Professional Documents

Culture Documents

Enercare Lubricant Analysis: Rating Summary Table For Lombardia (9208485)

Uploaded by

David Ortiz de ZevallosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Enercare Lubricant Analysis: Rating Summary Table For Lombardia (9208485)

Uploaded by

David Ortiz de ZevallosCopyright:

Available Formats

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

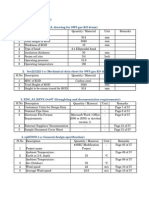

RATING SUMMARY TABLE FOR LOMBARDIA (9208485)

MACHINE MEZZX AEZZT AEZZT AEZZT BTHZZ LOCATION 1 1 2 3 1 SAMPLE GK024618 GK024619 GK024620 GK024621 GK024622 SAMPLED 12-Mrz-2009 12-Mrz-2009 12-Mrz-2009 12-Mrz-2009 12-Mrz-2009 RATING A. NORMAL A. NORMAL B. WARNING B. WARNING A. NORMAL

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

Enercare Lubricant Analysis - Glossary The BP Marine Enercare service utilises the latest analytical techniques and computer programming to offer an advanced lubricant analysis package that provides a valuable lubricant monitoring tool for the ship operator. Lubricant properties reported on Enercare lubricant analysis reports (tests conducted depend on machinery type and oil grade) Viscosity Closed Flash Point Insolubles Base Number Acid Number Water PQ Index Asphaltenes A measure of the resistance of a liquid to flow. Commonly referred to as the 'thickness of an oil'. Primarily a test for fuel dilution in engine oils. A decrease in flash point is generally an indication of fuel ingress which has contaminated the lubricant. A test for the total solids contamination in a lubricant such as combustion soot, dirt, oxidation products and metal wear debris. 'Previously known as Total Base Number (TBN) is a measure of the reserve alkalinity of an engine oil and its ability to neutralise harmful acids. Tests the acidity of the oil. Certain oils have an inherent acidity level related to their additive chemistry. Increasing acidity may be indicative of the presence of organic acids derived from oil oxidation. The percentage (by volume) of the total amount of water contamination. Not an oil property but an indices that provides a quantitative assessment, for trending purposes, of the amount of ferrous wear debris in the sample. Give an indication of heavy fuel derived components from raw fuel ingress and/or products of combustion from blow-by.

Elemental analysis with some typical sources (elements reported depend on machinery type and oil grade and are reported in PPM - Parts Per Million)

Aluminium Antimony Calcium Chromium Copper Iron Lead Magnesium Manganese Molybdenum Nickel Silicon Silver Sodium Tin Vanadium Zinc

Pistons, bearings, housings, fuel derivative Bearings Lubricant derivative Piston rings Bearings, gears, oil coolers, pipe-work, piston-rod glands Cylinder liners, crankshafts, piston rings, gears Bearings Casings, housings, lubricant derivative Cylinder liners Piston rings Bearings, valves, gears, fuel derivative Dust, dirt, fuel derivative, lubricant derivative Bearings Salt water, coolant derivative, fuel derivative Bearings Fuel derivative Lubricant derivative

The information above is considered to be accurate as of the dates specified. We have reviewed this information; however, no warranty or representation, express or implied, is made as to the accuracy or completeness of the data and the information contained in this note.

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

IMO Make Model Lubricant Schedule Lubricant In Use Port Landed Sample Point Machine Usage 9208485 MISC HYUNDAI NSD6RTA48T ENERGOL OE-HT 30 ENERGOL OE-HT 30 FUJAIRAH inlet to me MEZZX Customer Code Sample Code Sample Taken Received Report Date Total Machine Hrs Lubricant Hours Label Ref. 005677Z GK024618 12-Mrz-2009 19-Mrz-2009 23-Mrz-2009 41046 41046 BP3224691

mv/ss LOMBARDIA

MACHINE UNIT/LOCATION MAIN ENGINE, XHEAD/1

A. NORMAL B. WARNING C. CRITICAL

DIAGNOSIS: The analysis results, based on the tests performed, indicate that the lubricant is suitable for continued use.

12-Mrz-09 Sample Ref. GK024618 Lubricant Hours 41046 Rating BN (mgKOH/g) Insolubles (%wt) Water (%vol) Flash Point (C) KV@100C (cSt) Elements(ppm) Aluminium (Al) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Nickel (Ni) Silicon (Si) Sodium (Na) Tin (Sn) Vanadium (V) Antimony (Sb) A 11,7 0,17 0,06 > 190 11,88

31-Okt-08 GJ096759 39057 A 8,7 < 0,15 0,06 > 190 11,6

12-Jul-08 GJ061017 A 8,3 < 0,15 0,06 > 190 11,9

1 0 6 7 2 3 4 11 0 8 1

1 0 7 8 0 2 4 9 0 6 1

1 0 5 8 0 2 5 9 1 6 0 KEY: > Greater Than < Less Than

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

The latest sample, as supplied, has been taken as representative of the lubricant from the stated source.

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

IMO Make Model Lubricant Schedule Lubricant In Use Port Landed Sample Point Machine Usage 9208485 MAN-B&W 5L23/30 ENERGOL IC-HFX 303 ENERGOL IC-HFX 303 FUJAIRAH inlet to aux engine AEZZT Customer Code Sample Code Sample Taken Received Report Date Total Machine Hrs Lubricant Hours Label Ref. 005677Z GK024619 12-Mrz-2009 19-Mrz-2009 23-Mrz-2009 31645 308 BP3224690

mv/ss LOMBARDIA

MACHINE UNIT/LOCATION AUXY ENGINE/1

A. NORMAL B. WARNING C. CRITICAL

DIAGNOSIS: The analysis results, based on the tests performed, indicate that the lubricant is suitable for continued use.

12-Mrz-09 Sample Ref. GK024619 Lubricant Hours 308 Rating BN (mgKOH/g) Insolubles (%wt) Water (%vol) Flash Point (C) KV@100C (cSt) Elements(ppm) Aluminium (Al) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Nickel (Ni) Silicon (Si) Sodium (Na) Tin (Sn) Vanadium (V) Antimony (Sb) A 26,8 0,78 0,08 > 190 12,46

31-Okt-08 GJ096760 1039 A 23,7 0,93 0,08 > 190 13,01

12-Jul-08 GJ061018 48 A 29,6 0,24 0,12 > 190 12,02

3 1 0 14 1 19 10 35 1 64 1

4 1 1 16 0 26 10 36 1 75 2

3 0 0 6 0 3 9 25 0 8 0 KEY: > Greater Than < Less Than

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

The latest sample, as supplied, has been taken as representative of the lubricant from the stated source.

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

IMO Make Model Lubricant Schedule Lubricant In Use Port Landed Sample Point Machine Usage 9208485 MAN-B&W 5L23/30 ENERGOL IC-HFX 303 ENERGOL IC-HFX 303 FUJAIRAH inlet to engine AEZZT Customer Code Sample Code Sample Taken Received Report Date Total Machine Hrs Lubricant Hours Label Ref. 005677Z GK024620 12-Mrz-2009 19-Mrz-2009 23-Mrz-2009 34448 559 BP3224689

mv/ss LOMBARDIA

MACHINE UNIT/LOCATION AUXY ENGINE/2

A. NORMAL B. WARNING C. CRITICAL

DIAGNOSIS: The analysis results, based on the tests performed, indicate that it is suitable for further limited use, noting the insolubles level.

12-Mrz-09 Sample Ref. GK024620 Lubricant Hours 559 Rating BN (mgKOH/g) Insolubles (%wt) Water (%vol) Flash Point (C) KV@100C (cSt) Elements(ppm) Aluminium (Al) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Nickel (Ni) Silicon (Si) Sodium (Na) Tin (Sn) Vanadium (V) Antimony (Sb) B 24,7 1,41 0,1 > 190 13,06

31-Okt-08 GJ096761 50 A 28,4 0,35 0,09 > 190 11,93

12-Jul-08 GJ061019 199 A 27,4 0,82 0,1 > 190 12,77

4 1 2 28 1 41 14 45 1 134 0

3 0 0 8 0 7 12 28 0 15 1

4 0 0 12 0 15 9 32 1 41 0 KEY: > Greater Than < Less Than

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

The latest sample, as supplied, has been taken as representative of the lubricant from the stated source.

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

IMO Make Model Lubricant Schedule Lubricant In Use Port Landed Sample Point Machine Usage 9208485 MAN-B&W 5L23/30 ENERGOL IC-HFX 303 ENERGOL IC-HFX 303 FUJAIRAH inlet to engine AEZZT Customer Code Sample Code Sample Taken Received Report Date Total Machine Hrs Lubricant Hours Label Ref. 005677Z GK024621 12-Mrz-2009 19-Mrz-2009 23-Mrz-2009 38403 1410 BP3224688

mv/ss LOMBARDIA

MACHINE UNIT/LOCATION AUXY ENGINE/3

A. NORMAL B. WARNING C. CRITICAL

DIAGNOSIS: The analysis results, based on the tests performed, indicate that it is suitable for further limited use, noting the insolubles level.

12-Mrz-09 Sample Ref. GK024621 Lubricant Hours 1410 Rating BN (mgKOH/g) Insolubles (%wt) Water (%vol) Flash Point (C) KV@100C (cSt) Elements(ppm) Aluminium (Al) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Nickel (Ni) Silicon (Si) Sodium (Na) Tin (Sn) Vanadium (V) Antimony (Sb) B 26,3 1,44 0,1 > 190 12,69

31-Okt-08 GJ096762 1350 A 23,4 1,11 0,14 > 190 12,81

12-Jul-08 GJ061020 584 B 24,2 1,23 0,18 > 190 13,08

4 1 1 18 0 31 15 39 2 104 0

3 1 1 15 0 24 9 34 1 75 2

3 1 1 18 0 23 7 32 1 104 1 KEY: > Greater Than < Less Than

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

The latest sample, as supplied, has been taken as representative of the lubricant from the stated source.

ENERCARE LUBRICANT ANALYSIS

TECHNICAL DEPARTMENT AHRENKIEL SHIPMANAGEMENT BURCHARDSTRASSE 8 D 20095 HAMBURG GERMANY

IMO Make Model Lubricant Schedule Lubricant In Use Port Landed Sample Point Machine Usage 9208485 KAMOME 1650FP-K ENERGOL GR-XP 68 EPONA Z68 FUJAIRAH hp line after filters BTHZZ Customer Code Sample Code Sample Taken Received Report Date Total Machine Hrs Lubricant Hours Label Ref. 005677Z GK024622 12-Mrz-2009 19-Mrz-2009 23-Mrz-2009 960 960 BP3224687

mv/ss LOMBARDIA

MACHINE UNIT/LOCATION BOW THRUSTER/1

A. NORMAL B. WARNING C. CRITICAL

DIAGNOSIS: The analysis results, based on the tests performed, indicate that the lubricant is suitable for continued use. Noting the increased acid number which should be monitored for any further upward acidity trend. There is also an increase of particles of copper, lead and silicon. Please note that BP Marine has only limited information on the product analysed. It can therefore only provide general guidance on a competitor product.

12-Mrz-09 Sample Ref. GK024622 Lubricant Hours 960 Rating Colour Condition AN (mgKOH/g) Water (%vol) KV@40C (cSt) Elements(ppm) Aluminium (Al) Chromium (Cr) Copper (Cu) Iron (Fe) Lead (Pb) Nickel (Ni) Silicon (Si) Sodium (Na) Tin (Sn) 0 0 63 17 40 0 90 3 1 A Amber Hazy 0,82 < 0,05 66,21

31-Okt-08 GJ096763 900 A Dark Yellow Clear 0,36 < 0,05 68,36

14-Mrz-08 GJ026229 727 A Yellow Clear 0,53 < 0,05 68,6

0 0 4 3 0 0 2 6 0

0 0 5 3 0 0 2 13 0 KEY: > Greater Than < Less Than

From: Sven Thomsen Deutsche BP AG Tel: 040 6395 4639 eMail: sven.thomsen@de.bp.com

The latest sample, as supplied, has been taken as representative of the lubricant from the stated source.

You might also like

- Technical Data Z14XEPDocument5 pagesTechnical Data Z14XEPsupervizor100% (3)

- IHGStandards-IHG Technical SpecificationsDocument36 pagesIHGStandards-IHG Technical Specificationsatlcomputech100% (2)

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- 7S50MC-C7-TI TCA66-21 127.0 RPM 11060 KWDocument16 pages7S50MC-C7-TI TCA66-21 127.0 RPM 11060 KWАлександр ТихомировNo ratings yet

- 7S50MC-C8-TII TCA66-21 127.0 RPM 11060 KWDocument16 pages7S50MC-C8-TII TCA66-21 127.0 RPM 11060 KWАлександр ТихомировNo ratings yet

- Technical Data Z10XEPDocument6 pagesTechnical Data Z10XEPsupervizorNo ratings yet

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- Mds ScrubberDocument2 pagesMds ScrubberwahyuNo ratings yet

- High Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsDocument6 pagesHigh Performance Diesel Engine Oil: For Engines With Aftertreatment SystemsNadia SalemNo ratings yet

- HYUNDAI PowerplantDocument16 pagesHYUNDAI PowerplantDavid Ortiz de Zevallos100% (3)

- 1 1 6 Blood Splatter Analysis Experimental DesignDocument4 pages1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- Clan Survey Pa 297Document16 pagesClan Survey Pa 297Sahara Yusoph SanggacalaNo ratings yet

- Husqvarna 2008Document470 pagesHusqvarna 2008klukasinteria100% (2)

- Enercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Document11 pagesEnercare Lubricant Analysis: Rating Summary Table For British Osprey (9258882)Jagmohan SinghNo ratings yet

- Lub Oil AnalysisDocument11 pagesLub Oil AnalysisMeghali BorleNo ratings yet

- 124 250DDocument7 pages124 250Djag jakhaNo ratings yet

- 11249-Ispat Indo-500 Mill Rolling Mill BDocument1 page11249-Ispat Indo-500 Mill Rolling Mill BBahtiar YudhistiraNo ratings yet

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098No ratings yet

- CFM56 NDT ManualDocument103 pagesCFM56 NDT Manualmanishprajapati707100% (3)

- Oil Analysis Report ExplanationDocument2 pagesOil Analysis Report Explanationzrcjsyll100% (1)

- Pt. Corelab Indonesia: Oil Analysis ResultDocument1 pagePt. Corelab Indonesia: Oil Analysis ResultBahtiar Yudhistira100% (1)

- APT Emulsion Fuels: Environmental Management PresentationDocument33 pagesAPT Emulsion Fuels: Environmental Management Presentationdipali2229No ratings yet

- SWAG Fluessigkeiten 2012 2013Document33 pagesSWAG Fluessigkeiten 2012 2013Hatem NasrNo ratings yet

- Bearing Failure Service LetterDocument7 pagesBearing Failure Service LetterAurvin SinghNo ratings yet

- Full Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDocument2 pagesFull Bore Ball Valve - T12 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsjonnyhelluzNo ratings yet

- Wearcheck Oil Analysis ReportDocument2 pagesWearcheck Oil Analysis Reportapi-105696388100% (1)

- Inputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)Document3 pagesInputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)SIVANo ratings yet

- Diesel Academy Emissions 20 03 2007Document71 pagesDiesel Academy Emissions 20 03 2007walleyranNo ratings yet

- A7VO160Document19 pagesA7VO160Timon2005No ratings yet

- Utr - PLN Suar PDFDocument86 pagesUtr - PLN Suar PDFJaka Sembung Golok100% (1)

- T Cooler AKGDocument6 pagesT Cooler AKGGeorge MadisonNo ratings yet

- SL00 377Document7 pagesSL00 377Nazmul HassanNo ratings yet

- SL08 495KNBSL2008 495 PDFDocument6 pagesSL08 495KNBSL2008 495 PDFDenim102No ratings yet

- F8Q 632Document4 pagesF8Q 632macugowNo ratings yet

- DUN 35 2011-KlasserneDocument5 pagesDUN 35 2011-KlasserneŞansal DikmenerNo ratings yet

- 5 MaterialDocument7 pages5 MaterialMOHAMMAD ASIFNo ratings yet

- Delphi 5W40 Prestige PlusDocument1 pageDelphi 5W40 Prestige PlusStefan RoscaNo ratings yet

- 350 - Survey ULJ S50C 03 1Document8 pages350 - Survey ULJ S50C 03 1Gaurav WaliaNo ratings yet

- HP 1Document12 pagesHP 1api-273257329No ratings yet

- Innovation by Aluminium Castings, KSM PDFDocument31 pagesInnovation by Aluminium Castings, KSM PDFsengcan100% (1)

- Man B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesDocument347 pagesMan B&W K90Me9-Tii: Project Guide Electronically Controlled Two Stroke EnginesNguyễn Công HùngNo ratings yet

- CB3033BS66,1MI4P LS71 0,09kW 365V 87HzDocument4 pagesCB3033BS66,1MI4P LS71 0,09kW 365V 87Hzmagda_biricaNo ratings yet

- Sprinter 2003 PDFDocument4 pagesSprinter 2003 PDFManuel GuillenNo ratings yet

- DGA Methoden Der ZukunftDocument46 pagesDGA Methoden Der Zukunftjoaquin65No ratings yet

- Full Bore Ball Valve - T10 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDocument2 pagesFull Bore Ball Valve - T10 Series - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsFranedwalex Alvarez MaldonadoNo ratings yet

- Bomba de Engranajes Kracht KP5 - GB - 09-08Document12 pagesBomba de Engranajes Kracht KP5 - GB - 09-08Mauricio Ariel H. OrellanaNo ratings yet

- Anex 1Document59 pagesAnex 1rotatic_engineerNo ratings yet

- Scania dt12 02 470 Euro 3 Engine Emission Measurements For Vti and Cost 346 PDFDocument48 pagesScania dt12 02 470 Euro 3 Engine Emission Measurements For Vti and Cost 346 PDFsusundegiNo ratings yet

- Material Information Sheet For Plates: Erndtebrücker EisenwerkDocument2 pagesMaterial Information Sheet For Plates: Erndtebrücker EisenwerkAhmad KamilNo ratings yet

- MAN s26mc6 PGDocument347 pagesMAN s26mc6 PGRhaanzahNo ratings yet

- Basis of Engine ControlDocument10 pagesBasis of Engine ControlmihajlovichenkelNo ratings yet

- BHS KI Range Extension Oelkuehler GBDocument16 pagesBHS KI Range Extension Oelkuehler GBduongpndngNo ratings yet

- Oil Analysis Techniques For High Horsepower Diesel EnginesDocument31 pagesOil Analysis Techniques For High Horsepower Diesel EnginesAntonius Heppy Meylanata100% (1)

- Full Bore Ball Valve - Types T14 - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsDocument2 pagesFull Bore Ball Valve - Types T14 - Aluminium Lever Handle: Flow and Pressure Drop Pressure Temperature RatingsCarlos Gallardo Sanchez100% (1)

- Npi PDFDocument25 pagesNpi PDFHerrera Salazar VisnuNo ratings yet

- Type Omd-11: Deckma Hamburg GMBHDocument6 pagesType Omd-11: Deckma Hamburg GMBHArshad JummaniNo ratings yet

- Oil Analysis Techniques For High Horsepower Diesel EnginesDocument31 pagesOil Analysis Techniques For High Horsepower Diesel EnginesAli ArdinNo ratings yet

- Cim 28GDocument2 pagesCim 28Gfranciscobolognesi79No ratings yet

- PagesDocument72 pagesPagesAngel NajarroNo ratings yet

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-1-1Document165 pagesParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-1-1Hardiansyah Simarmata100% (2)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Hyundai-Man B&W 8l2832hDocument1,044 pagesHyundai-Man B&W 8l2832hDavid Ortiz de Zevallos100% (6)

- DANUBIADocument1 pageDANUBIADavid Ortiz de ZevallosNo ratings yet

- TiTAN User ManualDocument49 pagesTiTAN User ManualDavid Ortiz de ZevallosNo ratings yet

- LOMBARDIADocument1 pageLOMBARDIADavid Ortiz de ZevallosNo ratings yet

- PAC4200 Product GuideDocument4 pagesPAC4200 Product GuideHugo Alberto Malespin SolisNo ratings yet

- TQM Model ExamDocument5 pagesTQM Model ExamsaswarajNo ratings yet

- Shear Strength in The New Eurocode 2. A Step ForwardDocument10 pagesShear Strength in The New Eurocode 2. A Step ForwardChineseAssassinNo ratings yet

- 7.sieve Analysis AhmedDocument9 pages7.sieve Analysis AhmedJin AhmedNo ratings yet

- Beechcraft Heritage MuseumDocument16 pagesBeechcraft Heritage MuseumCAP History LibraryNo ratings yet

- Digital Data, Digital SignalDocument8 pagesDigital Data, Digital SignalBastomi Adi NugrohoNo ratings yet

- Homework 1Document3 pagesHomework 1Bukhosi MsimangaNo ratings yet

- DepEd Learner Information System (LIS) PDFDocument36 pagesDepEd Learner Information System (LIS) PDFshasagailNo ratings yet

- NetflixDocument16 pagesNetflixGianluca VenturiNo ratings yet

- Swaroop (1) ResumeDocument4 pagesSwaroop (1) ResumeKrishna SwarupNo ratings yet

- How Cell Phones WorkDocument12 pagesHow Cell Phones Workavinash_knitNo ratings yet

- Lesson 1 DataDocument4 pagesLesson 1 Dataapi-435318918No ratings yet

- Bomba Submersa FE - Petro STPDocument6 pagesBomba Submersa FE - Petro STProbsonlagambaNo ratings yet

- 4ghz Low Noise Amplifier For Satellite D ImpDocument5 pages4ghz Low Noise Amplifier For Satellite D ImpAbhishek JajuNo ratings yet

- 000 139 PDFDocument17 pages000 139 PDFtareqcccccNo ratings yet

- Turnitin Originality ReportDocument47 pagesTurnitin Originality ReportStillward Laud Mark-MillsNo ratings yet

- Fortinet Configuration Report: Hostname: "FG3600-Internet"Document21 pagesFortinet Configuration Report: Hostname: "FG3600-Internet"rizkymulyawan89No ratings yet

- Particle Packing in Concrete 30-04-20Document49 pagesParticle Packing in Concrete 30-04-20b ramachandraNo ratings yet

- 12.turbulent Flow Jan 2015 PDFDocument12 pages12.turbulent Flow Jan 2015 PDFburhanuddinNo ratings yet

- Claa150xp Shenzhen HBDocument22 pagesClaa150xp Shenzhen HBSatya NarayanNo ratings yet

- Pump Primer 1 AssDocument34 pagesPump Primer 1 AssGkou DojkuNo ratings yet

- DC and AC InterferenceDocument40 pagesDC and AC InterferenceREJI JOY ThoppilNo ratings yet

- Invisible EyeDocument16 pagesInvisible EyeSushmita Paul0% (1)

- Void Acoustics 2017 BrochureDocument28 pagesVoid Acoustics 2017 BrochureCraig ConnollyNo ratings yet

- Kirsten Koyle Grade 5 Science and Technology Understanding Matter and EnergyDocument10 pagesKirsten Koyle Grade 5 Science and Technology Understanding Matter and Energyapi-311535995No ratings yet

- Series: 25 TON (222 KN)Document2 pagesSeries: 25 TON (222 KN)Marius IlcaNo ratings yet