Professional Documents

Culture Documents

Appendix

Uploaded by

niiamoo2002Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix

Uploaded by

niiamoo2002Copyright:

Available Formats

Appendix

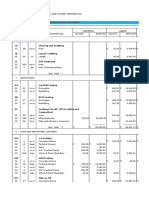

Table A-1: U-Values of Building Envelope Components as Required by TJRBEEDS (W/mK) TJRBEEDS-97 TJRBEEDS-04 Shape coefficient 0.30<Shape Buildings with 5 or Buildings with 4 or <= 0.30 coefficient <=0.35 more stories fewer stories Roof 0.80 0.60 0.50 0.40 Exterior wall 1.16 0.82 0.60 0.45 Un-heated stairwell Partition wall 1.70 1.70 1.50 1.50 Apartment entry door 1.70 1.70 1.50 1.50 Window 4.00 4.00 2.70 2.50 Balcony door Glazed portion 4.00 4.00 2.70 2.70 Non-glazed portion 1.70 1.70 1.50 1.50 Building entry door Glazed portion NA NA 4.00 4.00 Non-glazed portion 1.70 1.70 1.50 1.50 Exposed floor 0.50 0.50 0.50 0.50 (to outside air) Basement ceiling floor 0.55 0.55 0.55 0.55 Ground NA NA Perimeter 0.52 0.52 Non-perimeter 0.30 0.30 Sources: Liu (2006); Tianjin Residential Building Energy-Efficient Design Standards, 1997 and 2004 Table A-2. Assumptions on intervention of buildings envelope performance enhancement with U-value in parentheses BEE Scenario Roof Exterior wall Window exposed floor Air tightness (V/hr) 0.6

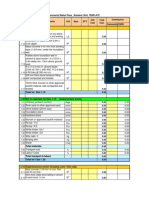

Base case

(without thermal insulation)

-100mm steel reinforced concrete floor -20 mm cement mortar -4mm water proof -4m joint mortar - 40mm stone concrete (2.0) + 50mm EPS (0.59)

Simpleglazed with steel frame (6.4) Concrete floor: 100 mm -20mm of interior finish 20mm exterior plaster -mortar190mm concrete block -90mm decorative brick

(4,37)

TJ-97

( 1.6) + 40mm EPS

Doubleglazed in northern, Eastern and Western faade, simpleglazed in south faade

50mm EPS panel

0.5

TJ- 2004

+80mm EPS

(0.67) +60mm EPS

(4.7 ;2.7) Double glazed with PVC frame

(0,7) 0.5 +20mm EPS panel and 35mm XPS panel plus finish (0,52) 0.45 +20mm EPS panel and 35mm XPS panel plus finish

(0.42) TJ-CAN (3500 +90mm HDD) EPS

(0.51) +80mm EPS

(0.4)

(0.42)

TJ-RT2005

+80mm EPS

+70 mm EPS

TJ-SWE

(0.44) +220mm XPS (0.12)

(0.43) +210mm EPS

(2.7) 6 Low-E+12 air filling + 6 transparent , ratio of window to wall is 25% (2.9) 6+ 12mm argon filling +6 , PVC 25% of window surface (2.6) 6mm Low-E with argon filling

(0,52) 0.35 +20mm EPS panel and 35mm XPS panel plus finish (0,52) 0.3 +20mm EPS panel and 35mm XPS panel plus finish 0,52

(0.17) Note: U-value of PVC window frames: 2.7 W/m K U-value of metal window frames: 5.3 W/m K Building envelope integrity U-value

(2.0)

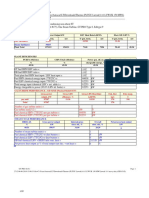

Table A-3 Energy conversion efficiency * in different supply systems considered in the model capacity Plant thermal efficiency Electric efficiency Distribution networks efficiency Heat to power ratio

th

ele

dist

District coal fired boiler District coalfired CHP District gasfired CHP Municipal gasfired plant Household gas boiler

20 t /h 20t/h + 2000KWe 11 t/h + 4000 KWe 3 116 MWth

60% 50% 51% 40% 88% 15% 30% 33%

90% 90% 90% 85% 100% 3.3 1.7 1.2

* All efficiency numeraires refer to the average operation efficiency instead of rated efficiency which may vary depending on the load factor and actual operation condition. Table A-4 Costs in different heat supply systems Capital cost O&M cost

Supply option District coal fired boiler District coal-fired CHP District gas-fired CHP Municipal gas-fired plant Household gas boiler

Yuan/KWth 450

Yuan/KWe

yuan/MJ (heat) 0.0035 0.0056 0.007 0.00675 16 yuan/KW/an

Yuan/KWh (electricity)

8500 5000 4500 600

0.05 0.042 0.0536

Note: Heating supply system capital costs and O&M cost in the thermal power plants is estimated based on Liu(2006) in which a dozen of both public and private heat supply utility companies have been interviewed; Ye et al., (2001); Cummins(2004); CNMEDI (2006).

You might also like

- Proposed one storey residential cost estimateDocument18 pagesProposed one storey residential cost estimatePapsi Pap100% (1)

- Annex V-Bill of Quantities (BoQ)Document18 pagesAnnex V-Bill of Quantities (BoQ)SCReddy100% (1)

- Boq (110912)Document144 pagesBoq (110912)Ali AlaliNo ratings yet

- Heat Pump Sizing CalculatorDocument37 pagesHeat Pump Sizing CalculatorBambang Hermawan100% (1)

- Electrical Installation-Sample Design LightingDocument9 pagesElectrical Installation-Sample Design LightingasdthuNo ratings yet

- Fan Static Pressure CalculationDocument6 pagesFan Static Pressure CalculationVõ Tấn Thùy100% (2)

- Community Market Foundation Construction BoQDocument4 pagesCommunity Market Foundation Construction BoQPirated Soul100% (1)

- Electrical Instalation Report For G+6Document18 pagesElectrical Instalation Report For G+6Hamdi KedirNo ratings yet

- Grupel generators provide over 40 years of energy experienceDocument20 pagesGrupel generators provide over 40 years of energy experienceJ Alberto P ArrazateNo ratings yet

- Steam Power Reviewer Terms and Problem SolvingDocument9 pagesSteam Power Reviewer Terms and Problem SolvingCherry May Basinang-RamosNo ratings yet

- Sugar Manual PDFDocument66 pagesSugar Manual PDFRajesh KtrNo ratings yet

- UAEU Phthalic Anhydride ProjectDocument78 pagesUAEU Phthalic Anhydride ProjectminumcincauNo ratings yet

- Interior Detailing: Concept to ConstructionFrom EverandInterior Detailing: Concept to ConstructionRating: 4 out of 5 stars4/5 (1)

- EE Benchmarking For Cement IndustrysDocument41 pagesEE Benchmarking For Cement Industrysshoaibhassan23100% (2)

- Thermal insulation calculation for building envelopeDocument23 pagesThermal insulation calculation for building envelopeMircea TirziuNo ratings yet

- Seminar-Energy Recovery From Municipal Solid Waste by Anaerobic DigestionDocument43 pagesSeminar-Energy Recovery From Municipal Solid Waste by Anaerobic DigestionPankaj GargNo ratings yet

- Design of CFBC BoilerDocument86 pagesDesign of CFBC Boilerhalder.kalyan88% (8)

- Fundamentals of Supercritical Coal PowerDocument7 pagesFundamentals of Supercritical Coal PowerEngr Imtiaz Hussain GilaniNo ratings yet

- Structural Design Criteria-March 2008Document14 pagesStructural Design Criteria-March 2008mtaha82No ratings yet

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Literature Review On Cement Industry WHRDocument24 pagesLiterature Review On Cement Industry WHRnihal attarNo ratings yet

- Project 2: Building Science Final ProjectDocument22 pagesProject 2: Building Science Final ProjectSurayyn SelvanNo ratings yet

- Plate heat exchanger insulation technical specificationDocument2 pagesPlate heat exchanger insulation technical specificationMurrali Raj JeyagapalNo ratings yet

- Appendix A: Tables of U-ValuesDocument15 pagesAppendix A: Tables of U-ValuesJoAnn NgNo ratings yet

- ABI Economic of Construction ProjectDocument8 pagesABI Economic of Construction ProjectMigara MapalagamaNo ratings yet

- Final ReportDocument26 pagesFinal ReportNurul Izzaty HayesNo ratings yet

- Thermoelectric Fan Powered by A CandleDocument4 pagesThermoelectric Fan Powered by A CandleMohd Farihan Bin JamaludinNo ratings yet

- Arval Floline E-Floline Curved Metal PanelsDocument24 pagesArval Floline E-Floline Curved Metal PanelsCorbean AlexandruNo ratings yet

- Energy Performance: Thermal Transmittance, Also Known As U-Value, Is The Rate of Transfer of Heat (In Watts)Document10 pagesEnergy Performance: Thermal Transmittance, Also Known As U-Value, Is The Rate of Transfer of Heat (In Watts)Brahmam GuruNo ratings yet

- LG CommerciaL Air Conditioner - Sinlge Split Type - (Non-Inverter)Document18 pagesLG CommerciaL Air Conditioner - Sinlge Split Type - (Non-Inverter)Minhvan LeNo ratings yet

- Digital FM ReceiverDocument16 pagesDigital FM Receiverapi-27099960100% (1)

- Recuperator de Caldura Eco V DX Coil - PliantDocument58 pagesRecuperator de Caldura Eco V DX Coil - PliantDana LoreNo ratings yet

- Luminaire Data Sheet: ELBA FIPAD-04-236Document4 pagesLuminaire Data Sheet: ELBA FIPAD-04-236Sandra AldeaNo ratings yet

- SP Processing HallDocument1 pageSP Processing HallOsama AhmadNo ratings yet

- Brunner tile stoves and masonry heaters price listDocument48 pagesBrunner tile stoves and masonry heaters price listAlupei BijjaNo ratings yet

- Electrical Design ReportDocument16 pagesElectrical Design ReportEPHREM TENSAENo ratings yet

- General ToleranceDocument15 pagesGeneral TolerancerenebbNo ratings yet

- TETC1 24127T200 74 EnglishDocument3 pagesTETC1 24127T200 74 EnglishJoko Mardi UtomoNo ratings yet

- Design Presentation (Compatibility Mode)Document28 pagesDesign Presentation (Compatibility Mode)Wissam JarmakNo ratings yet

- U-Values From Domestic Heating Design Guide v1.0Document13 pagesU-Values From Domestic Heating Design Guide v1.0gaurankushNo ratings yet

- Standard BoQ TEMPLATE Market PlaceDocument4 pagesStandard BoQ TEMPLATE Market PlaceAntoine YabichinoNo ratings yet

- Room Temperature Sensors and Transmitters for HVACDocument2 pagesRoom Temperature Sensors and Transmitters for HVACLullaby summerNo ratings yet

- Sala E Projeto LuminotecnicoDocument1 pageSala E Projeto Luminotecnicoe_alternativoNo ratings yet

- 64 Push-to-Close LatchDocument8 pages64 Push-to-Close Latchdiegoh_silvaNo ratings yet

- Community Medical Centre construction detailsDocument1 pageCommunity Medical Centre construction detailsウィン二No ratings yet

- General SpecsDocument5 pagesGeneral Specsreygrant3900No ratings yet

- جدول الكميات رقم 2 الأعمال الميكانيكية والكهربائية مبنى 608 مشروع OPM الحرس الوطني بخشم العانDocument7 pagesجدول الكميات رقم 2 الأعمال الميكانيكية والكهربائية مبنى 608 مشروع OPM الحرس الوطني بخشم العانمهدي الرشيدNo ratings yet

- EN Series Steels Characterization and Burnishing Process OptimizationDocument18 pagesEN Series Steels Characterization and Burnishing Process OptimizationRebekah WilsonNo ratings yet

- Drill String TorqueDocument2 pagesDrill String TorqueMuhammad Naufal Nazhib KhanNo ratings yet

- Repair To Fan GeyserDocument10 pagesRepair To Fan GeyserkihtrakaNo ratings yet

- Calcul TermicDocument23 pagesCalcul TermicgoeadiNo ratings yet

- Pressure Gauge MountingDocument2 pagesPressure Gauge MountingGayathri ShanmugamNo ratings yet

- Electricals DetailsDocument15 pagesElectricals DetailsSanjeev GulyaniNo ratings yet

- CPWD SOR Electrical1Document201 pagesCPWD SOR Electrical1Sricharan MajhiNo ratings yet

- Stelrad Radiator Technical Information PDFDocument6 pagesStelrad Radiator Technical Information PDFmarklam1985No ratings yet

- Chummary Quarters at KilinochchiDocument44 pagesChummary Quarters at KilinochchiMohamed Faiz Issma LebbeNo ratings yet

- ( Wilsonart Laminates On 12mm THK Board Backings) : Sub-TotalDocument2 pages( Wilsonart Laminates On 12mm THK Board Backings) : Sub-TotalVholts Villa VitugNo ratings yet

- Calcul TermicDocument23 pagesCalcul Termicc_i_jNo ratings yet

- Baguio BOQ FormatDocument176 pagesBaguio BOQ FormatronatabbuNo ratings yet

- Quantity of Shuttering With ExampleDocument2 pagesQuantity of Shuttering With Examplesri projectssNo ratings yet

- IBS Scoresheet Calculator for Precast Construction ProjectDocument1 pageIBS Scoresheet Calculator for Precast Construction ProjectAsraf MuidinNo ratings yet

- Baguio BOQ Format-1Document97 pagesBaguio BOQ Format-1ronatabbuNo ratings yet

- R410A Service Manual for Split-Type Air ConditionersDocument187 pagesR410A Service Manual for Split-Type Air ConditionersVahida KozicNo ratings yet

- Heating Equipment World Summary: Market Values & Financials by CountryFrom EverandHeating Equipment World Summary: Market Values & Financials by CountryNo ratings yet

- 1 tonne carbon treeDocument2 pages1 tonne carbon treeniiamoo2002No ratings yet

- Modeling Principles GaBi Databases 2021Document229 pagesModeling Principles GaBi Databases 2021niiamoo2002No ratings yet

- Grade DescriptorsDocument32 pagesGrade Descriptorsniiamoo2002No ratings yet

- IEA Printindex In..Document1 pageIEA Printindex In..niiamoo2002No ratings yet

- Comparative Life-Cycle Assessment of A Mass Timber Building and Concrete AlternativeDocument14 pagesComparative Life-Cycle Assessment of A Mass Timber Building and Concrete Alternativeniiamoo2002No ratings yet

- International Comparison of Energy Standards - 0091414Document29 pagesInternational Comparison of Energy Standards - 0091414niiamoo2002No ratings yet

- Standard PreviewDocument8 pagesStandard Previewniiamoo2002No ratings yet

- Writing ChecklistDocument1 pageWriting Checklistniiamoo2002No ratings yet

- Parameters For Simulation of Energy DemandDocument1 pageParameters For Simulation of Energy Demandniiamoo2002No ratings yet

- Final - Buildings 10 00005Document22 pagesFinal - Buildings 10 00005niiamoo2002No ratings yet

- Buildings RoadmapDocument56 pagesBuildings RoadmapmaxmanfrenNo ratings yet

- Energy and Buildings enDocument2 pagesEnergy and Buildings enniiamoo2002No ratings yet

- Tap RoofDocument147 pagesTap Roofniiamoo2002No ratings yet

- TenantDocument8 pagesTenantniiamoo2002No ratings yet

- IEA-ECBCS Annex 51: Energy Efficient Communities. Experience From DenmarkDocument8 pagesIEA-ECBCS Annex 51: Energy Efficient Communities. Experience From Denmarkniiamoo2002No ratings yet

- Växjö MonDocument1 pageVäxjö Monniiamoo2002No ratings yet

- New Electricity Technologies - 71FA1A6Dd01Document25 pagesNew Electricity Technologies - 71FA1A6Dd01niiamoo2002No ratings yet

- Concrete: - Co Is Re-Absorbed Into The Concrete Matrix by Carbonation ReactionDocument1 pageConcrete: - Co Is Re-Absorbed Into The Concrete Matrix by Carbonation Reactionniiamoo2002No ratings yet

- 150MW GE Power Plant ReportDocument2 pages150MW GE Power Plant ReportgancanNo ratings yet

- New Enhancements For The 9FA Gas TurbineDocument8 pagesNew Enhancements For The 9FA Gas TurbinePrakash Chinnii100% (1)

- Biogas Technology Suppliers Directory 2018: Internati NalDocument6 pagesBiogas Technology Suppliers Directory 2018: Internati NalRazvan PetricaNo ratings yet

- Dry Coolers Condensers PDFDocument36 pagesDry Coolers Condensers PDFChethan GowdaNo ratings yet

- EOI PurchaseDocument2 pagesEOI PurchaseavilfNo ratings yet

- Welcome To The Seminar On MICROTURBINESDocument13 pagesWelcome To The Seminar On MICROTURBINESAnonymous vxNf3n3yMNo ratings yet

- SAV Achieving Low Return Temperatures From RadiatorsDocument7 pagesSAV Achieving Low Return Temperatures From RadiatorsNikolay GeorgievNo ratings yet

- Chapter - 5-Energy - and - AtmosphereDocument45 pagesChapter - 5-Energy - and - AtmosphereGAT 1124No ratings yet

- 0 0 19092014A2NEUAnnexure-Updated Form1 PDFDocument103 pages0 0 19092014A2NEUAnnexure-Updated Form1 PDFAKHIL BABU SNo ratings yet

- 2006 AR2 ElowDocument38 pages2006 AR2 ElowAnonymous AoUv7GzNo ratings yet

- BS en 15217-2007 PDFDocument34 pagesBS en 15217-2007 PDFqmarinelNo ratings yet

- ME8595-Thermal Engineering-II Valliammai PDFDocument19 pagesME8595-Thermal Engineering-II Valliammai PDFSiva SubramaniamNo ratings yet

- C11 NR Romania-EN PDFDocument99 pagesC11 NR Romania-EN PDFgimasaviNo ratings yet

- Biomass Energy: Empowering a “Renewable” FutureDocument11 pagesBiomass Energy: Empowering a “Renewable” FutureNishant BhadiyadraNo ratings yet

- Dokumen - Tips Saacke Boiler House Log Book Saacke Boiler House Log Book Saacke Service ContractDocument8 pagesDokumen - Tips Saacke Boiler House Log Book Saacke Boiler House Log Book Saacke Service Contractgeo3tripNo ratings yet

- Report Mali ZvornikDocument61 pagesReport Mali ZvornikSrbislav GenicNo ratings yet

- Support The Technical and Financial Sustainability of The Renewable Energy and Energy Efficiency Sectors Europeaid/138795/Dh/Ser/EgDocument205 pagesSupport The Technical and Financial Sustainability of The Renewable Energy and Energy Efficiency Sectors Europeaid/138795/Dh/Ser/EgahmedNo ratings yet

- A Novel Solution Towards Zero Waste in Dairy Farms A T 2021 Energy ConversiDocument19 pagesA Novel Solution Towards Zero Waste in Dairy Farms A T 2021 Energy ConversiLindawati DoloksaribuNo ratings yet

- Tar measurement standardizationDocument168 pagesTar measurement standardizationmanuelNo ratings yet

- Economic Comparison of Grate and BFB FiringDocument23 pagesEconomic Comparison of Grate and BFB FiringradanpetricaNo ratings yet

- RETScreen Combined Heat and Power CogenerationDocument24 pagesRETScreen Combined Heat and Power CogenerationArul SankaranNo ratings yet

- Research Article: Journal of Scientific and Engineering Research, 2020, 7 (7) :109-121Document13 pagesResearch Article: Journal of Scientific and Engineering Research, 2020, 7 (7) :109-121Chidi DiyokeNo ratings yet