Professional Documents

Culture Documents

CL Btech 2010

Uploaded by

Kanjakha PalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CL Btech 2010

Uploaded by

Kanjakha PalCopyright:

Available Formats

Indian Institute of Technology Guwahati

Chemical Engineering Department

BTech Course Structure CHEMICAL ENGINEERING

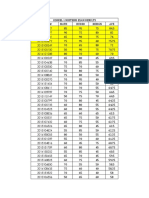

Course No. CH101 CH110 EE101 MA101 ME 110/ PH 110 ME 111 PH101 SA 101 Course Name Semester - 1 Chemistry Chemistry Laboratory Electrical Sciences Mathematics - I Workshop / Physics Laboratory Engineering Drawing Physics - I Physical Training -I NCC/NSO/NSS 3 0 3 3 0 0 2 0 0 11 Semester 3 MA201 CL201 CL202 CL203 ME212 HS2xx SA 201 Mathematics - III Chemical Process Calculations Fluid Mechanics Chemical Engineering Thermodynamics - I Solid Mechanics - I HSS Elective - I Physical Training - III NCC/NSO/NSS 3 2 3 2 2 3 0 0 15 Semester 5 Solid and Fluid-Solid Operations Chemical Reaction Engineering - I Process Equipment Design - II Mass Transfer Operation - II HSS Elective - III Heat Transfer Lab Mass Transfer Lab Semester 7 CL402 CL403 CLxxx XXxxx CL416 CL417 CL498 Chemical Process Technology Process Equipment Design - III Departmental Elective - I Open Elective - II Process Control Lab Chemical Reaction Engineering Lab Project - I 3 2 3 3 0 0 0 11 0 0 0 0 0 0 0 0 0 2 0 0 3 3 6 14 6 6 6 6 3 3 6 36 CL401 CL404 CLxxx HS4xx XX4xx CL499 1 1 1 1 1 0 0 0 5 0 0 0 0 0 0 2 2 0 8 6 8 6 6 6 0 0 40 CL204 CL205 CL206 CL207 HS2xx CL210 CL211 SA 202 1 0 1 1 0 0 1 0 0 4 0 3 0 0 3 3 0 2 2 9 8 3 8 8 3 3 6 0 0 39 BT101 CS 101 CS110 EE102 MA102 ME101 PH102 PH 110/ ME 110 SA 102 Modern Biology Introduction to Computing Computing Laboratory Basic Electronics Laboratory Mathematics - II Engineering Mechanics Physics - II Physics Laboratory/ Workshop Physical Training -II NCC/NSO/NSS Semester 4 Heat Transfer Operations Mass Transfer Operations - I Process Equipment Design - I Chemical Engineering Thermodynamics II HSS Elective - II Fluid Mechanics Lab Thermodynamics Lab Physical Training - IV NCC/NSO/NSS Semester 6 3 2 1 2 3 0 0 11 0 1 0 1 0 0 0 2 0 0 3 0 0 3 3 9 6 6 5 6 6 3 3 35 Semester 8 Process Design and Project Engineering Material Science Departmental Elective - II HSS Elective - IV Open Elective - III Project - II 3 3 3 3 3 0 15 1 0 0 0 0 0 1 0 0 0 0 0 6 6 8 6 6 6 6 6 38 CL307 CL308 CL309 CL314 XXxxx CL315 Transport Phenomena Chemical Reaction Engineering II Process Control and Instrumentation Numerical Methods in Chemical Engineering Open Elective - I Mechanical Operation Lab 2 3 3 2 3 0 13 1 0 1 0 0 0 2 0 0 0 2 0 3 5 6 6 8 6 6 3 35 3 2 1 2 3 0 0 0 0 11 CL301 CL303 CL304 CL306 HS3xx CL312 CL313 1 1 0 1 0 0 0 0 0 3 0 0 3 0 0 3 3 2 2 9 8 6 5 6 6 3 3 0 0 37 L T P C Course No. Course Name Semester -2 3 3 0 0 3 3 2 0 0 0 14 0 0 0 0 1 1 1 0 0 0 3 0 0 3 3 0 0 0 3 2 2 9 6 6 3 3 8 8 6 3 0 0 43 L T P C

Indian Institute of Technology Guwahati

Chemical Engineering Department

Semester - 3

Cl 201 Chemical Process Calculations (2-1-0-6)

Steady-state and dynamic processes; lumped and distributed processes; single and multi-phase systems; correlations for physical and transport properties; equilibrium relations; ideal gases and gaseous mixtures; vapor pressure; Vapor liquid equilibrium; Material balances: non-reacting singlephase systems; systems with recycle, bypass and purge; processes involving vaporization and condensation. Intensive and extensive variables; rate laws; calculation of enthalpy change; heat of reaction; fuel calculations; saturation humidity, humidity charts and their use; energy balance calculations; flow-sheeting; degrees of freedom and its importance in flow-sheeting.

Texts: 1. R. M. Felder and R. W.Rousseau, Elementary principles of chemical processes, 3 Ed., Wiley, 1999. th 2. D. M. Himmelblau, Basic Principles and Calculations in Chemical Engineering, 6 Ed., Prentice Hall of India, 2001. References: 1. 2. N. Chopey, Handbook of Chemical Engineering Calculations, 3 Ed., Mc-Graw Hill, 2004 A. Olaf, K.M. Watson and R. A. R.Hougen, Chemical Process Principles, Part 1: Material and Energy Balances, John Wiley & Sons, 1968

rd rd

CL 202

Fluid Mechanics

(3-1-0-8)

Properties and classification of fluids; fluid statics; velocity field; stream function; irrotational flow; integral and differential analysis for fluid motion: Reynolds' transport theorem; Navier-Stoke's equation; Euler & Bernoulli's equation; dimensional analysis and similitude; internal and external fluid flow: friction factor; energy losses in fittings, valves etc.; flow measuring devices; fluid machinery: pump, blower; agitation; introduction to non-Newtonian fluid; introduction to compressible flow.

Texts: 1. 2. R. W. Fox and A. T. McDonald, Introduction to fluid mechanics, 5 Ed., John Wiley & Sons, 1998. th W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill, International Edition, 2001.

th

References: 1. 2. B. R. Bird, E. W. Stewart, and N. E. Lightfoot, Transport Phenomena, John Wiley & Sons, 2 Ed., 2003. J. M. Coulson and J.F. Richardson, Chemical Engineering, Vol-1: Fluid flow, Heat Transfer and Mass th Transfer, Pergamon Press, 4 Ed., 1990.

nd

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 203

Chemical Engineering Thermodynamics - I

(2-1-0-6)

Thermodynamic systems; thermodynamic laws; equations of state; reversible and irreversible processes; entropy; application of first and second laws to steady/unsteady processes in open/closed systems; Gibbs and Helmholtz free energies; chemical potential and criteria of equilibrium; Maxwell equations and thermodynamic properties of pure substances; phase equilibria; chemical reaction equilibria; homogeneous reaction system.

Text: 1. J. M. Smith, H. C. V. Ness and M. M. Abott, Introduction to Chemical Engg. Thermodynamics, 7 Ed., McGraw Hill International Edition, 2010.

th

Reference: 1. S. I. Sandler, Chemical Engg. Thermodynamics, Wiley, New York, 1977.

Semester - 4

CL 204 Heat Transfer Operation (3-1-0-8)

Basic modes of heat transfer. Conduction: basic equations of one-dimensional, two-dimensional and three-dimensional conduction; steady conduction in slabs, cylinders and spheres; critical thickness of insulation; transient conduction: analytical solution for slabs; use of transient temperature charts for slabs, cylinders, and spheres; lumped system of analysis. Convection: equation of motion; equation of energy; hydrodynamic and thermal boundary layers; forced convection inside tubes, over cylinders and spheres; natural convection, Empirical equations for free and forced convection; boiling and condensation heat transfer; basic types of heat exchangers; overall heat transfer coefficient; LMTD method, effectiveness-NTU method. Radiation: black body and gray body radiation; shape factor; Kirchhoff's law; Radiation shields; radiation from gases. Evaporation: evaporator capacity, economy and types; single and multiple effect evaporators, forward and backward feed evaporation, evaporator calculations.

Texts: 1. 2. J. P. Holman, Heat Transfer, 8 Ed., McGraw - Hill, 1997. B. K. Dutta, Heat Transfer, Prentice Hall of India, 2001.

th

References: 1. 2. D.Q. Kern, Process Heat Transfer, 2 Ed., Tata McGraw - Hill, 1997. th W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill, International Edition, 2001.

nd

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 205

Mass Transfer Operation - I

(2-1-0-6)

Concepts of molecular diffusion and mass transfer coefficient; interphase mass transfer; the equilibrium stage approximation; conservation relations; reflux; constant molal overflow; batch distillation; Ponchon-Savarit and McCabe- Thiele analysis of binary distillation; introduction to multicomponent distillation; equilibrium solubility of gases in liquids; counter-current multi-stage absorption; continuous contact equipment; multi-component systems; absorption with chemical reaction

Texts: 1. 2. R. E. Treybal, Mass Transfer Operations, 3 Ed., McGraw -Hill International Edition, 1981. st B.K. Dutta, Principles of Mass Transfer and Separation Processes, 1 Ed., Prentice Hall of India, 2007.

rd

References: 1. 2. 3. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill International Edition, 2001 P. C. Wankat, Equilibrium-Staged Separations, Prentice Hall, 1989 rd C. J. Geankoplis, Transport Processes and Unit Operations, 3 Ed., Prentice Hall, India,1993.

th

CL 206

Process Equipment Design - I

(1-0-3-5)

Design of pressure vessel and vessel accessories like heads, nozzles, flanges, openings and supports; computer aided design (CAD) of heat exchanger; mechanical and fabricational aspects. Design of condenser, reboiler, and evaporator.

Texts: 1. 2. B. C. Bhattacharyya, Introduction to Chemical Equipment Design, CBS Publishers & Distributors, New Delhi, 2003. J. M. Coulson, J. F.Richardson and R. K. Sinnot, Coulson and Richardson's Chemical rd Engineering: Chemical Engineering Design (Vol. 6), 3 Ed.(Indian Print), Butterworth-Heinemann, 2004.

References: 1. 2. 3. E. Ludwig, Chemical Process Equipment Design, 3 Ed., Gulf Pub., 2002. S. M. Walas, Chemical Process Equipment Selection and Design, Butterworth-Heinemann, 1999. J. Douglas, Conceptual Design of Chemical Processes, Mc Graw-Hill, 1988.

rd

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 207

Chemical Engineering Thermodynamics - II

(2-1-0-6)

Pre-requisite: CL 203 or equivalent Chemical potential and criteria of equilibrium ; phase equilibria; phase-rule; partial molar quantities; Gibbs-Duhem Equation; thermodynamics of ideal and non-ideal solutions; excess properties; fugacity and activity coefficient models; vapour-liquid and liquid-liquid equilibria; solid-liquid equilibria; solubility of gases in liquids; chemical reaction equilibria; homogeneous reaction system ; heterogeneous reaction system; multiple reactions, work of separation.

Texts: th 1. J. M. Smith, H. C. V. Ness and M. M. Abott, Introduction to Chemical Engg. Thermodynamics, 7 . Ed., McGraw Hill, International Edition, 2010. References: 1. S. I. Sandler, Chemical Engg. Thermodynamics, Wiley, New York, 1977. 2. J. M. Prasusnitz, R. N. Lichtenthaler, and E. G. de Azevedo, Molecular Thermodynamics of FluidPhase Equilibria, Prentice Hall, Inc., 1986. th 3. S. I. Sandler, Chemical, Biochemical and Engineering Thermodynamics, 4 Ed., Wiley India, 2006.

CL 210

Fluid Mechanics Laboratory

(0-0-3-3)

Pre-requisite: CL 202 or equivalent. Laboratory experiments on Fluid flow, which include basic experiments on flow through pipes, channels, nozzles, packed beds, pipe-fittings and flow meters, pump test rigs, etc.

Text: 1. R. W. Fox and A. T. McDonald, Introduction to fluid mechanics, 5 Ed., John Wiley & Sons, 1998.

th

Reference: 1. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill, International Edition, 2001.

th

CL 211

Thermodynamics Laboratory

(0-0-3-3)

Pre-requisite: CL 203 or equivalent Laboratory experiments on Chemical Engineering Thermodynamics, which include basic experiments on vapor pressure estimation, vapour - liquid equilibrium; liquid - liquid equilibrium; heat of reaction; Joule - Thomson coefficient experiment and Equilibrium flash Distillation.

Indian Institute of Technology Guwahati

Chemical Engineering Department

Texts/References: 1. J. M. Smith, H. C. V. Ness and M. M. Abott, Introduction to Chemical Engg. Thermodynamics, 7 Ed., McGraw Hill, International Edition, 2010. 2. S. I. Sandler, Chemical Engg. Thermodynamics, Wiley, New York, 1977. th 3. S. I. Sandler, Chemical, Biochemical and Engineering Thermodynamics, 4 Ed., Wiley India, 2006.

th

Semester - 5

CL 301 Solid and Fluid-Solid Operations (3-0-0-6)

Particles: particle size and shape; particulate mass, size and shape distribution; measurement and analysis of average particle diameter. Size reduction: crushing, grinding and ultra-fine grinding; laws of grinding; size enlargement; agglomeration; screening and design of screens. Storage of solids; flow of solids by gravity; transportation of solids. Fluid solid systems: fluid particle interaction; forces on submerged bodies; flow around single particle; drag force and drag coefficient; settling velocity of a single particle in a fluid; hindered settling of particles; design of thickeners; gravity separation; heavy media separation; mineral jigs; tabling; flotation; packed bed; filtration; flow through packed bed and fluidized beds; cyclones; bag filters; centrifuges; hydro-cyclones; particle collection systems.

Text: 1. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill, International Edition, 2001.

th

References: 1. 2. W. L. Badgerand J. T. Banchero, Introduction to Chemical Engineering, Tata McGraw-Hill, International Edition, 1997. rd C. J. Geankoplis, Transport Processes and Unit Operations, 3 Ed., Prentice Hall, India,1993.

CL 303

Chemical Reaction Engineering - I

(2-1-0-6)

Classification of chemical reactions; single, multiple, elementary and nonelementary homogeneous reactions; order and molecularity; temperature dependency; constant and variable volume batch reactor; reaction rate; rate constant; collection and interpretation of kinetic data; parallel and series reaction; batch, ideal plug flow and CSTR reactor design with and without recycle; temperature and pressure effects; Residence Time Distribution.

Indian Institute of Technology Guwahati

Chemical Engineering Department

Texts: 1. 2. H. S. Fogler, Elements of Chemical Reaction Engineering, Prentice Hall, 2 Ed., New Jersey, 1992. nd O. Levenspiel, Chemical Reaction Engineering, 2 Ed., Wiley Eastern, 1972.

nd

Reference: 1. J. M. Smith, Chemical Engineering Kinetics, 3 Ed., McGraw Hill, 1980.

rd

CL 304

Process Equipment Design - II

(1-0-3-5)

Pre-requisite: CL205 or equivalent Computer aided design of sieve tray & packed bed absorption and distillation column, liquid-liquid extraction systems, dryer, adsorber, humidification chamber, reactors etc.

Texts: 1. 2. E. Ludwig, Chemical Process Equipment Design, 3 Ed., Gulf Pub., 2002 . J. Douglas, Conceptual Design of Chemical Processes, Mc Graw-Hill, 1988

rd

References: 1. 2. 3. B. C. Bhattacharyya, Introduction to Chemical Equipment Design, CBS Publishers & Distributors, New Delhi, 2003. S. M. Walas, Chemical Process Equipment Selection and Design, Butterworth-Heinemann, 1999. J. M. Coulson, J. F.Richardson and R. K. Sinnot, Coulson and Richardson's Chemical rd Engineering: Chemical Engineering Design (Vol. 6), 3 Ed. (Indian Print), Butterworth-Heinemann, 2004.

CL 306

Mass Transfer Operation - II

(2-1-0-6)

Pre-requisite: CL 205 or equivalent Simultaneous Heat and Mass Transfer; Drying: rate of drying for batch and continuous dryers; Humidification and Dehumidification: design of cooling towers; Adsorption: types and nature of adsorption, isotherm, stage wise and continuous adsorption; fixed, fluidized and moving beds; ionexchange; Extraction: triangular diagram; Leaching: single and multistage operation, equipment for leaching; Crystallization: Millers theory, yield calculations, crystallizers; Membrane processes: liquid & gas separation processes, microfiltration, ultra-filtration, nanofiltration, reverse osmosis.

Indian Institute of Technology Guwahati

Chemical Engineering Department

Texts: 1. 2. R. E. Treybal, Mass Transfer Operations, 3 Ed., McGraw -Hill International Edition, 1981. st B.K. Dutta, Principles of Mass Transfer and Separation Processes, 1 Ed., Prentice Hall of India, 2007.

rd

References: 1. 2. 3. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw-Hill International Edition, 2001 P. C. Wankat, Equilibrium-Staged Separations, Prentice Hall, 1989 rd C. J. Geankoplis, Transport Processes and Unit Operations, 3 Ed., Prentice Hall, India, 1993.

th

CL 312

Heat Transfer Laboratory

(0-0-3-3)

Pre-requisite: CL 204 or equivalent Laboratory experiments on Heat transfer operations, which include basic experiments on conduction, convection, condensation, heat exchanger, etc.

Texts: 1. 2. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw Hill, International Edition, 2001. th J. P. Holman, Heat Transfer, 8 Ed., McGraw - Hill, 1997

th

Reference: 1. D.Q. Kern, Process Heat Transfer, 2

nd

Ed.,Tata McGraw - Hill, 1997.

CL 313

Mass Transfer Laboratory

(0-0-3-3)

Pre-requisite: CL 205 or equivalent Laboratory experiments on mass transfer operations, which include basic experiments on distillation, absorption, crystallization, diffusion, drying, mass transfer with & without chemical reaction, cooling tower, etc.

Text: 1. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw Hill, International Edition, 2001.

th

Reference: 1. R. E. Treybal, Mass Transfer Operations, 3 Ed., McGraw Hill, International Edition, 1981.

rd

Indian Institute of Technology Guwahati

Chemical Engineering Department

Semester - 6

CL 307 Transport Phenomena (2-1-0-6)

Introduction to transport phenomena; molecular transport mechanisms and general properties; analogies amongst momentum, heat, and mass transport; boundary layer analysis for momentum, heat, & mass transfer; estimation of transport coefficient, non-Newtonian fluids, rheological characteristics of materials, agitation of non-Newtonian fluids. Heat & mass transfer with chemical reaction; Diffusion and chemical reaction inside a porous catalyst.

Text: 1. B. R. Bird, E. W. Stewart, N. E. Lightfoot, Transport Phenomena, 2

nd

Ed., John Wiley & Sons, 2003.

References: 1. 2. 3. J. W. Thomson, Introduction to Transport Phenomena, Pearson Education Asia, 2001. rd R. E. Treybal, Mass Transfer Operations, 3 Ed., McGraw -Hill International Edition, 1981 th J. P. Holman, Heat Transfer, 8 Ed., McGraw - Hill, 1997.

CL 308

Chemical Reaction Engineering - II

(2-1-0-6)

Pre-requisite: CL 303 or equivalent Heterogeneous reaction kinetics; selectivity; heterogeneous reactors: fluid-solid catalytic fixed bed reactor design principles; isothermal, adiabatic and non-isothermal operations; gas-solid noncatalytic reactor design; fluidized bed reactors; thermal stability in reactor operation.

Texts: 1. 2. H. S. Fogler, Elements of Chemical Reaction Engineering, 2 Ed., Prentice Hall, New Jersey, 1992. nd O. Levenspiel, Chemical Reaction Engineering, 2 Ed., Wiley Eastern, 1972.

rd nd

Reference: 1. J. M. Smith, Chemical Engineering Kinetics, 3 Ed., McGraw Hill, 1980.

CL 309

Process Control and Instrumentation

( 3-1-0-8)

First Principles model development; dynamics of first, second and higher order linear systems, open loop and closed loop systems; linearisation; feed back control; stability; root locus diagram; frequency response analysis; Bode stability criterion; Nyquist stability criterion; design of controller; dynamics of some complex processes; control valves and introduction to real time computer control of process equipment; cascade, feed forward, adaptive control; SISO; MIMO; A/D conversion, PLC architecture; Multi-variable control strategies.

Indian Institute of Technology Guwahati

Chemical Engineering Department

Text: 1. G. Stephanopoulos, Chemical Process Control: An Introduction to Theory and Practice, Prentice-Hall, New Jersey, 1984.

nd

References: 1. 2. D. R. Coughanowr, and L. B. Koppel, Process systems Analysis and Control, 2 Ed., Mc-Graw-Hill, 1991. W. L. Luyben, Process Modelling Simulation and Control for Chemical Engineers, McGraw Hill, 1990

CL 314

Numerical Methods in Chemical Engineering

(2-0-2-6)

Solution of simultaneous linear and non-linear equations; Eigenvalues and eigenvectors of matrixes; Statistical analysis of data; Curve fitting; Approximation of functions; Interpolation; Numerical integration and differentiation; Solution of ordinary differential equations - initial and boundary value problems; Solution of partial differential equations; Analysis of error and stability in numerical computing; Implementation of numerical methods on computer through programming in FORTRAN/C++ and commercial software such as MATLAB, NAG and IMSL routines.

Texts: 1. 2. S. C. Chapra and R. P. Canale, Numerical methods for engineers, Tata-McGraw-Hill, 2002. S. K. Gupta, Numerical methods for engineers, New Age International, 2001.

References: 1. A. Constantinides, Numerical methods with personal computers, McGraw-Hill, 1987. 2. F. Gerald, and P. O. Wheatley, Applied numerical methods, Pearson Education, 2003. 3. R. M. Somasundaram and R. M. Chandrasekaran, Numerical methods with C++ programming, Prentice-Hall of India, 2005. 4. W. H. Press, S. A. Teukolsky, W. T. Vellerling and B. P. Flannery, Numerical recipes in FORTRAN: the art of scientific programming, Cambridge University Press, 1992.

CL 315

Mechanical Operation Laboratory

(0-0-3-3)

Pre-requisite: CL 301 or equivalent This includes basic experiments on size reduction and size separation, filtration, settling, centrifuging, classification, gas-solid separation.

Text: 1. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw - Hill, International Edition, 2001. W. L. Badger and J. T. Banchero, Introduction to Chemical Engineering, Tata McGraw-Hill, International Edition, 1997. rd C. J. Geankoplis, Transport Processes and Unit Operations, 3 Ed., Prentice Hall, India, 1993.

th

References: 1. 2.

10

Indian Institute of Technology Guwahati

Chemical Engineering Department

Semester 7

CL 402 Chemical Process Technology (3-0-0-6)

Raw materials and principles of production of olefins and aromatics; typical intermediates from olefins and aromatics such as ethylene glycol, ethyl benzene, phenol, cumene and DMT, dyes, and pharmaceuticals; chemical processes based on raw materials sugar, starch, alcohol, cellulose, paper, glyceride, oils, soaps, detergents; industrial processes for the production of inorganic heavy chemicals such as acids, alkalis, salts, and fertilizers such as sulphuric, nitric, and phosphoric acids, soda ash, ammonia, etc.

Text: 1. C. L. Dryden, Outlines of Chemical Technology, Edited and Revised by M.Gopala Rao and S. Marshall rd , 3 Ed., Affiliated East West, New Delhi, 1997.

References: 1. 2. 3. T. G. Austin and S. Shreve, Chemical Process Industries, 5 Ed., McGraw Hill, New Delhi, 1984. th R. E. Kirk, and D. F. Othmer, Encyclopaedia of Chemical Technology, 4 Ed., Interscience, New York, 1991. th P. H. Groggins, Unit Processes in Organic Synthesis, 5 Ed., McGraw Hill, 1984.

th

CL 403

Process Equipment Design - III

( 2-0-2-6)

Pre-requisite: CL 205 or equivalent Principles of heat integration: Setting energy targets, Problem table algorithm, heat recovery pinch, heat exchanger network (HEN) representation, HEN design for maximum recovery, stream splitting, capital energy tradeoffs; Principles of multi-component distillation: Basic distillation design, sequencing of simple distillation columns, complex distillation columns, short-cut modeling of complex columns; Design of azeotropic and extractive distillation systems using residue curve maps.

Texts: 1. S. M. Walas, Chemical Process Equipment Selection and Design, Butterworth-Heinemann, 1999. 2. J. Douglas, Conceptual Design of Chemical Processes, McGraw-Hill, 1988 References: 1. 2. 3. 4. 5. 6. B. C. Bhattacharyya, Introduction to Chemical Equipment Design, CBS Publishers & Distributors, New Delhi, 2003. rd E. Ludwig, Chemical Process Equipment Design, 3 Ed., Gulf Pub., 2002. G. K. Sahu, Handbook of Piping Design, New Age Publisher, 2002. R. Smith, Chemical Process Design, McGraw Hill, New York, 1995. L.T. Biegler, I.E. Grossmann and A.W. Westerberg, Systematic Methods of Chemical Process Design, Prentice Hall, International Series, 1997 J. M. Coulson, J. F.Richardson and R. K. Sinnot, Coulson and Richardson's Chemical Engineering: rd Chemical Engineering Design (Vol. 6), 3 Ed. (Indian Print), Butterworth - Heinemann, 2004.

11

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 416

Process Control Laboratory

(0-0-3-3)

Pre-requisite: CL 309 or equivalent Laboratory experiments on process control & instrumentation, which include basic experiments on controlling namely pressure, temperature, flow and level. The cascade control and control valve characterization etc are also covered in this course.

Texts/References: 1. 2. 3. G. Stephanopoulos, Chemical Process Control: An Introduction to Theory and Practice, Prentice-Hall, New Jersey,1984. nd D. R. Coughanowr and L. B. Koppel, Process systems Analysis and Control, 2 Ed., Mc-Graw-Hill, 1991. W. L. Luyben, Process Modelling Simulation and Control for Chemical Engineers, McGraw Hill, 1990.

CL 417

Chemical Reaction Engineering Laboratory

(0-0-3-3)

Pre-requisite: CL 303 plus CL 308 or equivalent Laboratory experiments on reaction engineering which include basic experiments on different types of reactors with residence time distribution (RTD) study.

Texts: 1. O. Levenspiel, Chemical Reaction Engineering, 2

nd

Ed., Wiley Eastern1972.

References: 1. 2. H. S. Fogler, Elements of Chemical Reaction Engineering, 2 Ed., Prentice Hall, New Jersey, 1992. rd J. M. Smith, Chemical Engineering Kinetics, 3 Ed., McGraw Hill, 1980.

nd

CL 498

Project - I

(0-0-6-6)

Semester - 8

CL 401 Process Design & Project Engineering (3-1-0-8)

Pre-requisite: CL 403 or equivalent Input information and batch versus continuous; input-output structure of the flow sheet; recycle structure of the flowsheet; application of separation system principles for case studies; application of heat exchanger network design principles for case studies; cost diagrams and quick screening of process alternatives; preliminary process optimization; process retrofitting. Equipment sizing and costing for different process units; Cost information, estimating capital and operating costs, total capital investment and total product costs, time value of money, measures of process profitability, simplifying economic analysis for conceptual designs, techno-economic feasibility report writing.

12

Indian Institute of Technology Guwahati

Chemical Engineering Department

Texts: 1. 2. J. Douglas, Conceptual Design of Chemical Processes, McGraw Hill, 1989. th P. Timmerhaus, Plant Design and Economics for Chemical Engineers, 4 Ed, McGraw-Hill, 1991.

References: 1. 2. 3. L.T. Biegler, I.E. Grossmann, A.W. Westerberg, Systematic Methods of Chemical Process Design, Prentice Hall, International Series, 1997 R. Smith, Chemical Process Design, McGraw Hill, New York, 1995. nd E. E. Ludwig, Applied Project Engineering, 2 Ed., Gulf Publishing Company, Houston, 1988.

CL 404

Material Science

(3-0-0-6)

Atomic structure and interatomic bonding; structure of crystalline solids; imperfections; diffusion; Mechanical properties of metals; dislocation; strengthening; failure; phase diagram; structure, properties, applications, processing of ceramics and polymers; composites; corrosion degradation of materials; corrosion protection; electrical, thermal, magnetic and optical properties; property requirements and material selection.

Text: 1. V. Raghavan, V., Material Science & Engineering, Prentice Hall, 1996.

References: 1. 2. W. D. Callister (Jr.), Material Science and Engineering - an Introduction, 6 Ed., John Wiley & Sons, 2003. rd J.F. Shackelford and W. Alexander, Material Science and Engineering Handbook, 3 Ed., CRC, 2000.

th

CL 499

Project - II

(0-0-6-6)

13

Indian Institute of Technology Guwahati

Chemical Engineering Department

BTECH ELECTIVES

CL 420 Polymer Technology ( 3-0-0-6)

Classification of polymerization reactions such as condensation, free radical, ionic, coordination reactions, their mechanism and rate; suspension and emulsion polymerization; copolymerization; batch and continuous reactors; different molecular weights with methods of determination; molecular weight distribution; crystalline and amorphous structure; viscoelasticity; rubber elasticity; glass transition; production of plastics, rubbers, fibers; polymer rheology; polymer processing; analysis using nonNewtonian fluid model.

Text/References: 1. J. R. Fried, Polymer Science & Technology, Prentice Hall of India, 2000. 2. P. Bahadur and N. V. Sastry, Principles of Polymer Science, Narosa Publishing House, 2002. 3. V. R. Gowariker, N. V. Viswanathan and J. Sreedhar, Polymer science, New Age International (P) LTd., 2001.

CL 421

Introduction. Microbiology:

Biochemical Engineering

Cell structure, characterization,

(3-0-0-6)

classification of microorganisms;

environmental and industrial microbiology; cell nutrients and growth media. Chemicals of Life: Repetitive and non repetitive biological polymers, lipids, fatty acids and other related lipids, carbohydrates, mono-, di- and polysaccharides, amino acids and proteins, structure of proteins, protein denaturation and renaturation, antibodies, nucleic acids, nucleotides to RNA and DNA, DNA double helix model. Kinetics of Enzyme-Catalyzed Reactions: Chemical kinetics fundamentals, introduction to enzymes, classification of enzymes, enzymes of industrial importance, enzyme catalyzed reactions and kinetics, determination of kinetic parameters, inhibitors and inhibition kinetics, enzyme deactivation, immobilized enzyme technology. Metabolism and Bioenergetics: Thermodynamic principles, metabolic pathways for carbohydrates, lipids and proteins; ATP, TCA cycles etc. Cell Growth and Product Formation: Growth patterns and kinetics in batch culture, models with growth inhibitors, the ideal chemostat; Stochiometry of microbial growth, theoretical prediction of yield coefficients. Bioprocess Systems: Transport phenomena in bioprocesses, mass transfer in bioreactors, solid-liquid mass transfer, power requirement, heat transfer; Various types of bioreactors, Scale-up and its difficulties; Downstream Processing: Strategies to recover and purify products Control of microorganism: Control fundamentals, antimicrobial action, control of microorganisms by physical and chemical method.

14

Indian Institute of Technology Guwahati

Chemical Engineering Department

Texts/References: 1. J. E. Bailey and D. F. Ollis, Biochemical Engineering Fundamentals, 2 Ed., McGraw Hill, 1986. 2. B. Atkinson, Biochemical Reactors, Pion Ltd., London, 1974. nd 3. S. Aiba, A. E. Humhrey and N. F. Mills, Biochemical Engineering, 2 Ed., Academic Press, New York, 1973. nd 4. M. L. Schuler and F. Kargi, Bioprocess Engineering: Basic Concepts, 2 Ed., Prentice Hall, International Series, 2002.

nd

CL 422

Process Plant Safety

(3-0-0-6)

Concepts and definition; safety culture; storage of dangerous materials; plant layout; safety systems; technology and process selection; scale of disaster; vapor cloud explosions; control of toxic chemicals; runaway reactions; relief systems; risk and hazard management; safety versus production; risk assessment and analysis; hazard models and risk data; identification, minimization, and analysis of hazard; tackling disasters: plan of emergency; risk management routines; emergency shut down systems; human element in the design of safety.

Texts/References: 1. 2. 3. 4. P. C. Nicholas, Safety management practices for hazard waste materials, Dekker, 1996. F. P. Lees, Loss Prevention in Process Industries, Vols.1 and 2, Butterworth, 1983. W. E. Baker, Explosion Hazards and Evaluation, Elsevier, Amsterdam, 1983. O. P. Kharbanda and E.A.Stallworthy, Management of Disasters and How to Prevent Them, Grower, 1986.

CL 423

Non-traditional Optimization Techniques

(3-0-0-6)

Non-traditional optimization techniques; population based search algorithms; evolutionary strategies; evolutionary programming; simulated annealing; genetic algorithm; differential evolution; different strategies of differential evolution; memetic algorithms; scatter search; ant colony optimization; selforganizing migrating algorithm; other emerging hybrid evolutionary computation techniques; engineering applications involving highly non-linear process with many constraints and multiobjective optimization problems.

Texts/References: 1. 2. 3. 4. T. F. Edgar and D. M. Himmelblau, Optimization of Chemical Processes, McGraw Hill, International Editions: Chemical Engineering Series, 1989. G. S. Beveridge, and R.S. Schechter, Optimization Theory and Practice, McGraw Hill, New York, 1970. G. V. Rekllaitis, A. Ravindran and K. M. Ragsdell, Engineering Optimization- Methods and Applications, John Wiley, New York, 1983.

15

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 424

Environmental Pollution Control

(3-0-0-6)

Sources of water, air and land pollution; environmental laws & standards; design of pollution abatement systems for particulate matter and gaseous constituents; hazardous waste disposal and treatment; solid-waste disposal and recovery of useful products; specification of clean technologies and recovery schemes of useful chemicals; pollution prevention through process modification; recovery of by-products; energy recovery; waste utilization and recycle and reuse and waste generation minimization; design of control equipment and systems.

Text/References: 1. 2. 3. 4. 5. S.P. Mahajan, Pollution Control in Process Industries, Tata-McGraw Hill, 1985. N. L. Nemerow, Liquid waste of Industry - Theories, Practices and Treatment, Addison Weseley, NewYork, 1971. W. J. Weber, Physico-Chemical Processes for Water Quality Control, Wiley Interscience, New York,1969. W. Strauss, Industrial gas Cleaning, Pergamon, London, 1975. A.C. Stern, Air Pollution, Vols. I to VI, Academic Press, New York 1968.

CL 425

Novel Separation Techniques

(3-0-0-6)

Concepts and definitions in adsorption; adsorbents types; their preparation and properties; different types of adsorption isotherms and their importance; adsorption types; basic mathematical modeling with suitable initial and boundary conditions for different cases such as thermal swing, pressure swing, and moving bed adsorption; chromatography; membrane classification, chemistry, structure and characteristics; resistances for mass transfer; design consideration for reverse osmosis, ultrafiltration and electrodialysis; pervaporation; gaseous separations; liquid membrane; introduction to other processes such as reactive distillation, supercritical fluid extraction, biofiltration, etc.

Text/References: 1. P.C. Wankat, Large Scale Adsorption and Chromatography, CRC Press, Boca Raton, 1986. 2. D. M. Ruthven, Principles of adsorption and adsorption processes, John Wiley & sons, 1984. 3. D. M. Ruthven, S. Farooq and K. S. Knaebel, Pressure Swing Adsorption, Wiley-VCH, 1994. 4. S. Sourirajan and T. Matsura, Reverse Osmosis and Ultra-filtration-Process Principles, NRC Publication, Ottawa, 1985. 5. J. G. S. Marcano and T. T. Tsotsis, Catalytic membranes and membrane reactor, John Wiley, 2002. 6. M.A. McHugh and V. J. Krukonis, Supercritical fluid extraction, Butterworths, Boston, 1985.

16

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 426

Introduction to Interfacial Science & Engineering (3-0-0-6)

Phenomenology of colloidal materials; Brownian diffusion; long range van der Waals forces; double layer forces and short range forces; DLVO theory of stability of lyphobic colloids; electrokinetic phenomena; association colloids; interfacial tension; wetting and contact angle; capillary hydrostatics; interfacial rheology and stability; some selected applications of principles of colloid and interface science in detergents, personal products, pharmaceuticals, food, textile, paint and petroleum industries.

Text/References : 1. 2. 3. 4. 5. P. C. Hiemenz and R.Rajgopalan, Principles of Colloid and Surface Chemistry, 3 Ed., Dekker, 1997. C. A. Miller, and P.Neogi, Interfacial Phenomena : Equilibrium and Dynamic Effects, Dekker, 1985. V.G. Levich, Physicochemical Hydrodynamics, Prentice Hall Inc., 1962. R.J. Hunter, Foundations of Colloid Science, Vols. I and II, Oxford Science Publications, 1989. D. A. Edwards, H. Brenner and D. T. Wasan, Interfacial Transport Processes and Rheology,Butterworth, Heinmen, 1991.

rd

CL 427

Petroleum Refinery & Petrochemicals

(3-0-0-6)

Origin and occurrence, composition, classification and physico-chemical properties of petroleum; testing and uses of petroleum products; refining Processes such as distillation, cracking, reforming; conversion of petroleum gases into motor fuel, aviation fuel; lubricating oils and petroleum waxes; chemicals and clay treatment of petroleum products, desulfurization; refining operations Dehydration, Desalting, Gas separation, Natural gas production and gas sweetening; tube still heater design; product profile of petrochemicals; petrochemical feed stocks; olefin and aromatic hydrocarbons production; Treatment and upgrading of olefinic C4 and C5 cuts; chemicals from C1 compounds, ethylene and its derivatives, propylene and its derivatives, butadiene and butene; BTX chemicals.

Text/References: 1. 2. 3. W.L. Nelson, Petroleum Refinery Engineering, McGraw Hill, New York, 1961. K. H. Altgelt and M. M. Boduszynski, Composition and analysis of heavy petroleum fractions, Dekker, 1994. th J. H. Gary and G. E. Handwork, Petroleum refining technology and economics, 4 Ed., Dekker, 2001.

17

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 428

Fuel Engineering

( 3-0-0-6)

Conventional and non-conventional energy sources; solar energy; wind energy; energy from biomass; energy survey in India. Solid fuels: origin and composition of coal; analysis and properties of coal; coal classification; properties and storage of coal; coal carbonization, gasification and liquefaction. Liquid fuels: origin and composition of petroleum; petroleum processing; petroleum refining in India. Combustion process: combustion stoichiometry and combustion thermodynamics; gas burners; oil burners; coal burning equipment.

Texts/References: 1. 2. 3. S. Sarkar, Fuel & combustion, 2 Ed., Orient Longman, 1990. J. G. Speight, Fuel Science & Technology Handbook, Dekker, 1990. R. E. Haytes and S.T. Kocaczkowski, Introduction to catalytic combustion, Gordon & Beach, 1997.

nd

CL 429

Catalysis

(3-0-0-6)

Principle of catalytic reaction engineering; mechanism of contact catalysis; kinetics of chemical reaction in homogeneous and heterogeneous catalysis; selecting catalytic agents. Fluid catalytic cracking; Design and developing industrial catalysts: preparation of catalysts; characterization of catalysts; analytical instruments, monitors and controllers that are used to prepare and characterize catalysts and to conduct detailed kinetic studies. Practical examples of industrial catalysts: Zeolite catalyst applications: Transformation and Synthesis of Zeolite using by experimental apparatus for characterization, reactivity test; Heavy oil cracking, Development of Clay Adsorbent for KeroMerox Refining Process, Dimethylamine synthesis using mordenite catalyst.

Texts/References: 1. 2. 3. J. J. Carberry, Chemical and Catalytic Reaction Engineering, Dover, 2001. J. Weitkamp, and L. Puppe (eds.), Catalysis and Zeolites: Fundamentals and Applications, Springer Verlag, 1999. S. S. E. H. Elnashaie and S. S. Elshishini, Dynamic Modelling, Bifurcation and Chaotic Behaviour of GasSolid Catalytic reactors, Taylor and Francis, 1996.

---000---

18

Indian Institute of Technology Guwahati

DEPARTMENT OF CHEMICAL ENGINEERING

Course Structure & Syllabi for MINOR programme in Chemical Engineering

Semester 3 th 4 5

th rd

Course Code CL 251M CL 252M CL 351M CL 352M CL 451M

Course Title Fluid Mechanics Thermodynamics and Heat Transfer Mass Transfer Operations Chemical Reaction Engineering Process Engineering Total credits

L-T-P-C 3-0-0-6 3-0-0-6 3-0-0-6 3-0-0-6 3-0-0-6 15 -0 -0 -30

6 th 7

th

CL 251M

Preamble:

Fluid Mechanics

(3-0-0-6)

Fluid mechanics is the study of fluids (e.g., gases, liquids and plasmas) and the forces on them. It is a branch of continuum mechanics. The aim of this course is to formulate chemical engineering problems in mathematical terms by employing the appropriate balances and/or correlations, solve the resulting equations using an appropriate solution method, and analyze experimental and theoretical results. Course contents: Properties and classification of fluids: Viscosity, surface tension, Newtonian and non-Newtonian fluids, Physical classification and types of flow; Fluid statics; Fluid kinematics: concept of stress, rate of strain, streamlines, streak lines, path lines, stream function; Mathematical models of fluid motion: Navier-Stokes equation, Euler and Bernoulli equation; Dimensional Analysis and dimensionless numbers; Boundary layer flow and flow in pipes and ducts, friction factor, energy losses in fittings, valves etc., flow in multiple-pipe systems ; Flow measuring devices: pitot tube, venturi meter, orifice meter, rotameter etc.; Pumps; Flow through packed beds.

Texts:

1. V. Gupta and S. K. Gupta, Fluid Mechanics and its applications, New Age Intl., 1984. th 2. W.L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw-Hill, 2001.

References: 1. R.W. Fox and A. T. McDonald, Introduction to fluid mechanics, 5th. Ed., John Wiley & Sons, 1998. 2. F.M. White, Fluid Mechanics, 5th Ed., MacGraw Hill, 2005.

19

Indian Institute of Technology Guwahati

Chemical Engineering Department

CL 252M

Preamble:

Thermodynamics and Heat Transfer

(3-0-0-6)

This course encompasses thermodynamics and heat transfer. Thermodynamics is primarily concerned with the application to phase and reaction equilibria in multi-component systems. Its application includes heat-to-work and work-to-heat conversion devices. Thermodynamic properties of non-ideal solutions, vaporliquid and liquidliquid equilibria are covered in this course. Heat Transfer deals with the flow of heat via three common modes, viz. conduction, convection and radiation. The principles behind these modes and their applications to chemical engineering problems are covered.

Course contents:

Thermodynamic systems; thermodynamic laws; equations of state; reversible and irreversible processes; entropy; application of first and second laws; Gibbs and Helmholtz free energies; Maxwell relations; chemical potential and criteria of equilibrium; vapour liquid equilibrium. Steady conduction in slabs, cylinders and spheres; critical thickness of insulation; use of transient temperature charts; lumped system of analysis; hydrodynamic and thermal boundary layers; forced and natural convection; boiling and condensation heat transfer; basic types of heat exchangers; overall heat transfer coefficient; LMTD method; black body and gray body radiation; radiation shields; single and multiple effect evaporators.

Texts: 1. J.M. Smith, H. C. Van Ness and M. M. Abott, Introduction to Chemical Engg. Thermodynamics, McGraw th Hill International edition, 5 Ed., 1996. 2. B.K. Dutta , Heat Transfer, Prentice Hall of India, 2001. References: 1. S.I. Sandler, Chemical Engg. Thermodynamics, Wiley, New York, 1977 th 2. J.P. Holman, Heat Transfer, McGraw - Hill, 8, Ed., 1997. th 3. W.L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, 6 Ed., McGraw Hill, International Edition, 2001. nd 4. D.Q. Kern, Process Heat Transfer, Tata McGraw Hill, 2 Ed., 1997.

CL 351M

Preamble:

Mass Transfer Operations

(3-0-0-6)

This course will provide the fundamental concepts of mass transfer principles like diffusive and convective mass transfer, interphase mass transfer and application of these concepts to real engineering problems using distillation and absorption. This course will also provide an introductory concept of chemical process calculation.

20

Indian Institute of Technology Guwahati

Chemical Engineering Department

Course contents:

Concepts of molecular diffusion and mass transfer coefficient; Introduction to multi-phase systems; vapor pressure; humidity and saturation; phase equilibrium; ideal and non-ideal mixtures; interphase mass transfer; conservation relations with recycle, bypass and purge; reflux; constant molal overflow; batch distillation; McCabe-Thiele analysis of binary distillation; equilibrium solubility of gases in liquids; counter-current multi-stage absorption.

Texts:

1. 2. R. E. Treybal, Mass Transfer Operations, McGraw -Hill International Edition, 3rd Ed., 1981. D. M. Himmelblau, Basic Principles and Calculations in Chemical Engineering, 6th Ed., Prentice Hall of India, 2001.

References: 1. 2. 3. 4. Dutta, B. K., Principles of Mass Transfer and Separation Processes, Prentice Hall, India, 2007. rd C. J. Geankoplis, Transport Processes and Unit Operations, 3 Ed., Prentice Hall, India, 1993. W. L. McCabe, J. Smith and P. Harriot, Unit Operations of Chemical Engineering, McGraw - Hill th International Edition, 6 Ed., 2001. rd R. M. Felder, Elementary Principles of Chemical Processes, 3 Ed., John Wiley & Sons, Asia, 1999.

CL 352M

Preamble:

Chemical Reaction Engineering

(3-0-0-6)

This course will provide an overview of chemical kinetics and reactor design from the basics to an intermediate level. The coverage will be rather broad. This course applies the concepts of reaction rate, stoichiometry and equilibrium to the analysis of chemical reacting systems such as derivation of rate expression from reaction mechanism, equilibrium or steady state assumptions, design of chemical reactors via synthesis of chemical kinetics, and mass and energy balances. The target is to provide students with the theoretical/analytical background to understand chemical kinetics and reactor design and to handle the complex problems. Course contents: Introduction to chemical kinetics and engineering; Stoichiometry; Kinetics of homogeneous reactions; Interpretation of batch reactor data; Ideal reactors for a single reaction; Design for single and parallel reactions; Temperature and pressure effects; Introduction to Non-ideal flow in a reactor.

Texts: 1. O. Levenspiel, Chemical Reaction Engineering, Third edition, Wiley-India, New Delhi 2006. th 2. H. S. Fogler, Elements of Chemical Reaction Engineering, 4 Ed., Prentice-Hall of India, New Delhi, 2009.

21

Indian Institute of Technology Guwahati

Chemical Engineering Department

Reference:

1. L. D. Schmidt, The Engineering of Chemical Reactions, 2

nd

Ed., Oxford University Press, 2010.

CL 451M

Preamble:

Process Engineering

(3-0-0-6)

The vast subject of process engineering involves the analysis, design and operation of chemical and biochemical processes. While other undergraduate subjects in chemical engineering addresses the engineering aspects associated to either unit processes or unit operations, process engineering attempts to assimilate the principles involved in these functional operations to evolve towards a mature understanding of the process along with its efficacy. This course broadly outlines two functional features of process engineering, namely, conceptual design and analysis of chemical processes with special reference to process flow-sheeting and application of control theory principles in order to relate the dependence of dependent variables on independent variables associated to a process. Course contents: Process flow-sheeting; PFD and P&ID, documents and symbols; outlines of unit operations and unit processes; sizing and costing of process equipment; first principles model development; degrees of freedom; linearization of nonlinear process; dynamics of first order and second order linear systems; stability analysis of open loop process; frequency response analysis; Bode and Nyquist stability criterion; design of feedback controller P, PI and PID.

Texts: 1. S. M. Walas, Chemical Process Equipment Selection and Design, Butterworth-Heinemann, 1999. 2. G. Stephanopoulos, Chemical Process Control: An Introduction to Theory and Practice, Prentice-Hall, New Jersey, 1984. References: 1. W. L. Badger and J. T. Banchero, Introduction to Chemical Engineering, Tata McGraw-Hill International Edition, 1997. 2. R. Smith, Chemical Process Design, McGraw Hill, New York, 1995.

----000---

22

You might also like

- Escaping The Sword of Damocles PDFDocument10 pagesEscaping The Sword of Damocles PDFKanjakha PalNo ratings yet

- Harvard ModeloDocument45 pagesHarvard ModeloRodrigo Cru Cruz HNo ratings yet

- Deloitte NL Manufacturing Opportunities For The Fermentation Based Chemical Industry 2014 PDFDocument58 pagesDeloitte NL Manufacturing Opportunities For The Fermentation Based Chemical Industry 2014 PDFKanjakha PalNo ratings yet

- Manual Casio Fx-9860GIIDocument412 pagesManual Casio Fx-9860GIISantiagoNo ratings yet

- Medieval India Satish ChandraDocument139 pagesMedieval India Satish ChandraPruthvi Kommu90% (10)

- 20 Transferable Skills For PhDs in Biotech, Biomed & BiopharmaDocument37 pages20 Transferable Skills For PhDs in Biotech, Biomed & BiopharmaSneha Gupta100% (1)

- Harvard ModeloDocument45 pagesHarvard ModeloRodrigo Cru Cruz HNo ratings yet

- Top 20 Industry Positions for PhDs: Application Scientist & Quantitative AnalystDocument58 pagesTop 20 Industry Positions for PhDs: Application Scientist & Quantitative AnalystTwinkle KheraNo ratings yet

- Nusselt Number Liq MetalsDocument7 pagesNusselt Number Liq MetalsKanjakha PalNo ratings yet

- 2017ss Sheen CatalogDocument12 pages2017ss Sheen CatalogKanjakha PalNo ratings yet

- Manual Casio Fx-9860GIIDocument412 pagesManual Casio Fx-9860GIISantiagoNo ratings yet

- 20 Transferable Skills For PhDs in Biotech, Biomed & BiopharmaDocument37 pages20 Transferable Skills For PhDs in Biotech, Biomed & BiopharmaSneha Gupta100% (1)

- Manual Casio Fx-9860GIIDocument412 pagesManual Casio Fx-9860GIISantiagoNo ratings yet

- State Space ModellingDocument19 pagesState Space Modellingindula123No ratings yet

- +50 Business Model Examples PDFDocument119 pages+50 Business Model Examples PDFKanjakha Pal50% (2)

- Lec 1Document20 pagesLec 1Kanjakha PalNo ratings yet

- Success Story Uni HD - BASFDocument1 pageSuccess Story Uni HD - BASFKanjakha PalNo ratings yet

- Span TweenDocument0 pagesSpan Tweenbexigaobrother100% (1)

- PGSG Spring Career Fair Report Data Student DemographicsDocument4 pagesPGSG Spring Career Fair Report Data Student DemographicsKanjakha PalNo ratings yet

- Guideline: Computational Interdisciplinary Graduate ProgramsDocument16 pagesGuideline: Computational Interdisciplinary Graduate ProgramsKanjakha PalNo ratings yet

- Soy Products GDocument48 pagesSoy Products GKanjakha PalNo ratings yet

- BMV Documentation ListDocument1 pageBMV Documentation ListKanjakha PalNo ratings yet

- CH10Document5 pagesCH10Kanjakha PalNo ratings yet

- Global Top 50Document4 pagesGlobal Top 50Kanjakha Pal100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The ICIS Top 100 Chemical Companies saw the good times roll in 2007, but 2008 brings a more challenging environment, testing their mettleDocument5 pagesThe ICIS Top 100 Chemical Companies saw the good times roll in 2007, but 2008 brings a more challenging environment, testing their mettle123456789pppppNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Design Plan: A Performance Task in GeometryDocument12 pagesDesign Plan: A Performance Task in GeometryRobert Ryan SantiagoNo ratings yet

- Control PhilosophyDocument2 pagesControl PhilosophytsplinstNo ratings yet

- Linear Thermal Expansion of Solid Materials With A Vitreous Silica DilatometerDocument7 pagesLinear Thermal Expansion of Solid Materials With A Vitreous Silica Dilatometerluis_may22No ratings yet

- Manual 1Document37 pagesManual 1Şahin GüngörNo ratings yet

- Biology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014Document13 pagesBiology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014santosh.manojNo ratings yet

- Sequelize GuideDocument5 pagesSequelize Guidemathur1995No ratings yet

- Centrifugal Compressor Operation and MaintenanceDocument16 pagesCentrifugal Compressor Operation and MaintenanceNEMSNo ratings yet

- Qualcomm LTE Performance & Challenges 09-01-2011Document29 pagesQualcomm LTE Performance & Challenges 09-01-2011vembri2178100% (1)

- ASP Flashcards - QuizletDocument36 pagesASP Flashcards - QuizletRehman MuzaffarNo ratings yet

- 10th Term Exams Computer Science PaperDocument2 pages10th Term Exams Computer Science PaperMohammad Tariq JavaidNo ratings yet

- FDocument1 pageFDiego PorrasNo ratings yet

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioNo ratings yet

- PTP - Level MethodsDocument23 pagesPTP - Level Methodssasikiran mNo ratings yet

- Astm A6 A6m-08Document62 pagesAstm A6 A6m-08Vũ Nhân HòaNo ratings yet

- Bilstein SZ SL Sls 2010Document16 pagesBilstein SZ SL Sls 2010Wimin HungNo ratings yet

- Bill of Material: The Hanover CompanyDocument17 pagesBill of Material: The Hanover CompanyLIVIANo ratings yet

- Displaymax JR 1500 SpecsDocument1 pageDisplaymax JR 1500 SpecsFRANCISCONo ratings yet

- Silo Cement CalculationDocument11 pagesSilo Cement CalculationFikriaraz AfifNo ratings yet

- Smart Dustbin using ArduinoDocument22 pagesSmart Dustbin using ArduinoEr Dinesh TambeNo ratings yet

- PDS - GulfSea Hydraulic AW Series-1Document2 pagesPDS - GulfSea Hydraulic AW Series-1Zaini YaakubNo ratings yet

- WPS Office 2016Document22 pagesWPS Office 2016Muhammad Aliff SyukriNo ratings yet

- Eltek PSR 327Document2 pagesEltek PSR 327fan liuNo ratings yet

- Lsantos - Reflecting Writing For Optimization ProjectDocument2 pagesLsantos - Reflecting Writing For Optimization Projectapi-341418797No ratings yet

- DSD - Assignment 1 2018Document3 pagesDSD - Assignment 1 2018Naveen KumarNo ratings yet

- Wartsila CPP PaperDocument4 pagesWartsila CPP Papergatheringforgardner9550No ratings yet

- Visualizing Interstellar WormholesDocument14 pagesVisualizing Interstellar WormholesFranciscoNo ratings yet

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocument12 pagesProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1No ratings yet

- Color Order SystemsDocument30 pagesColor Order SystemsBeyene DumechaNo ratings yet

- Turbine Buyers Guide - Mick Sagrillo & Ian WoofendenDocument7 pagesTurbine Buyers Guide - Mick Sagrillo & Ian WoofendenAnonymous xYhjeilnZNo ratings yet

- SERVICE MANUAL CRAWLER EXCAVATOR R210LC-7Document1 pageSERVICE MANUAL CRAWLER EXCAVATOR R210LC-7DmitryNo ratings yet