Professional Documents

Culture Documents

ACEE 434 ACEE 434 ACEE 434 ACEE 434 Environmental Systems Design Environmental Systems Design

Uploaded by

divya0909Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACEE 434 ACEE 434 ACEE 434 ACEE 434 Environmental Systems Design Environmental Systems Design

Uploaded by

divya0909Copyright:

Available Formats

ACEE 434

Environmental Systems Design

Week 11

November 11,

11 2009

ACEE 434 Fall 2009 HDP 1

Secondary Clarifier

Reynolds and Richards Figure 9-34

Circular settling tank (Center feed by pipe

under tank bottom)

ACEE 434 Fall 2009 HDP 2

Settling Activated Sludge

MetCalf and Eddy Figure 8-8

Field test for determining sludge volume index (SVI) Reynolds and Richards Figure 9-20

Settling of a concentrated suspension

ACEE 434 Fall 2009 HDP 3

Settling

g in a Secondary

y

Clarifier

C0

Cu

Reynolds and Richards Figure 9-21

Settling in a final clarifier for the activated sludge

ACEE 434 Fall 2009 HDP 4

Solid Flux

GS

GS = CtVt

Vt

C

Reynolds and Richards Figure 9-22 Reynolds andt Richards Figure 9-23

Zone or hindered settling velocity versus Solids flux versus solid concentration

solid concentration

ACEE 434 Fall 2009 HDP 5

Solid Flux

Gs = CtVt

where Gs = solids flux by gravity

Ct = solids concentration

Vt = hindered settling velocity

Gb = CtVb Qu

Vb =

where Gb = bulk flux A

Vb = bulk velocity where Qu = flowrate of the underflow

A = plan area of the tank

Gt = Gs + Gb = CtVt + CtVb

where Gt = total flux

ACEE 434 Fall 2009 HDP 6

Solid Flux

M t = Q0C0 = Qu Cu Assumption: effluent solids concentration is negligible

where M t = rate of solids settling

Q 0 = influent flowrate to the tank (= Q + Q r )

C0 = influent solids concentration

M t Q0C0 Limiting condition: ????

A= =

GL GL

where GL = limiting (critical) flux

Mt

Qu =

Cu

Qu M G

Vb = = t = L

A Cu A Cu

ACEE 434 Fall 2009 HDP 7

Solid Flux

Reynolds and Richards Figure 9-24

Solid flux versus solid concentration

ACEE 434 Fall 2009 HDP 8

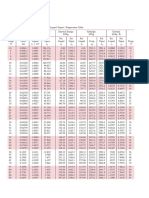

Example

Design a secondary clarifier

Reynolds and Richards Example 9-2

Final clarifier

Batch settling test have been performed using an acclimated activated sludge

to give the data in the following Table. The design mixed liquor flow to the

secondary clarifier is 160 L/s

L/s, the MLSS is 2500 mg/L

mg/L, and the underflow

concentration is 12,000 mg/L. Determine the diameter of the final clarifier.

Test C (mg/L) V (m/h) G = CV (kg/h/m2)

1 12,460 0.125 1.56

2 9,930

, 0.249 2.47

3 7,450 0.465 3.46

4 5,220 1 5.22

5 3 140

3,140 2 94

2.94 9 24

9.24

6 1,580 4.18 6.6

ACEE 434 Fall 2009 HDP 9

Example

Design a secondary clarifier

GL = 8.90 /h/ 2

8 90 kkg/h/m

Reynolds and Richards Figure 9-27 Reynolds and Richards Figure 9-28

Cu = 12,000 mg/L

ACEE 434 Fall 2009 HDP 10

Example

Design a secondary clarifier

1. Determine mass rate of solids settling (Mt)

M t = Q0C0 = (160 L / s)(3600s / hr )(kg / 1000 g ) = 1,440 kg / hr

2. Determine limiting flux (GL)

from the solid flux curve GL = 8.9 kg/h/m2

applying a scale-up factor of 1.5 GL = 8.9/1.5 = 5.93 kg/h/m2

3. Determine the diameter of the secondary clarifier (D)

Mt 1440 kg / hr

A= = 2

= 242.8 m 2

GL 5.93 kg / hr / m

1/ 2

⎡4 ⎤

D = ⎢ (242.8 m 2 )⎥ = 17.6 m

⎣π ⎦

ACEE 434 Fall 2009 HDP 11

Summary

1. Solid flux theory

2. Determine a secondary clarifier based on the theory

ACEE 434 Fall 2009 HDP 12

You might also like

- 7B. Other Abnormal Pressure Detection MethodsDocument57 pages7B. Other Abnormal Pressure Detection Methodsdriller22100% (1)

- Discharge Coefficient DeterminationDocument5 pagesDischarge Coefficient DeterminationMansoob BukhariNo ratings yet

- Chapter 9 Mass TransferDocument21 pagesChapter 9 Mass TransferSanjeev PawarNo ratings yet

- BearingDocument2 pagesBearingSameer ShashwatNo ratings yet

- Mass Transfer CoefficientsDocument17 pagesMass Transfer CoefficientsHemila PriyaNo ratings yet

- Turbomachinery For Compressible FluidsDocument70 pagesTurbomachinery For Compressible FluidsArun BeniwalNo ratings yet

- BC-CALC-ANALYSIS - Jetty Modul Near Gantry Crane - Su 20, 0.5 M Thk. and 1.1 M THK For Travelling AreaDocument4 pagesBC-CALC-ANALYSIS - Jetty Modul Near Gantry Crane - Su 20, 0.5 M Thk. and 1.1 M THK For Travelling Areanoto.sugiartoNo ratings yet

- Terzaghi Results: Bearing Capacity of Shallow Foundations Terzaghi MethodDocument4 pagesTerzaghi Results: Bearing Capacity of Shallow Foundations Terzaghi MethodCléudes RodriguesNo ratings yet

- Bearing Capacity All MethodsDocument2 pagesBearing Capacity All MethodsJayChristian QuimsonNo ratings yet

- GRADO EN INGENIERÍA QUÍMICA - Tema 9. SedimentaciónDocument16 pagesGRADO EN INGENIERÍA QUÍMICA - Tema 9. SedimentaciónHugo de la FuenteNo ratings yet

- Chapter 7 - Gas Flow: Important Soil GasesDocument24 pagesChapter 7 - Gas Flow: Important Soil GasesJorge CabreraNo ratings yet

- ECH 158B hw1Document5 pagesECH 158B hw1Trường Tùng LýNo ratings yet

- Bearing Capacity of Shallow Foundations Terzaghi and Vesic MethodsDocument2 pagesBearing Capacity of Shallow Foundations Terzaghi and Vesic MethodsFrank NarhNo ratings yet

- Gas Production III 2018Document35 pagesGas Production III 2018Akib ImtihanNo ratings yet

- Cellulose and Its DerivativesDocument1 pageCellulose and Its Derivativesvzimak2355No ratings yet

- Solution: First Sum Moments Clockwise About The Hinge A of The HandleDocument5 pagesSolution: First Sum Moments Clockwise About The Hinge A of The HandleUzziel De jesus OsorioNo ratings yet

- Solutions 2018 Mains 2Document11 pagesSolutions 2018 Mains 2sudhir_kumar_33No ratings yet

- Ultimate Bearing Capacity Xls ProgramDocument1 pageUltimate Bearing Capacity Xls Programaggrey noah100% (1)

- BearingDocument2 pagesBearingJustin MusopoleNo ratings yet

- WH Chapter ExercisesDocument25 pagesWH Chapter ExercisesMegh Raj KCNo ratings yet

- Exercicio KT-J2 MICHIGAN 2016 PDFDocument4 pagesExercicio KT-J2 MICHIGAN 2016 PDFLucas VieiraNo ratings yet

- Bearing Capacity All MethodsDocument2 pagesBearing Capacity All MethodsCléudes RodriguesNo ratings yet

- Column Diameter and Hetp CheckDocument6 pagesColumn Diameter and Hetp Checkmayur1980100% (1)

- Units: PE in (FT-LBF) Fluid Pressure: P GH/G G/GDocument2 pagesUnits: PE in (FT-LBF) Fluid Pressure: P GH/G G/GElizabeth Cares LiraNo ratings yet

- BearingDocument2 pagesBearingIslam DawoodNo ratings yet

- Supercritical CO2 Tutorial TE2014 - FinalDocument126 pagesSupercritical CO2 Tutorial TE2014 - Finaljing qiang100% (3)

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaNo ratings yet

- Bearing Capacity of Shallow Foundations Terzaghi and Vesic MethodsDocument2 pagesBearing Capacity of Shallow Foundations Terzaghi and Vesic MethodsFriDoniZANo ratings yet

- Design of a Vacuum Distillation ColumnDocument20 pagesDesign of a Vacuum Distillation Columndefred100% (1)

- Chapter 5.2 - Pipe NetworkDocument19 pagesChapter 5.2 - Pipe NetworkLin YanNo ratings yet

- Advanced Reservoir EngineeringDocument75 pagesAdvanced Reservoir Engineeringedwin mpouho100% (1)

- Bearing Capacity 3Document2 pagesBearing Capacity 3Alfredo De FexNo ratings yet

- Bearing CapacityDocument2 pagesBearing CapacityAlfredo De FexNo ratings yet

- Meyerhof Results: Bearing Capacity of Shallow Foundations Meyerhof MethodDocument2 pagesMeyerhof Results: Bearing Capacity of Shallow Foundations Meyerhof MethodAlfredo De FexNo ratings yet

- Bearing CapacityDocument2 pagesBearing CapacityAlfredo De FexNo ratings yet

- Sizing Criteria For Gas - Liquid Two-Phase LinesDocument79 pagesSizing Criteria For Gas - Liquid Two-Phase LinesMarcelo PerettiNo ratings yet

- RE CHP 7B Water InfluxDocument59 pagesRE CHP 7B Water InfluxKaoru AmaneNo ratings yet

- Minimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)Document17 pagesMinimum Loads: Thayer's Formula (From Steel Structures 3rd Ed 2012 by Z.A. Siddiqi, p.261)JHON CLYDE SEPADANo ratings yet

- CH 01Document9 pagesCH 01Mary Lorelyn EscoteNo ratings yet

- BearingDocument2 pagesBearingkrishnendu.bbitNo ratings yet

- Crystallizer ProblemDocument4 pagesCrystallizer ProblemNICOLE SALAZARNo ratings yet

- Soal Braja 4.5. Dimas.Document2 pagesSoal Braja 4.5. Dimas.Fikri DzikrillahNo ratings yet

- Examination Paper For TKP 4155 / KP 8903 Reaction Kinetics and CatalysisDocument7 pagesExamination Paper For TKP 4155 / KP 8903 Reaction Kinetics and CatalysislinnNo ratings yet

- CHAPTER 3 Gas Absorption Lec-2Document13 pagesCHAPTER 3 Gas Absorption Lec-2Sata AjjamNo ratings yet

- The University of Danang Danang University of Science and TechnologyDocument35 pagesThe University of Danang Danang University of Science and TechnologyLenh LeNo ratings yet

- NORDEN vessel draft survey recordsDocument8 pagesNORDEN vessel draft survey recordsfragkyc100% (14)

- Pipe Friction + Fitting (Type 2)Document3 pagesPipe Friction + Fitting (Type 2)AmroKashtNo ratings yet

- Deep Foundations: Limit State Design, Tensile Load and Load TestsDocument46 pagesDeep Foundations: Limit State Design, Tensile Load and Load TestsSteven KuaNo ratings yet

- Comparative study of heat requirements for batch cooking processesDocument5 pagesComparative study of heat requirements for batch cooking processesVinay KumarNo ratings yet

- Analisis Kekuatan Kolom Pier Beton BertulangDocument4 pagesAnalisis Kekuatan Kolom Pier Beton Bertulangsteny worangNo ratings yet

- CVEN9857 - Wastewater Treatment 1Document29 pagesCVEN9857 - Wastewater Treatment 1onlynameNo ratings yet

- Modelling Water Quality and Oxygen SagDocument9 pagesModelling Water Quality and Oxygen SagPrathamesh KanganeNo ratings yet

- Gas Well LoadingDocument9 pagesGas Well LoadingalyshahNo ratings yet

- JETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyDocument2 pagesJETTY 3000dwt: Title Document No.: Breasting Dolphin-Engineering Calculation Revision: Issued Date: CompanyAnonymous nXGOGxyeNo ratings yet

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Gas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsFrom EverandGas Hydrates 2: Geoscience Issues and Potential Industrial ApplicationsLivio RuffineNo ratings yet

- Cutting-Edge Technology for Carbon Capture, Utilization, and StorageFrom EverandCutting-Edge Technology for Carbon Capture, Utilization, and StorageKarine Ballerat-BusserollesNo ratings yet

- Rotational Motion 8.0Document11 pagesRotational Motion 8.0adnan khanNo ratings yet

- Experimental Comparison of Single and Multistage Air Compressor EfficienciesDocument11 pagesExperimental Comparison of Single and Multistage Air Compressor EfficienciesJohn barry CorpuzNo ratings yet

- Electrical Part ListDocument10 pagesElectrical Part Listgilberto gutierrezNo ratings yet

- Tension and Compression TestDocument37 pagesTension and Compression TestLydiaNo ratings yet

- Equivalent Force Systems and Free Body Diagrams Solved ProblemsDocument14 pagesEquivalent Force Systems and Free Body Diagrams Solved ProblemsYun RamNo ratings yet

- 194 - EE6604 Design of Electrical Machines - Important QuestionsDocument28 pages194 - EE6604 Design of Electrical Machines - Important QuestionsNiteshNarukaNo ratings yet

- UnravellingDocument1 pageUnravellingpkrakeshNo ratings yet

- PRA PSPM 2 Sesi 20212022Document10 pagesPRA PSPM 2 Sesi 20212022Loga KumaranNo ratings yet

- Cfx-Flo11 TsDocument2 pagesCfx-Flo11 Tsinessa_aksNo ratings yet

- Vibrations 2Document11 pagesVibrations 2boud3No ratings yet

- Unit Viib Fans and BlowersDocument8 pagesUnit Viib Fans and BlowersRaffy Calamonte CanoyNo ratings yet

- Moran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Document5 pagesMoran Introduction To Thermal Systems Engineering Thermodynamics Fluid Mechanics and Heat Transfer 2002 09Marco GassaniNo ratings yet

- Payal Sharma PHD Scholar (Part Time) Mechanical and Automation Engineering DeptDocument82 pagesPayal Sharma PHD Scholar (Part Time) Mechanical and Automation Engineering Deptpayaliya91100% (1)

- Ansi Ashrae Acca 183-2007 (Ra 2014)Document10 pagesAnsi Ashrae Acca 183-2007 (Ra 2014)Ahmed Labib100% (3)

- TAMU Transport Phenomena SyllabusDocument2 pagesTAMU Transport Phenomena SyllabusfrankNo ratings yet

- Macroscopic Conductors: θR. The corresponding θ/R. This noise is referred to asDocument21 pagesMacroscopic Conductors: θR. The corresponding θ/R. This noise is referred to asJU PMIT SabujNo ratings yet

- Irjet V5i5256 PDFDocument5 pagesIrjet V5i5256 PDFMuhsinaNo ratings yet

- Calorimetry and Phase ChangesDocument6 pagesCalorimetry and Phase ChangesVAN STEVEN SANTOSNo ratings yet

- The Nature and Perception of SoundDocument21 pagesThe Nature and Perception of Soundsheila louiseNo ratings yet

- Science 6.5Document6 pagesScience 6.5Nestlee ArnaizNo ratings yet

- Class 2 Certificate Syllabus For Hong Kong Marine Engg, CertificateDocument14 pagesClass 2 Certificate Syllabus For Hong Kong Marine Engg, Certificatedannynoronha755271100% (6)

- 3.) Heat ExchangerDocument5 pages3.) Heat ExchangerFranzes Mar EriaNo ratings yet

- SP 8004 - Panel FlutterDocument51 pagesSP 8004 - Panel FlutterElumalai SrinivasanNo ratings yet

- BUITEMS Entry Test Sample Paper NAT IMDocument10 pagesBUITEMS Entry Test Sample Paper NAT IMShawn Parker100% (8)

- Beam/Slab Flexural Design ConceptDocument20 pagesBeam/Slab Flexural Design ConceptAmrit RegmiNo ratings yet

- Remote Sensing Session 2 Modern Surveying - 20Ce32P: Study MaterialDocument14 pagesRemote Sensing Session 2 Modern Surveying - 20Ce32P: Study Materialshashi kumarNo ratings yet

- Handheld Handheld Handheld Handheld Digital Digital Digital Digital Multimeter Multimeter Multimeter MultimeterDocument16 pagesHandheld Handheld Handheld Handheld Digital Digital Digital Digital Multimeter Multimeter Multimeter MultimeterAntonio MarcosNo ratings yet

- Latticework of Mental Models by Robert HagstromDocument25 pagesLatticework of Mental Models by Robert Hagstromchubbyenoch100% (4)

- Electromagnetics in Power Engineering SimulationDocument8 pagesElectromagnetics in Power Engineering SimulationSamuel NóbregaNo ratings yet

- Anti-Icing in Gas Turbines PDFDocument133 pagesAnti-Icing in Gas Turbines PDFAbelio TavaresNo ratings yet