Professional Documents

Culture Documents

15 Minute PowerPoint Presentations on Materials Topics

Uploaded by

Suresh Meshram0 ratings0% found this document useful (0 votes)

44 views3 pagesStudents are required to give a 15 minute PowerPoint presentation on an assigned material topic. Three presentations will be given in each class. Presentations must include classifications, properties, microstructures, applications with pictures, and for application topics, the material requirements. Students must clarify any doubts well in advance and properly cite any figures from outside sources. Presentations will be evaluated based on quality and understanding demonstrated during questions.

Original Description:

Original Title

PresentationsAML750

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStudents are required to give a 15 minute PowerPoint presentation on an assigned material topic. Three presentations will be given in each class. Presentations must include classifications, properties, microstructures, applications with pictures, and for application topics, the material requirements. Students must clarify any doubts well in advance and properly cite any figures from outside sources. Presentations will be evaluated based on quality and understanding demonstrated during questions.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views3 pages15 Minute PowerPoint Presentations on Materials Topics

Uploaded by

Suresh MeshramStudents are required to give a 15 minute PowerPoint presentation on an assigned material topic. Three presentations will be given in each class. Presentations must include classifications, properties, microstructures, applications with pictures, and for application topics, the material requirements. Students must clarify any doubts well in advance and properly cite any figures from outside sources. Presentations will be evaluated based on quality and understanding demonstrated during questions.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 3

Students are required to make a 15 minute PowerPoint presentation

Three presentations will be made in one class

The submission will be the soft copy of the power point file (to Indranil Das on or before 27 Nov 2006

(Tue)).

The presentation should include aspects regarding:

■ Classification ■ Properties (& how they arise; including microstructures)

■ Applications with pictures (the talk should bring out the important features of the topic)

In case of application based presentation- the requirements (in terms of the properties) of the application

should be presented (with key aspects being brought out)

If there are parts to the presentations (Part I & II); then the students should discuss and divide the

subtopics appropriately

Evaluation will be based on quality of presentation and that of slides. Session will be open to questions

and the understanding of the candidate will be tested.

The presenters (all three) are requested to bring their PPT files in ONE CD.

Get the doubts regarding your presentation clarified well in advance.

For material (especially figures/graphs…) taken from any source reference should be given in the same

slide as the appearance of the material.

Copying from any source is strictly forbidden.

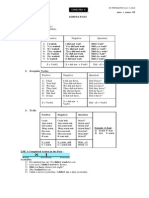

STUDENT Date TOPIC

1 2006AME3085 Sanjeev Kumar Soni 23 Oct An overview of composites

2 2007AME2262 Anurag Dixit Classes of metallic alloys and classification scheme

3 2007AME2951 Prashant G Nair An overview of Steels

4 2007AME2954 Shyam Sundar Sahu 25 Tool steels

5 2007AME2955 Sankar Kumr Roy Stainless steels

6 2007AME2956 Md. Mazhar Wahab Maraging steels

7 2007AME2960 S M Sundaram 29 Non-ferrous alloys

8 2007AME2962 Sandeep Srisvastav Superalloys

9 2007AME2963 Rabijit Dutta. Metallic foams

10 2007AME2966 Dilesh P.V. 30 Shape memory alloys

11 2007AME2968 Satish Kumar Bonthu Metallic Glasses

12 2007AME2970 Jitendra Kumar Agrahari Metal matrix composites

13 2007AME3034 Sd Imadul Islam 1 Nov Testing of materials

14 2007AME3036 Gangipamula Raja Vamsi Semiconducting materials

15 2007AME3039 Prashant Bagde Ceramics: an overview

16 2007AME3040 Kalyan Chakravarthi T.V.S. 2 Processing of ceramics to form components

17 2007AME3042 Nagvendra Kumar Kanoje Structural ceramics

18 2007AME3043 Nitin Kumar Waghmare Electroceramics

19 2007AME3051 Satish Kumar T. 6 Glasses and glass ceramics

20 2007AME3053 Karumanchi Vijayalakshmi Ceramic matrix composites

21 2007AME3076 Indranil Das Transformation toughened materials

22 2007AME3108 Dharmraj Singh 8 Classification of polymers

23 2006AMX5501 Amit Khajuria Important polymeric materials

24 2006AMX5502 Anirudha Pratap Singh Chauhan Polymer Matrix Composites

25 2007AMX5501 Nishant Bhaskaran 12 Quasicrystals

26 2007AMX5502 Suraj S.R Fabrication of polymers and polymer composites*

27

2007AMX5503 Nirmal P Additives and their effect on polymeric materials

28

2007AMX5504 Rajkumar T 13 Liquid crystals

29 2007AMX5505 Shanas Surface Engineering

30 2007AMX5506 Arun.E Non-destructive testing

31 2007AMX5507 Krishna G. Das 15 Forms of carbon

32 2007AMX5508 Subir Kumar Singh Nanomaterials

33 2007AMX5509 Nitin Gosian Functionally graded materials

34 2007AMX5510 Krishane Chakraborty 16 Smart materials

35 2007AMX5511 Manish Prakash Magnetic materials

36 2007AMX5512 Ashish Ravindran Materials for Tribological applications

37 2007AMX5513 Sandip Roy 20 Materials for nuclear applications

38 2007AMX5514 Maneesh Mathew Materials for armament applications

39 2007AMX5515 N.Kamesh Materials for marine environments

40 2007AMX5516 Rajat Singh 22 Materials for aerospace applications

41 2007AMX5517 Ganesh S Material joining processes

42 2007MEP2596 Sushik Kumar Parid Material forming processes

43 2006MET2151 Sapre Durga Ashok 23 Material casting processes

44

45

46 Materials for Tribological applications

47 Powder processing technology

48 Machining

49 Materials for pressure vessels

50 Ni & Ni based alloys

51 Precious Metals

52 Mg2O3

53 Al2O3, SiC, ZrO2

54 Mn steels

55 Ni steels

56 Mg & Mg based alloys

57 Cu & Cu based alloys

58 Al & Al based alloys

59 Ni & Ni based alloys

60 Zn & Zn based alloys

61 Ti & Ti based alloys

62 High strength low alloy steels

* Do NOT talk about synthesis of polymers

You might also like

- Industry Company PIN Location Email AddressDocument4 pagesIndustry Company PIN Location Email AddressAbhijit BarmanNo ratings yet

- Single Aging Characteristics of Aluminum 6063 AlloyDocument12 pagesSingle Aging Characteristics of Aluminum 6063 Alloychenna kesavaNo ratings yet

- SL - No. Name Contact NoDocument5 pagesSL - No. Name Contact NoAjay Kumar DasNo ratings yet

- Download ebook Encyclopedia Of Materials Composites Composites Volume 1 Pdf full chapter pdfDocument67 pagesDownload ebook Encyclopedia Of Materials Composites Composites Volume 1 Pdf full chapter pdfjason.green261100% (19)

- Dance Club_2023-24_II YearDocument2 pagesDance Club_2023-24_II YearraghavNo ratings yet

- APQP Contact ListDocument2 pagesAPQP Contact ListVikash KumarNo ratings yet

- Sheet Metal Products 3940Document298 pagesSheet Metal Products 3940maxisinc.in100% (1)

- Course Allocation - Jan-May 2022 - To Be Sent To Students - FinalDocument2 pagesCourse Allocation - Jan-May 2022 - To Be Sent To Students - FinalCh PrasadNo ratings yet

- Contact details of 40 engineering companiesDocument3 pagesContact details of 40 engineering companiesKapil KaliyanNo ratings yet

- Indian Steel and Building Material Dealers DatabaseDocument4 pagesIndian Steel and Building Material Dealers DatabaseAbhijit BarmanNo ratings yet

- Jeedimetla IndustriesDocument119 pagesJeedimetla Industriesnikhil indoreinfolineNo ratings yet

- Industry Company PIN Location Email AddressDocument4 pagesIndustry Company PIN Location Email AddressAbhijit BarmanNo ratings yet

- Project Report UpdatedDocument24 pagesProject Report UpdatedArpit PandeyNo ratings yet

- OMD Crs LSTDocument4 pagesOMD Crs LSTenk_0No ratings yet

- Aluminium Metal Matrix Composites Reinforced With Palm AshDocument58 pagesAluminium Metal Matrix Composites Reinforced With Palm AshSai RamNo ratings yet

- Characterization of SG Iron: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofDocument58 pagesCharacterization of SG Iron: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofavnishchauhan8_46499No ratings yet

- Full download book Renewable Polymers And Polymer Metal Oxide Composites Synthesis Properties And Applications Pdf pdfDocument41 pagesFull download book Renewable Polymers And Polymer Metal Oxide Composites Synthesis Properties And Applications Pdf pdfcarlotta.hernandez697100% (13)

- Fabrication of AZ91D - SIC Stir Casting and Grinding Report PDFDocument15 pagesFabrication of AZ91D - SIC Stir Casting and Grinding Report PDFJerry AndrewsNo ratings yet

- 01 Mechanical Engineering PDFDocument8 pages01 Mechanical Engineering PDFAlvin Smith33% (3)

- صغيرDocument53 pagesصغيرkhaledfarrag281No ratings yet

- Manufacturing Process 2nd Edition by U K Singh and Manish DwivediDocument290 pagesManufacturing Process 2nd Edition by U K Singh and Manish DwivediManjunath MaratheNo ratings yet

- M.tech Project Mid Sem Evalauation Sept19 and 20Document1 pageM.tech Project Mid Sem Evalauation Sept19 and 20Naman JainNo ratings yet

- Company AddressDocument38 pagesCompany AddressNaveen MNo ratings yet

- Contractors Details Amit SinhaDocument496 pagesContractors Details Amit SinhaPeehu ChatterjeeNo ratings yet

- Manufacturing Process-2 PDFDocument290 pagesManufacturing Process-2 PDFKarthik RaoNo ratings yet

- U.K.Singh Manufacturing ProcessesDocument290 pagesU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- Motu ThesisDocument97 pagesMotu ThesissoundrapandianNo ratings yet

- Industry Company PIN Location Email AddressDocument4 pagesIndustry Company PIN Location Email AddressAbhijit BarmanNo ratings yet

- SUPPLIER (Recovered) (Recovered)Document15 pagesSUPPLIER (Recovered) (Recovered)Abhijeet AnkushNo ratings yet

- Engineering Metallurgy Course OverviewDocument86 pagesEngineering Metallurgy Course OverviewDKNo ratings yet

- Fabrication and Testing of Aluminum Based Composite MaterialDocument10 pagesFabrication and Testing of Aluminum Based Composite MaterialTJPRC PublicationsNo ratings yet

- Architects in TiruppurDocument10 pagesArchitects in TiruppurShivani Raghuvanshi100% (1)

- Kurikulum Jurusan Teknik Material Dan Metalurgi - Its TH 2009-2014 Semester 1Document4 pagesKurikulum Jurusan Teknik Material Dan Metalurgi - Its TH 2009-2014 Semester 1Indera PradanaNo ratings yet

- TUGAS PRESENTASI PROSMAN KELAS C GANJIL 2020/2021Document2 pagesTUGAS PRESENTASI PROSMAN KELAS C GANJIL 2020/2021Ridwan HakimNo ratings yet

- NEW Manual - MSE315 2022-2023Document42 pagesNEW Manual - MSE315 2022-2023yhjklNo ratings yet

- Nikhil MTP ReportDocument19 pagesNikhil MTP ReportNikhilNo ratings yet

- Evaluation of Tribological Behaviour and Microstructure of AA6063 - B4C - Al2O3 Hybrid CompositesDocument10 pagesEvaluation of Tribological Behaviour and Microstructure of AA6063 - B4C - Al2O3 Hybrid CompositesJeyakumar NNo ratings yet

- A Mini Project ReportDocument38 pagesA Mini Project ReportalexNo ratings yet

- Wear Property of Metal Matrix Composite: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofDocument45 pagesWear Property of Metal Matrix Composite: A Thesis Submitted in Partial Fulfillment of The Requirements For The Degree ofArun Auto2024No ratings yet

- Industry Company PIN Location Email AddressDocument4 pagesIndustry Company PIN Location Email AddressAbhijit BarmanNo ratings yet

- Full download book Advances In Metal Oxides And Their Composites For Emerging Applications Pdf pdfDocument41 pagesFull download book Advances In Metal Oxides And Their Composites For Emerging Applications Pdf pdfeleanor.fink700100% (11)

- Document Final Mini ProjectDocument54 pagesDocument Final Mini ProjectBhanu KishoreNo ratings yet

- Metals: Processing and Properties of Aluminum and Magnesium Based Composites Containing Amorphous Reinforcement: A ReviewDocument20 pagesMetals: Processing and Properties of Aluminum and Magnesium Based Composites Containing Amorphous Reinforcement: A Reviewtanzil10No ratings yet

- ICAMM-2016 Conference Technical Sessions ScheduleDocument19 pagesICAMM-2016 Conference Technical Sessions SchedulePurna Suresh PedamalluNo ratings yet

- Current Topics in Amorphous Materials: Physics & TechnologyFrom EverandCurrent Topics in Amorphous Materials: Physics & TechnologyY. SakuraiRating: 5 out of 5 stars5/5 (1)

- Thixoforming: Semi-solid Metal ProcessingFrom EverandThixoforming: Semi-solid Metal ProcessingGerhard HirtNo ratings yet

- Mechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsFrom EverandMechanical Engineers' Handbook, Volume 1: Materials and Engineering MechanicsNo ratings yet

- Modern Physical Metallurgy and Materials EngineeringFrom EverandModern Physical Metallurgy and Materials EngineeringRating: 5 out of 5 stars5/5 (1)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Diffusion Bonding of MaterialsFrom EverandDiffusion Bonding of MaterialsN.F. KazakovNo ratings yet

- Magnetic Materials in Japan: Research, Applications and PotentialFrom EverandMagnetic Materials in Japan: Research, Applications and PotentialNo ratings yet

- Advanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingFrom EverandAdvanced Materials '93: Ceramics, Powders, Corrosion and Advanced ProcessingShigeyuki SomiyaNo ratings yet

- Overcurrent ProtectionDocument8 pagesOvercurrent ProtectionAdhyartha KerafNo ratings yet

- Block Diagram and Effect Presets of EURORACK UB1204FX-PRODocument2 pagesBlock Diagram and Effect Presets of EURORACK UB1204FX-PROAndreea IonescuNo ratings yet

- The Euphonians - Jamboree 2024Document2 pagesThe Euphonians - Jamboree 2024Mahalaksshmi .DNo ratings yet

- MFA SetupDocument7 pagesMFA SetupZachary MendizNo ratings yet

- Poem Book 2 PDFDocument7 pagesPoem Book 2 PDFluximanNo ratings yet

- DDD Basic CombosDocument5 pagesDDD Basic CombosOtaku DomoNo ratings yet

- Simple Past: Semester IiDocument67 pagesSimple Past: Semester IiSultan Aulia RahmanNo ratings yet

- Beethoven Lesson Plans K-2Document15 pagesBeethoven Lesson Plans K-2Gabriel FriedmanNo ratings yet

- Vetina ES3Document2 pagesVetina ES3darkdevotionNo ratings yet

- Cabin Crew Training (City Airways)Document4 pagesCabin Crew Training (City Airways)LIM JIA CHUN LIMNo ratings yet

- Harman Kardon DVD 39 230 Service Manual PDFDocument113 pagesHarman Kardon DVD 39 230 Service Manual PDFtantung phamNo ratings yet

- Tourism Projects For The Past 5 YearsDocument5 pagesTourism Projects For The Past 5 YearsGolda CagolNo ratings yet

- (HW F750 F751 Za) Ah68 02617a 06eng 0626Document26 pages(HW F750 F751 Za) Ah68 02617a 06eng 0626HarveyNo ratings yet

- Dma602 Marketing CommunicationDocument42 pagesDma602 Marketing CommunicationBen OusoNo ratings yet

- Acoustics - QuestionnaireDocument8 pagesAcoustics - QuestionnaireLorenz ArdienteNo ratings yet

- Pool and Billiards Glossary GuideDocument39 pagesPool and Billiards Glossary GuideJulie MerrillNo ratings yet

- Unit 3: Bulgaria Is A Small Country That Is Cheap To Travel in by BusDocument2 pagesUnit 3: Bulgaria Is A Small Country That Is Cheap To Travel in by BusFlorencia RaggioNo ratings yet

- The Ultimate Tiramisu Layer Cake - ASSEMBLYDocument2 pagesThe Ultimate Tiramisu Layer Cake - ASSEMBLYJason BirdNo ratings yet

- Speaker Detachment in PoetryDocument10 pagesSpeaker Detachment in Poetryapi-320935565No ratings yet

- Grammar GuideDocument78 pagesGrammar GuideMalashini MalaNo ratings yet

- SRP List 01 March 2017Document5 pagesSRP List 01 March 2017Joshua ArrojoNo ratings yet

- ESL Brains Fancy A Game TV 2475Document6 pagesESL Brains Fancy A Game TV 2475Yamila FranicevichNo ratings yet

- Common Errors in English GrammarDocument13 pagesCommon Errors in English GrammarPavan GollakotiNo ratings yet

- Networked Production System: BZNS-2000 Series BZNS-700 SeriesDocument12 pagesNetworked Production System: BZNS-2000 Series BZNS-700 SeriesДраган МиљићNo ratings yet

- Novomatic PercentageDocument3 pagesNovomatic PercentagePVL Mwanza0% (1)

- For Professional Results: Digital Videocassette RecorderDocument9 pagesFor Professional Results: Digital Videocassette Recorderflorinou51No ratings yet

- Vocabulary Booster Intermediate Sounds of Music Lead-InDocument3 pagesVocabulary Booster Intermediate Sounds of Music Lead-InLekso LobzhanidzeNo ratings yet

- DODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsDocument4 pagesDODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsMuhammadAmmarNo ratings yet

- Bohemian RhapsodyDocument1 pageBohemian RhapsodyElizabeth MorettiNo ratings yet

- The Collected Stories of Arthur C. Clarke - Arthur C. Clarke - 2016Document3 pagesThe Collected Stories of Arthur C. Clarke - Arthur C. Clarke - 2016aroul1027No ratings yet