Professional Documents

Culture Documents

Raw Material Inspection: CIP/SIP of All Equipment and Machines

Uploaded by

Lehar Asip KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Raw Material Inspection: CIP/SIP of All Equipment and Machines

Uploaded by

Lehar Asip KhanCopyright:

Available Formats

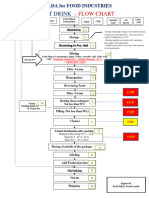

Raw Material Inspection

Concentrate Mixing in Conc. Tank

Raw Material Storage , Pulp= 5C

CIP/SIP of All

Orange Juice = 3C, PI Conc @ 21C

Pulp Shifting Through CMC Tank Equipment and

Machines

Stablizier Mixing @ 60C in CMC Tank

Treated Water

Filtration Through Strainer 1 OPRP#1

Treated Water

Blending Tank Recycle Cooler

Simple Syrup Product Cooling

Up to < 38C

Hot Fill Line-Bottle Filler

Re-Adjustment

Un-Homo Tank Homo Tank

Pre-Homo Strainer #2 Product Shifting to THE Balance Tank

Aseptic Line Tetra Pack

Homo-Tank 2 Homogenization (210 bar) Pasteurization at 88.9-90.6 C for 30 sec

Product Shifting to PHE Balance Tank CCP#1 Pre-Filler Strainer #3 and #4

Filtration through strainer #5 and #6 CCP#2 Filling at 82-86C

Pasteurization at 96C and cooling up to

Capping & Crowning

30C

Packing Material

Filling in aseptic environment on TP

Sterilization @ Bottle inverter 6-9 sec

filler

70C

PET Bottle Rinsing

with <1ppm Chlorine

Solution

Cooling from > 79.4C (Cooling tunnel

Straw Application

Glass Bottle Washing/ in) to <38C (Cooling tunnel out

Rinsing

Caustic 2, 3.5%

Shrink Wrapping Screening Inspection

Caustic Temp.

70-80C

Caustic Contact

=6min

Storage & Shipping Sleeving/ Shrinking / Packing

Storage & Shipping

You might also like

- Water SystemDocument21 pagesWater SystemAulia RizkhanNo ratings yet

- Process Flow Diagram (Update)Document4 pagesProcess Flow Diagram (Update)sumon.dey.1494No ratings yet

- Wa0021Document19 pagesWa0021Anonymous vrPpNvjRNo ratings yet

- Whole Blood Component Separation ProcessDocument2 pagesWhole Blood Component Separation ProcessGlenn PerezNo ratings yet

- Flow Chart - Fruit Drink - E - 1Document1 pageFlow Chart - Fruit Drink - E - 1Mohamed HabibNo ratings yet

- Material Preparation and Handling: FORM B. Flow DiagramDocument4 pagesMaterial Preparation and Handling: FORM B. Flow DiagramNadila ApriliyanNo ratings yet

- Various Refrigeration Systems A Part III 17062020Document14 pagesVarious Refrigeration Systems A Part III 17062020khanmattani123No ratings yet

- Flowsheet WWT IKPPDocument5 pagesFlowsheet WWT IKPPDiffa achmadNo ratings yet

- Molasses Conditioning & CentrifugungDocument5 pagesMolasses Conditioning & CentrifugungGun SmithNo ratings yet

- Om Assignment - ProcessDocument11 pagesOm Assignment - ProcessNuwani ManasingheNo ratings yet

- Drawing 1Document1 pageDrawing 1Agung SuharmantoNo ratings yet

- CEeNews2 04 PDFDocument6 pagesCEeNews2 04 PDFJohn AnthoniNo ratings yet

- Distillery Tank Column Functions and ParametersDocument2 pagesDistillery Tank Column Functions and ParametersMarthy DayagNo ratings yet

- Distribusi Penggunaan Air Pabrik Baturaja 2Document1 pageDistribusi Penggunaan Air Pabrik Baturaja 2teknik lingkunganNo ratings yet

- Sapporo JapanDocument2 pagesSapporo JapanBaitulNo ratings yet

- Cookbook: A Reference Guide For All GTX Series UsersDocument12 pagesCookbook: A Reference Guide For All GTX Series UserskicsispermaNo ratings yet

- Creamery Juice HACCP Plan New - RtfwordDocument28 pagesCreamery Juice HACCP Plan New - RtfwordShenneth De CastroNo ratings yet

- LC Vapors-Phenomonex-FusionDocument8 pagesLC Vapors-Phenomonex-Fusionpraveen.singh.rajput21No ratings yet

- Protecting Your Juice Processing Plant From: Alicyclobacillus ContaminationDocument4 pagesProtecting Your Juice Processing Plant From: Alicyclobacillus ContaminationAsif MerajNo ratings yet

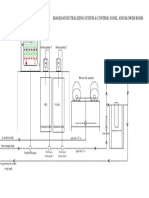

- Neutralizing SystemDocument1 pageNeutralizing SystemBewiyan NstNo ratings yet

- Crosbe PT Grout TDS - v2Document2 pagesCrosbe PT Grout TDS - v2tuan.nguyendinh.vslauNo ratings yet

- PSP PDF2 TILL 16 Feb-1Document19 pagesPSP PDF2 TILL 16 Feb-1Muskan KNo ratings yet

- PRESENTATION CcwsDocument61 pagesPRESENTATION CcwsRamkiNo ratings yet

- USDA-FSIS MLG 4 Appendix 2.02 (29-06-14)Document2 pagesUSDA-FSIS MLG 4 Appendix 2.02 (29-06-14)Fernando YañezNo ratings yet

- Mix B Process Flow DiagramDocument1 pageMix B Process Flow DiagramKhaledAhmedNo ratings yet

- Jacketed Reactor Vessel PDFDocument1 pageJacketed Reactor Vessel PDFSH1961No ratings yet

- 3 - SVM Process Flow Chart HACCPDocument3 pages3 - SVM Process Flow Chart HACCPc.ramNo ratings yet

- Desain Baru, Perbaikan Dan Instalasi SistemDocument2 pagesDesain Baru, Perbaikan Dan Instalasi Sistemlius talithaNo ratings yet

- CDQ Layout 567Document1 pageCDQ Layout 567Amit BalotNo ratings yet

- Loi Boiler Water Treatment SchemaDocument1 pageLoi Boiler Water Treatment SchemaRATSITOHARA EricNo ratings yet

- SlideDocument13 pagesSlideAisarya DasNo ratings yet

- SUNJIN Surfactant Catalogue - Fabric SoftenerDocument36 pagesSUNJIN Surfactant Catalogue - Fabric SoftenerTo Ra100% (3)

- Laxit Nirma Presentation 2Document13 pagesLaxit Nirma Presentation 2Alpesh SolankiNo ratings yet

- 2021 Int'l Conf on Chem & Sci Ed: Chitosan/Na-MMT/GLA Film Antibacterial Tests vs S. aureus & SalmonellaDocument13 pages2021 Int'l Conf on Chem & Sci Ed: Chitosan/Na-MMT/GLA Film Antibacterial Tests vs S. aureus & SalmonellaazizilhamidNo ratings yet

- Steamer Line: Installation and Operating Instructions Hollow Fiber CartridgesDocument8 pagesSteamer Line: Installation and Operating Instructions Hollow Fiber CartridgesQuỳnh Anh Phạm NgọcNo ratings yet

- Optimizing Energy Efficiency With VRV Heat Recovery Hot Water System For Hotel ApplicationDocument19 pagesOptimizing Energy Efficiency With VRV Heat Recovery Hot Water System For Hotel Applicationezuri muhamadoNo ratings yet

- Learning Area: Presented By: Deep DuttaDocument14 pagesLearning Area: Presented By: Deep DuttaRavish RathoreNo ratings yet

- Chipper: Turpentine ChipsDocument1 pageChipper: Turpentine ChipsMeghanathi BhavinNo ratings yet

- Nitol Curtis Paper Mills LTD.: Primary Settling TankDocument1 pageNitol Curtis Paper Mills LTD.: Primary Settling TankMr. JahirNo ratings yet

- Papaya Clarified FrozenDocument2 pagesPapaya Clarified FrozenSanjay RangrooNo ratings yet

- dugulin-celinaDocument1 pagedugulin-celinathomasredgleyNo ratings yet

- Scanima Mixer Process at WPP L2 LineDocument19 pagesScanima Mixer Process at WPP L2 Linemaherianto 29No ratings yet

- Aseptic Juice with Pulp ProcessingDocument2 pagesAseptic Juice with Pulp Processingexergy 33No ratings yet

- INDUSTRIAL REPORT: PRE-TREATMENT, DYEING AND FINISHING PROCESSESDocument26 pagesINDUSTRIAL REPORT: PRE-TREATMENT, DYEING AND FINISHING PROCESSESSyed Maarij ShoaibNo ratings yet

- Fermentation Process ReviseDocument5 pagesFermentation Process Revisethái học “hochaha”No ratings yet

- Postpartum Hemorrhage AlogorithmDocument1 pagePostpartum Hemorrhage AlogorithmMeghana MaddaliNo ratings yet

- Manuali PDF 413Document1 pageManuali PDF 413Rakib Hossain 3A-159No ratings yet

- CH (CO H), Pyr, Heat K CO Water or AcetoneDocument4 pagesCH (CO H), Pyr, Heat K CO Water or AcetoneAlexander Niño CarvajalNo ratings yet

- Study of Power Generating System in Captive Power Plant (VSP)Document32 pagesStudy of Power Generating System in Captive Power Plant (VSP)siva24ysrNo ratings yet

- LEARNING BOP MECHANICAL MAINTENANCEDocument14 pagesLEARNING BOP MECHANICAL MAINTENANCERavish RathoreNo ratings yet

- Thermal Oxidizer Process FlowDocument5 pagesThermal Oxidizer Process FlowArjay ArnucoNo ratings yet

- Drinking Water Process Flow DiagramDocument2 pagesDrinking Water Process Flow DiagramSaad Zia0% (1)

- Beta CaroteneDocument2 pagesBeta CaroteneRizky AzizahNo ratings yet

- Surabaya Seminar CRSDocument35 pagesSurabaya Seminar CRSAsa Kaki LangiNo ratings yet

- DCM ReportDocument66 pagesDCM ReportSomesh JaipuriaNo ratings yet

- Sample Container, Volumes, Preservatives, and Holding Times: General ChemistryDocument23 pagesSample Container, Volumes, Preservatives, and Holding Times: General ChemistryJoseph NemeshNo ratings yet

- Quality and Microbial TestsDocument21 pagesQuality and Microbial TestsAisarya DasNo ratings yet

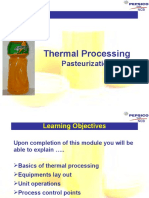

- Thermal Processing PasteurizationDocument76 pagesThermal Processing PasteurizationAisarya DasNo ratings yet

- 270-Caustic Recovery-EN-230418-webDocument8 pages270-Caustic Recovery-EN-230418-webmakiyama37No ratings yet

- Internal Combustion Engines Course OverviewDocument20 pagesInternal Combustion Engines Course OverviewLehar Asip KhanNo ratings yet

- 1.1 Purpose: 1.2.1 SelectionDocument7 pages1.1 Purpose: 1.2.1 SelectionLehar Asip KhanNo ratings yet

- PCM Selection Tool Data TableDocument1 pagePCM Selection Tool Data TableLehar Asip KhanNo ratings yet

- Temp. Vs Heater TempDocument2 pagesTemp. Vs Heater TempLehar Asip KhanNo ratings yet

- Study of PCMSDocument7 pagesStudy of PCMSLehar Asip KhanNo ratings yet

- Etihad Sugar Mills Internship ReportDocument14 pagesEtihad Sugar Mills Internship ReportLehar Asip KhanNo ratings yet

- Angle Vs RadiationsDocument1 pageAngle Vs RadiationsLehar Asip KhanNo ratings yet

- Lec 6 on Internal Combustion EnginesDocument18 pagesLec 6 on Internal Combustion EnginesLehar Asip KhanNo ratings yet

- The Spread of Islam in The SubDocument1 pageThe Spread of Islam in The SubLehar Asip KhanNo ratings yet

- Lec 7 Fall 2018Document23 pagesLec 7 Fall 2018Lehar Asip KhanNo ratings yet

- Daftar PustakaDocument4 pagesDaftar PustakaRamli UsmanNo ratings yet

- Ch07 Spread Footings - Geotech Ultimate Limit StatesDocument49 pagesCh07 Spread Footings - Geotech Ultimate Limit StatesVaibhav SharmaNo ratings yet

- AE-Electrical LMRC PDFDocument26 pagesAE-Electrical LMRC PDFDeepak GautamNo ratings yet

- Single-Phase Induction Generators PDFDocument11 pagesSingle-Phase Induction Generators PDFalokinxx100% (1)

- Material Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008Document6 pagesMaterial Safety Data Sheet Lime Kiln Dust: Rev. Date:5/1/2008suckrindjink100% (1)

- Course: Citizenship Education and Community Engagement: (8604) Assignment # 1Document16 pagesCourse: Citizenship Education and Community Engagement: (8604) Assignment # 1Amyna Rafy AwanNo ratings yet

- Common Size Analys3esDocument5 pagesCommon Size Analys3esSaw Mee LowNo ratings yet

- THE PEOPLE OF FARSCAPEDocument29 pagesTHE PEOPLE OF FARSCAPEedemaitreNo ratings yet

- Binomial ExpansionDocument13 pagesBinomial Expansion3616609404eNo ratings yet

- Put The Items From Exercise 1 in The Correct ColumnDocument8 pagesPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)

- IMM Indian Oil Case Group 3Document13 pagesIMM Indian Oil Case Group 3Soniya AgnihotriNo ratings yet

- Key ssl101 Academic Skills For University Success ssl101cDocument196 pagesKey ssl101 Academic Skills For University Success ssl101cHùng NguyễnNo ratings yet

- Lanegan (Greg Prato)Document254 pagesLanegan (Greg Prato)Maria LuisaNo ratings yet

- Extensive Reading Involves Learners Reading Texts For Enjoyment and To Develop General Reading SkillsDocument18 pagesExtensive Reading Involves Learners Reading Texts For Enjoyment and To Develop General Reading SkillsG Andrilyn AlcantaraNo ratings yet

- Corn MillingDocument4 pagesCorn Millingonetwoone s50% (1)

- Planview Innovation Management Maturity Model PDFDocument1 pagePlanview Innovation Management Maturity Model PDFMiguel Alfonso Mercado GarcíaNo ratings yet

- Wacker Neuson RTDocument120 pagesWacker Neuson RTJANUSZ2017100% (4)

- NGPDU For BS SelectDocument14 pagesNGPDU For BS SelectMario RamosNo ratings yet

- School Quality Improvement System PowerpointDocument95 pagesSchool Quality Improvement System PowerpointLong Beach PostNo ratings yet

- PA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDocument18 pagesPA Inspection Guidelines For Single Site Acceptance: 1 © Nokia Siemens NetworksDenny WijayaNo ratings yet

- Lecture 4Document25 pagesLecture 4ptnyagortey91No ratings yet

- Basf Masterseal 725hc TdsDocument2 pagesBasf Masterseal 725hc TdsshashiNo ratings yet

- Reflection Paper #1 - Introduction To Action ResearchDocument1 pageReflection Paper #1 - Introduction To Action Researchronan.villagonzaloNo ratings yet

- Childrens Ideas Science0Document7 pagesChildrens Ideas Science0Kurtis HarperNo ratings yet

- Amana PLE8317W2 Service ManualDocument113 pagesAmana PLE8317W2 Service ManualSchneksNo ratings yet

- Fiera Foods - Production SupervisorDocument1 pageFiera Foods - Production SupervisorRutul PatelNo ratings yet

- PW CDocument4 pagesPW CAnonymous DduElf20ONo ratings yet

- Introduction To OpmDocument30 pagesIntroduction To OpmNaeem Ul HassanNo ratings yet

- Symmetry (Planes Of)Document37 pagesSymmetry (Planes Of)carolinethami13No ratings yet

- Unit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledDocument6 pagesUnit 1 - International Banking Meaning: Banking Transactions Crossing National Boundaries Are CalledGanesh medisettiNo ratings yet