Professional Documents

Culture Documents

Aerosol Smoke Detector Testers FSE Magazine

Uploaded by

Archie NairOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aerosol Smoke Detector Testers FSE Magazine

Uploaded by

Archie NairCopyright:

Available Formats

Article reprinted from the September 2004 issue of Fire Safety Engineering SEPTEMBER 2004

www.fsemags.com

FIRE SAFETY ENGINEERING

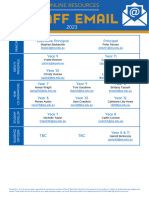

Liqueed propellant becoming gas mixed with product

Gaseous propellant exerting pressure

Product concentrate and liqueed propellant

AEROSOL SMOKE DETECTOR TESTERS

by Stewart Pepper, Technical Director

No Climb Products Ltd, Edison House, 163 Dixons Hill Road, Welham Green, Hertfordshire, AL9 7JE, UK. Tel: +44 (0)1707 282760 Fax: +44 (0) 1707 282777 E-mail: info@noclimb.com Web: www.noclimb.com

THE DEFINITIVE JOURNAL FOR FIRE PROFESSIONALS

DETECTION FSE

www.fsemags.com

AEROSOL

SMOKE DETECTOR TESTERS

Gaseous propellant exerting pressure Liqueed propellant becoming gas mixed with product Product concentrate and liqueed propellant

everyday usage, it refers more often to the pressurised containers that we know and use in so many of our activities. Aerosol canisters contain two essential components: the propellant and the active ingredient. The propellants two main jobs are: a) to create pressure within the canister to push out the active ingredient, and b) to help break up the liquid droplets and make a ne spray. The active ingredient (often a blend) is dependent on the application, and is the wanted product from the can (e.g. the synthetic smoke particles). Put together in a canister, which is designed to contain the pressure of the propellant, they are regulated and dispensed by a valve and actuator combination. The valve and actuator determine the rate and type of spray pattern as well as providing a heavy inuence on the particle characteristics (themselves also a function of the chemical ingredients). Aerosol smoke detector testers produce a ne mist of particles, providing sizes and characteristics comparable to various types of smoke. Ideally, they also provide a mix of particles optimised to activate quickly both optical and ionisation smoke detectors. Selection of the correct chemicals for use within these products is of paramount importance since there is a need to balance the often conicting requirements of environmental and health and safety regulations, (non) ammability, low cost and, most importantly, compatibility with the components from which detectors are manufactured. Technological Issues and Design Criteria Particulate The particle size, particle distribution and particle lifetime of the purposelySEPTEMBER 2004

Stewart Pepper, Technical Director of No Climb Products, explains the basic principles and discusses the functional and safety issues which need to be considered.

generated aerosol particles play a crucial role in the responses and clearing times of the detectors on which they are used. Ionisation detectors are more sensitive to smoke particles between 0.01 and 1 micron and photoelectric (optical) between 1 and 10 microns. A universal test product therefore needs to be producing particles to cover a range of particle sizes (0.01 10m). Other characteristics of the aerosol particles are also crucial for activation of the detector.

Codes and standards around the world require functional tests to conrm that smoke can enter the detection chamber of point type smoke detectors. This can be done by generating simulated smoke or by the use of suitable aerosols. Aerosol smoke detector testers are widely accepted as the popular method of performing such tests because they are quick, simple and controllable. The substance used for the test must not cause damage to, nor affect the subsequent performance of, the detector. Environmental and health and safety issues must also not be forgotten. Basic principles of aerosol detectors The scientic term aerosol refers to small particles suspended in a gas but, in

FIRE SAFETY ENGINEERING

he concept of aerosol smoke detector testers was invented and rst led as a patent application in Switzerland in 1969 by Cerberus AG.

Figure 1. Particle sizes By simulating these characteristics the aerosol canister simulates not just smoke but probably a wider spectrum of smokes than is produced by tests using certain real smokes (the characteristics of which will depend on what substance is being burned under what conditions). As such, aerosol testing can be argued to be a more rounded test than using real smoke. It is certainly one that meets the core requirement of a test to: "confirm(s) that smoke can enter the detector chamber and produce a fire alarm signal (e.g. by use of apparatus that

www.fsemags.com

FSE DETECTION

generates simulated smoke or suitable aerosols around the detector)" BS 58391:2002 45.4 (d). Clearing time A thorough test of the system will seek to ensure that the horns / bells / sirens will be activated by each detector individually, Both BS 5839 and NFPA 72, for example, require the checking of both smoke entry to the sensing chamber and an alarm response. This means the panel being automatically or manually re-set after each test (which cannot be done until the detector is clear of smoke). Clearing time is therefore almost as important as activation time (not to mention probably being more heavily inuenced by the test media). Ideally smoke detectors will respond in the fastest time (as allowed by circuitry design) and the test aerosol will clear (dissipate) in the shortest time to allow the detector to be reset. A product whose particulate dissipates very quickly either needs more spray (to remain long enough for time delayed detectors) or must be contained within an aerosol dispenser. Longer lasting sprays (where less spray is required) have the disadvantage that they take longer to clear (so delaying re-set) and, often, a greater propensity for residue and contamination. Use of a dispenser enables an aerosol with quick clearing time to be used on detectors that require longer particle presence. Residue and Contamination Over the years there have been concerns about using aerosol canisters, because of the residues that can be left through their (mis)use. These residues have the potential for attracting dirt, dust and other contaminants and therefore ultimately affecting the detector performance. Residue can be left by many things in addition to aerosols (real smoke being one of the worst offenders) and this is a key issue particularly when it is so avoidable. Particles from aerosol smoke detector testers are created, in liquid form, by the break-up of the chemical constituents as they pass through the aerosol valve and actuator. As volatile liquid particles travel through the air larger particles diminish in size, so that an aerosol spray canister designed to project a long distance or remain for a period without dissipating, may need to start by producing larger particles. Larger particles are also somewhat desirable in hand held applications on account of their ability to travel further in the air due to their additional momentum. Unfortunately, the larger the size of the particle and the higher their momentum, the more likely it is that particles will impact a surface and then form a residue. Depending on the chemicals involved, this residue may be volatile or non-volatile. Residue volatility is heavily inuenced by the use of oil or non-volatile active

ingredient. Whilst excellent at meeting the demand for longer lifetime particles, oily or non-volatile ingredients can result in the formation of a lm of residue over the detector surfaces and / or are more likely to be left as deposits capable of attracting dust, dirt and moisture. Even if a residue is not apparent immediately there is the danger of oil based or non-volatile ingredients having a cumulative effect over time. No Climb no longer uses oil based ingredients in its newer aerosol products, focussing instead on those that are much more volatile. These, more volatile, ingredients are much better as they leave far less long term residue and have a shorter particle lifetime (much quicker detector clearing and re-set times). Using them in conjunction with a dispenser enables them to be contained and controlled both from the residue and particle lifetime standpoint. Silicon Highly volatile ingredients (at the other end of the extreme) are not, however, without their problems either. One group of commonly used highly volatile ingredients that can cause problems are derived from silicon. This substance has a sticking power and, when used in an aerosol, sticks on the item being tested / sprayed, even if apparently volatile. The surface of the item then becomes slippery, not allowing anything to adhere to it. This can cause problems in a variety of instances most obviously clean air environments, areas where paint is to be applied, and places where there is any mechanical equipment. If in doubt, users need to contact the manufacturer of the aerosol product and check for the presence of silicon. Plastic and Component Compatibility Stress cracking is (the premature) cracking and embrittlement (of a plastic) due to the simultaneous action of stress and strain. It may be caused or accentuated by contact with certain chemicals. Damage caused to the detector under test is, obviously, a serious issue. Most plastics, including those used in re detectors, have limited chemical resistance. The SOLO aerosol smoke detector tester development project included what is almost certainly the most in depth plastic compatibility tests undertaken in this area to date. Within these tests, different samples of different plastic material types commonly used in the manufacture of smoke detectors were sprayed under conditions of abuse with samples of different aerosol test products. Tested also were materials used in the construction of the SOLO dispenser. The plastics were then examined under a Scanning Electron Microscope (SEM). Under the powerful magnication of the SEM it was / is immediately apparent that at least one of the aerosol products tested

(some of which had been approved by third party test houses) caused stress cracking to plastics. As time passed, the stress cracks increased (see photo below). The SOLO Detector Tester aerosol and previous products from No Climb did not, however, show any signs of such plastic incompatibility.

Photo: Stress cracking of plastics. Even though it is not always possible for the naked eye to see this type of damage (and may even be unknown to the manufacturer of the aerosol) it can affect the long-term durability and structural reliability of the detector. Environmental & Health and Safety Issues International differences Users of pressurised aerosol products must be condent that safety considerations have been fully reviewed and met. Worryingly, what is suitable for one country or trading bloc may prove unsuitable / unacceptable or in contravention of norms and standards for / in another. SOLO products have been developed and certied with regard to appropriate regulations for ammability, product labelling, packaging, pressure and transportation across the world. Environment & Flammability Historically, manufacturers of aerosol smoke testers used CFCs in their products up until (and for a while after) 1987 when their use in such manufacture was outlawed under the Montreal Protocol. Since then, the choice of chemical propellants has been between: 1) HFCs expensive but non-ammable, and 2) hydrocarbons such as propane or butane - cheap but ammable. Smoke detector test aerosols lled with ammable propellants present a greater hazard than non-ammable ones. Spraying ammable contents at sources of ignition (such as live electrical circuits found in detectors) can be exceedingly dangerous (as controlled tests at No Climb have shown). In the event of a re or explosion, ammable aerosols constitute a

FIRE SAFETY ENGINEERING

For the manufacturer, approving a smoke aerosol tester can help assure the user that the test product is compatible for use on their own products, and also ensures that their clients have a good test product.

SEPTEMBER 2004

DETECTION FSE

www.fsemags.com

considerably greater risk to safety. Nonammable, environmentally friendly propellants are more expensive than ammable alternatives but many of us in the life safety / re detection industry feel it is better to use a non-ammable product, even if more expensive, than a cheap ammable alternative. Pressure The internal pressure of an aerosol product and its suitability for its canister are key issues in a good and safe product. The pressure depends not just on the propellant and the other ingredients but also outside inuences such as ambient temperature and atmospheric pressure. Internal pressure can change very signicantly when any of these inuences changes. The ability for the nished product to safely withstand pressure changes depends wholly on the components used in manufacture and their relative ratings. Two canisters may look identical but use very different pressure rating capacities. At elevated temperatures one could fail. Users should satisfy themselves that the aerosol product they elect to use day-in day-out meets national guidelines such as the EEC Council directives and BAMA guidelines in the UK. Not all products available in today's UK and European market meet such requirements. Toxicity Even worse, some aerosol test products have been known to contain toxic chemicals that can potentially damage the user who is testing the detectors! Potentially toxic chemicals such as phthalate esters, (which are suspected carcinogens) and / or teratogens (capable of causing birth defects or testicular damage) have been found in aerosol smoke test products available in the world today. Users should check the manufacturers Material Safety Data Sheet (MSDS) for the product to ensure that it is t for purpose and, if in any doubt, ask specic questions of the manufacturer. Approvals Approvals come in many guises. In terms of aerosol smoke detector testers, two obvious approvals stand out as being of importance. Firstly, approvals by third party certication bodies and secondly, approvals by detector manufacturers. Third party approvals are useful for the end user in determining overall safety of product, lack of adverse affect on the detector under test, and compliance with statutory regulations. However since there are few countries whose legislation requires a test product of this type to have third party approval, few have test regimes for

FIRE SAFETY ENGINEERING SEPTEMBER 2004

this sort of product (an exception being Underwriters Laboratories of the US, against whose test regime SOLO aerosol smoke detector tester has been approved). However, a third party approval should only be a starting point in terms of making a decision on which product to use to test the system. The role of detector manufacturer endorsement of aerosols (or any test product) can be critical in selecting the correct tester. Both in the UK and elsewhere in the world, standards that call for smoke entry testing also state that the manufacturer should approve the test method used. For the manufacturer, approving a smoke aerosol tester can help assure the user that the test product is compatible for use on their own products, and also ensures that their clients have a good test product that will enhance the integrity and lifetime of the system. Within this approval and endorsement process, obviously, plastics and electronic compatibility, as discussed earlier, are crucial. Packaging and labelling It is more difcult for users to ensure that the product they intend to use meets with safety approvals (including ammability, leakage, ll pressure, toxicity, appropriate labelling and packaging) since the requirements and regulations differ by market (and, it has to be said, policing of the system can be thin on the ground). In some markets, for example, there is nothing to prevent a manufacturer making available a large canister (which looks like good value for money) but putting only a fraction of what one might expect inside. Weight does not assist the user either because, in the case of aerosols, some propellants are much heavier than others. The European Prescribed Quantities Directive (EPQD) discourages the possibility of only halflling a large canister with product in an attempt to mislead the consumer over the size. Users can identify products which conform to the EPQD because they are marked with an e symbol on the canister. In addition users should look to see that the canister is marked with a reverse epsilon. This mark means that the product does not fall short of the nominal minimum quantity for the can size under the European

Aerosols Directive. These marks are not a total guarantee but, if they are present, they should go along way to convince the user that some thought at least has been put into the safety and labelling accuracy of the product. Cost The words cheap or cheaper have negative connotations for good reason. The issues outlined in this article should have gone some way to showing that the unit / item cost of a smoke aerosol canister in isolation can be dangerously misleading and to rely on it is short-sighted. The true cost of an aerosol is very difcult to calculate and is a function of a wide number of factors. The price paid for the canister is only the start and users should begin by looking at the minimum contents of the canister (not the canister size). Here, it is the volume (not weight) which is important since the specic gravity of different chemicals differs widely. More important still is the number of tests that can be obtained. This, in turn, depends on the method of use, the number of sprays required, the duration of each spray, the chemical mix of the product, the rate of product discharge from the can, the make, model and condition of the detector under test, the ambient temperature, relative humidity, airow and canister temperature when conducting the test and the system conguration amongst others! At the same time, calculations of cost per test should take account of whether the aerosol can be relied on to activate all makes and models of detector. Failure to activate a particular detector when it should have done so, means time and money wasted. Finally in the regrettable situation that some aerosols cause damage to the detector, this too must be taken into account. Conclusion Production of smoke detector testers has become increasingly commoditised over recent years but we should never be fooled into thinking cheap products are necessarily good products. A re alarm system is designed to protect life (as well as last a number of years). Any product used to test it needs to enhance its life and dependability, not shorten or detract from it. Detector test aerosols need to be compatible with the plastics from which detectors are manufactured let alone not harm the user or the environment. Incompatibility can cause stress cracking or affect detector sensitivity, harming the very system under test. A good smoke detector test product is not one that simply sets common detectors into alarm and which is available at low cost. A good product is one that accommodates the test requirements of increasingly sophisticated re alarm systems, is well supported and meets the many and diverse health, safety and compatibility requirements about which a satised user never should need to worry.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Exponential Smoothing - The State of The ArtDocument28 pagesExponential Smoothing - The State of The ArtproluvieslacusNo ratings yet

- BurfiDocument1 pageBurfiArchie NairNo ratings yet

- Mechanics of Materials HW 2Document2 pagesMechanics of Materials HW 2Archie NairNo ratings yet

- Creating The Revised ProblemDocument3 pagesCreating The Revised ProblemArchie NairNo ratings yet

- Noise Reduction Tecnologies For Turbofan EnginesDocument17 pagesNoise Reduction Tecnologies For Turbofan EnginesPytocheNo ratings yet

- Chocolate Gluttony With Spun SugarDocument2 pagesChocolate Gluttony With Spun SugarArchie NairNo ratings yet

- Tài Liệu Hướng Dẫn Cài Đặt Rơ Le MPS 3000Document55 pagesTài Liệu Hướng Dẫn Cài Đặt Rơ Le MPS 3000nguyenquangtonNo ratings yet

- 105 2Document17 pages105 2Diego TobrNo ratings yet

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document1 pageS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNo ratings yet

- Prognostic Factors and Management of Patients With Choanal AtresiaDocument7 pagesPrognostic Factors and Management of Patients With Choanal Atresiafarah maulida martaNo ratings yet

- Bioinformatics Computing II: MotivationDocument7 pagesBioinformatics Computing II: MotivationTasmia SaleemNo ratings yet

- Verniers Micrometers and Measurement Uncertainty and Digital2Document30 pagesVerniers Micrometers and Measurement Uncertainty and Digital2Raymond ScottNo ratings yet

- Java Complete Collection FrameworkDocument28 pagesJava Complete Collection FrameworkkhushivanshNo ratings yet

- Adaptive Leadership: Leadership: Theory and PracticeDocument14 pagesAdaptive Leadership: Leadership: Theory and PracticeJose Daniel Quintero100% (1)

- Clint Freeman ResumeDocument2 pagesClint Freeman ResumeClint Tiberius FreemanNo ratings yet

- A2Document4 pagesA2Akshay KumarNo ratings yet

- Just in Time and TQMDocument8 pagesJust in Time and TQMBhramadhathNo ratings yet

- Chapter 20 AP QuestionsDocument6 pagesChapter 20 AP QuestionsflorenciashuraNo ratings yet

- Notice: Premerger Notification Waiting Periods Early TerminationsDocument5 pagesNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comNo ratings yet

- EngHub How To Break HabitsDocument13 pagesEngHub How To Break HabitsViktoria NovikovaNo ratings yet

- Veritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationDocument64 pagesVeritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationkarthickmsitNo ratings yet

- William Hallett - BiographyDocument2 pagesWilliam Hallett - Biographyapi-215611511No ratings yet

- Sales Forecast Template DownloadDocument9 pagesSales Forecast Template DownloadAshokNo ratings yet

- Flow of FoodDocument2 pagesFlow of FoodGenevaNo ratings yet

- Digital Electronics Chapter 5Document30 pagesDigital Electronics Chapter 5Pious TraderNo ratings yet

- FINAL BÁO-CÁO-THỰC-TẬP.editedDocument38 pagesFINAL BÁO-CÁO-THỰC-TẬP.editedngocthaongothi4No ratings yet

- Hannah Mancoll - Research Paper Template - 3071692Document14 pagesHannah Mancoll - Research Paper Template - 3071692api-538205445No ratings yet

- Preparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiDocument109 pagesPreparing For CPHQ .. An Overview of Concepts: Ghada Al-BarakatiBilal SalamehNo ratings yet

- Brosur YSIO X.preeDocument20 pagesBrosur YSIO X.preeRadiologi RSUD KilisuciNo ratings yet

- Directorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratDocument2 pagesDirectorate of Technical Education, Admission Committee For Professional Courses (ACPC), GujaratgamailkabaaaapNo ratings yet

- The Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationDocument28 pagesThe Body Shop Case Analysis. The Challenges of Managing Business As Holistic ConfigurationHanna AbejoNo ratings yet

- 2023 Teacher Email ListDocument5 pages2023 Teacher Email ListmunazamfbsNo ratings yet

- DAA UNIT 1 - FinalDocument38 pagesDAA UNIT 1 - FinalkarthickamsecNo ratings yet

- BÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Document4 pagesBÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Yến Vy TrầnNo ratings yet

- Community Architecture Concept PDFDocument11 pagesCommunity Architecture Concept PDFdeanNo ratings yet