Professional Documents

Culture Documents

SCADA

Uploaded by

Ali KayacanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SCADA

Uploaded by

Ali KayacanCopyright:

Available Formats

SCADA is an acronym that stands for Supervisory Control and Data Acquisition.

SCADA

refers to a system that collects data from various sensors at a factory, plant or in other remote

locations and then sends this data to a central computer which then manages and controls the

data.

SCADA is a term that is used broadly to portray control and management solutions in a wide

range of industries. Some of the industries where SCADA is used are Water Management

Systems, Electric Power, Traffic Signals, Mass Transit Systems, Environmental Control

Systems, and Manufacturing Systems.

SCADA as a System

There are many parts of a working SCADA

system. A SCADA system usually includes

signal hardware (input and output), controllers,

networks, user interface (HMI),

communications equipment and software. All

together, the term SCADA refers to the entire

central system. The central system usually

monitors data from various sensors that are

either in close proximity or off site (sometimes

miles away).

For the most part, the brains of a SCADA

system are performed by the Remote Terminal Units (sometimes referred to as the RTU). The

Remote Terminal Units consists of a programmable logic converter. The RTU are usually set

to specific requirements, however, most RTU allow human intervention, for instance, in a

factory setting, the RTU might control the setting of a conveyer belt, and the speed can be

changed or overridden at any time by human intervention. In addition, any changes or errors

are usually automatically logged for and/or displayed. Most often, a SCADA system will

monitor and make slight changes to function optimally; SCADA systems are considered

closed loop systems and run with relatively little human intervention.

One of key processes of SCADA is the ability to monitor an entire system in real time. This is

facilitated by data acquisitions including meter reading, checking statuses of sensors, etc that

are communicated at regular intervals depending on the system. Besides the data being used

by the RTU, it is also displayed to a human that is able to interface with the system to

override settings or make changes when necessary.

SCADA can be seen as a system with many data elements called points. Usually each point is

a monitor or sensor. Usually points can be either hard or soft. A hard data point can be an

actual monitor; a soft point can be seen as an application or software calculation. Data

elements from hard and soft points are usually always recorded and logged to create a time

stamp or history

User Interface (HMI)

A SCADA system includes a user interface, usually called Human Machine Interface (HMI).

The HMI of a SCADA system is where data is processed and presented to be viewed and

monitored by a human operator. This interface usually includes controls where the individual

can interface with the SCADA system.

HMI's are an easy way to standardize the facilitation of monitoring multiple RTU's or PLC's

(programmable logic controllers). Usually RTU's or PLC's will run a pre programmed

process, but monitoring each of them individually can be difficult, usually because they are

spread out over the system. Because RTU's and PLC's historically had no standardized

method to display or present data to an operator, the SCADA system communicates with

PLC's throughout the system network and processes information that is easily disseminated by

the HMI.

HMI's can also be linked to a database, which can use data gathered from PLC's or RTU's to

provide graphs on trends, logistic info, schematics for a specific sensor or machine or even

make troubleshooting guides accessible. In the last decade, practically all SCADA systems

include an integrated HMI and PLC device making it extremely easy to run and monitor a

SCADA system.

SCADA Software and Hardware Components

SCADA systems are an extremely advantageous way to run and monitor processes. They are

great for small aplications such as climate control or can be effectively used in large

applications such as monitoring and controlling a nuclear power plant or mass transit system.

SCADA can come in open and non proprietary protocols. Smaller systems are extremely

affordable and can either be purchased as a complete system or can be mixed and matched

with specific components. Large systems can also be created with off the shelf components.

SCADA system software can also be easily configured for almost any application, removing

the need for custom made or intensive software development.

You might also like

- Smart Water Management System Using ArduinoDocument4 pagesSmart Water Management System Using ArduinoGRD JournalsNo ratings yet

- River Channel Maintenance ProceduresDocument25 pagesRiver Channel Maintenance Proceduresdoel.xyz100% (1)

- SCADA System Call Center Training Manual-Revised Sept 2013Document112 pagesSCADA System Call Center Training Manual-Revised Sept 2013bengalsacNo ratings yet

- Detention Basin Design To Mitigate Regional Peak Flow ImpactsDocument120 pagesDetention Basin Design To Mitigate Regional Peak Flow ImpactscigarbarNo ratings yet

- Civil Engineering Practice (CE-203)Document31 pagesCivil Engineering Practice (CE-203)AliNo ratings yet

- River Flood Modelling For Nzoia River - A Quasi 2-D ApproachDocument14 pagesRiver Flood Modelling For Nzoia River - A Quasi 2-D Approachsalt2009No ratings yet

- PLC Dcs Scada 2docxDocument19 pagesPLC Dcs Scada 2docxMuhammad FaizanNo ratings yet

- Detention Pond MaintenanceDocument4 pagesDetention Pond MaintenancehlkhlkhlhkhkhkljhvvvNo ratings yet

- MAIN REPORT VOL 4-Drainage DevelopmentDocument88 pagesMAIN REPORT VOL 4-Drainage Developmentsoleb100% (2)

- Automatinghecras Excel Conversion Gate01Document11 pagesAutomatinghecras Excel Conversion Gate01Dario Prata100% (1)

- Dam Safety: Preventing Australia From DisastersDocument10 pagesDam Safety: Preventing Australia From DisastersRaju KandelNo ratings yet

- FLO-2D EPA SWMM Guidelines PDFDocument28 pagesFLO-2D EPA SWMM Guidelines PDFJuan MolinaNo ratings yet

- Green Infrastructure - PhiladelphiaDocument27 pagesGreen Infrastructure - PhiladelphiaGreen Action Sustainable Technology GroupNo ratings yet

- Me (Wre&gis)Document15 pagesMe (Wre&gis)Mohamed Nageeb SalemNo ratings yet

- A GIS Based Evaluation of University of Ilorin Primaryy Water Distribution NetworkDocument14 pagesA GIS Based Evaluation of University of Ilorin Primaryy Water Distribution NetworkDr Olayinka Okeola100% (2)

- Rice IrrigationDocument40 pagesRice IrrigationAndrew ReidNo ratings yet

- Flow Duration Curve (FDC) Derivation For Mini Hydropower Development Study ApplicationDocument8 pagesFlow Duration Curve (FDC) Derivation For Mini Hydropower Development Study ApplicationSipuk NorisNo ratings yet

- ODMP Hydrology and Water Resources Inception ReportDocument68 pagesODMP Hydrology and Water Resources Inception ReportAse JohannessenNo ratings yet

- Application of Hec-Hms in Rainfall-Runoff and Flood Simulations in Lower Tapi BasinDocument56 pagesApplication of Hec-Hms in Rainfall-Runoff and Flood Simulations in Lower Tapi Basinankitbalyan100% (3)

- River Training Manual Final Wecs 2020-06-15 (F)Document190 pagesRiver Training Manual Final Wecs 2020-06-15 (F)sandeshNo ratings yet

- Ya'a Bure Climate & Hydrology Final Report August, 2022Document76 pagesYa'a Bure Climate & Hydrology Final Report August, 2022sent TNo ratings yet

- Sala Ta Orn Dam Development Specification PDFDocument182 pagesSala Ta Orn Dam Development Specification PDFSothearaThengNo ratings yet

- Hydrology Calc.Document9 pagesHydrology Calc.Rupesh Mishra100% (1)

- Developing Reservoir Rule Curves with the Rule Curve ToolDocument3 pagesDeveloping Reservoir Rule Curves with the Rule Curve ToolAnonymous 1880JHcGNo ratings yet

- HachFlow Selection GuideDocument20 pagesHachFlow Selection GuideSuhaili YahyaNo ratings yet

- Socio-Economic Baseline Survey of CHTDocument355 pagesSocio-Economic Baseline Survey of CHTSyed Muztuza AliNo ratings yet

- Groundwater Management Plan for Iloilo CityDocument92 pagesGroundwater Management Plan for Iloilo CityMae Ann GonzalesNo ratings yet

- Introduction to MIKE FLOOD modelling softwareDocument68 pagesIntroduction to MIKE FLOOD modelling softwarealmutaz9000100% (1)

- Pix4dmapper enDocument3 pagesPix4dmapper enDavid Alexander RojasNo ratings yet

- Orientation Program for Officers of NYKS on Catch the Rain CampaignDocument54 pagesOrientation Program for Officers of NYKS on Catch the Rain CampaignAsif AhmedNo ratings yet

- Rapid Climate Change Vulnerability Assessment for Eastern and Southern CaribbeanDocument181 pagesRapid Climate Change Vulnerability Assessment for Eastern and Southern CaribbeanMike Seager100% (1)

- REG 265-Surface DrainageDocument43 pagesREG 265-Surface DrainageAdam Chow Wen YanNo ratings yet

- Smart 2020 Report: Global ICT Solution Case StudiesDocument87 pagesSmart 2020 Report: Global ICT Solution Case StudiesICTdocsNo ratings yet

- A Brief Guide To HydroinformaticsDocument28 pagesA Brief Guide To Hydroinformaticsaishen2506No ratings yet

- Optimizing The Reservoir Operating Rule Curves by Genetic AlgorithmsDocument13 pagesOptimizing The Reservoir Operating Rule Curves by Genetic AlgorithmsRobert AguedoNo ratings yet

- Paper 16-Designing of Hydraulically Balanced Water Distribution PDFDocument8 pagesPaper 16-Designing of Hydraulically Balanced Water Distribution PDFAnonymous uNErA4k1PNo ratings yet

- Press Release On Rule CurveDocument7 pagesPress Release On Rule CurvePranab Ranjan ChoudhuryNo ratings yet

- Software For Water Resource and Environmental EngineeringDocument11 pagesSoftware For Water Resource and Environmental EngineeringBawa Sheriff MohammedNo ratings yet

- BAA 3922 Research Methodology and Pre-Project Water Profile Analysis at The Kuantan River, Kuantan, PahangDocument12 pagesBAA 3922 Research Methodology and Pre-Project Water Profile Analysis at The Kuantan River, Kuantan, PahangkynNo ratings yet

- Urban Sector and Water Supply and Sanitation in BangladeshDocument154 pagesUrban Sector and Water Supply and Sanitation in BangladeshIndependent Evaluation at Asian Development BankNo ratings yet

- Chapter 3-Surface Irrigation DesignDocument68 pagesChapter 3-Surface Irrigation DesignEng Ahmed abdilahi IsmailNo ratings yet

- IIA - Enginnering Final Feasibility ReportDocument265 pagesIIA - Enginnering Final Feasibility ReportbelshaNo ratings yet

- Handout 6901 CI6901-L AU 2012-OgdenDocument28 pagesHandout 6901 CI6901-L AU 2012-OgdenericfgNo ratings yet

- Indus Basin Irrigation System of PakistanDocument23 pagesIndus Basin Irrigation System of Pakistansafder_ali9085% (27)

- Muskinghum Method of Flood RoutingDocument7 pagesMuskinghum Method of Flood RoutingSudharsananPRSNo ratings yet

- Flood Early Warning System FLEWSDocument44 pagesFlood Early Warning System FLEWSYoo HooNo ratings yet

- Hydrological Modelling of Upper Gurara Watershed in Nigeria Using GeoSFMDocument98 pagesHydrological Modelling of Upper Gurara Watershed in Nigeria Using GeoSFMCADsyncNo ratings yet

- Stormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneDocument11 pagesStormwater Analysis and Solution of Waterlogging in Kothrud Region, PuneIJRASETPublicationsNo ratings yet

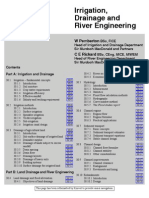

- Irrigation Drainage and River Engineering PDFDocument26 pagesIrrigation Drainage and River Engineering PDFAlvaro Gamboa Pretel100% (1)

- BSC Thesis Work (Final Year Project)Document159 pagesBSC Thesis Work (Final Year Project)yared sitotaw100% (1)

- Saline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentDocument13 pagesSaline Water Conversion Corporation Kingdom of Saudi Arabia Projects Engineering DepartmentBhavanishankar ShettyNo ratings yet

- SWAT Hydrological ModellingDocument19 pagesSWAT Hydrological ModellingPrasadNo ratings yet

- Development of A Dual Mode Frequencycontroller ForDocument72 pagesDevelopment of A Dual Mode Frequencycontroller ForKira ChakuriNo ratings yet

- Fhwa Culvert Design Manual PDFDocument2 pagesFhwa Culvert Design Manual PDFSamanthaNo ratings yet

- 2020 Step by Step Installation Model Set UpDocument47 pages2020 Step by Step Installation Model Set UpNagasa KumsaNo ratings yet

- Climate Change Impact Assessment and Hydrological Simulation Final Report Climate Change Impact Assessment and Hydrological Simulation Final ReportDocument104 pagesClimate Change Impact Assessment and Hydrological Simulation Final Report Climate Change Impact Assessment and Hydrological Simulation Final ReportlamboksimorangkirNo ratings yet

- Baseline Survey Report 2011Document91 pagesBaseline Survey Report 2011Benny Aryanto SihalohoNo ratings yet

- Regulatory Frameworks for Dam Safety: A Comparative StudyFrom EverandRegulatory Frameworks for Dam Safety: A Comparative StudyNo ratings yet

- Knet Cissp 10Document847 pagesKnet Cissp 10Ali KayacanNo ratings yet

- Tutorial (IntegraXor A Web-Based SCADA Software)Document58 pagesTutorial (IntegraXor A Web-Based SCADA Software)Ali KayacanNo ratings yet

- A View of Cloud ComputingDocument9 pagesA View of Cloud ComputingeliezerrianiNo ratings yet

- Bilgisayar Terimleri KısaltmalarıDocument27 pagesBilgisayar Terimleri KısaltmalarıAli KayacanNo ratings yet

- Manual - RouterOS Features - MikroTik WikiDocument5 pagesManual - RouterOS Features - MikroTik WikiAnonymous LU6nvFNo ratings yet

- InteliCompact NT 2 1 Reference Guide r1Document291 pagesInteliCompact NT 2 1 Reference Guide r1Елена Ахметзянова100% (2)

- Efficient Priority Queue Hardware ImplementationDocument16 pagesEfficient Priority Queue Hardware ImplementationFaisal IrfanNo ratings yet

- Atlas Copco Power Macs 4000 Quick Guide UKDocument32 pagesAtlas Copco Power Macs 4000 Quick Guide UKsldksNo ratings yet

- TMN LectureDocument51 pagesTMN LectureNishchay AilaniNo ratings yet

- Unit 1 - Introduction - V5Document45 pagesUnit 1 - Introduction - V5Aleix Cánovas EstebanNo ratings yet

- Networking Middleware MQTTDocument12 pagesNetworking Middleware MQTTPranjal SwarupNo ratings yet

- Frontline Defense Against Network AttackDocument15 pagesFrontline Defense Against Network AttackRyan Roman CatogNo ratings yet

- Transmission EngineerDocument25 pagesTransmission EngineerStephen AdokwuNo ratings yet

- g4 Project ReportDocument60 pagesg4 Project ReportDrake Moses KabbsNo ratings yet

- Enfsuite64 Admin Database PDFDocument40 pagesEnfsuite64 Admin Database PDFRichard KaufmannNo ratings yet

- Load RunnerDocument25 pagesLoad Runnerapi-3813837100% (5)

- The Essential Guide For Understanding O RANDocument21 pagesThe Essential Guide For Understanding O RANNarcis IlieNo ratings yet

- DNP3Document108 pagesDNP3tlaloui_grte2010_271100% (2)

- Configure A Site-To-Site UsingVTI On ASADocument6 pagesConfigure A Site-To-Site UsingVTI On ASATapan DoshiNo ratings yet

- Network Programming in Java Internet Protocols (IP, UDP, TCP), B01DY9BNOA, Apr. 6, 2016, by Alan MOUHLIDocument19 pagesNetwork Programming in Java Internet Protocols (IP, UDP, TCP), B01DY9BNOA, Apr. 6, 2016, by Alan MOUHLIElMorrisNo ratings yet

- DT Nokia 1830 PSS-32Document13 pagesDT Nokia 1830 PSS-32Jim Jr . Oyola100% (1)

- STP-or-Ether-Channel in (ROMAN URDU)Document14 pagesSTP-or-Ether-Channel in (ROMAN URDU)Fayyaz AhmedNo ratings yet

- P 3 UsermDocument344 pagesP 3 UsermHarvey PenleyNo ratings yet

- Nexus Switches OverviewDocument15 pagesNexus Switches OverviewSantanuNo ratings yet

- Wireless Power TheftDocument13 pagesWireless Power TheftManjeet JunejaNo ratings yet

- Intermec SR30 PDFDocument56 pagesIntermec SR30 PDFAlex RaduNo ratings yet

- Product Data Sheet AMS Trex Device CommunicatorDocument9 pagesProduct Data Sheet AMS Trex Device CommunicatorSardar PerdawoodNo ratings yet

- Sencore OmniHub 6RFX V1.5Document112 pagesSencore OmniHub 6RFX V1.5alabadiNo ratings yet

- Datasheet Flatpack2 48V HE RectifiersDocument2 pagesDatasheet Flatpack2 48V HE Rectifiersmichaelliu123456No ratings yet

- By: Mona Marie Bergantinos 10 - OrchidDocument7 pagesBy: Mona Marie Bergantinos 10 - OrchidCeleste D. Bering100% (1)

- NetSDK Programming ManualDocument49 pagesNetSDK Programming ManualRodrigo VieiraNo ratings yet

- Engineers List - Convergent Wireless Communications PVT LTDDocument2 pagesEngineers List - Convergent Wireless Communications PVT LTDmajunath bgNo ratings yet

- VM NotesDocument4 pagesVM Noteshemanth-07No ratings yet

- EPON OLT Web Command Manual - NeutralDocument185 pagesEPON OLT Web Command Manual - NeutralLuiz GustavoNo ratings yet