Professional Documents

Culture Documents

Low Noise Solutions For Turbine Bypass To Air-Cooled Condensers

Uploaded by

Elavarasan RamalingamOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Low Noise Solutions For Turbine Bypass To Air-Cooled Condensers

Uploaded by

Elavarasan RamalingamCopyright:

Available Formats

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

ASME

Air-Cooled Condenser Plants Demand Low- Noise Bypass Equipment

Introduction In a power plant with an air-cooled condenser (ACC), steam is carried from the steam turbine exhaust to the condenser via a large, thin wall, uninsulated duct. Noise sources that discharge into the ACC duct have much less attenuation than in a water-cooled condenser. The ACC duct is typically external to the turbine building and has a very large surface area. High noise levels at the ACC duct surface can generate unacceptable noise levels at the plant boundary and in neighboring communities. This problem is especially important in combined cycle power stations. Combined cycle power stations have 100% turbine bypass systems. The combined steam flow and desuperheater cooling flow

Figure 1: ACC duct on a large combined cycle power station. The duct is long, large, and uninsulated.

from the bypass system discharges nearly 50% more mass flow into the duct than the steam turbine, and at a higher enthalpy. This large amount of mass flow is discharged into a dump device that is much smaller than the steam turbine exhaust, concentrating noise energy into a very small area. Single-stage control valves and dump elements can generate external noise levels in excess of 130 dBA at a distance of 1m from the ACC duct surface, and 75 dBA up to a kilometer from the plant. With many combined cycle plants on daily cycling, start-up noise can become a severe constraint in plant operation. Combined cycle power stations are also relatively compact, and are much more likely to be sited in a sensitive environment than a large coal-fired boiler. Plants with excessive noise levels may face financial penalties and, in some cases, suspension of plant operation. Due to the large size of the ACC duct, traditional noise treatment methods like acoustic enclosures or insulation are impractical or insufficient. The source noise must be treated in order to meet plant noise requirements. Complete Noise and Bypass System Specification It is important to establish correct and complete noise specifications for ACC systems. Almost all plants establish near field sound pressure levels of 90 dBA for insulated pipes in order to provide a safe working environment. In ACC plants the far field requirements will usually dictate the near field requirements. Far field requirements of 60 dBA at 400 feet from duct may require near field requirements of 85 dBA at 3 feet from duct. Since the duct is

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

Figure 2: Noise at the surface of the duct can propagate to nearby communities.

Figure 3: Compact dump element with elliptical or fish mouth discharge. These designs generate large noise at the surface of the ACC duct.

not insulated, the noise performance of the bypass system must be significantly lower than is applied in conventional power stations.

Total ACC Noise is the Result of Many Individual Noise Sources

In a bypass system, there will be a variety of service conditions corresponding to the different plant operating modes. Typical operating modes include full-load trip, duct firing, cold start, and hot start. The duration and frequency of these operation modes varies significantly, and the far field noise requirements for the plant may be different for each operating mode. The noise requirements and operating conditions for the bypass system must be completly defined and reviewed to insure that plant noise requirements are met. The noise requirements and operating conditions also have a significant effect on the cost, size, and complexity of the bypass

Figure 4: Compact dump tube.

system design. Sources of Noise in ACC Systems The noise from the bypass system comes from two primary sources, the steam bypass control valve and the final dump element that discharges all steam flow and spraywater flow into the ACC duct. The sound power and peak frequency of each source must be controlled in order to reduce overall system noise. The dominant source in large power stations is the final dump element in the bypass to condenser systems. The most common dump element designs feature a large array of 12 mm or 6 mm drilled holes, densely packed on a flat circular plate, an elliptical

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

Figure 5: Cracks at a lifting hub on the surface of an ACC duct. The cracks were generated by the high power, low frequency jet generated by a compact dump element.

fish mouth device, or a dump tube (Figures 3 and 4). These designs can generate noise levels in excess of 130 dBA at a distance of 1m from the ACC duct surface. The large amount of concentrated sound power creates vibration that can cause cracks in the duct walls and dump element mounting ring (Figure 5). The noise generated by the dump element at the ACC duct surface

Noise vs Freqency, Drag Resistor and Dump Tubes

160.0

140.0

can be significantly reduced by using a combination of smaller orifice sizes and multi-stage pressure reduction. Smaller orifice sizes shift the peak frequency of jets discharging from the dump element. Multi-stage pressure reduction reduces the discharge velocity of jets on the surface of the dump element. In some cases

10 100

Sound Power, dB

120.0

100.0

80.0

60.0

40.0

Frequency, Hz Low Noise Dump Tube

1000

10000

100000

we must apply both approaches in order to achieve the necessary noise performance. DRAG multi-stage technology provides the best possible noise performance in bypass to condenser applications (Figure 6).

DRAG Resistor

Compact Dump Tube

Figure 6: Comparison of the sound power and frequency spectrum for three dump element technologies. The DRAG resistor combines a multi-stage pressure letdown design with frequency shifting to reduce overall system noise.

Low Noise Performance Requires a Total System Solution

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

Figure 7: Comparison of far field noise performance for a CCPS with ACC duct. The first figure shows the noise field around a plant when the plant is in normal operation, with 85 dBA ambient noise level. The second figure shows the noise field around a plant when the bypass system is in operation. The bypass system generates 117 dBA at 1m from the duct surface, and significant far field noise.

Total System Design The overlay on pages 8 and 9 shows an illustration of a typical bypass system. The bypass system includes many elements, including the steam bypass control valve, diffusers, one or more desuperheaters, and the final dump element. The total system design must be reviewed to meet noise requirements. Noise sources upstream of the final dump element will transmit downstream into the ACC duct. The steam bypass control valve and diffusers may require multi-stage technology. In bypass to condenser applications the temperature after desuperheating is saturated because typically design temperatures for ACC ducting is around 120C (250F). To control steam enthalpy to conditions acceptable for ACC, steam is saturated at the higher pressures existing upstream of the dump device. These applications require very large amounts of spraywater, and the source for this is often cold water from the condensate extraction pumps (CEP). The design of the desuperheater, the velocities in the pipe system, and spraywater control logic must be carefully made to ensure reliable operation. Bypass to condenser applications require consideration of total system design and more so in air-cooled condensers where noise requirements, control and evaporation of spray water are required to be more stringent.

DRAG Multi-Stage Technology

Benefits of DRAG Multi-Stage Technology CCI designs and manufactures a unique technology that provides the best possible noise performance. This technology is available for the steam bypass valve trim and for the final dump element. The DRAG design divides the flow through the control valve or dump element into hundreds of multi-path multi-stage streams. Each flow path consists of a specific number of right angle turns. These flow paths establish a tortuous path, and each turn reduces the pressure of the flowing medium. The pressure drop on the last stage of a DRAG disk is many times less than the pressure drop on a single-stage orifice. With this technology we can specify the necessary number of stages to achieve plant noise requirements. CCI can provide this technology both within the control valve trim and in the final dump element in the ACC duct.

Figure 8: Image of a typical DRAG resistor for HRH bypass air-cooled condensers.

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

The DRAG resistor provides additional benefits in bypass to condenser applications. The steam entering the condenser dump element is typically wet steam, with 95% to 97% quality. MultiStage conventional drilled hole dump devices are not recommended as they will gradually be eroded by impinging high velocity wet steam jets from the individual stages onto the material (diffuser) of the next stage. DRAG velocity control protects the dump element from wet steam erosion, and stainless steel construction of the disks ensures long service life. The DRAG resistor also gives much greater pipe and system design flexibility. The DRAG resistor can provide lower system noise with much higher inlet pressures. This gives plant designers the flexibility to specify higher pressures and smaller pipes sizes for the intermediate pipe between the bypass valve and dump element. It also gives the bypass system designer more flexibility to optimize system velocities for improved noise control and desuperheating. Special DRAG Hex Resistors The DRAG resistor disks for bypass to condenser applications are assembled from hundreds of disk strips. The disk strips are held together using a series of pins that cross link the strips. This unique design provides the durability and toughness required to withstand the dynamic forces that act on the resistor during a fullload trip. The disks are manufactured from 12 chrome stainless steel, which resists the thermal gradients and erosion from steam quality variations associated with condenser discharge systems. The disks use a special version of the DRAG flow path that has been optimized for discharge to the condenser applications.

Figure 9: DRAG multi-stage valve trim minimizes noise generation through velocity control.

DRAG Resistor Dump Element Incorporating DRAG Technology

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

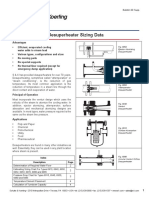

Figure 10: Schematic of a standard DRAG resistor and a typical bell housing assembly.

Table 1: Standard DRAG Resistor Configurations

HRH Bypass Steam Flow (excl spray water) 100000 - 300000 lbm/hr (45450 - 136360 mt/hr)

Nominal Diameter (DN)

Resistor Height (HR) 33 (82 cm) 39 (99 cm) 47 (120 cm) 54 (137 cm) 40 (102 cm)

Max Resistor Diameter (DMAX)

Bell Housing Diameter 70 100

24 (61 cm)

40 (102 cm) (180 254 cm)

dif bre

175000 - 450000 lbm/hr (79545 - 204550 mt/hr)

30 (76 cm)

48 (122 cm) 55 (140 cm 64 (163 cm) 49 (125 cm)

85 125 44 (112 cm) (216 318 cm)

300000 - 675000 lbm/hr (136360 - 306820 mt/hr)

36 (91 cm)

57 (145 cm) 66 (168 cm) 76 (193 cm) 57 (145 cm)

105 150 51 (130 cm) (267 381 cm)

450000 - 900000 lbm/hr (181800 - 450000 mt/hr)

42 (107 cm)

66 (168 cm) 76 (193 cm) 86 (219 cm)

125 175 60 (154 cm) (318 445 cm)

Notes: The size of the DRAG resistor may require the use of a bell housing to avoid excessive ACC duct blockage. - The bell housing diameters above assume that the DRAG resistor is 100% contained in the bell housing and assumes an ACC duct pressure of 2 psia (.13 bara), and an enthalpy of 1170 BTU/lbm ( 2720 kJ/kg). - The bell housing diameter may be reduced if the DRAG resistor is only partially contained.

Preferred System Configuration

Total System Design

For every bypass system, CCI performs a complete system noise analysis using industry standard IEC & ISA calculation methods, optimizing system geometry and intermediate operating conditions to intelligently manage steam velocity and minimize noise generation in regions of area expansion.

Closed-Coupled Horizontal Piping Arrangement

Installing the bypass valve and desuperheater horizontially and close to the ACC duct eliminates the need for pipe elbows. This provides the simplest solution for system control and minimizes the risk of wet steam erosion.

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

DRAG Technology

CCIs DRAG multi-stage valve trim minimizes noise generation through velocity control.

Small Diameter Drilled-Hole Technology

Small diameter drilled-hole valve trim and flow diffusers greatly minimize audible noise generation by breaking up large diameter jets and frequency shifting.

DRAG Multi-Stage Dump Device

CCIs DRAG multi-stage technology incorporated into a condenser dump device.

Alternate Configurations

SUMMARY ACC plants can be a noise problem because: n n Turbine bypass systems dump into a large-diameter, uninsulated, thin-walled duct. They are commonly located very close to residential areas. Low noise performance requires a total system solution: n n n n DRAG Multi-Stage Valve Trim Small-Drilled-Hole Diffusers DRAG Multi-Stage Dump Device Intelligently designed system geometry

Total ACC noise is a product of many individual sources: n n Bypass valves Regions of area expansion n Dump Devices

Alternate Configuration: Two-Stage Desuperheating

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

Two-Stage Desuperheating In some situations, it is necessary to break up the desuperheating into two separate stages. This is due to the fact that turbine bypass systems, especially IP bypass systems, operate with wet steam downstream of the desuperheater. The system geometry determines if twostage desuperheating is necessary. This includes: Systems with long outlet pipe runs: Long pipe runs flowing wet steam lead to excess spraywater fallout and can lead to a water hammer effect on the dump element. Systems with pipe elbows: Pipe elbows not only increase spraywater fallout, but are also very prone to erosion caused by water droplets in the wet steam flow. In addition, elbows located close to the dump element can lead to nonuniform temperature gradients that can cause damage. Two-stage desuperheating works by splitting the desuperheating to maintain superheated steam in the intermediate piping before the ACC duct. This minimizes the risks associated with flowing wet steam. The remainder of the spraywater is injected immediately before the condenser dump element.

Alternate Configuration: Two-Stage Desuperheating

Low Noise Solutions for Turbine Bypass to Air-Cooled Condensers

For more information, refer to the following documents:

CCI Installation Guidelines CCI Preventative Maintenance Program

Preventative Maintenance Program for Turbine Bypass Systems

Contact us at: info@ccivalve.com For sales and service locations worldwide, visit us online at: www.ccivalve.com Throughout the world, customers rely on CCI companies to solve their severe service control valve problems. CCI has provided custom solutions for these and other industry applications for more than 80 years.

DRAG is a registered trademark of CCI. 20 08 CCI 893 02/08 5K

You might also like

- Air-Cooled Condenser Piping Design RequirementsDocument3 pagesAir-Cooled Condenser Piping Design RequirementsHoney TiwariNo ratings yet

- Basic Desuperheating TheoryDocument4 pagesBasic Desuperheating TheoryAnonymous CX51waINo ratings yet

- DAM DesuperheaterDocument4 pagesDAM DesuperheaterangeloNo ratings yet

- Deaerator Volume Calculation ReportDocument1 pageDeaerator Volume Calculation Reportpsk.pranesh5520No ratings yet

- Key Parameters For Air Cooled Condenser DesignDocument12 pagesKey Parameters For Air Cooled Condenser DesignmohantyomNo ratings yet

- Design of Fluid Systems PDFDocument66 pagesDesign of Fluid Systems PDFVirendra KumarNo ratings yet

- Desuperheater Catalog of DAEJU CONTROL CO., LTD.Document28 pagesDesuperheater Catalog of DAEJU CONTROL CO., LTD.Ki Ho ChungNo ratings yet

- Dry Wet Cooling Systems and Flue Gas System ENEXIODocument55 pagesDry Wet Cooling Systems and Flue Gas System ENEXIOAmir AbbaszadehNo ratings yet

- Acc Vs Heller CTDocument37 pagesAcc Vs Heller CTkiddjoe1470No ratings yet

- Basic Desuperheater Types PDFDocument17 pagesBasic Desuperheater Types PDFLiège CostaNo ratings yet

- Dry Cooling SystemDocument53 pagesDry Cooling Systemxlxjrv0% (1)

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- High-Rise Fan - Coil - EngineerDocument15 pagesHigh-Rise Fan - Coil - EngineerMIN GUINo ratings yet

- Performance NT100M HVDocument1 pagePerformance NT100M HVAnonymous 3fTYXaW7WNo ratings yet

- Calculate the Heat Transfer Area (HTA) Required for a Steam CondenserDocument6 pagesCalculate the Heat Transfer Area (HTA) Required for a Steam CondensersakalidhasavasanNo ratings yet

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumarNo ratings yet

- Suc DrumsDocument6 pagesSuc DrumsrkoGear100% (1)

- Check Vacuum System Sizing for High Condenser BackpressureDocument3 pagesCheck Vacuum System Sizing for High Condenser Backpressurehappale2002No ratings yet

- Data SheetDocument7 pagesData SheetPaulkumar RamaiahNo ratings yet

- Thermal Storage Vessel Sizing - 1-9Document9 pagesThermal Storage Vessel Sizing - 1-9Tomás CVNo ratings yet

- Air Cooled CondenserDocument7 pagesAir Cooled Condensermoreds1983No ratings yet

- Air Cooled Condenser and Non PerformanceDocument67 pagesAir Cooled Condenser and Non Performanceparthi20065768100% (2)

- DesuperheaterDocument4 pagesDesuperheaterNaama RahavNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument3 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- Header & Piping SizingDocument9 pagesHeader & Piping Sizingmedicbest0% (1)

- Howden Netherlands air condenser performance analysisDocument24 pagesHowden Netherlands air condenser performance analysisDSGNo ratings yet

- KOSO Turbine Bypass Systems - (Sales Training, March 10 2011) - Rev ADocument78 pagesKOSO Turbine Bypass Systems - (Sales Training, March 10 2011) - Rev Atriplbingazi100% (2)

- 2 - Thermal Energy Storage SystemsDocument21 pages2 - Thermal Energy Storage SystemsAbed NaemNo ratings yet

- Vaccum Air Systems ASPE CEU 197Document14 pagesVaccum Air Systems ASPE CEU 197Mohamed AdelNo ratings yet

- Gland steam condenser specification sheetDocument2 pagesGland steam condenser specification sheetRais RijalNo ratings yet

- Stim-03.006 - en Control FluidDocument17 pagesStim-03.006 - en Control Fluidbikendiaguirre100% (1)

- Steam and Hot Water Boiler RegulationsDocument29 pagesSteam and Hot Water Boiler Regulationsraymart caluagNo ratings yet

- Steam Pipe SizingDocument16 pagesSteam Pipe SizingsamvendanNo ratings yet

- CondenserDocument44 pagesCondenserNeil John CatapangNo ratings yet

- Water Cooled Chiller Package Data SheetDocument9 pagesWater Cooled Chiller Package Data SheetMohan VarkeyNo ratings yet

- Air Cooled CondensersDocument6 pagesAir Cooled CondensersruchiajmerNo ratings yet

- Guide to Industrial Leakage TestingDocument109 pagesGuide to Industrial Leakage TestingMarzuki AlkindiNo ratings yet

- 2001 Standard For: Desuperheater/ Water HeatersDocument13 pages2001 Standard For: Desuperheater/ Water HeatersPrasad GujarNo ratings yet

- Ref Pipe Sizing Ver 02 21 11Document12 pagesRef Pipe Sizing Ver 02 21 11Ahmef100% (1)

- 6DSUPP Desuperheater Supplement BrochureDocument4 pages6DSUPP Desuperheater Supplement BrochureПавел ЛукьяновNo ratings yet

- Introducing Standards for AIR COOLED CONDENSERSDocument8 pagesIntroducing Standards for AIR COOLED CONDENSERSSyed HafeezNo ratings yet

- 15182B Steam Condensate PipingDocument8 pages15182B Steam Condensate PipingAltaf ur RehmanNo ratings yet

- Cooling Tower Performance Test (Id CT) : Manual Input SheetDocument13 pagesCooling Tower Performance Test (Id CT) : Manual Input SheetSHIVAJI CHOUDHURY100% (1)

- Evaluation of Steam Jet EjectorsDocument11 pagesEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- Heller System PPT 3 Cooling SystemsDocument34 pagesHeller System PPT 3 Cooling SystemsShrey DattaNo ratings yet

- BoilBal SpreadsheetDocument16 pagesBoilBal SpreadsheetZulkarnain NasrullahNo ratings yet

- Inline Heater DatasheetDocument11 pagesInline Heater DatasheetMuhammad AhsanNo ratings yet

- Modern steam trap monitoring and steam leakage calculation Excel sheetDocument3 pagesModern steam trap monitoring and steam leakage calculation Excel sheetvazzoleralex6884No ratings yet

- Glaxo Vol IDocument164 pagesGlaxo Vol IPrakash WarrierNo ratings yet

- 660MW Air Cooled CondenserDocument26 pages660MW Air Cooled CondenserRaj_Jai030% (1)

- 893 Low Noise Solutions For Turbine Bypass To Air Cooled CondensersDocument10 pages893 Low Noise Solutions For Turbine Bypass To Air Cooled CondensersfelramNo ratings yet

- Vacuum Pumps and Compressors For The Electric Power IndustryDocument6 pagesVacuum Pumps and Compressors For The Electric Power Industryfallo1989No ratings yet

- VANEC Vent & Blowdown Silencer Selection GuideDocument19 pagesVANEC Vent & Blowdown Silencer Selection Guidektsnl100% (1)

- Aissms Coe Be (Mechanical)Document60 pagesAissms Coe Be (Mechanical)Chinmoy BelpatreNo ratings yet

- VAV BrochureDocument28 pagesVAV BrochureMuralidharan SudhakarNo ratings yet

- Design and Size DuctworkDocument6 pagesDesign and Size Ductworkwilderness_666No ratings yet

- Recent Advances Turbine BypassDocument4 pagesRecent Advances Turbine BypassretrogradesNo ratings yet

- Sound ReductionDocument11 pagesSound ReductionWilliam GrecoNo ratings yet

- Motors Ametek Tech Cross Ref PDFDocument19 pagesMotors Ametek Tech Cross Ref PDFYe Alhadar0% (1)

- Aero SonicsDocument97 pagesAero SonicsYamen SleimanNo ratings yet

- Yamaha Rd200 Workshop ManualDocument36 pagesYamaha Rd200 Workshop ManualElavarasan RamalingamNo ratings yet

- Bed Material Specification CFBC BoilerDocument1 pageBed Material Specification CFBC BoilerElavarasan RamalingamNo ratings yet

- RD200 (’78) Parts List GuideDocument109 pagesRD200 (’78) Parts List GuidePhil FeatherstoneNo ratings yet

- 350 Ab PartsDocument54 pages350 Ab PartsAbin AndrewsNo ratings yet

- Lockout TagoutDocument27 pagesLockout TagoutMohammed Al-OdatNo ratings yet

- Ministerial Order, Local OrderDocument37 pagesMinisterial Order, Local OrderElavarasan Ramalingam100% (1)

- Refrigeration Compressors and Air Conditioning Compressors InformationDocument17 pagesRefrigeration Compressors and Air Conditioning Compressors InformationElavarasan RamalingamNo ratings yet

- Yamaha RD200C 581-000101 Service ManualDocument36 pagesYamaha RD200C 581-000101 Service ManualElavarasan RamalingamNo ratings yet

- Chemical Storage GuideDocument6 pagesChemical Storage GuideipliprensNo ratings yet

- Sour Gas Processing PDFDocument1 pageSour Gas Processing PDFElavarasan Ramalingam0% (1)

- Hazid Vs HazopDocument5 pagesHazid Vs HazopElavarasan RamalingamNo ratings yet

- Nebosh AnswersDocument6 pagesNebosh AnswersTushar Kanti JhaNo ratings yet

- Examiner Reports January 2009 Unit IADocument13 pagesExaminer Reports January 2009 Unit IAElavarasan RamalingamNo ratings yet

- Lockout TagoutDocument27 pagesLockout TagoutMohammed Al-OdatNo ratings yet

- HSE HSG 065 Successful Health and Safety Management 2nd EditionDocument98 pagesHSE HSG 065 Successful Health and Safety Management 2nd EditionAxolotl20% (1)

- Tutopia Solutions - NEBOSH - DefinitionsDocument3 pagesTutopia Solutions - NEBOSH - DefinitionsElavarasan RamalingamNo ratings yet

- Geeraga SambaDocument1 pageGeeraga SambaElavarasan RamalingamNo ratings yet

- Poynting OMNI A0098 BrochureDocument2 pagesPoynting OMNI A0098 BrochurekaminareNo ratings yet

- GU - Cabine MT BT (EN) - 1VCP000591 1511Document88 pagesGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariNo ratings yet

- John Deere 772d 6wd GraderDocument6 pagesJohn Deere 772d 6wd GraderyaserattiaNo ratings yet

- Class XII Computer Project - Hotel ManagementDocument29 pagesClass XII Computer Project - Hotel ManagementLakshmi Puthiyedath71% (7)

- DBMS Queries OverviewDocument98 pagesDBMS Queries OverviewAbhinay YadavNo ratings yet

- Cessna 172Document4 pagesCessna 172James DeatoNo ratings yet

- Mid Drive Vs HubDocument15 pagesMid Drive Vs HubRivan PamungkasNo ratings yet

- Solid angles in perspective: Ω, have a small but essential role in physics. For example, howDocument8 pagesSolid angles in perspective: Ω, have a small but essential role in physics. For example, howashkarkabeer08No ratings yet

- Measure Runoff and Soil Loss at Erosion Plots in TanzaniaDocument19 pagesMeasure Runoff and Soil Loss at Erosion Plots in TanzaniaMohd Sofiyan Bin SulaimanNo ratings yet

- UCE802 Earthquake SyllabusDocument2 pagesUCE802 Earthquake Syllabuskullu88No ratings yet

- Manual LDM5 U enDocument3 pagesManual LDM5 U enLuizAugustoMedeirosNo ratings yet

- Leica CME ManualDocument24 pagesLeica CME ManualMaria DapkeviciusNo ratings yet

- ScanKromsator ManualDocument9 pagesScanKromsator ManualcensoredchapterNo ratings yet

- Recurrent Neural Network-Based Robust NonsingularDocument13 pagesRecurrent Neural Network-Based Robust NonsingularDong HoangNo ratings yet

- Midterm - ICT1 ExamDocument4 pagesMidterm - ICT1 ExamHelen PerlasNo ratings yet

- Maths Comparison Summary ReportDocument274 pagesMaths Comparison Summary ReportShahrukh MunirNo ratings yet

- The Use and Misuse of SEMDocument30 pagesThe Use and Misuse of SEMPPDTBM renNo ratings yet

- Redirection & PipingDocument16 pagesRedirection & PipingPraveen PatelNo ratings yet

- Maths Class VIII: Chapter As Per NCERT LessonsDocument1 pageMaths Class VIII: Chapter As Per NCERT Lessonsabhijeet_sangwanNo ratings yet

- 1 - Introduction - Derivatives GreeksDocument50 pages1 - Introduction - Derivatives GreeksThomas GallantNo ratings yet

- Physico-Chemical Properties of DrugsDocument64 pagesPhysico-Chemical Properties of DrugsYap Jacky33% (6)

- Leviton ManualDocument82 pagesLeviton ManualRobby Larson100% (1)

- Section 1 Atoms, Molecules and StoichiometryDocument27 pagesSection 1 Atoms, Molecules and Stoichiometryapi-3734333100% (2)

- Introduction To Probability: Business Statistics: Communicating With Numbers, 4eDocument52 pagesIntroduction To Probability: Business Statistics: Communicating With Numbers, 4eRetno Ajeng Anissa WidiatriNo ratings yet

- CS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Document23 pagesCS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Kamal WaliaNo ratings yet

- Convert Decimal To Binary Sunday ClassDocument14 pagesConvert Decimal To Binary Sunday ClassLaila HammadNo ratings yet

- TVS Apache RTR 180 Service ManualDocument25 pagesTVS Apache RTR 180 Service ManualSandino JoseNo ratings yet

- Introduction to Nautilus 8 Mold Qualification and Design of Experiments SoftwareDocument66 pagesIntroduction to Nautilus 8 Mold Qualification and Design of Experiments SoftwareJohn SuperdetalleNo ratings yet

- Magnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingDocument10 pagesMagnetic Field Analysis of SynRel and PMASynRel Machines With Hyperbolic Flux Barriers Using Conformal MappingedumacerenNo ratings yet

- Suunto Core UserguideDocument58 pagesSuunto Core UserguidePriyo AkuntomoNo ratings yet