Professional Documents

Culture Documents

IUGNewsletter3 2

Uploaded by

89hariharanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IUGNewsletter3 2

Uploaded by

89hariharanCopyright:

Available Formats

Edi t ori al

Welcome t o Edit ion 5 of t he

newslet t er.

The purpose of t his newslet t er

is t o provide specialised inf or-

mat i on t o users of Pharmaceu-

t ical Isolat ors. There are st ill

many aspect s of Isolat ors t hat

are causing some concern wit h

t he users and managers of t he

services t hat use Isolat ors.

We are st ill not achieving some

of t he object ives of t his news-

let t er and I hope you, as a

reader, are able t o help us de-

velop. I am confident t hat you

are probabl y wil l ing t o hel p us

improve communicat ions be-

t ween users but probably

haven t quit e got round t o writ -

ing anyt hing done yet ! It is dif f i -

cult t o know t he best way of

helping you communicat e wit h

us but we are devel oping a

websit e, have email, f ax and

t elephone communicat ions so

all t his should help.

We would like you t o make a

small cont ribut ion in t he way

of a comment or quest ion. We

very much appreciat e a larger

art icle describing some special

Isol at or int erest of yours or a

t echnical dissert at ion.

Topical news includes a recent

communicat ion f rom t he HSE

indicat ing t hat t heir report on

some of t he risks relat ing t o

handl i ng hazar dous su b -

st ances in posit ive or negat ive

pressure Isolat ors is nearing

complet ion. The deliberat ions

of t he ISO group in developing

st andards is progressing but

will not be available unt il 2001

or lat er. The Working Part y has

been meet ing during 2000

and 2001. It was accept ed

t hat t o wait unt il t he ISO group

had complet ed t heir deliber a-

t ions was unaccept ably long in

rel at ion t o publ icat ion of Edi -

t ion 3 of t he Yellow Guide . We

have t heref ore commit t ed ou r-

selves t o go ahead and revise

and ext end t hi s usef ul book as

soon as possible and t his

should become available mid

2 0 0 1 . The 5

th

Isol at or Conf er-

ence was well at t ended and

generally regarded as a suc-

cess by t he majorit y of dele-

gat es, speakers and exhibi -

t ors.

The next (6

th

) Isolat or Conf er-

ence is t o be held on Oct ober

2 8 t h30t h. If you know of a

part icularly suit able venue f or

f ut ure Conf erences, please let

us know. Venue reservat ions

need t o be made wel l i n ad-

vance. If you would like t o pre-

sent a paper, short communi -

cat ion, post er, lead a seminar

please let us know and we will

t ry and f it you int o a f ut ure

Conf erence schedul e. Any

ot her comment s or advice

would also be appreciat ed.

Free Advert ising is available

f or t he next i ssue. It i s nor-

mally charged at a mere 50

when you can purchase a half

page advert isement in t he

Newslet t er. It is hoped t hat you

regard t his as an ext remely at -

t ract ive of f er, (especially f or

t he next issue) and an oppor-

t unit y t o inf orm a t arget ed au-

di ence, int erest ed in Isolat ors,

about your specialist services

and your specialist equipment ,

what ever t his may be!

Al l t he cont act det ails are on

t he last page of t he newslet t er

so we look forward t o hearing

f rom you.

Oct ober 2001

Vol ume 3, I ssue 2 5

Pharmaceutical Isolator User

Group N ewsletter

Speci al poi nt s of i nt er est : i n

t hi s i ssue

Edit orial

Conference number 5 Report

Ways of looking at leaks

News Items in brief

Quest ions and answers

Cont act References

I nsi de t hi s i ssue:

So your Isol at or Leaks 2

People Profile 4

Quest i ons and Answers 5

PIUG on t he Web 5

Conf erence Report 5

New Yel l ow Gui deReport 6

A si ck Isol at or St ory 7

Isol at or User Group Informat i on 8

Would you benefit from seeing your Company name displayed here. You could have your

name noticed by a target audience for a very reasonable cost as well as the satisfaction of

knowing you were helping support the publication of this newsletter. Contact IUG committee

Colour or Black and White

This issue of the Newsletter is in

glorious colour. As reproduction in

colour is expensive we have had to

settle for a quick edition in glorious

monochrome. To produce 500 cop-

ies in colour would cost 300

400. Perhaps your organisation

would like to sponsor an edition. If

you would like to help please con-

tact your User Group Chairman.

Page 2 Pharmaceut i cal Isol at or User Group Newsl et t er

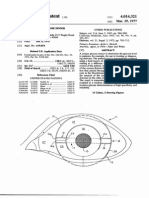

So Your I sol at or Leaks!

F

ollowing the comment about leaking Isolators in

the last issue, I will remind you of the comments

made then and go on to provide more information

on how to assess the significance of such leaks. I will

again ask you for your views on this so we may try to

obtain a better perspective on this problem.

The MCA Inspectorate is developing an ever greater

level of understanding of Isolator technology. If you

have a licensed unit you may have already been asked to

quantify the leak rate of your Isolator. If not, then when

your next inspection is due the question may be asked

then. For unlicensed units, there is an increasing level of

commissioning, validation, and testing going on s o there

will be more data available that could be used for calcu-

lation of leak rates.

An inspection in Leeds licensed Pharmaceutical Manu-

facturing Unit referred to the question about the rate of

leak from our production Isolator. Having been relatively

content with a knowledge of the time it takes for a pres-

sure drop to occur between defined limits, it apparently

seemed reasonable for us to have a better knowledge of

the actual size of the leak. The question we could not an-

swer at the time of the Inspection was What is the leak

rate expressed as an equivalent hole size?. In other

words, a pressure drop knowledge is all very well but

what does it really mean? Is 5,10 20, 50 pascals reason-

able for your Isolator or does it mean we have a serious

leak. If all the leaks were to be combined into a single

hole, just how big would be that hole.

I am indebted to John Neiger and Time Coles for the fun-

damental consideration of leaks and how to measure such

leaks. If you have scanned ahead in your reading and do

not much care for mathematical explanations all I can

hope you will note is dont panic the maths is quite

simple and the principles of physics described and the

ones you have probably already met and knew but may

have forgotten. This wi ll be a reminder to give a better

understanding of what is going on and is something you

ought to understand anyway. For the engineers and sci-

entists you will be able to scan through the following as a

reminder and it will be something you probably know

but may not have considered.

There now follows a number of leak test formulae to

place things in perspective. The first deals with the Gas

Laws. Essentially these laws describe the relationship

between temperature, pressure and volume of a gas. If

you have a sample of gas in a container, a jar, a cylinder

or even an Isolator then if the temperature changes so

will the pressure, assuming the volume remains constant.

If the pressure changes and the volume remains the same,

then the temperature will alter. If the volume is allowed

to change then the pressure will change if the tempera-

ture remains constant or the pressure will stay the same if

the temperature alters.

These potential changes need to be considered when an Isolator

is checked on a daily basis, for example for a pressure decay

test. If the room temperature or the Isolator controlled work-

space changes whilst the test is carried out, or the atmospheric

pressure alters, then the test results will be affected. These rela-

tionships are expressed in the Gas Laws which makes equiva-

lent the ratios of initial pressure (P

1

), volume (V

1

) and tempera-

ture (T

1

) to the final pressure (P

2

), volume (V

2

) and temperature

(T

2

).

The Gas Law states:

If a calculation is required then the units must be consid-

ered as they are for P in Pa, T is in degrees absolute and V

is in m

3

For the same temperature during the measurements,

where T is constant, then the equation is simplified to ig-

nore temperature.

This can be rearranged to determine the second pressure

P

2

in terms of the first pressure and the initial and final

volumes.

Using the different volumes implied after a pressure de-

cay test then if there is n% leakage difference the new

volume after the test can be calculated.

If there is leakage of n%, then

And substituting for VP

2

in the above equation Thus,

And using the pressure increments to assess for differ-

ences in pressure

or

So we now have an expression which gives the percent-

age volume of leakage in a given Isolator. If we use this

formula with some vales we can see how it will work.

,

_

+

100

1

1 2

n

V V

,

_

,

_

100

1

100

1

1

1

1 1

2

n

P

n

V

V P

P

,

_

,

_

+

n

n

P

n

P P P P

100

100

1

1

1

1 1 2 1

2

2 2

1

1 1

T

V P

T

V P

2 2 1 1

V P V P

2

1 1

2

V

V P

P

100

P

100P

n

2

1

Suggesting a test pressure of 250Pa, with 0.5% volume

loss per hour allowable:

Using a 10 minute test.

Hence,

So now we have determined a pressure drop for a type of

Isolator we now need to calculate the SHE or single hole

equivalent.

The area of this single hole is given by the volume of air

passing through this imaginary orifice divided by the ve-

locity of this air:-

Further consideration of the velocity relates to the pres-

sure difference and the density of air passing through it.

So

or

Using some of the above derivations we can try these on

an Isolator which is reasonably large at 5 m

3

volume. The

pressure decay readings could be typically as follows:-

Isolator = 5 m

3

Start Pressure = 140 Pa

End Pressure = 110 Pa

Time = 10 minutes

Single Hole Equivalent:

If you need to calculate what is the equivalent hole size of

the leak from the pressure decay tests this is one of the

ways it can be done.

Having done such a calculation, it is interesting to note

that, in the example chosen, the size of the hole is note

very great. If we now speculate how significant this is, it

may help to judge how big a risk is presented to the op-

erator or to the product.

Having indicated the hole is small, bacteria are very much

smaller. How big is the risk of contamination? What does

it depend on and how contaminated is the background en-

vironment? We also need to remember we have just cal-

culated a single hole equivalent. It is reasonably likely

that your Isolator will not just have the one hole. So are

we any nearer to estimating the risk of contamination?

How large will the largest hole be? What will become an

acceptable pressure drop for your Isolator?

I look forward to views and comments for future newslet-

ter issues.

Help Wanted.

It would be interesting to collect this type of data from a

number of different Isolators. Would you help by doing

some similar calculations and passing on the information?

We will generate a table of results for members to see so

we can judge just how leaky are our Isolators. If you

send in your calculations we will need the dimensions of

the Isolator and the type (+/-ve) together with the class of

transfer device.

There have been a number of engineering considerations

relating to leaks, how they may occur, what effect they

may have, how big a risk they may be to either product or

operator, the concept of jet velocities and more.

For unlicensed units; you are subject to audit by your

friendly Quality Controller. Where the MCA lead the QC

auditor is likely to follow. This level of understanding

may be a more widespread requirement than you may

have thought. The above information may be helpful.

drop 83Pa

6

499

) sec velocity(

) sec ( flow volume

) ( hole of area

1

1 3

2

m

m

m

2

e wher

225 . 1

2 2

= velocity

2 1

P P

P

P P

m

m m

seconds in test of duration where

sec

100

= flow volume

1 3 1

t

m

t

n V

2 6

m

1

mm 10

1.225

2P

100t

n V

a

'

Pa 499

5 . 100

5 . 0

250 , 100

,

_

P

microns

p

a

2,000

microns 472

175 . 0

000 , 2

a

2 6

10

225 . 1

125 2

600 100

03 . 0 5

mm a

'

Page 3 Pharmaceut i cal Isol at or User Group Newsl et t er

Page 4 Pharmaceut i cal Isol at or User Group Newsl et t er

This is an opportunity to get to know a little about

your User Group Committee. We have experienced a

natural reduction in numbers down to about 6 regular

workers on the committee. These are:

Ken Baker. Ken joined the committee, bringing with

him the valuable specialist experience relating to

gloves and gauntlets. Although Ken is essentially re-

tired, he has many contacts from his specialist Associ-

ates links. Such links were mostly in the nuclear in-

dustry and it is vitally important that access devices

like gloves and gauntlets were well controlled. Al-

though Ken has some limitations on travelling due to

health reasons, he is always enthusiastic about matters

relating to Isolators and his connections have been

valuable in the planning of Isolator Conferences. Ken

will also be involved in the forthcoming conference.

Caroline Coles. Caroline is a founder member of the

committee. She has brought a very significant drive

and enthusiasm to the group. She played an important

role in the production of the first newsletter and her

background of the Institution of Containment and Iso-

lation was a useful communication base in the estab-

lishment of speakers for conferences and courses. Her

background of organisation and management and been

one of assets in the group. Caroline now runs a new

Isolator supply company which will exclude her from

many more activities in the committee

Beverley Ellis. Bev is a specialist Radiopharmacist at

the Nuclear Medicine Department, Manchester Royal

Infirmary. She has been a member of the UK Radio-

pharmacist specialist committee for some years and

has a good clinical relationship with the Nuclear

Medicine Department in this specialist hospital. Bev

is a relatively new member of the committee but has

brought a wealth of enthusiasm to the group. One of

her specialities is training and she is combining her

experiences with Lynn at the forthcoming Isolator

Conference. Another specialist interest is in Internet

Web design. Her position on the National education

and Training Group TSET is one of Web Mistress.

This experience was tapped to start the generation of

the PIUG website.

Margaret Horsey Margaret has been one of the foun-

der members of the committee. She has been acting as

treasurer although the funds are held within the Uni-

versity and she has not been required to perform nor-

mal treasurer duties. She has been a pharmacist who

has specialised in quality control and performed this

important role from her base hospital in Rotherham.

Recently Margaret has taken up a QC pharmacist post

in Bradford. Here she has a quality role in a large

aseptic services unit and an audit responsibility for the

local hospitals.

Lynn Lawler. Lynn is employed by Baxter Health-

care as a Quality Supervisor, based in the Aseptic Dis-

pensing Unit at Manchester Christie Hospital. Here

she leads a team of dedicated technical staff who pre-

pare a range of aseptic products for use in the hospital.

Baxter utilises gassed sterilised isolators, Lynn is re-

sponsible for monitoring and maintaining this equip-

ment which includes training of operators in their use

and management of the validation program to ensure

compliance and maintenance of the quality system.

Baxter also collaborate with other local hospitals to

provide their needs for specialist treatments. The com-

pany regard Lynn as a specialist in one of the most im-

portant elements of any system; Quality and Training.

She has recently been involved in updating company

systems and ensuring the staff have the best possible

support. Lynns specialist role in the User Group is

that of Secretary. She also participates in Conferences

and will be leading a training seminar in this months

Isolator Conference.

David Morley. David has also been a founder mem-

ber of the committee. From a specialist microbiology

education, he has developed expertise in validation of

mostly industrial systems and procedures. David is

now employed as a consultant and is involved with a

number of companies in a range of validation projects.

He has been a member of the well established Scottish

Society S

2

C

2

. David is also a recognised presenter,

particularly of validation issues, at recent conferences

and training courses. He will also be involved in the

forthcoming conference. There is much travelling in

his life style but if time permits, it is time itself that

has an appeal, as David is an officia l timekeeper for

vintage car rallies for which there is a long established

enthusiasm.

.

Peopl e Prof i l e

Quest i ons and Answers

PI UG on t he WebSt at us Report

Conf er ence Repor t

Q We have a 10 year old Isolator running at negative

pressure. It is used to dispense cytototoxic drugs aseptically.

The Isolator is in a dedicated room and exhausts into the

room. The staff operating the unit are concerned about their

exposure. Should t he old Isolator be replaced ?

A The level of aseptic dispensing is at a low level, only

a few units a day and not every day of the week. Measure-

ments of any room environment contamination had not been

done so it was recommended that suitable analytical measure-

ments could be made. If there was any cytotoxic drugs

found then the situation was more serious and leaks should be

investigated.

The Isolator is tested regularly and it always passed the nor-

mal monitoring tests

Q We us a negative pressure Isolator for Cytotoxic

preparations. Do we have to vent the exhaust to the outside?

We are not on an outside wall so can we use a carbon filter

instead? What precautions do we need to take?

A -anyone please help -

There was a comment in the last newsletter indicating that we

were hoping to have an active website by the time the next is-

sue was published. A design was completed in early Autumn

2000 and much of the initial material was posted into the linked

pages. Some agreement was reached for links to relevant or-

ganisations and after further delays, the necessary web ad-

dresses were incorporated.

The website has been developed and became live in July 2001.

It provides information and links to other relevant sites. A form

to ask for information, register for membership and for confer-

ences has also been generated. Information enetered onto these

forms is sent directly by email to the administration office at

Leeds University (Samantha Armitage)

The newsletter is ready to be posted onto the website and future

information will be generated in a similar manner.

If your organisation or company would like to be linked to our

website please let us know. We would be anxious for the web

IRL to be linked to you in exchange and in this way communi-

cation should improve.

The 6th Pharmaceutical Isolator Conference is to be held

at The Cairn Hotel, Harrogate in North Yorkshire from

Sunday evening 28th October to Tuesday 30th October

2001. The venue is a recently refurbished hotel just to the

north of the town centre with good facilities. The main

conference venue will be the hotel ballroom and we are

arranging good quality audio visual equipment. There are

suitable facilities to be used for the seminar sessions and

good break out areas. Access to the exhibition area is easy

from both the exhibitors and the delegates point of view.

The Conference will again be administered by the School

of Continuing Education, University of Leeds.

Many current topics relating to Isolators are planned.

There will shortly be a new International Standard relating

to what we understand to be Isolators. Preceding this, there

is to be a revision of the Yellow Book. The new public a-

tion was planned to be available in time for the Conference

but with so many new sections to check this target is

unlikely to be met. There should be a demonstration copy

available for consideration by delegates on the PIUG

stand.

The Conference program will include presentations on the

positive and negative Isolator debate and where or how

these should be used. We will have an opportunity to com-

pare the developing new ISO standards with other recog-

nised standards. There will be sessions on maintenance

and validation, use of biological indicators, training, prac-

tical and user experiences. There will also be a poster ses-

sion and an appraisal of innovations from manufacturers.

One of the most important aspects is the general discusion

and interaction between delegates as lots of questions can

be asked and much information exchanged. This will be in

addition to the scheduled discussion session during Con-

ference.

6t h Pharmaceut i cal Isol at or Conf erence

For further information please contact:

Mr Brian Midcalf

Chairman Isolator User Group

Please register your interest by contacting Samantha Ar-

mitage Department of Continuing Education, University of

Leeds.

0113 233 3236

Email: s.armitage@leeds.ac.uk

Page 5 Pharmaceut i cal Isol at or User Group Newsl et t er

Page 6 Pharmaceut i cal Isol at or User Group Newsl et t er

New Yel l ow Gui deProgress Report

The Isolator Working Party has been working very en-

thusiastically to produce the new edition of the popular

User Guide, Isolators for Pharmaceutical Applica-

tions; affectionately known as the Yellow Guide

The group have been fully aware that the Guide was in

need of revision for some years now. It was decided that

we needed to wait for the development of the new ISO

Standard to avoid any potential conflicts with the re-

vised Guide.

The Group started the work in 2000 after considering

the potential conflicting demands of users and the set-

ters of standards. Initially, knowing there was going to

be a standard developed by ISO it was accepted that we

would delay the development of the next user guide un-

til the standard terminology had been agreed. This was

sensible as a user guide using a set of different terms to

the Standard would likely cause confusion and misun-

derstanding.

As time past, we realised that the most optimistic sched-

ule for the ISO development was subject to a serious of

set backs or delays. There was also an ever increasing

demand for the new edition of the Yellow Book. The

Working Party set about developing the new guide. It

was to be expanded significantly and have more ex-

plicit, user friendly guidance for all Isolator practices.

The problem of terminology conflicts was to be re-

solved as far as possible by using the development i n-

formation made available from the deliberations of

WG7. It was then likely that there would be very few

conflicts.

We agreed therefore that we should make progress on

the 3rd Edition as soon as we could. The mechanism of

gathering the information for the text was an interesting

challenge to the group.

After some discussion, we readily agreed to form

groups from our membership. A member was selected

as section leader following the particular speciality or

interest of the individual where possible The group

members then combined their expertise and when a

chapter has enough agreement it was circulated for

wider comment to the whole WP.

To facilitate all this combination of effort, the modern

communication methods were adopted. This meant the

Internet with its email communication systems helped

enormously in the exchange of material.

The agree main sections of the book are as follows:

1 Introduction

2 Definition of Terms

3 Design

4 Transfer Devices

5 Siting and the Environment

6 Validation

7 Training

8 Gloves and gauntlets

9 Applications for Isolators

10 Standards

11 Cleaning, sanitisation and decontamination

12 Leak testing

The aim was always to produce a book which would be

used by many Isolators users in a wide range of differ-

ent situations. It was to be a practical and useful guide.

This objective is still a main focus of the Group.

Another objective was to produce the book in time for

the next Isolator Conference. We have given an assur-

ance that this would be maintained. During the last year

very good progress had been made. Although our target

was in sight, wit h so much material from different

groups, the editorial process was becoming a very time

consuming business. A small group has been making

very good progress in the editorial screening but there is

still more work to do.

As more of the main Working Party saw, considered

and criticised the assembled chapters of the book, sug-

gested additions were made. The realisation that some

items had not been included immediately stretched the

completion date. These factors are responsible for an

extended fianl completion date.

Recently the Working Party agreed that it would be un-

wise to release a book that was not complete or a book

where errors had not been corrected. Neither did we thin

it was wise to release part of a book. We do hope to ex-

hibit a computer version of the latest draft so that Con-

ference delegates can see how much progress has been

made. It will present an early opportunity to receive

feedback from potential users.

The outcome of all this is the realistic prospect of the

publication of the new edition in 2002. We hope to have

both a printed and CD Rom version available and the

normal printed copy will be published via the Pharma-

ceutical Press.

Meanwhile the current edition 2 is still in print.

H

e

l

p

n

e

e

d

e

d

f

o

r

I

s

o

l

a

t

o

r

s

P

H

A

R

M

A

C

E

U

T

I

C

A

L

I

S

O

L

A

T

O

R

U

S

E

R

G

R

O

U

P

Vol ume 3, Issue 2

5

Oct ober 2001

Message for sick Isolators

I am a sick Isolator. I said that last time. I am still not feeling

too well. In fact, I am only improved because I am receiving

some attention.

Just receiving attention doesnt mean I

am going to be cured but at least there

is a ray of hope.

I said before that I was looking for other Isolators in a similar

state to contact me to share experiences. Where are you? Is

every other Isolator but me in peak condition? Is the

situation so much better than I had first been led to

believe? Or is it even more serious than I had at first

thought? You may be so sick that you havent the

strength to put pen to paper. Maybe your electronic

plug has been pulled!

Just as a reminder; some of you might now be or

may never have been quite up to the required

standard .. Seals loose, rusty bits, handles fal-

ling off, HEPA filters with holes in them rickety

hinges, faulty gauges.. Some of you may not

have been tested properly and your ailment may

not have been picked up.

Are you struggling on, day after day, not really

being able to reassure your owners that you will provide the required envi-

ronment in which they must prepare their products or carry out their proce-

dures.

Ive just heard! At the next Conference to be held this month

someone is going to discuss some Isolator disasters. I understand there are

some amusing tales to relate. I will keep my ailing sensors tuned as best I

can and report back in the next issue.

A Sick Isolator Story (continued)

Advertising Feature

Why not put your Isolator in touch with the unit featured above? There may be comfort

in the comradeship of other units facing a similar problem. If these neglected Isolators

can register with the User Group as associate members who knows how such a united

approach could dramatically improve the controlled environment required by so many

of us. Please send your neglected Isolators list of problems to the editorial team.

ENOUGH IS

ENOUGH!

Page 7 Vol ume 3, Issue 2 5

Mr Brian Midcalf

Chairman Pharmaceutical Isolator User Group

School of Continuing Education

Springfield Mount

University of Leeds

Leeds

LS2 9NG

Tel 0 1 1 3 2 3 3 3 2 3 6

Fax 0 1 1 3 2 3 3 3 2 4 0

Email s.armit age@l eeds.ac.uk

Emai l bri an@mi dcal f .cl ub24.co.uk

Mrs Lynn Lawl er

Ms Margaret Horsey

Mr Davi d Morl ey

Dr Bev Ellis

Mrs Carol ine Col es

Mr Ken Baker

T he Isolator U ser Group was created following a number of

successful Pharmaceutical Isolator Conferences. T hese events

drew together delegates involved in the use of Isolators, the de-

sign, construction and testing of Isolators as well as specialists

in associated fields. D elegates to these conferences formed the

nucleus of the U ser Group. A committee was elected and off i-

cers appointed to run the User Group.

T he objectives of the Group are to promote good practice in

the use of Pharmaceutical Isolators; to provide a forum for

the ex change of information; to promote a platform for di s-

cussion on any isolator topic, to deliberate over testing and

evaluations associated with Isolators and to facilitate train-

ing.

T here is considerable support for a wide range of membership,

within the U K and in other neighbouring countries. If you

are reading this and you are not a member we would be

pleased to hear from you and indicate how you could join our

group for a modest subscription. Contact any of the User

Group Committee or E mail the chairman.

Chairman: Mr Brian Midcalf

S ecretary: Ms L ynn L awler

T reasurer: Mrs M H orsey

Committee::

Mr Ken Bak er, Mrs Caroline Coles, D r Beverley E llis, Mr

D avid Morley.

Pharmaceutical Isolator U ser Group

Your Cont ri but i ons Want ed.

Experi ences requi red!

Begi nners probl ems?

User Di f f i cul t i es?

Hi nt s and Ti ps t o of f er?

A sui t abl e venue for a conference?

Page 8 Pharmaceut i cal Isol at or User Group Newsl et t er

Please write or fax or email your comments

and contributions to:-

Mr Brian Midcalf at the above address or to

any member of the User Group Committee

or to

Ms Samantha Armitage

School of Continuing Education

Springfield Mount

University of Leeds

H ow to contact us:-

You might also like

- Foleys ThesisDocument6 pagesFoleys Thesisjenwilliamsneworleans100% (2)

- Cell expression sequencing tool to find DNA fragments presentDocument4 pagesCell expression sequencing tool to find DNA fragments present轴心赫米No ratings yet

- Scientology Price ListDocument6 pagesScientology Price ListdorkykongNo ratings yet

- 2009 135 1 1 1 TurpinDocument1 page2009 135 1 1 1 TurpinAnne C. TorresNo ratings yet

- Signaller S HandbookDocument92 pagesSignaller S HandbookjbrhewittNo ratings yet

- Questions and Answers for the Specialty Recruitment AssessmentFrom EverandQuestions and Answers for the Specialty Recruitment AssessmentRating: 2 out of 5 stars2/5 (5)

- Statistics: 1,001 Practice Problems For Dummies (+ Free Online Practice)From EverandStatistics: 1,001 Practice Problems For Dummies (+ Free Online Practice)Rating: 3 out of 5 stars3/5 (1)

- Cjo Journal 77-2 Online FinalDocument54 pagesCjo Journal 77-2 Online FinalNanggala Putra RahandaNo ratings yet

- Scientology Price ListDocument6 pagesScientology Price ListsirjsslutNo ratings yet

- Thesis Sheet PresentationDocument7 pagesThesis Sheet Presentationgj9zvt51100% (2)

- WWW Kelvintopset Com Resources How To Write The InvestigatioDocument9 pagesWWW Kelvintopset Com Resources How To Write The InvestigatioKushan Mayuranga Ruphasinghe100% (1)

- 1St International PHD Symposium On Offshore Renewable EnergyDocument70 pages1St International PHD Symposium On Offshore Renewable EnergyRyan SmithNo ratings yet

- Thesis Topics For Bachelor DegreeDocument6 pagesThesis Topics For Bachelor Degreecourtneybennettshreveport100% (2)

- Ielts Summary WriteDocument8 pagesIelts Summary WriteantoineNo ratings yet

- Unilever Sample TestDocument9 pagesUnilever Sample TestSherif Eltoukhi75% (4)

- House of Commons Library Research PapersDocument6 pagesHouse of Commons Library Research Paperslemvhlrif100% (1)

- United States Patent (19) : MarchDocument7 pagesUnited States Patent (19) : Marchghftr456No ratings yet

- Thesis No ResultsDocument4 pagesThesis No Resultsafcmayfzq100% (2)

- Dentist BurnoutDocument7 pagesDentist BurnoutNg JunnNo ratings yet

- Robert Lacoste's The Darker Side: Practical Applications for Electronic Design Concepts from Circuit CellarFrom EverandRobert Lacoste's The Darker Side: Practical Applications for Electronic Design Concepts from Circuit CellarNo ratings yet

- Essential Examination Aid For Dental NursesFrom EverandEssential Examination Aid For Dental NursesRating: 3.5 out of 5 stars3.5/5 (3)

- How To Write Final Research PaperDocument8 pagesHow To Write Final Research Papergvytgh3b100% (1)

- Academic Entrepreneurship: How to Bring Your Scientific Discovery to a Successful Commercial ProductFrom EverandAcademic Entrepreneurship: How to Bring Your Scientific Discovery to a Successful Commercial ProductNo ratings yet

- Dissertation Project Expert ReportDocument5 pagesDissertation Project Expert ReportOrderPaperOnlineCanada100% (1)

- Pols142 Test 5Document4 pagesPols142 Test 5Mohammed AlgendyNo ratings yet

- 101 Ways to Score Higher on Your Series 7 Exam: What You Need to Know Explained SimplyFrom Everand101 Ways to Score Higher on Your Series 7 Exam: What You Need to Know Explained SimplyRating: 1 out of 5 stars1/5 (1)

- Open Single Best Answers For MRCOG Part 2 - Brian A MagowanDocument231 pagesOpen Single Best Answers For MRCOG Part 2 - Brian A MagowanDr. Faeba JosephNo ratings yet

- Writing Paragraph Detailed GuideDocument7 pagesWriting Paragraph Detailed GuideHu ChiNo ratings yet

- Thesis Paper Sample PDFDocument7 pagesThesis Paper Sample PDFmelissawilliamsdenver100% (2)

- Thesis Pending OptDocument5 pagesThesis Pending Optfj9dbfw4100% (2)

- Communication BarrierDocument16 pagesCommunication BarriermahendrabpatelNo ratings yet

- Writing: Anne HiltonDocument36 pagesWriting: Anne HiltonSonu RaiNo ratings yet

- Practice Leaflet: Why Are Aptitude Tests Used?Document10 pagesPractice Leaflet: Why Are Aptitude Tests Used?Osagie AlfredNo ratings yet

- Thesis For Dental ClinicDocument4 pagesThesis For Dental Clinicbk1hxs86100% (2)

- Polotical Affairs - Written TestDocument17 pagesPolotical Affairs - Written TestGeorgeNo ratings yet

- Timing Solutions for Swing Traders: Successful Trading Using Technical Analysis and Financial AstrologyFrom EverandTiming Solutions for Swing Traders: Successful Trading Using Technical Analysis and Financial AstrologyNo ratings yet

- A2 Biology Coursework MemoryDocument4 pagesA2 Biology Coursework Memoryjxaeizhfg100% (2)

- by.M.-B - U1 - HLS,-NJ.: This Manual Is For Reference and Historical Purposes, All Rights ReservedDocument31 pagesby.M.-B - U1 - HLS,-NJ.: This Manual Is For Reference and Historical Purposes, All Rights ReservedzsdbgasdbsdadsbgNo ratings yet

- AETIDocument17 pagesAETIPatrick WeillNo ratings yet

- Edition: Life in The UK TestDocument40 pagesEdition: Life in The UK Testismailzaheer123No ratings yet

- Nutrition study sheds light on thanking partnersDocument6 pagesNutrition study sheds light on thanking partnersNunung KawaiNo ratings yet

- Essay Apa Format SampleDocument7 pagesEssay Apa Format Samplevdyvfjnbf100% (1)

- Chapter 1 Research Paper PDFDocument5 pagesChapter 1 Research Paper PDFtbwrxxvkg100% (1)

- Circulatory System EssayDocument5 pagesCirculatory System Essayfz75587x100% (2)

- Ensayos de Los Juegos Del HambreDocument7 pagesEnsayos de Los Juegos Del Hambrevxrtevhjf100% (1)

- Assignment 3.2 Survey QuestionnaireDocument3 pagesAssignment 3.2 Survey QuestionnaireLu LacNo ratings yet

- He Problem Statement of A ProposalDocument5 pagesHe Problem Statement of A ProposalAishatu Musa AbbaNo ratings yet

- Opening Remarks Thesis DefenseDocument5 pagesOpening Remarks Thesis Defensednr3krf8100% (2)

- SMDM Project Analysis and InsightsDocument29 pagesSMDM Project Analysis and InsightsSheetal MayanaleNo ratings yet

- Research Paper On ItalyDocument4 pagesResearch Paper On Italyc9jg5wx4100% (1)

- Harmonic Elliott Wave: The Case for Modification of R. N. Elliott's Impulsive Wave StructureFrom EverandHarmonic Elliott Wave: The Case for Modification of R. N. Elliott's Impulsive Wave StructureRating: 3 out of 5 stars3/5 (1)

- ADocument1 pageA89hariharanNo ratings yet

- Stagflation: Slow Growth, High Inflation & UnemploymentDocument8 pagesStagflation: Slow Growth, High Inflation & Unemployment89hariharanNo ratings yet

- Uncreatable Folder NamesDocument1 pageUncreatable Folder Names89hariharanNo ratings yet

- Sbiasb CL 962143Document2 pagesSbiasb CL 96214389hariharanNo ratings yet

- Peru 2Document1 pagePeru 289hariharanNo ratings yet

- RPWHG Guhzj Js GWG Nghus Kugfs : Tuyhw WPD Top Nghuf FHD Fhuzq FsDocument6 pagesRPWHG Guhzj Js GWG Nghus Kugfs : Tuyhw WPD Top Nghuf FHD Fhuzq Fs89hariharanNo ratings yet

- Kittel Charles - Introduction To Solid State Physics 8Th Edition - Solution ManualDocument60 pagesKittel Charles - Introduction To Solid State Physics 8Th Edition - Solution Manualnawarajbhandari86% (35)

- Propositional Logic and Set Theory Sample ExamDocument3 pagesPropositional Logic and Set Theory Sample Examzerihun MekoyaNo ratings yet

- Dealing With Inherent Variability - The Difference Between Service and ManufacturingDocument14 pagesDealing With Inherent Variability - The Difference Between Service and Manufacturinghoangnguyen7xNo ratings yet

- Deep Ecology Debate on Humans' Environmental RoleDocument8 pagesDeep Ecology Debate on Humans' Environmental RoleVidushi ThapliyalNo ratings yet

- Proposal GuidelinesDocument7 pagesProposal GuidelinesNoraimi AainaaNo ratings yet

- Diagnostic Test Grade 8Document6 pagesDiagnostic Test Grade 8Charlyne Mari FloresNo ratings yet

- Self Concept and Self EsteemDocument5 pagesSelf Concept and Self EsteemNurul DiyanahNo ratings yet

- Dasamsa-Loss and Gain in CareerDocument75 pagesDasamsa-Loss and Gain in Careerarthicse100% (9)

- Mix EcoprintDocument11 pagesMix EcoprintratihNo ratings yet

- Benchmarking 110611152521 Phpapp01Document133 pagesBenchmarking 110611152521 Phpapp01Sooraj Balakrishnan100% (1)

- Beckman - 1996 - The Parsing of ProsodyDocument53 pagesBeckman - 1996 - The Parsing of ProsodyNathacia Lucena RibeiroNo ratings yet

- 03 History Mains 2019Document2 pages03 History Mains 2019garg1209377No ratings yet

- Waldstein - What Is Integralism Today - Church Life J - 2018Document6 pagesWaldstein - What Is Integralism Today - Church Life J - 2018Alvino-Mario FantiniNo ratings yet

- Political ScienceDocument13 pagesPolitical SciencesumanthNo ratings yet

- Safety Induction Post Test Answer Sheet: Name: Nexus: Score: Instructor: DateDocument1 pageSafety Induction Post Test Answer Sheet: Name: Nexus: Score: Instructor: DateJunard Lu HapNo ratings yet

- Shs Daily Lesson Log in Practical Research 2Document36 pagesShs Daily Lesson Log in Practical Research 2Pepito Manloloko96% (25)

- Foundations of Qualitative Research: Orientations to MeaningDocument23 pagesFoundations of Qualitative Research: Orientations to MeaningKrishnaveni KNo ratings yet

- Introductory Concepts and Definitions: Dr. Codruta Gosa Codruta - Gosa@e-UvtDocument15 pagesIntroductory Concepts and Definitions: Dr. Codruta Gosa Codruta - Gosa@e-UvtMădălina TodincaNo ratings yet

- Formula FizikDocument1 pageFormula FizikAzizi Abdullah AbdullahNo ratings yet

- Introduction To The Philosophy of The Human Person: Prudence and Frugality Towards The EnvironmentDocument14 pagesIntroduction To The Philosophy of The Human Person: Prudence and Frugality Towards The EnvironmentPril Gueta100% (1)

- Figurative Language EssayDocument14 pagesFigurative Language EssayRosalía ImlNo ratings yet

- 7 Hermetic PrinciplesDocument2 pages7 Hermetic PrinciplesFabrizio Bertuzzi100% (2)

- A Study of Beggars Characteristics and Attitude of People Towards TheDocument14 pagesA Study of Beggars Characteristics and Attitude of People Towards TheLaiKamChongNo ratings yet

- Reflection EssayDocument1 pageReflection EssayWilliane PeñanuevaNo ratings yet

- Ignatian Values and Principles for Jesuit EducationDocument17 pagesIgnatian Values and Principles for Jesuit EducationKimberly RivasNo ratings yet

- Post Subcultural TheoryDocument6 pagesPost Subcultural TheoryAkhmad Alfan RahadiNo ratings yet

- Emma Castelnuovo's use of concrete materials in mathematics teachingDocument6 pagesEmma Castelnuovo's use of concrete materials in mathematics teachingNenden Mutiara SariNo ratings yet

- The Dangers of Emotional AttachmentDocument2 pagesThe Dangers of Emotional AttachmentMatthew JosephNo ratings yet

- The Program For Better VisionDocument223 pagesThe Program For Better VisionBlasa100% (6)

- Posted: 2012/06/17 - Author: Amarashiki - Filed Under: Physmatics, Relativity - Tags: Physmatics, Relativity - Leave A CommentDocument5 pagesPosted: 2012/06/17 - Author: Amarashiki - Filed Under: Physmatics, Relativity - Tags: Physmatics, Relativity - Leave A CommentAlfigueroaNo ratings yet

- Chapter 3 The Filipino WayDocument12 pagesChapter 3 The Filipino WayJoy Estela MangayaNo ratings yet