Professional Documents

Culture Documents

Wps Butt AWS

Uploaded by

Mohd AshrafCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps Butt AWS

Uploaded by

Mohd AshrafCopyright:

Available Formats

JLM FACADE SDN BHD

No. 654, Jalan Idaman 3/4, TAMAN PERINDUSTRIAN DESA IDAMAN,81400, SENAI, JOHOR

Email: adm.jlmfacade@gmail.com Tel. : 07-5908150

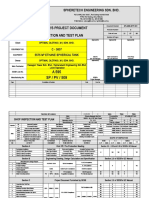

WELDING PROCEDURE QUALIFICATION SPECIFICATION (WPS) YES X

PREQUALIFIED YES QUALIFIED BY TESTING -

or PROCEDURE QUALIFICATION RECORDS (PQR) YES PAGE 1 OF 1

in accordance with AWS D1.1 / D1.1M - 2015

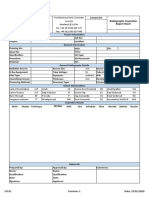

Company Name JLM FACADE SDN BHD WPS Identification# JLM/WPS-001 REV 0

Revision 0 Date By

Authorised by Date

Welding process (es) FCAW Type Manual Semi-Automatic X

Supporting PQR No. (s) JLM/PQR-001 REV 0 Machine Automatic

JOINT DESIGN USED POSITION

Type BUTT WELD Position of Groove: ALL Fillet: ALL

Single X Double weld Vertical Progression: Up X Down

Backing Yes X No ELECTRICAL CHARACTERISTICS

Backing material Metal Transfer Mode (GMAW) Short-Curcuiting

Root Opening 6mm (+2,-0) Root Face Dimension 1mm + 2 Globular Spray

Groove Angle: 60° (+10°,-0°) Radius (J-U) N/A Current: AC DCEP X DCEN Pulse

Back Gouging: Yes X No Method Grinding or Air Arc Other Not Applicable

BASE METAL Tungsten Electrode (GTAW)

Material Specification EN 10025:2 Size : Not Applicable

Type Or Grade S275 JR Type: Not Applicable

Thickness CJP Groove Over 3mm Fillet ALL TECHNIQUE

Diameter (pipe) Unlimited Stringer or Weave Bead: Both

Qualified Range N/a Multipass or Single Pass(per side): Multi pass

FILLER METAL Number of Electrodes: 1 Electrodes

AWS Specification A5.20 Electrode Spacing Longitudinal N/a

AWS Classification E71T-1C Lateral N/a

Brand of Consumables GOLDEN WELD or Equivalent Angle N/a

SHIELDING Contact Tube to Work Distance N/a

Flux N/a Gas CO₂ Peening N/a

Composition 99.90% Interpass Cleaning: Chipping, Grinding or Wire Brush

Electrode Flux (Class) - Flow Rate 10 -15 LPM Others:

Gas Cup Size -

PREHEAT POST WELD HEAT TREATMENT

Preheat Temp. Min. 125 °C Temperature N/a

Interpass Temp. Min 125 °C Max. 300 °C Time N/a

WELDING PROCEDURE

Filler metals Current

Pass or weld Travel Speed Wire speed

Process Heat input (KJ/mm)

Layer (s) Class Dia. (mm) Type & Polarity Amps Volts (mm/min) (cm/min)

Root FCAW E71T-1 ø1.2 DCEP 120 - 230 17 - 27 198 - 1.88

Hot Pass FCAW E71T-1 ø1.2 DCEP 120 - 230 17 - 27 176 - 2.12

Fill FCAW E71T-1 ø1.2 DCEP 120 - 230 17 - 27 189 - 1.97

Cap FCAW E71T-1 ø1.2 DCEP 120 - 230 17 - 27 180 - 2.07

Prepared By Approved By Witness / Verified By

JLM FACADE SDN BHD

No. 654, Jalan Idaman 3/4, TAMAN PERINDUSTRIAN DESA IDAMAN,81400, SENAI, JOHOR

Email: adm.jlmfacade@gmail.com Tel. : 07-5908150

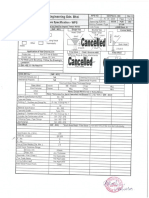

WELDING PROCEDURE QUALIFICATION SPECIFICATION (WPS) YES

PREQUALIFIED - QUALIFIED BY TESTING YES

or PROCEDURE QUALIFICATION RECORDS (PQR) YES X PAGE 1 OF 3

in accordance with AWS D1.1 / D1.1M - 2015

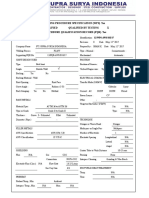

Company Name JLM FACADE SDN BHD PQR Identification# JLM/PQR-001 REV 0

Revision 0 Date By

Authorised by Date

Welding process (es) FCAW Type Manual Semi-Automatic X

WPS No. (s) JLM/WPS-001 REV 0 Machine Automatic

JOINT DESIGN USED POSITION

Type Position of Groove: 3G Fillet: -

Single X Double weld Vertical Progression: Up X Down

Backing Yes X No ELECTRICAL CHARACTERISTICS

Backing material Metal Transfer Mode (GMAW) Short-Curcuiting

Root Opening 6mm (+2,-0) Root Face Dimension 1mm + 2 Globular Spray

Groove Angle: 60° (+10°,-0°) Radius (J-U) N/A Current: AC DCEP X DCEN Pulse

Back Gouging: Yes No X Method N/A Other Not Applicable

BASE METAL Tungsten Electrode (GTAW)

Material Specification EN 10025:2 Size : Not Applicable

Type Or Grade S275 JR Type: Not Applicable

Thickness Groove 30mm Fillet - TECHNIQUE

Diameter (pipe) N/a Stringer or Weave Bead: Both

Qualified Range N/A Multipass or Single Pass(per side): Multi pass

FILLER METAL Number of Electrodes: 1 Electrodes

AWS Specification AWS A5.20 Electrode Spacing Longitudinal N/a

AWS Classification E71T-1C Lateral N/a

Brand of Consumables GOLDEN WELD or Equivalent Angle N/a

SHIELDING Contact Tube to Work Distance N/a

Flux N/a Gas CO₂ Peening N/a

Composition 99.90% Interpass Cleaning: Chipping, Grinding or Wire Brush

Electrode Flux (Class) - Flow Rate 10 -15 LPM Others:

Gas Cup Size -

PREHEAT POST WELD HEAT TREATMENT

Preheat Temp. Min. 125 °C Temperature N/a

Interpass Temp. Min 125°C Max. 300 °C Time N/a

WELDING PROCEDURE

Filler metals Current

Pass or weld Travel Speed Wire speed

Process Heat input (KJ/mm)

Layer (s) Class Dia. (mm) Type & Polarity Amps Volts (mm/min) (cm/min)

Refer Sheet 3 of 3

Prepared By Approved By Witness / Verified By

JLM FACADE SDN BHD

No. 654, Jalan Idaman 3/4, TAMAN PERINDUSTRIAN DESA IDAMAN,81400, SENAI, JOHOR

Email: adm.jlmfacade@gmail.com Tel. : 07-5908150

WELDING PROCEDURE QUALIFICATION SPECIFICATION (WPS) YES

PREQUALIFIED - QUALIFIED BY TESTING YES

or PROCEDURE QUALIFICATION RECORDS (PQR) YES X PAGE 2 OF 3

in accordance with AWS D1.1 / D1.1M - 2015

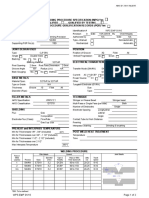

PQR No. : JLM/PQR-001 REV 0 WPS No. : JLM/WPS-001 REV 0

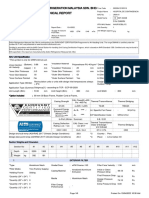

Test Results.

Reduced Section Transverse Weld TENSILE TEST (4.9.3.4)

Specimen Width Thickness Area Ultimate Tensile Ultimate Unit Stress, Character of Failure

No. (mm) (mm) (mm²) Load, (kN) (N/mm²) and Location

T1 20 30.58 611.6 307.76 503 Ductile failure & broken at base metal

T2 20 30.62 612.4 312.88 511 Ductile failure & broken at base metal

Report No. : MTS/27663-1/19 PAGE 1 OF 4

Bend Angle: 180° GUIDE BEND RESULT (4.9.3.1)

Specimen No. Type of Bend Result Remarks

S1 SIDE BEND Accepted Open defect 0.39mm at weld

S2 SIDE BEND Accepted No defect was observed

S3 SIDE BEND Accepted Open defect 0.53mm at weld

S4 SIDE BEND Accepted No defect was observed

Report No. : MTS/27663-1/19 PAGE 1 OF 4

VISUAL INSPECTION (4.9.1) RADIOGRAPHIC EXAMINATION (4.9.2)

Appearance : Accepted RT Report No. : RE/RT-6369/1-1/001/2019 Result : Accepted

Undercut : Accepted RT Report No. : - Result : -

Piping porosity : Accepted FILLET WELD TEST RESULTS

Convexity : Accepted Minimum size multiple pass . Maximum size single pass.

Test Date : 25th Jan 2019 Macroetch Macroetch

Witness By : Hairudin (JLM) 1. - 3. - 1. - 3. -

Nor Azli (BV) 2. - 2. -

Other Tests ALL-WELD METAL TENSION TEST (4.9.3.6)

Macroetch Test - MTS/27663-1/19 PAGE 4 OF 4 Tensile strength , psi : : -

Hardness Test - MTS/27663-1/19 PAGE 2 OF 4 Yield point/strength, psi : -

Elongation in 2 inch. % : -

Laboratory test No. : -

Welder's Name 1) ZAINUDIN BRAU (IC NO. 681222-01-5133) Stamp No. TBC

2) - Stamp No. -

Test Conducted By : MOHD HANAFIAH (MENTRADE TESTING SERVICES SDN BHD)

Test number : MTS/27663-4/19

Reference : -

We, the undersigned certify that the statements in this record are correct and that the test were prepared, welded and tested in conformance with the

requirements of Section 4 of AWS D1.1 / D1.1M 2015 Structural Welding Code-Steel.

Prepared By Certified By Witness / Verified By

JLM FACADE SDN BHD

No. 654, Jalan Idaman 3/4, TAMAN PERINDUSTRIAN DESA IDAMAN,81400, SENAI, JOHOR

Email: adm.jlmfacade@gmail.com Tel. : 07-5908150

WELDING PROCEDURE QUALIFICATION SPECIFICATION (WPS) YES

PREQUALIFIED - QUALIFIED BY TESTING YES

or PROCEDURE QUALIFICATION RECORDS (PQR) YES X PAGE 3 OF 3

in accordance with AWS D1.1 / D1.1M - 2015

PQR No. : JLM/PQR-001 REV 0 WPS No. : JLM/WPS-001 REV 0

WELDING PARAMETER

Filler Metal Current Travel Speed Range

Weld Layer (s) Process Volt Heat Input (KJ/mm)

(mm/min)

Class Dia. (mm) Typ & Polarity Amps

1 FCAW E71T-1 ø1.2 DCEP 138 27 181.82 1.23

2 FCAW E71T-1 ø1.2 DCEP 182 27 144.00 2.05

3 FCAW E71T-1 ø1.2 DCEP 165 28 155.17 1.79

4 FCAW E71T-1 ø1.2 DCEP 175 27 131.39 2.16

5 FCAW E71T-1 ø1.2 DCEP 156 29 163.64 1.66

6 FCAW E71T-1 ø1.2 DCEP 175 29 233.77 1.30

7 FCAW E71T-1 ø1.2 DCEP 166 26 120.81 2.14

8 FCAW E71T-1 ø1.2 DCEP 175 29 173.08 1.76

9 FCAW E71T-1 ø1.2 DCEP 156 29 137.40 1.98

10 FCAW E71T-1 ø1.2 DCEP 175 27 185.57 1.53

11 FCAW E71T-1 ø1.2 DCEP 184 27 185.57 1.61

12 FCAW E71T-1 ø1.2 DCEP 175 27 150.00 1.89

13 FCAW E71T-1 ø1.2 DCEP 158 27 114.65 2.23

14 FCAW E71T-1 ø1.2 DCEP 174 27 147.54 1.91

15 FCAW E71T-1 ø1.2 DCEP 152 26 150.00 1.58

16 FCAW E71T-1 ø1.2 DCEP 177 26 150.00 1.84

17 FCAW E71T-1 ø1.2 DCEP 164 26 148.76 1.72

18 FCAW E71T-1 ø1.2 DCEP 175 27 138.46 2.05

19 FCAW E71T-1 ø1.2 DCEP 168 26 120.00 2.18

20 FCAW E71T-1 ø1.2 DCEP 179 26 206.90 1.35

21 FCAW E71T-1 ø1.2 DCEP 168 26 122.45 2.14

22 FCAW E71T-1 ø1.2 DCEP 179 26 132.35 2.11

23 FCAW E71T-1 ø1.2 DCEP 163 26 122.45 2.08

24 FCAW E71T-1 ø1.2 DCEP 177 26 155.17 1.78

25 FCAW E71T-1 ø1.2 DCEP 176 28 171.43 1.72

26 FCAW E71T-1 ø1.2 DCEP 175 28 144.00 2.04

27 FCAW E71T-1 ø1.2 DCEP 183 28 144.00 2.14

28 FCAW E71T-1 ø1.2 DCEP 183 26 206.90 1.38

29 FCAW E71T-1 ø1.2 DCEP 183 26 206.90 1.38

30 FCAW E71T-1 ø1.2 DCEP 183 26 206.90 1.38

31 FCAW E71T-1 ø1.2 DCEP 186 26 206.90 1.40

32 FCAW E71T-1 ø1.2 DCEP 186 25 206.90 1.35

33 FCAW E71T-1 ø1.2 DCEP 186 25 206.90 1.35

34 FCAW E71T-1 ø1.2 DCEP 168 26 250.00 1.05

35 FCAW E71T-1 ø1.2 DCEP 175 26 136.36 2.00

36 FCAW E71T-1 ø1.2 DCEP 153 25 122.45 1.87

37 FCAW E71T-1 ø1.2 DCEP 146 25 122.45 1.79

38 FCAW E71T-1 ø1.2 DCEP 175 25 122.45 2.14

Welding Joint Detail

60⁰(+10°,-0°)

30mm thk

1mm+ 2

6mm(+2,-0)

Prepared By Witnessed By Witness / Verified By

You might also like

- Wps Fillet AWSDocument4 pagesWps Fillet AWSMohd Ashraf100% (1)

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- Welder Qualification Form for Rana Pratap ChouhanDocument1 pageWelder Qualification Form for Rana Pratap ChouhanMahendra singhNo ratings yet

- Welding Procedure Specification GuideDocument2 pagesWelding Procedure Specification GuidepoulmackNo ratings yet

- Blank Welding Procedure Spec.Document1 pageBlank Welding Procedure Spec.pjbedelNo ratings yet

- Welding Procedure Specification Register (Structural Steel) : AWS D1.1Document14 pagesWelding Procedure Specification Register (Structural Steel) : AWS D1.1murshid badshah100% (2)

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- Hard Facing OverlayDocument2 pagesHard Facing OverlayAmanSharmaNo ratings yet

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (1)

- WPS Format For AWS D1.1 - WPS - SMAWDocument1 pageWPS Format For AWS D1.1 - WPS - SMAWThe Welding Inspections CommunityNo ratings yet

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Wps Aws d1.1 NEWDocument2 pagesWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Electrode SelectionDocument85 pagesElectrode SelectionShaheen Andre Chikku100% (2)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS)Ravelo Jeisson100% (2)

- 6GR RequirementsDocument1 page6GR Requirementswalitedison100% (1)

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Radiographic Inspection Report SheetDocument1 pageRadiographic Inspection Report SheetMike BoyesNo ratings yet

- WPS E6013+e7018Document2 pagesWPS E6013+e7018Anvesh Vaddi100% (1)

- Sample Wps Multi ProcessDocument1 pageSample Wps Multi ProcessMohammed Elmodathir Ali100% (1)

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Weld Matrix Format 1Document7 pagesWeld Matrix Format 1Arslan WaheedNo ratings yet

- All Position Stainless Steel Welding ProcedureDocument6 pagesAll Position Stainless Steel Welding ProcedureJaime PatrónNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument95 pagesASME SECTION IX INTERPRETATIONSnizam1372No ratings yet

- Wps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Document5 pagesWps - 09 Mt-Imecol Asme304 Gtaw Sheet-Tubesheet Rev 0Oscar Iván Duque DíazNo ratings yet

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 pagesIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- WPS Format For AWS D1.1 - WPS - FCAWDocument1 pageWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityNo ratings yet

- Sample API 1104 WpsDocument3 pagesSample API 1104 WpsMuhammadShabbir0% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Welding ReportDocument52 pagesWelding ReportalidadNo ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- API Welding Procedure Specification PDFDocument3 pagesAPI Welding Procedure Specification PDFBob LeeNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Welding Procedure Specification for Vertical Storage TanksDocument6 pagesWelding Procedure Specification for Vertical Storage TanksYASH BARDHAN SinghNo ratings yet

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Visual Inspection Report FormDocument8 pagesVisual Inspection Report FormfriyantoNo ratings yet

- 1 5 1Document5 pages1 5 1daemsalNo ratings yet

- Painting & Inspection FormatDocument1 pagePainting & Inspection FormatABEC Trombay siteNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- Stainless steel welding procedure qualification recordDocument1 pageStainless steel welding procedure qualification recordchandraNo ratings yet

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- RADIOGRAPHIC TEST PROCEDURE (RT Procedure)Document17 pagesRADIOGRAPHIC TEST PROCEDURE (RT Procedure)Senthil Kumaran100% (1)

- Weldspec ASME PQRDocument2 pagesWeldspec ASME PQRSunil KumarNo ratings yet

- Draf WPSDocument2 pagesDraf WPSMj EdinNo ratings yet

- Wps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Document2 pagesWps Emp 01-16 s275jr - s275jr BW P Smaw Awsd1 1Touil HoussemNo ratings yet

- Welding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YesDocument2 pagesWelding Procedure Specification (WPS) Yes Prequalified X Qualified by Testing or Procedure Qualification Records (PQR) YessdgshhNo ratings yet

- Standard Test Method For Vickers Hardness of Metallic MaterialsDocument10 pagesStandard Test Method For Vickers Hardness of Metallic MaterialsSanjay RamasamyNo ratings yet

- Astm F789Document8 pagesAstm F789Mohd AshrafNo ratings yet

- Astm E570Document6 pagesAstm E570Mohd AshrafNo ratings yet

- PQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponDocument2 pagesPQR: Emsb/Pqr-002: Groove Design of Test Coupon Welding Sequence of Test CouponMohd AshrafNo ratings yet

- Hydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeDocument7 pagesHydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeMohd AshrafNo ratings yet

- Iso - TR - 20172: 2009Document44 pagesIso - TR - 20172: 2009vrapciudorian100% (1)

- Hydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeDocument7 pagesHydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeMohd AshrafNo ratings yet

- Hydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeDocument7 pagesHydrogen Testing Reveals Sour Corrosion Dependence on Exposure TimeMohd AshrafNo ratings yet

- Shop Construction and Field Assembly: Asme Code Section Viii Division 1Document8 pagesShop Construction and Field Assembly: Asme Code Section Viii Division 1Mohd AshrafNo ratings yet

- Steel Screw Spikes: Standard Specification ForDocument2 pagesSteel Screw Spikes: Standard Specification ForKrishna Sai100% (1)

- BS 1290 PDFDocument19 pagesBS 1290 PDFAhmed IrakyNo ratings yet

- Flange-Jis-B2220-E 2004 01Document58 pagesFlange-Jis-B2220-E 2004 01Mohd AshrafNo ratings yet

- Shop Construction and Field Assembly: Asme Code Section Viii Division 1Document8 pagesShop Construction and Field Assembly: Asme Code Section Viii Division 1Mohd AshrafNo ratings yet

- Tank ErectionDocument13 pagesTank Erectionsajay2010No ratings yet

- High Frequency Induction Bending PDFDocument22 pagesHigh Frequency Induction Bending PDFMohd AshrafNo ratings yet

- Weld Inspection and RepairDocument10 pagesWeld Inspection and RepairDeepak Kumar Kant KesriNo ratings yet

- ShopITP U2 STAMPDocument13 pagesShopITP U2 STAMPMohd Ashraf0% (1)

- Shop Construction and Field Assembly: Asme Code Section Viii Division 1Document8 pagesShop Construction and Field Assembly: Asme Code Section Viii Division 1Mohd AshrafNo ratings yet

- p92 & t23 - Esope France, 2004Document13 pagesp92 & t23 - Esope France, 2004adityadhNo ratings yet

- Flux Cored Arc Welding PDFDocument147 pagesFlux Cored Arc Welding PDFCedric MercadoNo ratings yet

- Metrode Welding Consumables For P11, P22 & CrMoV Creep Resisting Steels in Power Generation & PetroDocument23 pagesMetrode Welding Consumables For P11, P22 & CrMoV Creep Resisting Steels in Power Generation & PetroClaudia MmsNo ratings yet

- Store Issue NoteDocument1 pageStore Issue NoteMohd AshrafNo ratings yet

- Release For Shipment and Installation Note: HEX-V6109 16-200-001 3Document7 pagesRelease For Shipment and Installation Note: HEX-V6109 16-200-001 3Mohd AshrafNo ratings yet

- Metrode Welding Consumables For P11, P22 & CrMoV Creep Resisting Steels in Power Generation & PetroDocument23 pagesMetrode Welding Consumables For P11, P22 & CrMoV Creep Resisting Steels in Power Generation & PetroClaudia MmsNo ratings yet

- Method Statement For Storage Tanks PDFDocument27 pagesMethod Statement For Storage Tanks PDFMohd AshrafNo ratings yet

- Pneumatic Test ReportDocument5 pagesPneumatic Test ReportMohd Ashraf50% (2)

- Sewpscs-090 WPS SS To CS Er309 LDocument10 pagesSewpscs-090 WPS SS To CS Er309 LMohd AshrafNo ratings yet

- WPS 116 - CS With PWHTDocument11 pagesWPS 116 - CS With PWHTMohd AshrafNo ratings yet

- Diagrama Ele C18 CatDocument8 pagesDiagrama Ele C18 Catdantespeak100% (1)

- Hss Watami - AriconDocument1 pageHss Watami - AriconJovani G. BallonNo ratings yet

- TECUMSEH Model Number CodesDocument6 pagesTECUMSEH Model Number Codesd3xter0% (1)

- DrillchartDocument5 pagesDrillchartcc6689No ratings yet

- Service Bulletin: - CorrectedDocument3 pagesService Bulletin: - CorrectedmichaeltibocheNo ratings yet

- Characteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30Document1 pageCharacteristics (Typical Figures) Eni CLADIUM 50 SAE Grade 30ranjanguptNo ratings yet

- RAPT - PT Slab and Beam Design Procedure Rev01Document17 pagesRAPT - PT Slab and Beam Design Procedure Rev01AlirezaNo ratings yet

- 2017 - Aquaflair Chillers Brochure PDFDocument76 pages2017 - Aquaflair Chillers Brochure PDFJeffNo ratings yet

- Electrical Power System OverviewDocument16 pagesElectrical Power System Overviewjunmech-1No ratings yet

- Application of Pump: CentrifugalDocument8 pagesApplication of Pump: CentrifugalLipika GayenNo ratings yet

- Daikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationDocument6 pagesDaikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationSicologo CimeNo ratings yet

- FEMA Precast Concrete Design ExamplesDocument175 pagesFEMA Precast Concrete Design ExamplesFeras TemimiNo ratings yet

- Inst Headers Install TitianDocument3 pagesInst Headers Install TitianhuntersgreenNo ratings yet

- Installation Instructions: CautionDocument4 pagesInstallation Instructions: CautionVMNo ratings yet

- Installation and Operation Manual: VRV IV System Air ConditionerDocument36 pagesInstallation and Operation Manual: VRV IV System Air Conditionerelectrowat engineeringNo ratings yet

- NABC Footing StructuresDocument3 pagesNABC Footing StructuresHanafiahHamzahNo ratings yet

- Method Statement For PlumbingDocument5 pagesMethod Statement For PlumbingParasNo ratings yet

- RX135 4TL4Document52 pagesRX135 4TL4Shibu Kumar S83% (6)

- Four Month Industrial TrainingDocument54 pagesFour Month Industrial Trainingsurbhi sharmaNo ratings yet

- Application Data Sheet: General InformationDocument5 pagesApplication Data Sheet: General InformationAugusto PenessiNo ratings yet

- Baja Design Report PDFDocument9 pagesBaja Design Report PDFZubair HussainNo ratings yet

- TC1625 Catalog Pgs41-43Document3 pagesTC1625 Catalog Pgs41-43G100% (1)

- Lean NOx Trap StudyDocument38 pagesLean NOx Trap Studydhruv royNo ratings yet

- Process Design of Distillation ColumnDocument6 pagesProcess Design of Distillation ColumncristianoNo ratings yet

- Gek 28138Document20 pagesGek 28138Mauricio GuanellaNo ratings yet

- Calibration of A Bourdon ManometerDocument5 pagesCalibration of A Bourdon ManometerMyat Thu HtetNo ratings yet

- 1981 Garden Way Pony Manual WMDocument70 pages1981 Garden Way Pony Manual WMbfranklin2000100% (1)

- Phy Lab ManualDocument18 pagesPhy Lab Manualkaeshav manivannanNo ratings yet

- Agma 908-B89-1999Document79 pagesAgma 908-B89-1999Alex OliveiraNo ratings yet

- Workshop Manual Freightliner M915a3Document20 pagesWorkshop Manual Freightliner M915a3jennifer100% (50)