Professional Documents

Culture Documents

Nepal Telecom: - LG G+ 124 +U Dalgwt CG' 'LR - 5

Uploaded by

AlamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nepal Telecom: - LG G+ 124 +U Dalgwt CG' 'LR - 5

Uploaded by

AlamCopyright:

Available Formats

-lg=g+= 124 ;+u ;DalGwt cg';'lr - 5_

Nepal Telecom

Nepal Doorsanchar Company Ltd.

Syllabus

Part II (Specialized subject for Mechanical Engineer Level 7 Tech.-

Free and Internal competition)

Time: 2 hours Full Marks: 100

Pass Marks: 40

Part II (Specialized Module) All the Questions are Compulsory

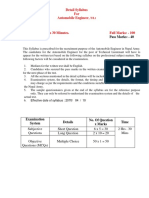

Types of question Number of Marks Total Remarks

questions Marks

Objective Questions 30 1 30 1/4 marks will be deducted

for each incorrect answer

Short Questions 10 4 40

Long Questions 3 10 30

100

Use of non-programmable calculator is permitted in the examination hall.

1. Strength of Materials (15 ~ 25%)

a) Stress & Strain : Concept of stress and strain, axial loading, normal stress,

shearing stress, bearing stress, components of stress, deformation, normal strain,

stress-strain diagram, Hook’s Law, modulus of elasticity, anisotropic and

isotropic elasticity, elastic and plastic behaviour, Poisson’s ratio, multi axial

loading, shearing strain, stress concentration & Plastic deformations,

transformation of stress and strain, principal stresses, Maximum shearing stress,

Mohr’s Circle for Plane Stress, general state of stress, yield criteria for ductile and

brittle material, principle of stationary potential energy, Castigliano’s theorem on

linear deflections, deflections of statically determinate and indeterminate

structures, theories of failure, fatigue strength, ductile and brittle material, factor

of safety

b) Torsion & Bending : Stresses and deformations in Uniform shaft, shear stresses

and angle of twist, shear stresses in a beam, beam stresses in pure bending,

deformations of symmetric member in pure bending, stresses and deformation in

the elastic range, stress concentration and plastic deformation, torsion of a bar of

cylindrical cross section, saint-Venant’s semi-inverse Method, linear elastic

solution, the Prandtl elastic member analogy, torsion of a narrow rectangular

cross section, fully plastic torsion

1

Part II-Specialized subject for Mechanical Engineer

c) Beam shaft and column: Shear and bending moment diagrams, relation among

load, shear and bending moment, principal stresses in a beam, stresses under

applied load, equation of beam bending, integrations to obtain deflected shape,

statically indeterminate beam, moment-area theorem, application to cantilever

beams and symmetric and unsymmetrical loading, maximum deflection in shaft,

stability of structure under load, Euler’s formula for Pin-ended columns.

2. Thermodynamic (15 ~ 25%)

a) Properties of gasses and gas laws: the ideal gas and equation of state, specific

heat, Boyle’s Law and Charle’s Law, the gas constant and relation between Cp

and Cv, Internal energy and Enthalpy, constant volume and constant ressure

process for P-V and T-S planes, Isothermal Process, adiabatic & Isentropic

process, relationship among p, V, T, work and heat

(b) Thermodynamic system and processes: thermodynamic properties, closed system,

open system, working substances, pure substance: properties and state, First Law

and Second Law of thermodynamics, Steady-state and steady flow process,

Uniform-state and uniform flow process, conservation of energy, potential, kinetic

and internal energy, heat and thermal equilibrium, Enthalpy applied to the steady

flow energy equation

(c) Heat transfer: Thermal conductivity, Fourier’s law of heat conduction, heat

transfer coefficient, Newton’s law of cooling, nature of radiation, Stefan-

Boltzmann law, Insulation, one and two dimensional steady state heat conduction,

laminar and turbulent boundary layers (flat plates and tubes), heat transfer for flat

plates and tubes, correlations for flow across cylinders & tube banks, free

convection from plates and cylinder, heat exchanger design considerations, nature

of radiation and concept of black body radiations, radiation properties, emissivity,

absorptivity and reflectifity, radiation interchange between grey bodies

3. Applied Thermodynamic (Air-Condition) (15 ~ 25%)

(a) Refrigeration system: Carnot cycles, refrigerators and heat pumps, vapor

compression refrigeration cycles, actual and ideal cycles, representation on T-s

and p-h diagrams, work done, absorption refrigeration system, basic absorption

cycle, refrigerants and their classification and properties, coefficient of

performance,

(b) Air-conditioning: Basic properties of air, moist air, Dalton’s law of partial

pressures, relative humidity, humidity ratio and dew point temperature,

Psychrometric properties and use of psychrometric chart, processes with moist air,

heating and cooling, cooling and dehumidification, heating and humidification,

evaporative cooling, unitary and central air-conditioning system

Part II-Specialized subject for Mechanical Engineer

(c) Components of Air-conditioning system: ducts, fans, air handling units, registers,

diffusers, humidifiers and dehumidifiers, reciprocating and scroll type

compressors

(d) Load design of air-conditioning system

4. Applied Thermodynamic (Heat Engine) (15 ~ 25%)

(a) Internal Combustion Engine: Classification of engine, basic engine parameters,

operating cycles, engine components.

(b) Air – Standard Engine Cycle: Pressure-volume diagrams, air-standard analysis for

constant volume cycle and constant pressure cycle.

(c) Performance of Internal Combustion Engine: Brake power, performance curves,

fuel and fuel system, ignitions systems, cooling systems, lubrication system

5. Machine Dynamics (5 ~ 15%)

(a) Linkages and mechanisms, kinematics of mechanisms, force analysis of

mechanism.

(b) Engine force analysis: Dynamically equivalent masses, force and torque analysis,

flywheel sizing for speed fluctuation control

(c) Force analysis of cams and followers: Classification and nomenclature of cams

and follower, graphical layout, standardized follower displacement or lift curves,

analytical cam design, other cam layouts, cam productions method, force analysis

(d) Forces on gear teeth: classification and nomenclature, spur gear, geometry of

involutes, characteristics of involute tooth action, Interference of involute gears,

numbers of teeth to avoid interference, backlash in involute gears, methods of

gear production, theory of straight bevel gears, bevel gear tooth proportions and

geometrical details, spiral and hypoid gears, theory of helical gears & tooth

geometry, parallel and crossed shaft for helical gears, worm gearing, theory of

planetary gear trains, speed ratio, formula and tabular methods, applications,

assembly of planetary gear trains, forces on gear teeth

(e) Flywheels and governor:

(f) Balance of Machinery and vibration: Single plane balancing of a disk, two plane

balancing of a rigid rotor, one and two-plane field balancing, types of balancing

machines, unbalance in single cylinder engine, balance of reciprocating masses,

balance of reciprocating masses, balance of multi-cylinder engines/compressor,

Part II-Specialized subject for Mechanical Engineer

ibration of single degree of freedom system, vibrations of discrete mass system,

continuous systems

(g) Metal fits and tolerances, factor of safety, types of failure

6. Workshop Technology (5 ~ 15%)

(a) Bench Tools and basic operations, different types of welding, sheet metal works

and metal jointing

(b) Power tools, measuring and gauging tools

(c) Machine and machine tools, lathe machine, shaping machine, drilling machine,

milling machine, grinding machine etc.

(d) Properties of materials, tolerance and fits

Part II-Specialized subject for Mechanical Engineer

You might also like

- Dynamic Damage and FragmentationFrom EverandDynamic Damage and FragmentationDavid Edward LambertNo ratings yet

- MPSC Lecturer Applied Mechanics PolytechnicDocument3 pagesMPSC Lecturer Applied Mechanics PolytechnicD JNo ratings yet

- Something For NothingDocument5 pagesSomething For Nothingyoungsport guruNo ratings yet

- Indicative Syllabus of Mechanical EngineeringDocument4 pagesIndicative Syllabus of Mechanical EngineeringSuryesh PathakNo ratings yet

- Gate Syllabus: Engineering MathematicsDocument5 pagesGate Syllabus: Engineering MathematicsAmit KhatriNo ratings yet

- Mechanical Engineering: Mechanical Engineering Sr. No. Core Areas Percent AgeDocument7 pagesMechanical Engineering: Mechanical Engineering Sr. No. Core Areas Percent AgeMuaaz AliNo ratings yet

- Nepal AirlinesDocument4 pagesNepal AirlinesAadarsh bhandariNo ratings yet

- Gate Syllabus For Mechanical EngineeringDocument4 pagesGate Syllabus For Mechanical EngineeringSushil KumarNo ratings yet

- Recruitment of Engineer (S/G - E1 & E2) at HRRL: Computer Based Test (CBT) : Paper Pattern and SyllabusDocument10 pagesRecruitment of Engineer (S/G - E1 & E2) at HRRL: Computer Based Test (CBT) : Paper Pattern and SyllabusAman PalNo ratings yet

- Pass Marks: - 40: Detail Syllabus For Automobile EngineerDocument7 pagesPass Marks: - 40: Detail Syllabus For Automobile EngineerSaurav AdhikariNo ratings yet

- EB SyllabusDocument4 pagesEB Syllabusram ANo ratings yet

- 7th Semester UET TaxilaDocument4 pages7th Semester UET TaxilaRameez AnwarNo ratings yet

- Asst. Prof Mechanical EngineeringDocument5 pagesAsst. Prof Mechanical EngineeringNitin RajeevNo ratings yet

- Technical Officer, Level-I (Post Code-6.1) : Examination Pattern and SyllabusDocument2 pagesTechnical Officer, Level-I (Post Code-6.1) : Examination Pattern and SyllabusRohit SahuNo ratings yet

- Third Year Mechanical Engineering SyllabusDocument54 pagesThird Year Mechanical Engineering SyllabusTonya WhitneyNo ratings yet

- Gate SyllabusDocument5 pagesGate SyllabusRohit JindalNo ratings yet

- Mechanical Au 3-1Document10 pagesMechanical Au 3-1Venkata Sai Kumar NunnaNo ratings yet

- S E M E S T E R: B.Tech. (Computer Science and Engineering)Document33 pagesS E M E S T E R: B.Tech. (Computer Science and Engineering)sid18june1996No ratings yet

- Btech IITK EEDocument33 pagesBtech IITK EESumanShekharSinghNo ratings yet

- 7ME7: P.E. LAB.-II 3 P MM 100 Minimum Any Ten Experiments Can Be PerformedDocument7 pages7ME7: P.E. LAB.-II 3 P MM 100 Minimum Any Ten Experiments Can Be PerformedappannusaNo ratings yet

- Gate 2015 Mechanical Engineering SyllabususDocument4 pagesGate 2015 Mechanical Engineering SyllabususGargavNo ratings yet

- Course ListDocument3 pagesCourse ListMohit BansalNo ratings yet

- Me RRB JeDocument5 pagesMe RRB JeErin BarryNo ratings yet

- GATE 2014: Syllabus For Mechanical Engineering (ME)Document3 pagesGATE 2014: Syllabus For Mechanical Engineering (ME)javed alamNo ratings yet

- IES Syllabus For Mechanical Engineering IES 2015 Syllabus MEDocument5 pagesIES Syllabus For Mechanical Engineering IES 2015 Syllabus MERohitMishraNo ratings yet

- Fo - QR Fohkkx: V.Meku RFKK Fudksckj Iz'Kklu Vèkh (KD VFHK Ark DK DK Kzy Iksvz Cys J & 744 101Document7 pagesFo - QR Fohkkx: V.Meku RFKK Fudksckj Iz'Kklu Vèkh (KD VFHK Ark DK DK Kzy Iksvz Cys J & 744 101Ranjit RajendranNo ratings yet

- Ganpat University: U.V.Patel College of EngineeringDocument13 pagesGanpat University: U.V.Patel College of EngineeringMalith MadushanNo ratings yet

- B.SC DrawingDocument7 pagesB.SC Drawingmazhar.hussain13066No ratings yet

- Syllabus For Mechanical Engineering (ME)Document3 pagesSyllabus For Mechanical Engineering (ME)Abhishek ShettyNo ratings yet

- Stcwcir4 2012 AnnexII ADocument16 pagesStcwcir4 2012 AnnexII ARavi VikneshNo ratings yet

- 2007-08 TE Engg MechDocument35 pages2007-08 TE Engg Mechmspiso2000No ratings yet

- Syllabus For Mechanical & Allied Engineering Exam Group - JEDocument2 pagesSyllabus For Mechanical & Allied Engineering Exam Group - JEmuralioooooNo ratings yet

- Aeronautical Lience SyllabusDocument5 pagesAeronautical Lience Syllabusgyanimahato.4345No ratings yet

- Syllabus For Mechanical Engineering (ME) - GATE 2013Document3 pagesSyllabus For Mechanical Engineering (ME) - GATE 2013Arun Anand A PNo ratings yet

- Indicative Syllabus of Mechanical EngineeringDocument4 pagesIndicative Syllabus of Mechanical EngineeringManinder Singh SainiNo ratings yet

- ME Vol 2 FMDocument364 pagesME Vol 2 FMDeepak Gupta100% (4)

- Gtu Be Civil First YearDocument14 pagesGtu Be Civil First YearHR Divya RanaNo ratings yet

- Civil - Sem - 3Document28 pagesCivil - Sem - 3Garima RajdevaNo ratings yet

- I) Mechanics: Statics of Particles, Equilibrium of Rigid Bodies, Properties of Surfaces and Solids, Dynamics ofDocument2 pagesI) Mechanics: Statics of Particles, Equilibrium of Rigid Bodies, Properties of Surfaces and Solids, Dynamics ofsdvikkiNo ratings yet

- Rtmnu Mechanical Engineering SyllabusDocument85 pagesRtmnu Mechanical Engineering SyllabusShobit JainNo ratings yet

- Mechanical Engineering (GATE 2020)Document2 pagesMechanical Engineering (GATE 2020)Murali DharanNo ratings yet

- Section 1: Engineering Mathematics: Linear AlgebraDocument9 pagesSection 1: Engineering Mathematics: Linear AlgebraBrajesh KumarNo ratings yet

- RRB JE Mech-SyllabusDocument2 pagesRRB JE Mech-SyllabusRandhir SinghNo ratings yet

- Neduet SyllabusDocument38 pagesNeduet SyllabusMuhammad SaimNo ratings yet

- Applied MathematicsDocument9 pagesApplied MathematicsbhabadnileshNo ratings yet

- 1st Year SyllabusDocument5 pages1st Year Syllabusgojosatoru101001No ratings yet

- First Year First SemesterDocument15 pagesFirst Year First SemesterAditya GainNo ratings yet

- Syllabus SSCJEDocument3 pagesSyllabus SSCJEsurinder thakurNo ratings yet

- Semester2015 2016Document37 pagesSemester2015 2016QqNo ratings yet

- SyllabusDocument12 pagesSyllabussubash durairajNo ratings yet

- B. Tech. (Third Semester) Mechanical Engineering: M.M.University, MullanaDocument10 pagesB. Tech. (Third Semester) Mechanical Engineering: M.M.University, MullanaVinod SukhijaNo ratings yet

- Previewpage - Do RemovedDocument16 pagesPreviewpage - Do RemovedGona SujathaNo ratings yet

- Semester-I: HS102 HS103 MS102 CV110 CV105 TopDocument14 pagesSemester-I: HS102 HS103 MS102 CV110 CV105 TopAbdul GhaffarNo ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Machine Design Elements and AssembliesFrom EverandMachine Design Elements and AssembliesRating: 3.5 out of 5 stars3.5/5 (2)

- Internal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsFrom EverandInternal Combustion Engine Bearings Lubrication in Hydrodynamic BearingsNo ratings yet

- DG FDM DesignConsiderationsFDMTooling 0618aDocument13 pagesDG FDM DesignConsiderationsFDMTooling 0618aAlamNo ratings yet

- Dimensional Accuracy Improvement of FDM Square Cross-Section Parts Using Artificial Neural Networks and An Optimization AlgorithmDocument13 pagesDimensional Accuracy Improvement of FDM Square Cross-Section Parts Using Artificial Neural Networks and An Optimization AlgorithmAlamNo ratings yet

- Singh-Trivedi2017 Article ExperimentalInvestigationsForSDocument9 pagesSingh-Trivedi2017 Article ExperimentalInvestigationsForSAlamNo ratings yet

- Polymers: Esther Molero, Juan Jesús Fernández, Oscar Rodríguez-Alabanda, Guillermo Guerrero-Vaca and Pablo E. RomeroDocument17 pagesPolymers: Esther Molero, Juan Jesús Fernández, Oscar Rodríguez-Alabanda, Guillermo Guerrero-Vaca and Pablo E. RomeroAlamNo ratings yet

- Durão2019 Article OptimizingAdditiveManufacturinDocument23 pagesDurão2019 Article OptimizingAdditiveManufacturinAlamNo ratings yet

- M.Tech Acad - IEOR at IIT BombayDocument4 pagesM.Tech Acad - IEOR at IIT BombayAlamNo ratings yet

- Saad2019 Article OptimizationOfSurfaceRoughnessDocument17 pagesSaad2019 Article OptimizationOfSurfaceRoughnessAlamNo ratings yet

- Microbial Processes For Oil RecoveryDocument4 pagesMicrobial Processes For Oil RecoveryAlamNo ratings yet

- 117 GP 112018Document2 pages117 GP 112018AlamNo ratings yet

- No Touch Key Chain ToolDocument9 pagesNo Touch Key Chain ToolAlamNo ratings yet

- Lerma AlvaroDocument1 pageLerma AlvaroAlamNo ratings yet

- LOR by Basanta BhusalDocument1 pageLOR by Basanta BhusalAlamNo ratings yet

- A Mini Project Report: "Design and Analysis of Impact Attenuator FOR Formula Cars"Document31 pagesA Mini Project Report: "Design and Analysis of Impact Attenuator FOR Formula Cars"AlamNo ratings yet

- Abhishek Sinha ResumeDocument4 pagesAbhishek Sinha ResumeAlamNo ratings yet

- Sama Gnaneshwar Reddy: Microsoft Jun 2014 - Aug 2014Document2 pagesSama Gnaneshwar Reddy: Microsoft Jun 2014 - Aug 2014AlamNo ratings yet

- Mechanical EngineerDocument4 pagesMechanical EngineerAlamNo ratings yet

- Daron@mit - Edu: Curriculum Vitae Daron AcemogluDocument19 pagesDaron@mit - Edu: Curriculum Vitae Daron AcemogluAlamNo ratings yet

- CVDocument5 pagesCVAlamNo ratings yet

- First Page, Certificate, ContentDocument8 pagesFirst Page, Certificate, ContentAlamNo ratings yet

- Walker Report FinalDocument47 pagesWalker Report FinalAlamNo ratings yet

- Tray EfficiencyDocument5 pagesTray EfficiencyShaharyar AbbasiNo ratings yet

- Chapter 8 Boundary LayersDocument22 pagesChapter 8 Boundary LayersGomish SharmaNo ratings yet

- Zeroth Review - GO SynthesisDocument9 pagesZeroth Review - GO SynthesisPaytm KaroNo ratings yet

- Handbook of Residual Stress and DeformationDocument478 pagesHandbook of Residual Stress and DeformationSneha KriNo ratings yet

- Tut 6Document3 pagesTut 6Jesús Alejandro SantillánNo ratings yet

- Powders For Powder Bed Fusion: A ReviewDocument15 pagesPowders For Powder Bed Fusion: A ReviewGuillermo RubinoNo ratings yet

- BS2752 C60 Neoprene RubberDocument1 pageBS2752 C60 Neoprene RubberMohit JangidNo ratings yet

- Biological Science Canadian 2nd Edition Freeman Test BankDocument36 pagesBiological Science Canadian 2nd Edition Freeman Test Bankcatmammotham9t4100% (25)

- Discussion and Conclusion Lab 3Document3 pagesDiscussion and Conclusion Lab 3api-406010100% (1)

- Optimization of Shell and Tube Heat Exchanger 2Document46 pagesOptimization of Shell and Tube Heat Exchanger 2SynesiusNo ratings yet

- UNIT 1aaDocument164 pagesUNIT 1aaDr.K.Krishna Veni ProfessorNo ratings yet

- Ijert Ijert: Fatigue Failure Analysis of Marine Engine CrankshaftDocument8 pagesIjert Ijert: Fatigue Failure Analysis of Marine Engine CrankshaftGazetoNo ratings yet

- Roll List 20EL-Batch 5TH Sem IDocument1 pageRoll List 20EL-Batch 5TH Sem IAisha ShaikhNo ratings yet

- Electronics Device PDFDocument38 pagesElectronics Device PDFFariz Azhar AbdillahNo ratings yet

- Electrical Measurements and Instrumentation July 2023Document7 pagesElectrical Measurements and Instrumentation July 2023Shanmukh VegiNo ratings yet

- Discovery of Sub Atomic ParticlesDocument4 pagesDiscovery of Sub Atomic ParticlesManasvi SharmaNo ratings yet

- Analysis of Anaerobic Adhesive's Role in Abutment Screw Final ReportDocument13 pagesAnalysis of Anaerobic Adhesive's Role in Abutment Screw Final ReportKevinTWilkinsNo ratings yet

- Basics: Ultrasonic Testing MethodDocument7 pagesBasics: Ultrasonic Testing Methodponnivalavans_994423No ratings yet

- C2 Cussler PDFDocument37 pagesC2 Cussler PDFGil PinheiroNo ratings yet

- Chapter 1: Properties of Fluid: Lagatic, Raquel D. Laurden, Christine Q. Realda, Mark Anthony HDocument34 pagesChapter 1: Properties of Fluid: Lagatic, Raquel D. Laurden, Christine Q. Realda, Mark Anthony HChristine LaurdenNo ratings yet

- Steel Making FundamentalsDocument42 pagesSteel Making FundamentalsHimadhar Sadu100% (1)

- Polymers 09 00593 v2 PDFDocument15 pagesPolymers 09 00593 v2 PDFmarco jaraNo ratings yet

- Friction FactorDocument6 pagesFriction Factorrajeshsapkota123No ratings yet

- Assignment 2 PDFDocument1 pageAssignment 2 PDFManojNo ratings yet

- Why Compression Ratio MattersDocument7 pagesWhy Compression Ratio MattersMTOLNo ratings yet

- DenalDocument1 pageDenalNORDBNo ratings yet

- Electropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild SteelDocument8 pagesElectropolishing Parameters Optimization For Enhanced Performance of Nickel Coating Electroplated On Mild Steelqnk7No ratings yet

- Materials Science and Engineering Mime-260 Midterm: Mid Term Test, Feb. 27, 2014 Duration: 2 HrsDocument10 pagesMaterials Science and Engineering Mime-260 Midterm: Mid Term Test, Feb. 27, 2014 Duration: 2 Hrsredviolet7371No ratings yet

- Section II A SA-430 - SA-430MDocument7 pagesSection II A SA-430 - SA-430MSocrates MoralesNo ratings yet

- Pile Foundation-IOE QuestionsDocument3 pagesPile Foundation-IOE QuestionsRajesh Khadka100% (1)