Professional Documents

Culture Documents

LCD

Uploaded by

Nayeli Michel RuizOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LCD

Uploaded by

Nayeli Michel RuizCopyright:

Available Formats

SPECIFICATION FOR LCD MODULE

Model No. TM162AAA6-1

Prepared by: Date:

Checked by : Date:

Verified by : Date:

Approved by: Date:

TIANMA MICROELECTRONICS CO.. LTD

1/23

REVISION RECORD

Date Ref. Page Revision No. Revision Items

Check &

Approval

2/23

1. General Specifications:

1.1 Display type: TN

1.2 Display color*:

Display color: Blue-Black

Background: White

1.3 Polarizer mode: Reflective/Positive

1.4 Viewing Angle: 6:00

1.5 Driving Method: 1/16 Duty 1/5 Bias

1.6 Backlight: None

1.7 Display Fonts: 5 x 7 dots + Cursor (1 Character)

1.8 Controller: HCD66701A00

1.9 Data Transfer: 8 Bit Parallel

1.10 Operating Temperature: 0----+50

Storage Temperature: -20----+60

1.11 Outline Dimensions: Refer to outline drawing on next page

1.12 Dot Matrix: 16 Characters X 2 Lines

1.13 Dot Size: 0.55X0.50(mm)

1.14 Dot Pitch: 0.60X0.55 (mm)

1.15 Weight: 20g

1.16 PCB edtion: TM162AD P1-2

* Color tone is slightly changed by temperature and driving voltage.

2

.

O

u

t

l

i

n

e

D

r

a

w

i

n

g

4

/

6

/

0

1

h

t

t

p

:

/

/

6

6

.

7

0

.

1

3

9

.

1

0

1

/

a

s

s

e

t

t

s

/

d

r

a

w

i

n

g

s

/

1

6

2

a

g

.

d

w

f

4/23

3. LCD Module Part Numbering System

OPTIONAL IC INDICATOR

(EOR EACTORY USE)

MODIEICATION

CODE DESIGNATOR

VIEWING DIRECTION

NONE: 6:00 VIEWING DIRECTION

BACKLIGHT TYPE

A: REELECTIVE.

WITHOUT BACKLIGHT

LCD TYPE

A: TN. POSITIVE

MODULE SERIES

MODULE TYPE

3 DIGITS INDICATING 16

CHARACTERS X 2 LINES

T: TIANMA

M: MODULE

5/23

4. Circuit Block Diagram

6/23

5. Absolute Maximum Ratings

Item Symbol Min. Max. Unit Remark

Power Supply Voltage V

DD

V

SS

-0.3 7.0

LCD Driving Voltage V

LCD

-0.3 13.0

V

Operating Temperature

Range

T

OP

0 +50

Storage Temperature

Range

T

ST

-20 +60

No

Condensation

7/23

6. Electrical Specifications and Instruction Code

6.1 Electrical characteristics

Item Symbol Min. Typ. Max. Unit

Supply Voltage

(Logic)

VDD VSS

4.5 5.0 5.5 V

Supply Voltage

(LCD Drive)

VLCD

- 4.7 - V

High

V

V

DD

=5.0

0.7V

DD

- V

DD

+0.3 V

Input

Signal

Voltage

Low

V

V

DD

=5.0

-0.3 -

0.2 V

DD

V

Supply current

(Logic)

I

VDD VSS

=5.0

- 1.5 2.0

mA

Supply current

(LCD Drive)

I

- 0.40 0.6

mA

8/23

6.2 Interface Signals

Pin No. Symbol Level Description

1 Vss 0V Ground

2 Vcc 5.0V Power supply voltage for logic and LCD(+)

3 Vee 0.3V Power supply voltage for LCD(-)

4 RS H/L Selects registers

5 R/W H/L Selects read or write

6 E H/L Starts data read/write

7 DB0 H/L Data bit0

8 DB1 H/L Data bit1

9 DB2 H/L Data bit2

10 DB3 H/L Data bit3

11 DB4 H/L Data bit4

12 DB5 H/L Data bit5

13 DB6 H/L Data bit6

14 DB7 H/L Data bit7

15

NC - No signal

16

NC - No signal

9/23

6.3 Interface Timing Chart

AC Characteristics (V

CC

= 2.7 to 5.5V, T

a

= 30 to +75C*

3

)

Write Operation

Item Symbol Min Typ Max Unit Test Condition

Enable cycle time t

cycE

1000 ns

Enable pulse width (high level) PW

EH

450

Enable rise/fall time t

Er

, t

Ef

25

Address set-up time (RS, R/W to E) t

AS

40

Address hold time t

AH

20

Data set-up time t

DSW

195

Data hold time t

H

10

Read Operation

Item Symbol Min Typ Max Unit Test Condition

Enable cycle time t

cycE

1000 ns

Enable pulse width (high level) PW

EH

450

Enable rise/fall time t

Er

, t

Ef

25

Address set-up time (RS, R/W to E) t

AS

40

Address hold time t

AH

20

Data delay time t

DDR

350

Data hold time t

DHR

10

10/23

Timing Characteristics

RS

R/W

E

DB0 to DB7

VIH1

VIL1

VIH1

VIL1

t

AS

t

AH

VIL1 VIL1

t

AH

PW

EH

t

Ef

VIH1

VIL1

VIH1

VIL1

t

Er

t

DSW H

t

VIH1

VIL1

VIH1

VIL1

t

cycE

VIL1

Valid data

Write Operation

RS

R/W

E

DB0 to DB7

VIH1

VIL1

VIH1

VIL1

t

AS

t

AH

VIH1 VIH1

t

AH

PW

EH

t

Ef

VIH1

VIL1

VIH1

VIL1

t

DDR DHR

t

t

Er

VIL1

VOH1

VOL1

VOH1

VOL1

Valid data

t

cycE

Read Operation

11/23

6.4 Instruction Code

Code

Execution Time

(max) (when f

cp

or

Instruction RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 Description f

OSC

is 320 kHz)

Clear

display

0 0 0 0 0 0 0 0 0 1 Clears entire display and

sets DDRAM address 0 in

address counter.

1.28 ms

Return

home

0 0 0 0 0 0 0 0 1 Sets DDRAM address 0 in

address counter. Also

returns display from being

shifted to original position.

DDRAM contents remain

unchanged.

1.28 ms

Entry mode

set

0 0 0 0 0 0 0 1 I/D S Sets cursor move direction

and specifies display shift.

These operations are

performed during data write

and read.

31 s

Display

on/off

control

0 0 0 0 0 0 1 D C B Sets entire display (D)

on/off, cursor on/off (C), and

blinking of cursor position

character (B).

31 s

Cursor or

display shift

0 0 0 0 0 1 S/C R/L Moves cursor and shifts

display without changing

DDRAM contents.

31 s

Function

set

0 0 0 0 1 DL N F Sets interface data length

(DL), number of display

lines (L), and character font

(F).

31 s

Set

CGRAM

address

0 0 0 1 ACG ACG ACG ACG ACG ACG Sets CGRAM address.

CGRAM data is sent and

received after this setting.

31 s

Set

DDRAM

address

0 0 1 ADD ADD ADD ADD ADD ADD ADD Sets DDRAM address.

DDRAM data is sent and

received after this setting.

31 s

Read busy

flag &

address

0 1 BF AC AC AC AC AC AC AC Reads busy flag (BF)

indicating internal operation

is being performed and

reads address counter

contents.

0 s

12/23

Code

Execution Time

(max) (when f

cp

or

Instruction RS R/W DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 Description f

OSC

is 320 kHz)

Write data

to CG or

DDRAM

1 0 Write data Writes data into DDRAM

or CGRAM.

31 s

t

ADD

= 4.7 s*

Read data

from CG or

DDRAM

1 1 Read data Reads data from DDRAM

or CGRAM.

31 s

t

ADD

= 4.7 s*

I/D = 1: Increment

I/D = 0: Decrement

S = 1: Accompanies display shift

S/C = 1: Display shift

S/C = 0: Cursor move

R/L = 1: Shift to the right

R/L = 0: Shift to the left

DL = 1: 8 bits, DL = 0: 4 bits

N = 1: 2 lines, N = 0: 1 line

F = 1: 5 10 dots, F = 0: 5 7 dots

BF = 1: Internally operating

BF = 0: Instructions acceptable

DDRAM: Display data

RAM

CGRAM: Character

generator RAM

ACG: CGRAM address

ADD: DDRAM address

(corresponds to

cursor address)

AC: Address counter

used for both DD and

CGRAM addresses

Execution time

changes when

frequency changes

Example:

When f

cp

or f

OSC

is 270 kHz,

31 s = 37 s

320

270

Note: indicates no effect.

* After execution of the CGRAM/DDRAM data write or read instruction, the RAM address counter

is incremented or decremented by 1. The RAM address counter is updated after the busy flag

turns off. In Figure 10, t

ADD

is the time elapsed after the busy flag turns off until the address

counter is updated.

Busy state

Busy signal

(DB7 pin)

Address counter

(DB0 to DB6 pins)

t

ADD

A A + 1

Note: t depends on the operation frequency

t = 1.5/(f or f ) seconds

ADD

ADD cp OSC

Figure 10 Address Counter Update

xxxx0000

xxxx0001

xxxx0010

xxxx0011

xxxx0100

xxxx0101

xxxx0110

xxxx0111

xxxx1000

xxxx1001

xxxx1010

xxxx1011

xxxx1100

xxxx1101

xxxx1110

xxxx1111

0000 0010 0011 0100 0101 0110 0111 1010 1011 1100 1101 1110 1111

Upper 4

Bits

Lower

4 Bits

CG

RAM

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Note: The user can specify any pattern for character-generator RAM.

13/23

6.5 Character generator ROM(HCD66701A00)

14/23

7. Optical Characteristics

7.1 Optical Characteristics Ta=25

Item Symbol Condition Min. Typ. Max. Unit

=0 35 -- 10

Viewing Angle

C

=0 -30 -- 30

Deg

Contrast Ratio C

=20

=0

3.0 - -

Turn

on

T - - 150

Response

Time

Turn

off

T

=20

=0

- - 150

ms

15/23

7.2 Definition of Optical Characteristics

7.2.1 Definition of Viewing Angle

Top Top

Bottom Bottom

7.2.2 Definition of Contrast Ratio

brightness state selected

brightness state unselected

B2/B1 Ratio Contrast

Measuring Conditions:

1) Ambient Temperature: 25 ; 2) Frame frequency: 64Hz

7.2.3 Definition of Response time

Turn on time:

=

d

+

r

Turn off time:

=

d

+

I

Measuring Condition:

1) Operating Voltage: 4.7V 2) Frame frequency: 64Hz

16/23

8. Reliability

8.1 Content of Reliability Test Ta=25

No. Test Item Content of Test

Test condition

1

High Temperature

Storage

Endurance test applying the high

storage temperature for a long time

60

96H

2

Low Temperature

Storage

Endurance test applying the low

storage temperature for a long time

-20

96H

3

High Temperature

Operation

Endurance test applying the

electric stress (voltage current)

and the thermal stress to the

element for a long time

50

96H

4

Low Temperature

Operation

Endurance test applying the

electric stress under low

temperature for a long time

0

96H

5

High Temperature

/Humidity Storage

Endurance test applying the high

temperature and high humidity

storage for a long time

40

90%RH

96H

6

Temperature

Cycle

Endurance test applying the low

and high temperature cycle

-20 25 60 25

30min 5min 30min 5min

1 cycle

-20 /60

10 cycles

7

Vibration Test

(package state)

Endurance test applying the

vibration during transportation

10Hz~150Hz,

50m/s

2

,

40min

8

Shock Test

(package state)

Endurance test applying the shock

during transportation

Half- sine wave,

100m/s

2

,

11ms

9

Atmospheric

Pressure Test

Endurance test applying the

atmospheric pressure during

transportation by air

40kPa

16H

17/23

8.2 Failure Judgment Criterion

Test Item No.

Criterion

Item

1 2 3 4 5 6 7 8 9

Failure Judgement Criterion

Basic

Specification

Out of the basic Specification

Electrical

specification

Out of the electrical

specification

Mechanical

Specification

Out of the mechanical

specification

Optical

Characteristic

Out of the optical specification

Note For test item refer to 8.1

Remark

Basic specification = Optical specification + Mechanical

specification

18/23

9. QUALITY LEVEL

Inspection

Examination

or Test

At Ta=25

(unless otherwise stated)

Min. Max. Unit IL AQL

External

Visual

Inspection

Under normal illumination

and eyesight condition, the

distance between eyes and

LCD is 25cm.

See Appendix A II

Major

1.0

Minor

2.5

Display

Defects

Under normal illumination

and eyesight condition,

display on inspection.

See Appendix B II

Major

1.0

Minor

2.5

Note: Major defects: Open segment or common, Short, Serious damages, Leakage

Miner defects: Others

Sampling standard conforms to GB2828

19/23

10. Precautions for Use of LCD Modules

10.1 Handling Precautions

10.1.1 The display panel is made of glass. Do not subject it to a mechanical

shock by dropping it from a high place, etc.

10.1.2 If the display panel is damaged and the liquid crystal substance inside it

leaks out, be sure not to get any in your mouth, if the substance comes

into contact with your skin or clothes, promptly wash it off using soap

and water.

10.1.3 Do not apply excessive force to the display surface or the adjoining areas

since this may cause the color tone to vary.

10.1.4 The polarizer covering the display surface of the LCD module is soft and

easily scratched. Handle this polarizer carefully.

10.1.5 If the display surface is contaminated, breathe on the surface and gently

wipe it with a soft dry cloth. If still not completely clear, moisten cloth

with one of the following solvents:

Isopropyl alcohol

Ethyl alcohol

Solvents other than those mentioned above may damage the polarizer.

Especially, do not use the following:

Water

Ketone

Aromatic solvents

10.1.6 Do not attempt to disassemble the LCD Module.

10.1.7 If the logic circuit power is off, do not apply the input signals.

10.1.8 To prevent destruction of the elements by static electricity, be careful to

maintain an optimum work environment.

a. Be sure to ground the body when handling the LCD Modules.

b. Tools required for assembly, such as soldering irons, must be properly

ground.

c. To reduce the amount of static electricity generated, do not conduct

assembly and other work under dry conditions.

d. The LCD Module is coated with a film to protect the display surface.

Be care when peeling off this protective film since static electricity may

be generated.

20/23

10.2 Storage precautions

10.2.1 When storing the LCD modules, avoid exposure to direct sunlight or to

the light of fluorescent lamps.

10.2.2 The LCD modules should be stored under the storage temperature range.

If the LCD modules will be stored for a long time, the recommend

condition is:

Temperature : 0 40

Relatively humidity: 80%

10.2.3 The LCD modules should be stored in the room without acid, alkali and

harmful gas.

10.3 The LCD modules should be no falling and violent shocking during

transportation, and also should avoid excessive press, water, damp and

sunshine.

21/23

Appendix A

Inspection items and criteria for appearance defects

Items Contents Criteria

Leakage Not permitted

Rainbow According to the limit specimen

Wrong polarizer

attachment

Not permitted

Not counted Max. 3 defects allowed Bubble between

polarizer and glass

<0.3mm 0.3mm 0.5mm

Polarizer

Scratches of

polarizer

According to the limit specimen

Not counted

Max. 3 spots allowed

X<0.2mm 0.2mm X 0.5mm

Black spot

(in viewing

area)

X=(a+b)/2

Not counted

Max. 3 lines allowed Black line

(in viewing

area)

a<0.02mm

0.02mm a 0.05mm

b 2.0mm

Max. 3

spots

(lines)

allowed

Progressive

cracks

Not permitted

22/23

Appendix B

Inspection items and criteria for display defects

Items Contents Criteria

Open segment or open common Not permitted

Short Not permitted

Wrong viewing angle Not permitted

Contrast radio uneven According to the limit specimen

Crosstalk According to the limit specimen

Not counted Max.3 dots allowed

X<0.1mm 0.1mm X 0.2mm

X=(a+b)/2

Not counted Max.2 dots allowed

Pin holes

and cracks

in segment

(DOT)

A<0.1mm

0.1mm A 0.2mm

D<0.25mm

Max.3

dots

allowed

Not counted Max.3 spots allowed

X<0.1mm 0.1mm X 0.2mm

Black spot

(in viewing

area)

X=(a+b)/2

Not counted Max.3 lines allowed

Black line

(in viewing

area)

a<0.02mm

0.02mm a 0.05mm

b 0.5mm

Max.3

spots

(lines)

allowed

23/23

Appendix B

Inspection items and criteria for display defects (continued)

Items Content Criteria

Not counted Max. 2 defects allowed

x 0.1mm 0.1mm x 0.2mm

x=(a+b)/2

Not counted Max. 1 defects allowed

a 0.1mm

0.1mm a 0.2mm

D>0

Max.3

defects

allowed

Transfor-

mation

of segment

Max.2 defects allowed

0.8W a 1.2W

a=measured value of width

W=nominal value of width

You might also like

- Tm162vca6 SpecDocument23 pagesTm162vca6 SpecMarius FerdyNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- NT C1641a Btsesw A0Document19 pagesNT C1641a Btsesw A0flo72afNo ratings yet

- AGM 1602F-212: Specification Specification Specification Specification FOR FOR FOR FOR LCM LCM LCM LCM ModuleDocument25 pagesAGM 1602F-212: Specification Specification Specification Specification FOR FOR FOR FOR LCM LCM LCM LCM Modulealess2056No ratings yet

- Truly Semiconductors LCD Module SpecificationsDocument17 pagesTruly Semiconductors LCD Module Specificationsalfredo de la hozNo ratings yet

- Emerging Display: - CAS-10042:NOV.18,1999Document12 pagesEmerging Display: - CAS-10042:NOV.18,1999Rahul JoeNo ratings yet

- Panasonic Cn-Tm4290a MazdaDocument18 pagesPanasonic Cn-Tm4290a Mazdaani huseinNo ratings yet

- AGM 0802B-305 LCD Module SpecificationDocument25 pagesAGM 0802B-305 LCD Module SpecificationWelleyNo ratings yet

- Specification For LCD Module: Model NoDocument22 pagesSpecification For LCD Module: Model NoNasir UddinNo ratings yet

- LCD 4x20 Large Digit DatasheetDocument29 pagesLCD 4x20 Large Digit DatasheetthuanNo ratings yet

- LED display module specificationsDocument11 pagesLED display module specificationsdemodlNo ratings yet

- WM c2002m 1ylydDocument24 pagesWM c2002m 1ylydJanio Mima0% (1)

- Batron: 39 8 MM Character Height LCD Modules - MACRO LINEDocument1 pageBatron: 39 8 MM Character Height LCD Modules - MACRO LINEDiego OliveiraNo ratings yet

- AGM-1602B-802 Meu DisplayDocument25 pagesAGM-1602B-802 Meu DisplayMaycon ViniciusNo ratings yet

- FS9721-LP1 4000 Counts Digital Multimeter: FortuneDocument31 pagesFS9721-LP1 4000 Counts Digital Multimeter: FortunealejandroNo ratings yet

- Arduino 16x2LCD 5vDocument28 pagesArduino 16x2LCD 5vKing TranNo ratings yet

- Wo12864h TFH#Document27 pagesWo12864h TFH#Paulina HozhoNo ratings yet

- Flatron l1742pDocument29 pagesFlatron l1742pAdalbertoNo ratings yet

- Product Specification SheetDocument16 pagesProduct Specification Sheetgem1144aaNo ratings yet

- GLCD 128x64 DatasheetDocument30 pagesGLCD 128x64 DatasheetXavier MuñozNo ratings yet

- JBC1602A00-08W LCD Module SpecificationsDocument25 pagesJBC1602A00-08W LCD Module SpecificationsGHOST 22035No ratings yet

- LCD162C# DatenblattDocument8 pagesLCD162C# Datenblattgeorgschmied100% (1)

- Winstar Display 12864A1-TFH# Specification SheetDocument24 pagesWinstar Display 12864A1-TFH# Specification SheetHalit YalçınkayaNo ratings yet

- Winstar Display Spec Sheet for 128x64 LCD ModuleDocument26 pagesWinstar Display Spec Sheet for 128x64 LCD ModuleHalit YalçınkayaNo ratings yet

- Winstar Display Specification SheetDocument26 pagesWinstar Display Specification SheetQuarmina HesseNo ratings yet

- Winstar Display Specification for WH1604A-TMI-CT# LCD ModuleDocument26 pagesWinstar Display Specification for WH1604A-TMI-CT# LCD ModuleСергейNo ratings yet

- SED1530 Series: Dot Matrix LCD Driver-ControllerDocument20 pagesSED1530 Series: Dot Matrix LCD Driver-ControllerJuan Carlos BarandicaNo ratings yet

- Winstar LCD Display ModuleDocument31 pagesWinstar LCD Display Moduleمعمر حميدNo ratings yet

- Sony Cxa3271age Fingerprint ScannerDocument16 pagesSony Cxa3271age Fingerprint ScannerPierina AstudilloNo ratings yet

- Winstar - WH2004A YGH JTDocument25 pagesWinstar - WH2004A YGH JTPhong DoNo ratings yet

- LG W1941SDocument39 pagesLG W1941SGunvant K. BhopleNo ratings yet

- Display LCD 40 Caracteres 2 Linhas Backlight Verde 182x33,5x13,6mm WH4002A YYH JTDocument25 pagesDisplay LCD 40 Caracteres 2 Linhas Backlight Verde 182x33,5x13,6mm WH4002A YYH JTFelipeMeloNo ratings yet

- N Winstar Display Co., LTD: SpecificationDocument29 pagesN Winstar Display Co., LTD: SpecificationВладимир СолонскийNo ratings yet

- Color Monitor: Service ManualDocument23 pagesColor Monitor: Service ManualSaimon SaimontonNo ratings yet

- CTK-230 Keyboard Technical ManualDocument15 pagesCTK-230 Keyboard Technical ManualDavid Emanuel Dauo0% (1)

- HDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightDocument1 pageHDM3224L-G: Dimensional Drawing 320 X240 Monochrome Graphics, White LED BacklightVallerynNo ratings yet

- Ym12864p-Dalian Good Display PDFDocument10 pagesYm12864p-Dalian Good Display PDFEvgeniyNo ratings yet

- Wg240128a Tmi VZ#Document25 pagesWg240128a Tmi VZ#حمزة صباحNo ratings yet

- WH1602B NYG CT WinstarDocument27 pagesWH1602B NYG CT Winstarsoros4No ratings yet

- Emerging Display: - CAS-10011: SEP.09,1999Document13 pagesEmerging Display: - CAS-10011: SEP.09,1999Plymouth Hemi BarracudaNo ratings yet

- WH2004A Winstar DisplayDocument28 pagesWH2004A Winstar DisplayКрасимир КостадиновNo ratings yet

- LCD DatasheetDocument17 pagesLCD DatasheetJuan SánchezNo ratings yet

- Winstar Display Co., LTD: SpecificationDocument28 pagesWinstar Display Co., LTD: SpecificationAdrian FerreyraNo ratings yet

- AGM 1602B-818 Spec SheetDocument25 pagesAGM 1602B-818 Spec Sheet19thmnlfreemsNo ratings yet

- Winstar Display Co., LTD: Specification Customer: Module No.: WH1602B-TMI-ET#Document28 pagesWinstar Display Co., LTD: Specification Customer: Module No.: WH1602B-TMI-ET#Bozidarka Uzelac LucicNo ratings yet

- Winstar Display Co., LTD: Specification Customer: Atlas Electronic Module No.: WG12864A-YYH-VDocument17 pagesWinstar Display Co., LTD: Specification Customer: Atlas Electronic Module No.: WG12864A-YYH-VElvis SilvaNo ratings yet

- Winstar Display Co., LTD: SpecificationDocument30 pagesWinstar Display Co., LTD: SpecificationAngel RojasNo ratings yet

- RVT70 UQTNWC0 XDocument18 pagesRVT70 UQTNWC0 XAdam RoguszczakNo ratings yet

- ST1602LDocument19 pagesST1602Lmoniri123No ratings yet

- Winstar Display Co., LTD Module Specification for WH1602C-YGB-CPDocument23 pagesWinstar Display Co., LTD Module Specification for WH1602C-YGB-CPLeandro SchenoneNo ratings yet

- Datasheet Display WH-2004L-YYHDocument25 pagesDatasheet Display WH-2004L-YYHmarcioNo ratings yet

- 162E Series Displaytech SpecDocument23 pages162E Series Displaytech SpecrochaseletronicaNo ratings yet

- 6969057Document24 pages6969057Андрій БілявськийNo ratings yet

- Aoc Le32w156Document91 pagesAoc Le32w156FabricioMigueldaSilvaNo ratings yet

- Aoc Le22h158Document78 pagesAoc Le22h158Regisk8 OliveiraNo ratings yet

- Three-Wire Serial EEPROM: 1. FeaturesDocument17 pagesThree-Wire Serial EEPROM: 1. FeatureskppsadiNo ratings yet

- Dem240128d SBH PW N D TouchDocument20 pagesDem240128d SBH PW N D TouchCatalin PancescuNo ratings yet

- Ssph011 Session 15 Biomechanic Moments (Torque) and ElasticityDocument55 pagesSsph011 Session 15 Biomechanic Moments (Torque) and ElasticityPortia NyakaneNo ratings yet

- Light SourcesDocument5 pagesLight Sources123vidyaNo ratings yet

- Revised Design Report of Jetty 06.04.2014Document10 pagesRevised Design Report of Jetty 06.04.2014Priodeep Chowdhury100% (2)

- Trư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Document2 pagesTrư NG Thcs : Question IV. Find and Correct The Mistake in Each Sentence. (1p)Anh ThưNo ratings yet

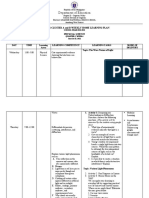

- Department of Education: Humss 12 Cluster A and B Weekly Home Learning PlanDocument3 pagesDepartment of Education: Humss 12 Cluster A and B Weekly Home Learning PlanRhomelyn AbellarNo ratings yet

- Sag Slurry PoolingDocument10 pagesSag Slurry PoolingalgroneNo ratings yet

- The Theory of Engineering DrawingDocument370 pagesThe Theory of Engineering Drawingcocotess100% (1)

- NTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINEDocument23 pagesNTMM LAB: MATERIAL REMOVAL RATE TEST ON ULTRASONIC MACHINETarundeep SinghNo ratings yet

- Irjet V5i5256 PDFDocument5 pagesIrjet V5i5256 PDFMuhsinaNo ratings yet

- GE Gas Turbine IGV AngleDocument10 pagesGE Gas Turbine IGV AngleSamir BenabdallahNo ratings yet

- Datasheet MPX5100DPDocument16 pagesDatasheet MPX5100DPKemahyanto Exaudi SiahaanNo ratings yet

- HW2 Solutions FinalDocument5 pagesHW2 Solutions Finalpande_100No ratings yet

- Vector CalculusDocument62 pagesVector CalculuswaleedNo ratings yet

- Latent Print DevelopmentDocument20 pagesLatent Print Developmentapi-272036460100% (1)

- Lab 3 - Intro To DynamicDocument36 pagesLab 3 - Intro To DynamicRacheal KirbyNo ratings yet

- TCL Air Conditioner Service ManualDocument138 pagesTCL Air Conditioner Service ManualFabian EtcheniqueNo ratings yet

- SABIC Innovative Plastics Lexan® 940 PC Data SheetDocument3 pagesSABIC Innovative Plastics Lexan® 940 PC Data SheetMRC RailNo ratings yet

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 pagesGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresNo ratings yet

- Reability PDFDocument396 pagesReability PDFMarcelo Ziulkoski100% (1)

- EVER11 Final ProgramDocument20 pagesEVER11 Final ProgramAdrian PopNo ratings yet

- XI Maths - I Terminal ExamDocument2 pagesXI Maths - I Terminal ExamPurisai Rajamani KumarNo ratings yet

- Additive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Document35 pagesAdditive Solutions For Low Sulphur Fuelsadditive Solutions For Low Sulphur Fuels July 10Mazhar HussainNo ratings yet

- Z I ARO: Applications of Axial and Radial Compressor Dynamic System ModelingDocument262 pagesZ I ARO: Applications of Axial and Radial Compressor Dynamic System ModelingRamzi BrkNo ratings yet

- Open Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566Document93 pagesOpen Stent Design: Craig Bonsignore NDC 47533 Westinghouse Drive Fremont, CA, 94566akire_aicragNo ratings yet

- Mohit SIR LATEST Notes (GATE+ESE-2020) )Document5 pagesMohit SIR LATEST Notes (GATE+ESE-2020) )Vipul MetaNo ratings yet

- C-30 Concrete Mix Design RatiosDocument5 pagesC-30 Concrete Mix Design RatiosAtm Tjah Radix LoegoeNo ratings yet

- 2 B.tech Biotechnology 27 38Document38 pages2 B.tech Biotechnology 27 38Anju GuptaNo ratings yet

- Assignment 2Document2 pagesAssignment 2ue06037No ratings yet

- HW1Document8 pagesHW1Anonymous fXSlye100% (1)

- E1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes TérmicasDocument3 pagesE1213-14 Práctica Estándar para La Diferencia Mínima de Temperatura Resoluble para Sistemas de Imágenes Térmicasfredy lopezNo ratings yet