Professional Documents

Culture Documents

1020-2009apr01 How Anodes Work

Uploaded by

surya0588Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1020-2009apr01 How Anodes Work

Uploaded by

surya0588Copyright:

Available Formats

GALVANIC SYSTEMS

VectorTM

Galvashield® XP

Galvanic Theory and Application

How Do Galvanic Anodes Work? to the steel that mitigates the formation of new corrosion sites on

When two dissimilar metals are coupled together in an electrolyte, the the reinforcing in the adjacent un-repaired areas. The result of this

metal with the higher potential for corrosion (more negative voltage) strategy is an economical extension of the service life of the concrete

will corrode in preference to the more noble metal. In concrete repair repair.

applications, the zinc core of the galvanic anode will corrode and

provide an electrical current to the reinforcing steel that mitigates

corrosion activity.

Metal Volts*

Magnesium -1.75

Zinc -1.10

Aluminum alloy (5% Zn) -1.05

Steel in concrete -0.20 to -0.35

*Typical potentials measured with respect to copper-copper sulfate electrode.

Patch Containing Galvashield Anode

Corrosion-Induced Repair

Corrosion Control

If concrete is repaired in accordance with industry guidelines,

A corrosion control strategy can be utilized when sites of active

which require the removal of concrete continues until clean steel is

corrosion remain after concrete removal. To control active corrosion,

encountered and the cleaning of corrosion by-products from the full

a higher level of protective current is required than for corrosion

circumference of the steel (ICRI Guidelines No. 03730), the process

prevention. Corrosion control may be preferred when:

of replacing damaged concrete will generally address areas of the

structure with the highest level of corrosion activity.

• Active corrosion is present beyond the area to be repaired

• The structure is in a severely corrosive environment

The new patch repair will protect the reinforcing embedded in the

• The concrete is highly contaminated with chlorides

repair zone, but in many cases the remaining concrete will still be

• The structure to be protected has a high steel density

chloride-contaminated and/or carbonated. This situation creates a

• The repair procedures do not require concrete removal to continue

high potential for the formation of new corrosion sites or “hot spots”

until clean steel is encountered

adjacent to the repair. If this occurs, additional patching may be

required in a little as three to five years.

Galvashield XP+ embedded galvanic anodes installed around the

perimeter of the patch repair are designed to significantly reduce or

stop on-going corrosion activity in localized areas adjacent to the

patch. If a broader area of corrosion control is desired, Galvashield

CC embedded galvanic anodes can be installed on a grid pattern in

the remaining unrepaired but contaminated areas.

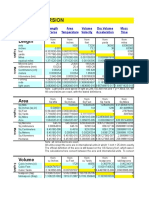

Level of Description Galvashield Galvashield Galvashield

Protection XP XP+ CC

Preventing new

Corrosion

Prevention

corrosion activity

from initiating

● ● ●

Significantly

reducing or

Corrosion

Control

stopping

on-going

● ●

Patch-Accelerated Corrosion Cell

corrosion activity

Highest level

Corrosion Prevention of protection

A localized corrosion prevention strategy is used when the objective Cathodic

intended to

Protection

is to prevent new corrosion activity from initiating in the sites adjacent stop on-going

to the repairs. Galvashield XP embedded galvanic anodes installed corrosion activity

1020 - 2009Apr01

around the perimeter of the patch repair provide a galvanic current

Vector Corrosion Technologies Ltd. 474 Dovercourt Drive Winnipeg, MB R3Y 1G4

Vector Corrosion Technologies, Inc. 13312 N. 56th Street, #102 Tampa, FL 33617

Vector products are provided with a standard limited warranty against defects for a period of 12 months from the date of the

sale. To obtain a complete copy of Vector’s limited warranty, contact Vector or visit www.vector-corrosion.com/warranty.pdf.

User shall determine the suitability of the products for the intended use and assume all risks and liability in connection there-

with. For professional use only; not for sale to or use by the general public.

Vector is a trademark. Galvashield and the Vector logo are registered trademarks. Phone: (204) 489-6300

Patents: US 6022469, 6303017, 6193857 Printed in Canada © 2009 Vector Corrosion Technologies

Fax: (204) 489-6033

Email: info@vector-corrosion.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 50 Years of Teaching PianoDocument122 pages50 Years of Teaching PianoMyklan100% (35)

- Reader's Digest (November 2021)Document172 pagesReader's Digest (November 2021)Sha MohebNo ratings yet

- Design of CulvertDocument12 pagesDesign of CulvertDebajani DekabaruahNo ratings yet

- RCC Water Tank Construction TenderDocument12 pagesRCC Water Tank Construction Tendersurya0588No ratings yet

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Current Diagnosis and Therapy For Head and Neck MalignanciesDocument249 pagesCurrent Diagnosis and Therapy For Head and Neck MalignanciesMara TomaNo ratings yet

- American App Examples 2007 CompleteDocument388 pagesAmerican App Examples 2007 CompleteJay NatoNo ratings yet

- Sysmex Xs-800i1000i Instructions For Use User's ManualDocument210 pagesSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- Lecture Ready 01 With Keys and TapescriptsDocument157 pagesLecture Ready 01 With Keys and TapescriptsBảo Châu VươngNo ratings yet

- ComFlor Manual PDFDocument92 pagesComFlor Manual PDFSofija KekezNo ratings yet

- Exp 8 - GPG - D12B - 74 PDFDocument4 pagesExp 8 - GPG - D12B - 74 PDFPRATIKSHA WADIBHASMENo ratings yet

- Smart Solutions Delivers Cutting-Edge Precast Concrete and Building ProductsDocument29 pagesSmart Solutions Delivers Cutting-Edge Precast Concrete and Building Productssurya0588No ratings yet

- Is800 Limiting Width To ThciknessDocument2 pagesIs800 Limiting Width To Thciknesssurya0588No ratings yet

- Hope ZWCAD 2017 Brochure-1Document2 pagesHope ZWCAD 2017 Brochure-1surya0588No ratings yet

- Automated Management Services: Welcome To AMSDocument9 pagesAutomated Management Services: Welcome To AMSsurya0588No ratings yet

- STeelDesign Slender SectionsDocument3 pagesSTeelDesign Slender Sectionssurya0588No ratings yet

- Civil Engineers Act 2006 19Document21 pagesCivil Engineers Act 2006 19surya0588No ratings yet

- Building 1Document6 pagesBuilding 1surya0588No ratings yet

- PDFDocument207 pagesPDFsurya0588No ratings yet

- 2007 NASPEC Modcom 3m Project Design LoadsDocument1 page2007 NASPEC Modcom 3m Project Design Loadssurya0588No ratings yet

- BrochureDocument5 pagesBrochuresurya0588No ratings yet

- 2007 NASPEC Modcom 3m Project Design LoadsDocument1 page2007 NASPEC Modcom 3m Project Design Loadssurya0588No ratings yet

- Building 1Document6 pagesBuilding 1surya0588No ratings yet

- Precast Walls For IndustrialDocument3 pagesPrecast Walls For Industrialsurya0588No ratings yet

- New Wind Load Provisions in Philippine Structural CodeDocument4 pagesNew Wind Load Provisions in Philippine Structural Codemelvin23100% (1)

- Iesl Guideline Structure For Engineering Consultancy Fees 10012013Document11 pagesIesl Guideline Structure For Engineering Consultancy Fees 10012013lalithniroshaNo ratings yet

- Mark No. Mass Grade Length Area Mass (KG/M) (M) (SQ.M) (T) Section SizeDocument90 pagesMark No. Mass Grade Length Area Mass (KG/M) (M) (SQ.M) (T) Section Sizesurya0588No ratings yet

- Sho DwgsDocument1 pageSho Dwgssurya0588No ratings yet

- Sheeting Rate ChartDocument2 pagesSheeting Rate Chartsurya0588No ratings yet

- Building Specifications Customer Information:: Buildingsystems, LLCDocument13 pagesBuilding Specifications Customer Information:: Buildingsystems, LLCsurya0588No ratings yet

- 1rail FootingDocument2 pages1rail Footingsurya0588No ratings yet

- Unit Conversion: LengthDocument35 pagesUnit Conversion: LengthAnonymous 8aj9gk7GCLNo ratings yet

- Introductry LetterDocument4 pagesIntroductry Lettersurya0588No ratings yet

- 2007 NASPEC Modcom 3m Project Design LoadsDocument1 page2007 NASPEC Modcom 3m Project Design Loadssurya0588No ratings yet

- PointerDocument26 pagesPointerpravin2mNo ratings yet

- Difference Between Text and Discourse: The Agent FactorDocument4 pagesDifference Between Text and Discourse: The Agent FactorBenjamin Paner100% (1)

- Krok2 - Medicine - 2010Document27 pagesKrok2 - Medicine - 2010Badriya YussufNo ratings yet

- Marketing Plan for Monuro Clothing Store Expansion into CroatiaDocument35 pagesMarketing Plan for Monuro Clothing Store Expansion into CroatiaMuamer ĆimićNo ratings yet

- Exercises 6 Workshops 9001 - WBP1Document1 pageExercises 6 Workshops 9001 - WBP1rameshqcNo ratings yet

- BIBLIO Eric SwyngedowDocument34 pagesBIBLIO Eric Swyngedowadriank1975291No ratings yet

- "Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecDocument5 pages"Behind The Times: A Look at America's Favorite Crossword," by Helene HovanecpspuzzlesNo ratings yet

- 3ccc PDFDocument20 pages3ccc PDFKaka KunNo ratings yet

- Us Virgin Island WWWWDocument166 pagesUs Virgin Island WWWWErickvannNo ratings yet

- Tension field beams: Aircraft wing spar analysisDocument19 pagesTension field beams: Aircraft wing spar analysisPrajeesh RajNo ratings yet

- Dole-Oshc Tower Crane Inspection ReportDocument6 pagesDole-Oshc Tower Crane Inspection ReportDaryl HernandezNo ratings yet

- Unit-1: Introduction: Question BankDocument12 pagesUnit-1: Introduction: Question BankAmit BharadwajNo ratings yet

- Brick TiesDocument15 pagesBrick TiesengrfarhanAAANo ratings yet

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićNo ratings yet

- Inventory Control Review of LiteratureDocument8 pagesInventory Control Review of Literatureaehupavkg100% (1)

- 10 1 1 124 9636 PDFDocument11 pages10 1 1 124 9636 PDFBrian FreemanNo ratings yet

- Polytechnic University Management Services ExamDocument16 pagesPolytechnic University Management Services ExamBeverlene BatiNo ratings yet

- Orc & Goblins VII - 2000pts - New ABDocument1 pageOrc & Goblins VII - 2000pts - New ABDave KnattNo ratings yet

- Os PPT-1Document12 pagesOs PPT-1Dhanush MudigereNo ratings yet

- 2023-Physics-Informed Radial Basis Network (PIRBN) A LocalDocument41 pages2023-Physics-Informed Radial Basis Network (PIRBN) A LocalmaycvcNo ratings yet

- Clark DietrichDocument110 pagesClark Dietrichikirby77No ratings yet

- Planning A Real Estate ProjectDocument81 pagesPlanning A Real Estate ProjectHaile SilasieNo ratings yet

- Sewage Pumping StationDocument35 pagesSewage Pumping StationOrchie DavidNo ratings yet