Professional Documents

Culture Documents

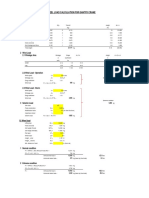

Design of Rope Drum Hoist

Uploaded by

Dheeraj VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Rope Drum Hoist

Uploaded by

Dheeraj VermaCopyright:

Available Formats

DLSIGN nILCSCn

IN1kCDUC1ICN

1he PolsL mechanlsm shall lnclude a drlvlng moLor a gear reducLlon unlL Lwo rope drums

ropes shafLs gears coupllngs brakes emergency manual arrangemenLs llmlL swlLches gaLe

poslLlon lndlcaLor (boLh analogue and dlglLal) covers eLc all mounLed on a fabrlcaLed sLeel

frame LlecLrlcal conLrols and all necessary elecLrlcal and mechanlcal accessorles shall be

provlded for Lhe saLlsfacLory operaLlon of Lhe holsL 1he holsL shall be capable of fully

openlng/closlng Lhe gaLe SufflclenL space shall be provlded around Lhe holsL componenLs for

repalr/malnLenance

nCIS1 DLSIGN CCNSIDLkA1ICN

Manual and power operaLed holsL are of Lwo Lypes Cne has drlve unlL cenLrally locaLed and

oLher has drlve unlL locaLed aL one of Lhe holsL whlch allows a narrower concreLe deck Lo use

PolsLlng speeds for power operaLed holsL vary from 03 Lo 06 m/mln 1he rope pull on each

drum ls assumed Lo be 60 of Lhe raLed holsL capaclLy slnce lnequallLy may exlsL due Lo greaLer

frlcLlon or sLlcklng of gaLe seals on one slde of gaLe whlch produce a greaLer load on drum Lhan

oLher

1he holsL drum gearlng and relaLed parLs are accordlngly deslgned on Lhe above basls 1he rope

ls sLeel holsLlng rope of 6x37 consLrucLlons wlLh a facLor of safeLy of noL less Lhan 3 for smaller

holsLs and 6 for large holsLs ln case of hlghly corroslve waLer sLalnless sLeel ropes may be used

all parLs of Lhe equlpmenL have sufflclenL sLrengLh Lo holsL Lhe forces produced by 23 break

down Lorque of moLor wlLhouL exceedlng 80 of Lhe yleld polnL of Lhe maLerlals 8all or roller

self allgnlng bearlng or ball bearlng allgnlng plllow block are used for all holsL excepL Lhose

operaLed manually llexlble coupllng are of Lhe all meLalllc and dusL proof and fully enclosed

gear Lype

Design criteria

1he deslgn requlremenLs for Lhe rope drum holsL are broadly menLloned as under as per lS

6938

1) CapaclLy of holsL

2) LlfL of CaLe

3) CperaLlng speed

4.) -umber of urums 2 (1wo) wlLh slngle/double layer of rope (for each holsL) wlLh

LP and 8P groove on drum for Lwo polnLs llfLlng of gaLe

5.) Rope : IS:2266 , 6x37 Construction

MATERIAL TECHNICAL SPECIFICATION

a) PolsL brldge PolsL supporLlng

SLrucLures LreasLles eLc SLrucLural SLeel lS 2062

b) 8ope drum and Cear wheels CasL SLeel lS1030

c) lnlons lorged SLeel lS2004

8S 970

d) ShafLs 8olled SLeel lS 2062

lorged SLeel 43C8 lS 2004

e) 8ush bearlngs Al 8ronze lS 303

Hoist Capacity:-

The hoist capacity shall be determined by taking into consideration the Iollowing Iorces

which might be required to overcome:

a) Weight oI the gate along with all its components including the weight oI wire rope and its

attachments and ballast, iI any;

b) All Irictional Iorces comprising oI

1) Wheel Iriction,

2) Guide Iriction, and

) Seal Iriction including Iriction due to initial interIerence;

c) Any hydrodynamic load, like downpull/upliIt Iorce, etc;

d) Silt and ice load wherever encountered;

e) Weight oI liIting beam, iI used; and

o) Any other consideration speciIic to a particular site.

The worst combination oI the above Iorces, during either lowering cycle or raising cycle,

shall be considered. The hoist capacity thus arrived at shall increased by 20 percent to cater

Ior the reserve hoist capacity.

The usual operating speed Ior such hoist shall be 300 to 700 mm/min. However, higher

values may be adopted depending upon the requirements.

Wire Rope:-

Wire rope diameter shall be decided by maximum rope tension which is calculated by using

pulley eIIiciency. The wire rope shall bemade Irom improved plough steel, galvanized ( iI

required ), Lang`s lay and Iibre core or normally oI 6 x 36 or 6 x 37 construction and shall

conIorm to 1S-2266. The breaking strength oI wire rope, shall be calculated on the basis oI

IS- 2266. The minimum Iactor oI saIety based on minimum breaking strength and saIe

working load oI the wire rope shall be as given in Table1.

S1 No. Operating Condition Minimum Factor oI SaIety

1 Normal operation condition 6

2 Breakdown torque condition 3

3 For counterweight suspension 5

Drum:-

The grooved drum shall be oI such a size that normally there will not be more than one layer

oI rope on the drum when the rope is in its Iilly wound position unless speciIied. The length

oI the drum shall be such that each lead oII rope has minimum two Iull turns on the drum

when the gate is at its lowest position, and one spare groove Ior each lead oII the drum when

the gate is at its highest position. The drum may be Ilanged at ends. The Ilanges shall project

to a height oI not less than two rope diameters above the rope. A spur gear secured to the

drum may be regarded as Iorming one oI the Ilanges.

The lead angle.( Ileet angle ) oI the rope shall not exceed 5 or1 in 12 on either side oI helix

angle oI groove in the drum.

The drums shall be made Irom one oI the Iollowing materials:

a) Cast iron conIorming to IS21 0,

b) Cast steel conIorming to IS 1030, and

c) Mild steel plates conIorming to |S 2062.

NOTE Use oI cast iron shall be limited to small capacity hoists only.

Strength of drum

The drum shall be strong enough to withstand the crushing as well as the bending. The

crushing strength oI drum shall be calculated by the Iollowing Iormula:

C

t

%59

where

C

t

compressive stress, in N/mm2;

K coeIIicient which depends upon the number oI layers oI rope over the drumand may be

taken Irom Table 2;

T tension on one wire rope in N;

P pitch oI scoring or centre to centre distance between adjoining grooves, in mm; and

t thickness oI drum.

NOTE The minimum thickness oI drum shall not be less than 16 mm in case oI cast steel

and 20 mm in case oI cast iron.

rooves on Drum

The rope drum shall be machine-grooved and contour at the bottom oI grooves shall be

circular over an angle oI at least 120. The radius oI groove shall be 0.53 times the diameter

oI rope rounded oII to next Iull millimeter. The depth oI groove shall not be less than 0.35

times the diameter oI the rope.

The grooves oI the drum shall be so pitched that there is a clearance oI not less than the

Iollowing values between adjacent turns oI rope:

a) 1.5 mm Ior ropes up to and including 12mm

diameter,

b) 2.5 mm Ior ropes over 12mm and including

30 mm diameter, and

c) 3.0 mm Ior ropes over 30 mm diameter.

Diameter of Drum

The minimum pitch diameter oI the drum shall be 20 times the diameter oI rope oI 6/36 or

6/37 construct ion.

Motor is designed as per IS-325.

Column and platIorm shall be designed as per IS-800.

You might also like

- Design of Rope DrumsDocument8 pagesDesign of Rope DrumsBhaskar AnupamNo ratings yet

- Design of Hoisting Mechanism For Crane R1Document45 pagesDesign of Hoisting Mechanism For Crane R1Bhalchandra Desai100% (2)

- SUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDocument17 pagesSUNCOR Standard Operating Procedures - Mobile Hoisting EquipmentDavid O'BrienNo ratings yet

- Design of Vertical Lift GATESDocument31 pagesDesign of Vertical Lift GATESDheeraj Verma90% (39)

- Design of Vertical Lift GATESDocument31 pagesDesign of Vertical Lift GATESDheeraj Verma90% (39)

- Daily Checklist For Electric Overhead Travelling CranesDocument3 pagesDaily Checklist For Electric Overhead Travelling CranestatonyNo ratings yet

- Crane Rail Selection: Calculation of Required Rail Head WidthDocument1 pageCrane Rail Selection: Calculation of Required Rail Head WidthMAHMOUD YOUNISNo ratings yet

- Bogged Vehicle Recovery PDFDocument2 pagesBogged Vehicle Recovery PDFcityofdarwingis100% (1)

- Wheel Load Calculation For Gantry Crane: A. Design Loads 1 Self WeightDocument1 pageWheel Load Calculation For Gantry Crane: A. Design Loads 1 Self WeightBang OchimNo ratings yet

- Hanbell Maintenance ManualDocument89 pagesHanbell Maintenance ManualLOUIE100% (1)

- Wheel Load Design Calculation of Eot CraneDocument12 pagesWheel Load Design Calculation of Eot Craneram_babu_59100% (3)

- SheaveDocument13 pagesSheaveGer Bos0% (1)

- OHE Mast - Bridges - PDFDocument37 pagesOHE Mast - Bridges - PDFMadhurimaMitra70% (10)

- IS 6938 (2005) - Design of Rope Drum and Chain Hoists For Hydraulic Gates - Code of PracticeDocument16 pagesIS 6938 (2005) - Design of Rope Drum and Chain Hoists For Hydraulic Gates - Code of PracticeSuleman KhanNo ratings yet

- 40t Rope Drum Hoist220512Document37 pages40t Rope Drum Hoist220512Anonymous sfkedkymNo ratings yet

- Hydraulic Winch Design Problem - Sizing of Hydraulic Pump and MotorDocument3 pagesHydraulic Winch Design Problem - Sizing of Hydraulic Pump and Motorgbm2246100% (2)

- Design 50t Rope Drum Hoist Tail Race GatesDocument30 pagesDesign 50t Rope Drum Hoist Tail Race GatesAnonymous sfkedkym100% (2)

- FinalDocument49 pagesFinalanon_118283479100% (1)

- 1 - Overview of Gate Operating SystemsDocument6 pages1 - Overview of Gate Operating SystemsPradeep VM100% (1)

- Design of Rope Drum and Chain HoistsDocument19 pagesDesign of Rope Drum and Chain Hoistssuresh_501100% (1)

- Winch DesignDocument132 pagesWinch Designzeek7767% (3)

- Din 15020-1 1974 PDFDocument12 pagesDin 15020-1 1974 PDFJuliete Maria Taparello100% (1)

- Crane gantry calculation data sheetDocument7 pagesCrane gantry calculation data sheetvinit soodNo ratings yet

- 11 Crane Frame StructuresDocument6 pages11 Crane Frame StructuresYonas YGNo ratings yet

- Design Specification of Hoist For Water Resources and Hydropower EngineeringDocument136 pagesDesign Specification of Hoist For Water Resources and Hydropower Engineeringramkumar121No ratings yet

- Is 807 Design and Testing of Cranes and HoistsDocument76 pagesIs 807 Design and Testing of Cranes and HoistsKarthick VenkateshNo ratings yet

- Hoist Design Procedure For EOT Crane - Tech ExpertDocument40 pagesHoist Design Procedure For EOT Crane - Tech ExpertBhadresh Shah100% (1)

- Luminos Tilt Lift ReplacementDocument32 pagesLuminos Tilt Lift Replacementbody2030No ratings yet

- TEC-GR-TX-OFC-020-01-MAR-11 - Armoured UG Fiber CableDocument37 pagesTEC-GR-TX-OFC-020-01-MAR-11 - Armoured UG Fiber Cablesatyam_scribdNo ratings yet

- Grooved Drum ArticleDocument2 pagesGrooved Drum ArticleLizardladNo ratings yet

- 40t Rope Drum Hoist220512Document37 pages40t Rope Drum Hoist220512Anonymous sfkedkymNo ratings yet

- Sheave DesignDocument6 pagesSheave DesignZach DockterNo ratings yet

- Seamanship ReviewerDocument16 pagesSeamanship ReviewerJohn Carl PitogoNo ratings yet

- Wire Ropes: Understanding Bending and Tensile StressesDocument6 pagesWire Ropes: Understanding Bending and Tensile Stressessiddharth Gautam100% (1)

- Calculation of Rope DrumDocument8 pagesCalculation of Rope Drumbambang satryojati100% (2)

- Gantry Cranes-Design ProcedureDocument29 pagesGantry Cranes-Design ProcedurePoulami Guchhait100% (5)

- Hydro Dynamic ForcesDocument34 pagesHydro Dynamic Forcesvikasgahlyan100% (1)

- Cable Pulling at E05 South InterconnectingDocument6 pagesCable Pulling at E05 South InterconnectingHERWIN SEPTIYANNo ratings yet

- Rope Winches and GearboxesDocument20 pagesRope Winches and Gearboxesiturcic9100% (1)

- Design & Validation of Eot CraneDocument106 pagesDesign & Validation of Eot CraneNishadhraj Vasava92% (13)

- Gate and Hoist DesignDocument15 pagesGate and Hoist DesignRajivNo ratings yet

- Fortran 77 Tutorial PDFDocument38 pagesFortran 77 Tutorial PDFDheeraj VermaNo ratings yet

- Fortran 77 Tutorial PDFDocument38 pagesFortran 77 Tutorial PDFDheeraj VermaNo ratings yet

- Motor Calculation of CraneDocument6 pagesMotor Calculation of Craneliftline engineersNo ratings yet

- Wire Drum DesignDocument8 pagesWire Drum DesignJonathan Lynch100% (2)

- Safe Working Load CalculationsDocument3 pagesSafe Working Load CalculationsShanAlanNo ratings yet

- FEM9.751 Engl PDFDocument52 pagesFEM9.751 Engl PDFserkanNo ratings yet

- Rope Winches and GearboxesDocument20 pagesRope Winches and GearboxesGogyNo ratings yet

- Is 4622 2003Document27 pagesIs 4622 2003Apurba Haldar100% (1)

- Ancient cranes lifted constructionDocument25 pagesAncient cranes lifted constructionIshaan00748850% (2)

- Calculate Thrust Block Dimensions for Horizontal PipesDocument2 pagesCalculate Thrust Block Dimensions for Horizontal PipesDheeraj Verma100% (3)

- Gravit 2Document15 pagesGravit 2Ivan MaltsevNo ratings yet

- PT. Bangun Arta Hutama Drum Winch CalculationDocument3 pagesPT. Bangun Arta Hutama Drum Winch CalculationWaris La Joi WakatobiNo ratings yet

- 7 T Manual Rope Drum Hoist R1Document14 pages7 T Manual Rope Drum Hoist R1Anonymous sfkedkym100% (1)

- Steel Wire Ropes For Cranes Problems and SolutionsDocument34 pagesSteel Wire Ropes For Cranes Problems and Solutionsaj3107900% (1)

- Winch DesignDocument132 pagesWinch DesignShreyas Raut100% (2)

- 5T X 25.5m DG CraneDocument10 pages5T X 25.5m DG CraneRv VaghasiaNo ratings yet

- Termination For Steel Wire Ropes-Safety - Asymmetric Wedge Socket BS-EN 13411-6 PDFDocument28 pagesTermination For Steel Wire Ropes-Safety - Asymmetric Wedge Socket BS-EN 13411-6 PDFMaazARazaNo ratings yet

- Axle holders DIN 15058Document1 pageAxle holders DIN 15058joseocsilvaNo ratings yet

- Design of Hoisting Mechanisms for Overhead CranesDocument8 pagesDesign of Hoisting Mechanisms for Overhead CranessoniNo ratings yet

- EOT Crane Mechanical Equipment Calculation 1Document17 pagesEOT Crane Mechanical Equipment Calculation 1satendra sharmaNo ratings yet

- CraneDocument19 pagesCranedeua2004No ratings yet

- Main Hoist Motor Power Calculations for 150 Tonne Single Girder Indoor EOT CraneDocument2 pagesMain Hoist Motor Power Calculations for 150 Tonne Single Girder Indoor EOT Cranesmarika_16No ratings yet

- Gantry Crane Design Calculations - Google SearchDocument2 pagesGantry Crane Design Calculations - Google SearchJebin Abraham100% (1)

- Hoist Capacity Calculation For Vertical Lift Fixed Wheel Type Gate With Rope Drum Hoist System (Size 6.50 M X 3.10 M HEAD 2.90 M)Document4 pagesHoist Capacity Calculation For Vertical Lift Fixed Wheel Type Gate With Rope Drum Hoist System (Size 6.50 M X 3.10 M HEAD 2.90 M)amardeepNo ratings yet

- Ship Security Alert System ConfigurationDocument30 pagesShip Security Alert System ConfigurationFabio Marcia GrassiNo ratings yet

- Din 15061 Translate EngDocument1 pageDin 15061 Translate EngMaey Akim50% (2)

- Handling Ropes and WiresDocument22 pagesHandling Ropes and WiresSeaman NavigatorNo ratings yet

- UX B160WG TecnicoDocument106 pagesUX B160WG TecnicoJonatán AscenNo ratings yet

- Travelling Tripper CalculationDocument5 pagesTravelling Tripper CalculationHarshGupta100% (1)

- Annex - E IS 3177 2020Document4 pagesAnnex - E IS 3177 2020dfdffNo ratings yet

- Basic Crane Design PrinciplesDocument3 pagesBasic Crane Design PrinciplesHeba Fathi100% (1)

- Designing of Cranes With StandardsDocument95 pagesDesigning of Cranes With Standardsank_mehraNo ratings yet

- 3938Document23 pages3938Ritu Saroa0% (1)

- Tub EtambouDocument8 pagesTub EtambouSpeedy Gonzales Riba RibaNo ratings yet

- Sillette Sonic Mk2 LegDocument28 pagesSillette Sonic Mk2 LegmallardfirstNo ratings yet

- Đặc Tính Kỹ Thuật Ghi Lò - EngDocument9 pagesĐặc Tính Kỹ Thuật Ghi Lò - EngLê Nguyễn Hữu TùngNo ratings yet

- Precision PulleyspecDocument2 pagesPrecision PulleyspecMani MaranNo ratings yet

- 9.form For TTA Claim PDFDocument3 pages9.form For TTA Claim PDFBalu Mahendra SusarlaNo ratings yet

- 9.form For TTA Claim PDFDocument3 pages9.form For TTA Claim PDFBalu Mahendra SusarlaNo ratings yet

- Root StockDocument2 pagesRoot StockDheeraj VermaNo ratings yet

- Reference BookDocument1 pageReference BookDheeraj Verma0% (1)

- 6300 L26 EnergyDissipationStructures PDFDocument18 pages6300 L26 EnergyDissipationStructures PDFalbertoafpNo ratings yet

- There Is Nothing To ShareDocument1 pageThere Is Nothing To ShareDheeraj VermaNo ratings yet

- Water Pipes As Per Is-4984 Dim Tables - Annex-2aDocument3 pagesWater Pipes As Per Is-4984 Dim Tables - Annex-2aDheeraj VermaNo ratings yet

- Drought Stress Affects Growth and Flowering in Marigold VarietiesDocument9 pagesDrought Stress Affects Growth and Flowering in Marigold VarietiesDheeraj VermaNo ratings yet

- Water Pipes As Per Is-4984 Dim Tables - Annex-2aDocument3 pagesWater Pipes As Per Is-4984 Dim Tables - Annex-2aDheeraj VermaNo ratings yet

- Burari Market: Building Material Rates For The 1st, 2nd, 3rd & 4th Quarters - 2015Document33 pagesBurari Market: Building Material Rates For The 1st, 2nd, 3rd & 4th Quarters - 2015ParminderSinghNo ratings yet

- Himachal Pradesh PCS Pre Exam 2012 General Studies ANSWER KEY PDFDocument2 pagesHimachal Pradesh PCS Pre Exam 2012 General Studies ANSWER KEY PDFDheeraj VermaNo ratings yet

- Income Tax Rate Ay 2010-11Document11 pagesIncome Tax Rate Ay 2010-11Dheeraj VermaNo ratings yet

- E-Books Download Weblog: Water Engineering WeblogDocument15 pagesE-Books Download Weblog: Water Engineering WeblogDheeraj VermaNo ratings yet

- Top 5 apple varieties grown in Himachal PradeshDocument2 pagesTop 5 apple varieties grown in Himachal PradeshDheeraj VermaNo ratings yet

- AppleDocument6 pagesAppleDheeraj VermaNo ratings yet

- Rope Wire PDFDocument2 pagesRope Wire PDFDheeraj VermaNo ratings yet

- SKF Spherical BearingDocument59 pagesSKF Spherical BearingDheeraj VermaNo ratings yet

- Base Plate For Thickness CalculationsDocument7 pagesBase Plate For Thickness CalculationsyunuswsaNo ratings yet

- Small Hydro PotentialDocument2 pagesSmall Hydro PotentialDheeraj VermaNo ratings yet

- Hydro Power ProjectDocument14 pagesHydro Power ProjectDheeraj VermaNo ratings yet

- Beam Column Base Plate DesignDocument10 pagesBeam Column Base Plate DesignSPUD1100% (3)

- Mechanical Stream BooksDocument1 pageMechanical Stream BooksDheeraj VermaNo ratings yet

- Why Thermal Power Plants Have A Relatively Low EfficiencyDocument8 pagesWhy Thermal Power Plants Have A Relatively Low Efficiencyjiwani87No ratings yet

- Book 1Document2 pagesBook 1Dheeraj VermaNo ratings yet

- Doodh Ganga Yojana - EditedDocument10 pagesDoodh Ganga Yojana - EditedDheeraj VermaNo ratings yet

- ProReact Analogue Installation Manual A1162Document16 pagesProReact Analogue Installation Manual A1162careNo ratings yet

- 2.method Statement For Installation of Cable Tray & Cable LayingDocument14 pages2.method Statement For Installation of Cable Tray & Cable LayingMD AbdullahNo ratings yet

- RRU3804 Introduction and Hardware InstallationDocument75 pagesRRU3804 Introduction and Hardware InstallationOsama El MesalawyNo ratings yet

- 3M 2179CE Fiber Optical Closure: ApplicationsDocument4 pages3M 2179CE Fiber Optical Closure: ApplicationsHữu Khánh NguyễnNo ratings yet

- Winch SafetyDocument22 pagesWinch SafetyAsad AyazNo ratings yet

- Wire Rope Lubrication System Dat Viet CoDocument4 pagesWire Rope Lubrication System Dat Viet ConghiaNo ratings yet

- TSUBAKI Kabelschlepp-02-Technical-HandbookDocument48 pagesTSUBAKI Kabelschlepp-02-Technical-Handbookjavier alvarezNo ratings yet

- A Simple Portable CablewayDocument8 pagesA Simple Portable CablewayJosué DavidNo ratings yet

- QS Seamless Aluminum Ferrules Safe Use and Instructions V01Document6 pagesQS Seamless Aluminum Ferrules Safe Use and Instructions V01beshoyNo ratings yet

- Samggh Catlog .Document84 pagesSamggh Catlog .Man BurstNo ratings yet

- Software For Structural Design and Analysis of Cables and Wire RopesDocument2 pagesSoftware For Structural Design and Analysis of Cables and Wire RopesHisham ButtNo ratings yet

- 01 Guidelines For Fiber Optic Cable InstDocument14 pages01 Guidelines For Fiber Optic Cable InstAdrián NavarroNo ratings yet

- Basic Principles in Building Conveying SystemDocument43 pagesBasic Principles in Building Conveying SystemJurenz Ibhan BonsolNo ratings yet

- Luluat Company ProfileDocument2 pagesLuluat Company ProfileR RatheeshNo ratings yet

- GeM Bidding 2553337Document12 pagesGeM Bidding 2553337gopal kumarNo ratings yet

- Seismic Design Guide (2010)Document102 pagesSeismic Design Guide (2010)ingcarlosgonzalezNo ratings yet