Professional Documents

Culture Documents

Drivemonitor: Embedded Product Intelligence That Enhances Lifecycle Management and Performance in Drive Systems

Uploaded by

Mazmur IrawanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drivemonitor: Embedded Product Intelligence That Enhances Lifecycle Management and Performance in Drive Systems

Uploaded by

Mazmur IrawanCopyright:

Available Formats

DriveMonitor

Embedded product intelligence that enhances lifecycle management

and performance in drive systems

Maciej Wnek, Michal Orkisz, Jaroslaw Nowak, Stefano Legnani

Good products offer more when they are combined with comprehensive support and

maintenance packages. Optimal performance and minimal costs can be achieved

through service agreements over the lifecycle of a product, but effective lifecycle

management requires continuous tracking of asset history – operation, wear, damage,

and maintenance. Careful monitoring of the condition and performance of assets allows

the implementation of predictive maintenance programs that significantly reduce

maintenance costs and the risk of failure. Without this information, performance suffers

and maintenance costs rise.

ABB Medium Voltage (MV) Drives, in cooperation wih ABB Corporate Research, has

developed a new customer support system – The DriveMonitorTM – a software package

that allows an operator to monitor the performance of an MV drive system, collect data

and store the drive’s history, all from a remote computer. The system is being tested

in the Gotthard base tunnel construction site in Switzerland and offers a significant

improvement in lifecycle management tools.

ABB Review 2/2006 35

DriveMonitor

Embedded system technologies

R eal plant systems comprise a wide

variety of assets. Some are straight-

forward, simplistic even, while others

The second aspect is the availability

of data: From “what’s already there”

to dedicated measuring systems that

In short, individual assets must be

assessed to determine the level of

investment that can be justified by

are “intelligent” and capable of self- detect vibrations, current, corrosion their individual roles in a process.

diagnosis or even self-correction. etc. The third aspect relates to in-

Large and critical assets often come creasing levels of knowledge content A good condition assessment system

with their own supervisory control and diagnostic functions: At one is:

systems, but all of the assets in a pro- extreme is a simple limit threshold, expandable, to accommodate single

cess chain are information providers – at the other are advanced lifetime or multiple asset objects

either directly, via built-in sensors, or prediction algorithms. able to apply rules of varying com-

indirectly, by reporting on other assets plexity to the assets – vibration-

in the chain. All of these assets need In order to keep tool costs down, based, temperature-based, electrical

careful monitoring. maintenance systems should be flexi- test-based, operation data-based,

ble and able to accommodate a wide statistics- and history-based etc.

Cost-effective data collection range of asset types. Similar assets able to acquire data from various

and processing should be treated similarly, but with sources, eg, drive systems, control

An efficient lifecycle management individual attention dependent on systems, vibration measuring tools,

system requires scalable tools that can their context in the system. For exam- manual entries, and the asset itself.

be adapted to the nature of an asset, ple, two electric motors might be iden-

its value, status, and general mainte- tical, but if one is running a ventilation ABB used this methodology in the

nance policy. The first aspect to be fan of low importance and the other a development of its Asset Optimiza-

considered is the comprehensiveness critical fume-exhaust fan, their mainte- tion/Asset Monitors concepts and

of the system, whether it be a single nance programs would be similar, but DriveMonitorTM is a part of this truly

asset (eg, a drive), or a whole produc- the level of investment in each would scalable solution 1 .

tion line, which contains many assets. differ according to their importance.

ABB Drives – assets as “knowledge

A scalable system is not the same containers”.

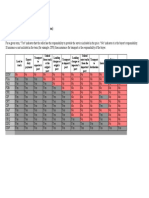

1 MV drive – an asset with a broad technology

thing as a combination of different ABB MV Drives focuses attention on

span and a rich information source

approaches that address different product design and development, but

aspects of lifecycle management. To also on configuration and optimiza-

Java/.Net be efficient, a tool must guarantee full tion in relation to customer applica-

data interoperability, single data entry tions. A quick look “under the hood”

points, and unified interfacing, usage of a drive unit will immediately show

Si Cu and reporting. Multiple systems can that the technological complexity of

be combined in an IT integration proj- this “torque delivery plant” ranges

ect, but only a scalable tool can pro- from copper bars to electronic circuit

vide true maintenance optimization. boards. Its software ranges from

Assembler

3 DriveMonitorTM – Analyzing the system’s heartbeat

TM

2 The DriveMonitor design principles

DriveMonitor Unit

Industrial PC

Router

VPN Firewall

Ethernet

TCP/IP

Optical Fibers

NDBU 95

ACS drivers

1 ........... 5

36 ABB Review 2/2006

DriveMonitor

Embedded system technologies

assembler code to the newest high- Ideally the asset should be intelligent al PC platform to provide the expect-

level languages. To obtain the highest enough to provide this information ed longevity and remote accessibility.

possible performance from such a de- to the operator. Alternatively, the Virtual Private Network (VPN) solu-

vice over its entire lifetime requires intelligence can be embedded as an tions are used for remote access to

some attention. However, drive units asset extension – intelligence that ensure high security.

– such as the MV Drive from ABB – fully utilizes the data processed in the

are represented by huge banks of data. drive. Scalability – the biggest challenge

This recorded information relates not The software layer is extremely flexi-

only to the drive converter perfor- The DriveMonitorTM system is designed ble with respect to the configuration

mance, but also to the driven equip- to meet these requirements. On the of diagnostic rules, the range of the

ment, and even to the whole down- one hand it provides continuous moni- assets with which it can be used, its

stream production process. Efficient toring and analysis of the drive state alarm and reporting functions, and its

use of these drive data is the first step and operation, supports root-cause data intake sources. Being compatible

towards lifecycle management – ini- analysis (RCA) and helps to follow with ABB’s Asset Monitor family,

tially for the converter itself and ulti- predictive maintenance paths. On the DriveMonitorTM opens the door to the

mately for the whole drive-powered other, it provides a platform upon whole ABB Asset Management portfo-

process. which to offer the customer unique lio, with Asset Optimizer and other

extension features that, by utilizing Asset Monitors as optional extensions.

drive signals, allow the operator to It can be integrated easily into auto-

An efficient lifecycle visualize the whole shaft state, along mation systems using the ABB 800xA

management system with application-related KPI’s, etc. In platform (other systems can be con-

requires scalable tools addition, customers can rely on the nected through OPC2) Servers). The

ABB Support Line1) with access to monitor is designed for use with a

that can be adapted to experts who can remotely monitor single drive, and with large systems.

the nature of an asset, its current situations. There are possibilities for expansion

to include other measurements such

value, status, and general Intelligent, scaleable and secure as corrosion, vibrations, additional

maintenance policy. The system comprises a hardware temperature sensors, etc. It provides

and a software layer 2 . The hardware millisecond-based sampling rates with

Efficient lifecycle management layer is a properly interfaced industri- year-based scheduling, event-driven

A pragmatic approach to lifecycle al PC that is factory installed with the actions and alarms, and more. The

management issues should answer the most powerful new ABB MV Drives various components of the system can

following questions: (it is also available as an upgrade to be distributed to different computers.

What should be done to the asset in existing models). The software layer For instance, several monitoring units

order to maintain the highest per- automatically collects and analyses can be configured in parallel to cover

formance and the lowest costs selected drive signals and parameters. larger installations and the results can

When should this action be taken? The hardware is based on an industri- be brought to a central control room

PC for operator convenience.

4 Extended support information facilitating root-cause analysis In order to keep tool

costs down, maintenance

systems should be flexible

and able to accommodate

a wide range of asset

types.

Scalability – hardware dimension.

MV drive configuration can cover a

broad range of products. Depending

on the application, several rectifier

and inverter units, each suitable for

monitoring purposes, can be included

in the set up. In order to acquire data

Footnotes

1)

ABB Suport Line is one of the service products

offered by MV Drives

2)

OPC-OLE for Process Control

ABB Review 2/2006 37

DriveMonitor

Embedded system technologies

quickly and reliably, multiple monitor- determining the root cause of an Integrated in the bigger picture

ing units can be configured around event. Without such a tool, by the time ABB’s Product Support organization

a single unit that acts as the access a service engineer arrives on site, this ensures the efficient deployment of

point for all the data acquisition. The information is lost, and some tell-tale lifecycle management policies to drive

central computer can again be placed events (such as threshold alarms) may products. Diagnostic tools such as

in a control room. Similar system solu- be ignored if they did not lead directly DriveMonitorTM play a central role in

tions can be configured for multi-drive to a fault. Altogether, the insight the support system, but are part of an

units. gained from the monitor’s data will integrated approach to customer care

lead to quicker elimination of faults that performs core maintenance func-

and quicker identification of failing tions, problem solving, spare part

ABB MV Drives focuses components, which result in more delivery and performance optimiza-

attention on product up-time for the customer. tion.

design and development,

With extra diagnostic packages, Drive-

but also on configuration MonitorTM can follow other shaft-train

DriveMonitorTM continu-

and optimization in relation components such as the main circuit ously monitors the drive

to customer applications. breaker, the transformer, and the status and responds

driven machine. At the highest level,

specialist packages directly related to when that status changes.

Application area specific application areas (such as

The basic function of the DriveMoni- rolling mills, water pumps, and com- Concluding remarks

torTM is to “watch” the converter part pressors) can be integrated into the Due to their complex role in industrial

of a drive shaft system 3 . It continu- system. This kind of expansion can be processes, drives generate and have

ously monitors the drive status and done at any point in time depending access to large quantities of data.

responds when that status changes. on the customer’s needs. It is also Though normally used to support a

Changes in drive status can be caused possible to incorporate extra measure- drive‘s controlling function, these data

by drive faults (unexpected drive stop- ments that go beyond the drive sig- can also be used for diagnostic pur-

pages), alarms (signals crossing thresh- nals. In such cases, the DriveMoni- poses. No additional measures are

old values), user-defined parameter torTM system, which can already incor- necessary as the data are already

changes, and higher level, DriveMoni- porate data from several sources, can available. ABB’s drive monitoring

torTM-generated application-specific accommodate a number of off-the- solution exploits this opportunity to

alarms. In this basic mode, when an shelf solutions. DriveMonitorTM-based the benefits of its customers. The sys-

event occurs, the software saves the diagnostic routines are valuable exten- tem is already being piloted at several

current state and commences in-depth sions to any plant-level Asset Manage- industrial locations, including the

monitoring of relevant drive sub- ment program like ABB Asset Optimi- Gotthard Tunnel construction site 5 ,

systems 4 . These data are critical to zation solution. where a powerful ABB hoist machine

has been installed, powered with a

ACS6000 drive unit. The hoist machine

is critical for the progress of the tun-

5 DriveMonitorTM connects experts to most remote locations, here the Gotthard Tunnel

nel since it removes the spoils from

construction site in Switzerland

the tunnel level up to the surface

through an 800-m long shaft. Drive-

MonitorTM helps to optimize the

machine’s performance and mainte-

nance processes.

Maciej Wnek

Michal Orkisz

Jaroslaw Nowak

ABB Corporate Research

Krakow, Poland

maciej.wnek@pl.abb.com

michal.orkisz@pl.abb.com

jaroslaw.nowak@pl.abb.com

Stefano Legnani

ABB MV Drives

Turgi, Switzerland

stefano.legnani@ch.abb.com

38 ABB Review 2/2006

You might also like

- Maintenance StrategyDocument9 pagesMaintenance Strategyganeshji@vsnl.comNo ratings yet

- Oracle Enterprise Asset ManagementDocument4 pagesOracle Enterprise Asset ManagementMH.SezanNo ratings yet

- Electric Motor PDMDocument125 pagesElectric Motor PDMShi Yoshi100% (1)

- QSP-05 Maintenance of Infrastructure TPM R2Document10 pagesQSP-05 Maintenance of Infrastructure TPM R2DhinakaranNo ratings yet

- Equipment Health Management: Arthur J. StackDocument7 pagesEquipment Health Management: Arthur J. StackHaryNo ratings yet

- Bearing Reliability Improvement SKF PDFDocument55 pagesBearing Reliability Improvement SKF PDFPandhuNo ratings yet

- Real-time Edge Analytics for IoT EnvironmentsDocument38 pagesReal-time Edge Analytics for IoT EnvironmentsAnupamaNo ratings yet

- Checklist For Selecting A CMMS Solution PDFDocument4 pagesChecklist For Selecting A CMMS Solution PDFambuenaflorNo ratings yet

- MAINTENANCE MANAGEMENT GUIDEDocument63 pagesMAINTENANCE MANAGEMENT GUIDEChoirul WahyuNo ratings yet

- SCADA in POWER DISTRIBUTION SYSTEMSDocument10 pagesSCADA in POWER DISTRIBUTION SYSTEMSrohinibhaskar0% (1)

- Training Abb Technical Training Booklet WebDocument98 pagesTraining Abb Technical Training Booklet Webman_y2kNo ratings yet

- Funds of Distributed Control Systems PDFDocument55 pagesFunds of Distributed Control Systems PDFhussamengNo ratings yet

- Predictive Maintenance With RDocument9 pagesPredictive Maintenance With Rcrazzy_cannuckNo ratings yet

- Terry Harris USADocument45 pagesTerry Harris USAAlex Astuhuaman100% (2)

- Unit Result Record Sheet: Amrinder SinghDocument45 pagesUnit Result Record Sheet: Amrinder SinghVirender Arya100% (1)

- Anomaly Detection and Predictive Maintenance For Photovoltaic Systems 8 PDFDocument10 pagesAnomaly Detection and Predictive Maintenance For Photovoltaic Systems 8 PDFCUCUTOCHE8100% (1)

- MaintenanceDocument23 pagesMaintenanceDeepankumar AthiyannanNo ratings yet

- 05 PACWorld TUA09 PaperDocument5 pages05 PACWorld TUA09 PaperfischerbastNo ratings yet

- Edge Processing and Enterprise Integration Closing The Gap On Sensor NetworksDocument11 pagesEdge Processing and Enterprise Integration Closing The Gap On Sensor NetworksSrioNo ratings yet

- More from your backupDocument4 pagesMore from your backupSudharsan KingNo ratings yet

- Siemens - Integrated Soln For Commerc. & Indust. Dist.Document4 pagesSiemens - Integrated Soln For Commerc. & Indust. Dist.b.baburaj4405No ratings yet

- ADMO Article Asset Management With ADMO OMICRON Magazine 2018 ENUDocument3 pagesADMO Article Asset Management With ADMO OMICRON Magazine 2018 ENUWaleed MuhammadNo ratings yet

- FactoryDocument17 pagesFactorycesar.econocomNo ratings yet

- CitectIIM TrackingDocument2 pagesCitectIIM TrackingrkponrajNo ratings yet

- Scada: S.Anbu Kaviraj & M. Mahendhiran Government College of Engineering Tirunelveli-627007Document7 pagesScada: S.Anbu Kaviraj & M. Mahendhiran Government College of Engineering Tirunelveli-627007Dinesh DinuNo ratings yet

- Neplan Am Flyer - enDocument2 pagesNeplan Am Flyer - enDarko RisteskiNo ratings yet

- SCADA System and Industrial Network GuideDocument21 pagesSCADA System and Industrial Network GuideMikhail McDowellNo ratings yet

- Monitoring, Analyzing, and Controlling Internet-Scale Systems With ACMEDocument14 pagesMonitoring, Analyzing, and Controlling Internet-Scale Systems With ACMElava bhaiNo ratings yet

- Oil and Gas - Solution Brief - 19 JulyDocument6 pagesOil and Gas - Solution Brief - 19 Julysridhar_eeNo ratings yet

- Grid Automation Solutions Brochure Br910006enDocument7 pagesGrid Automation Solutions Brochure Br910006enChintanPandyaNo ratings yet

- Grid Transformation Workshop Results: April 2012Document46 pagesGrid Transformation Workshop Results: April 2012Arjun SECINo ratings yet

- Ignatius A Tool To Build SCADA SystemsDocument6 pagesIgnatius A Tool To Build SCADA SystemsGWNo ratings yet

- CIRED2011 0716 FinalDocument4 pagesCIRED2011 0716 FinalkotiniNo ratings yet

- Autonomic Computing for Spacecraft Ground Systems Increases ReliabilityDocument8 pagesAutonomic Computing for Spacecraft Ground Systems Increases ReliabilityUppi VajralaNo ratings yet

- ATBAS MandM Processing 0204Document8 pagesATBAS MandM Processing 0204Francisco CampbellNo ratings yet

- CitectIIM ProductionDocument2 pagesCitectIIM ProductionrkponrajNo ratings yet

- Scada System and Industrial Network For Petroleum Industry: February 2017Document21 pagesScada System and Industrial Network For Petroleum Industry: February 2017sdjouldeNo ratings yet

- Four approaches to better data center availabilityDocument5 pagesFour approaches to better data center availabilityYashveer TakooryNo ratings yet

- Condition Monitoring Systems Readdressed and Revised - MaintWorld - 4-2015Document2 pagesCondition Monitoring Systems Readdressed and Revised - MaintWorld - 4-2015pham ngoc tuanNo ratings yet

- Brochure Operational IntelligenceDocument6 pagesBrochure Operational IntelligenceCristian Gonzalo MansillaNo ratings yet

- Gea S1210Document2 pagesGea S1210Noé ChungaNo ratings yet

- ATS Flyer System @MicroGrid 210913Document12 pagesATS Flyer System @MicroGrid 210913Phạm Tiến SaoNo ratings yet

- PT - PGIM Flyer DEABB 1184 05 EDocument4 pagesPT - PGIM Flyer DEABB 1184 05 EAlexey ShuvaevNo ratings yet

- The Efficacy and Challenges of SCADA and Smart Grid IntegrationDocument8 pagesThe Efficacy and Challenges of SCADA and Smart Grid Integrationgawe bitaNo ratings yet

- Power-MI Brochure enDocument4 pagesPower-MI Brochure engabriel pacovilca arhuataNo ratings yet

- Phongld2-Cntt PGDKT ThitruongDocument19 pagesPhongld2-Cntt PGDKT Thitruongvilaphong vongphachithNo ratings yet

- Dicim SgitDocument6 pagesDicim SgitFernando LópezNo ratings yet

- 3 - Product Sheet One Nds Health CheckDocument4 pages3 - Product Sheet One Nds Health CheckVity ugueNo ratings yet

- E Mesh Monitor BrochureDocument4 pagesE Mesh Monitor Brochuredave chaudhuryNo ratings yet

- Session 2000: How Operation Data Helps Manage Lifecycle CostsDocument8 pagesSession 2000: How Operation Data Helps Manage Lifecycle CostsNur FajarNo ratings yet

- Distributed Stream Management Using Utility-Driven Self-Adaptive MiddlewareDocument12 pagesDistributed Stream Management Using Utility-Driven Self-Adaptive MiddlewareMaria Irene Páez BencomoNo ratings yet

- E-Terraplatform 3.0 Trans - Gene 100615Document4 pagesE-Terraplatform 3.0 Trans - Gene 100615Edo AmaroNo ratings yet

- Termis2014 US WebDocument12 pagesTermis2014 US WebNick NaydenovNo ratings yet

- Comparative Study On Network Monitoring Tools: International Research Journal of Engineering and Technology (Irjet)Document3 pagesComparative Study On Network Monitoring Tools: International Research Journal of Engineering and Technology (Irjet)Irfaan Khan QasmiNo ratings yet

- ISCM Brochure EnDocument6 pagesISCM Brochure Endr salam darwishNo ratings yet

- Improved Efficiency, More Building Value: Energy Monitoring SolutionDocument30 pagesImproved Efficiency, More Building Value: Energy Monitoring SolutionlizukyNo ratings yet

- Iliev2018 PDFDocument7 pagesIliev2018 PDFMano DanoNo ratings yet

- PredictiveMaintenance ExcavatorDocument4 pagesPredictiveMaintenance ExcavatorDody Rakhmat RamadhanNo ratings yet

- Sentron Data Sheet 050310Document8 pagesSentron Data Sheet 050310Kevin GurungNo ratings yet

- Sieve - Actionable Insights From Monitored Metrics of MicroservicesDocument17 pagesSieve - Actionable Insights From Monitored Metrics of MicroservicesArmin OkićNo ratings yet

- WiCE Engine Control System For 2 Stroke Engines CIMAC2019 Paper 165 Wolfgang OstreicherDocument15 pagesWiCE Engine Control System For 2 Stroke Engines CIMAC2019 Paper 165 Wolfgang OstreicherSSiposNo ratings yet

- A New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266Document5 pagesA New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266sarkochileNo ratings yet

- A New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266Document5 pagesA New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266International Journal of Engineering and TechniquesNo ratings yet

- A New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266Document5 pagesA New Approach For Exactness Agriculture Monitoring Using IOT&ESP8266sarkochileNo ratings yet

- Substation Automation: IED Integration and Availability of InformationDocument10 pagesSubstation Automation: IED Integration and Availability of InformationSunil MakaNo ratings yet

- DS - ClearSee Network AnalyticsDocument4 pagesDS - ClearSee Network AnalyticsBronojackersNo ratings yet

- Siemens ISCMDocument5 pagesSiemens ISCMEngr Irfan AkhtarNo ratings yet

- Energy Management Systems: Ii - HistoryDocument5 pagesEnergy Management Systems: Ii - HistoryUjjwal PCE/15/ME/102No ratings yet

- SKF @ptitude Analyst Software For MultilogDocument20 pagesSKF @ptitude Analyst Software For MultilogFendyNo ratings yet

- Decentralized Control of Automatic Guided VehiclesDocument13 pagesDecentralized Control of Automatic Guided VehiclesAlanNo ratings yet

- Autonomic ComputingDocument32 pagesAutonomic ComputingNikhil PillaiNo ratings yet

- Embedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingFrom EverandEmbedded Deep Learning: Algorithms, Architectures and Circuits for Always-on Neural Network ProcessingNo ratings yet

- Convert Polar to Rectangular and Vice Versa FormulasDocument1 pageConvert Polar to Rectangular and Vice Versa FormulasMazmur IrawanNo ratings yet

- Gov (Regulator Terminal Block)Document3 pagesGov (Regulator Terminal Block)Mazmur IrawanNo ratings yet

- Capacitor Elco Foot PrintDocument1 pageCapacitor Elco Foot PrintMazmur IrawanNo ratings yet

- Contoh CV 1Document1 pageContoh CV 1Faridaa HanifaNo ratings yet

- AcdcblockDocument2 pagesAcdcblockAlok MishraNo ratings yet

- INCOTERM (International Commercial Term) : Seller's Payment ResponsibilityDocument2 pagesINCOTERM (International Commercial Term) : Seller's Payment ResponsibilityMazmur IrawanNo ratings yet

- Name Address (Home and Term) Telephone (Home) Telephone (Mobile) E-MailDocument1 pageName Address (Home and Term) Telephone (Home) Telephone (Mobile) E-MailMazmur IrawanNo ratings yet

- Chandra Saputra Bengkong Permai B.30 Batam, Indonesia 29457 (0778) 852-72220252Document1 pageChandra Saputra Bengkong Permai B.30 Batam, Indonesia 29457 (0778) 852-72220252Mazmur IrawanNo ratings yet

- SN 222Document19 pagesSN 222Mazmur IrawanNo ratings yet

- Sample CV 5Document1 pageSample CV 5Mazmur IrawanNo ratings yet

- Contoh CV 4Document1 pageContoh CV 4Muhammad FajarNo ratings yet

- DAC0808Document1 pageDAC0808Mazmur IrawanNo ratings yet

- LM555Document12 pagesLM555Mazmur Irawan100% (2)

- Transistor BD139Document4 pagesTransistor BD139Rodrigo FuentesNo ratings yet

- DAC0808Document2 pagesDAC0808Mazmur IrawanNo ratings yet

- 2 N 891Document2 pages2 N 891Mazmur IrawanNo ratings yet

- Practical Machinery Vibration Analysis and Predictive MaintenanceDocument3 pagesPractical Machinery Vibration Analysis and Predictive MaintenanceSafrul EfendiNo ratings yet

- Whitepaper explores Industry 4.0 vision and implementation strategiesDocument31 pagesWhitepaper explores Industry 4.0 vision and implementation strategiesThomas BerthelotNo ratings yet

- Maintenance and Reliability: © 2011 Pearson Education, Inc. Publishing As Prentice HallDocument55 pagesMaintenance and Reliability: © 2011 Pearson Education, Inc. Publishing As Prentice HallAle MariaNo ratings yet

- Research Paper - Predictive Maintenance Based On IoT and AIDocument6 pagesResearch Paper - Predictive Maintenance Based On IoT and AIABHISHEK BAGHNo ratings yet

- Potential Titles For ThesisDocument17 pagesPotential Titles For ThesisHilawie MinwagawNo ratings yet

- NR 13 - Comentada - InglêsDocument65 pagesNR 13 - Comentada - InglêsFilipe NicácioNo ratings yet

- Maintenance & Safety: On-Campus ENGG C242 PB Venkataraman 5. Maintenance ProcessesDocument6 pagesMaintenance & Safety: On-Campus ENGG C242 PB Venkataraman 5. Maintenance ProcessesShafi AsafaliNo ratings yet

- (2021 Minerals) Data Analytics Applied in Mining IndustryDocument273 pages(2021 Minerals) Data Analytics Applied in Mining IndustryFrank MosesNo ratings yet

- HR Om11 ch17Document53 pagesHR Om11 ch17Yopi TheaNo ratings yet

- MB Consultancy Company ProfileDocument21 pagesMB Consultancy Company ProfileamrNo ratings yet

- Sootblowing Maintenance Guide Addresses Steam, Water, and Air ProblemsDocument12 pagesSootblowing Maintenance Guide Addresses Steam, Water, and Air ProblemsRoberto CastilloNo ratings yet

- Dissertation OlivottiDocument204 pagesDissertation OlivottiNhan Dien Khuon MatNo ratings yet

- HB Mechanical ResponseDocument67 pagesHB Mechanical ResponsehtanhNo ratings yet

- ACEM-Rail D1.1 State of Practice r0Document136 pagesACEM-Rail D1.1 State of Practice r0ARTURDVARELANo ratings yet

- 40 Days SCHDocument23 pages40 Days SCHmailbkraoNo ratings yet

- Motor Vibration AnalysisDocument1 pageMotor Vibration AnalysispothirajNo ratings yet