Professional Documents

Culture Documents

Analiza Sumpora

Uploaded by

Pero DugicOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Analiza Sumpora

Uploaded by

Pero DugicCopyright:

Available Formats

Determination of sulfur in petroleum products and lubricants: A critical review of test performance

R.A. Kishore Nadkarni

ulfur and its compounds are present in most petroleum products and lubricants in varying concentrations. The origin of sulfur in these products may be from natural sources or the sulfur compounds may have been added during product processing as performance enhancers. The determination of sulfur content of crude oil is an integral part of the so-called crude assay of oil, since its concentration contributes to the complexity of the crude oil refining step. The presence of sulfur compounds in petroleum products is not desirable since they impart odor and may react with endproduct container vessels. Some sulfur compounds may corrode various metallic parts of internal combustion engines. Effects vary according to the chemical type of sulfur compounds present. Sulfur oxides formed during gasoline combustion can hinder the

esses, low levels of sulfur in feed stocks may poison expensive catalysts. Historically, the biggest environmental concern with the presence of sulfur in petroleum products was the emission of sulfur oxides formed during combustion of various fuel oils in large commercial or domestic applications. Consequently, industrial sulfur emissions are strictly controlled by most state and national government environmental pollution control agencies. With the advent of the 1990 Clean Air Act and actions by individual states such as Cali-

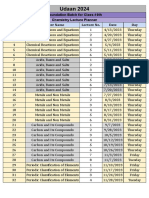

Table 1

As an outcome of this European round-robin study, it is pr oposed that the Wickbold and EDXRF methods be dropped from further consideration for analyzing fuels at the 30-mg/kg sulfur level for the year 2005.

performance of catalytic converters and can also be converted to acids, which promote rusting and corrosion of engine parts and piston rings and cause cylinder wall wear. In aviation gasoline, sulfur compounds have a deleterious effect on the antiknock efficiency of the alkyl lead compounds. Sulfur in diesel fuels causes wear due to the corrosive nature of the combustion products and increases the amount of deposits in the combustion chamber and on pistons. High boiling range fractions and residual fuels usually contain higher amounts of sulfur, which creates corrosion and pollution problems. The conversion of sulfur to SO3 during combustion and later reaction with water will form sulfuric acid, corroding the metal surfaces of equipment. In many petroleum rening proc-

Analysis** ASTM IP DIN AFNOR JIS ISO General bomb method D129 61 51577 T60-109 Lamp method D 1266 107 M07-031 High-temperature D 1552 M07-025 method WDXRF D 2622 51-400T6 K2541 14596 Oxyhydrogen burner D 2784 or lamp Oxidative microD 3120 16591 coulometry Oxidative microD 3246 373 M07-052 coulometry Hydrogeneolysis and D 4045 rateometric colorimetry EDXRF D 4294 336 M07-053 8754 Additives WDXRF D 4927 407 51-391T2 Additives ICP-AES D 4951 Additives ICP-AES D 5185 UV-uorescence D 5453 M07-059 WDXRF D 6334 Oxidative combustion D 6428 and electron capture detection Additives WDXRF D 6443 EDXRF D 6445 **This table was excerpted from a larger compilation of equivalent

test methods by Nadkarni.4 **IP = Institute of Petroleum (U.K.), DIN = Deutsche Institute fur Normang (Germany), AFNOR = Association Francaise de Normalization (France), JIS = Japan Industrial Standards, and ISO = International Organization for Standards (Geneva, Switzerland).

Analytical test methods used for the determination of sulfur in petroleum products and lubricants*

16

NOVEMBER 2000

SULFUR DETERMINATION continued

Table 2 ASTM Method D 129 Technique Bomb combustion and BaSO4 precipitation

Test methods for sulfur determination in petroleum products*

Scope Petroleum products, lube oils, adpacks, greases; >0.1% S Limitation Not applicable to samples that give insoluble residues: Fe Al, Ca, Si, Pb, silica, MoS2, asbestos, mica, used oils Acid or base forming compounds in titration; labor intensive

Repeatability Dependent on level

Reproducibility Dependent on level

Bias 0.05%high

D 1266

D 1552

D2622

Lamp combustion: BaSO4 precipitation, or NaOHtitration, or turbidometry if <0.01% High-temperature combustion:iodate titration or IR detection WDXRF

0.010.04% S in gasoline, kerosene, naphtha

0.005

0.010 + (0.025X) Not known

D 2784

D 3120

Oxyhydrogen burner or lamp combustion and BaClO4 titration or turbidometry Oxidative pyrolysis and microcoulometry Oxidative pyrolysis and microcoulometry Hydrogenolysis and rateometric colorimetry

Samples with boiling points >177 C and >0.06%S; petroleum cokes up to 8% S Diesel and jet fuels, kerosene, distillate oils, naphtha, residual oils, lube base oil, hydraulic oil, crude oil, unleaded gasoline, M-85 and M-100 fuels; range 3 mg/kg to 5.3% For liquid petroleum gas only; >1 ppm S

Iodate:>1% chlorine and >0.1% nitrogen interfere IR:none from N or S Volatile samples may not be suitable; standard and sample matrix must be matched for CH ratio; expensive instrument

Dependent on sulfur level See the test method

Dependent on level See the test method

Not known

~35% relative bias

>100 ppm halogens interfere

NA**

NA

NA

D 3246 D 4045

D 4294

EDXRF

D 4927 D 4951 D 5185 D 5453

WDXRF ICP-AES ICP-AES High-temperature combustionUV uorescence detection

D 6334

WDXRF

D 6428

Oxidative combustion EC detection

3100 ppm S in light liquid >10XCl, 1000XN, and 500 hydrocarbons, boiling range ppm heavy metals interfere 26274 C 1.5100 ppm S in petroleum >10XCl, >1% N, and 500 gas ppm heavy metals interfere 0.0210 ppm S in liquids with boiling points 30371 C, e.g., naphthas, kerosene, alcohol, steam condensate, distillates, jet fuel, benzene, toluene 150 ppm5% in hydrocarbons Spectral interference from such as diesel, naphtha, >0.1X of water, lead alkyls, kerosene, residuals, base Si, P, Ca, K, halides; matrix oils, hydraulic oils, jet fuel, effects; oxygen interferes in crude oils, unleaded gasoline, oxygenates and M-85 and M-100 fuels Additives, lube oils with Spectral and matrix inter0.012.0% S ferences can be compensated Lube oils and additives Viscosity index improver gives low bias but can be suppressed Used lube oils, base oils Same as D 4951; particulates with 9006000 ppm S will give low results Liquid hydrocarbons boiling >0.35% halogens interfere at 25400 C and viscosities 0.210 cSt at room temperature; naphtha, distillates, motor fuels, oils containing 18000 ppm S 15940 ppm S in gasoline Standards need to be matrix and oxygenate blends matched, e.g., oxygenates, gasohols 0.05100 ppm S in liquid Moisture produced in combustion aromatic hydrocarbons needs to be removed before detection

28%

38%

NA

0.4 ppm 0.16X 0.5

5 ppm 0.26X 0.5

NA NA

0.02894 (X + 0.1691)

0.1215 (X + 0.0555)

None

See the test method 0.016 for oils; 0.14 for additives 0.49X 0.81 0.1867X 0.63

See the test NA method 0.061 for oils; 0.372 for additives 1.2X 0.75 None 0.2217X 0.92 None

0.04 (X + 97.29)

0.1182 (X + 54.69)

None

0.06 @ 1 ppm S; NA 7.64 @ 80 ppm S

NA

continued

18

NOVEMBER 2000

SULFUR DETERMINATION continued

D 6443

WDXRF

Lube oils and additives with 0.51% S Gasoline 481000 ppm S

D 6445

EDXRF

Spectral interference from Mo and None Pb; in other elements, interference reduced by alpha corrections See D 4294 12.3 (X + 10)0.1 36.26 (X + 10)0.1 NA

**X is the mean of all results. **NA= not available.

fornia, an emphasis regarding mobile pollution sources (vehicles) has also evolved. The current highprole sulfur control issue is surely clean (low-sulfur) motor fuels, specically gasoline and diesel. On the other hand, several metal sulfur compounds are purposely added to lubricating oils and additives to enhance their performance. These include sulfonates of barium, calcium, magnesium, MoS2 , etc. Further information on the presence and importance of sulfur in petroleum products can be found in Boldt and Hall,1 Dyroff,2 and Nadkarni.3

Sulfur test methods

Given the importance of knowing the accurate concentration of sulfur in most petroleum products, it is not surprising that a variety of analytical techniques have been employed for this task. The methods vary from classical techniques such as sample combustion using a lamp or a bomb followed by gravimetric or titrimetric determination to modern techniques such as ultraviolet or X-ray fluorescence and inductively coupled plasmaatomic emission spectrometry (ICP-AES). The former methods are seldom used in modern laboratories because they are labor intensive, although they are often considered as referee methods. Table 1 lists the standard test methods published by the ASTM (American Society for Testing and Materials) DO2 Committee on Petroleum Products and Lubricants. Where available, equivalent international standard test methods are also included. It is not implied that the ASTM methods and their international counterparts are exactly identical, only that the pertinent methods are similar and based on similar analytical methodology. Table 2 is a comparative summary of available ASTM sulfur test methods with possible interferences in the analysis and their test precision. Given the plethora of test methods available for sulfur determination in petroleum products, the choice for a particular analysis would depend on the matrix, sulfur concentration, and desired precision of analysis. It is equally important to know the precision capabilities of the laboratories regardless of the method precision stated in the ASTM books. Experience shows that a large number of laboratories are not capable of obtaining the expected precision of the method. There could be multiple reasons for this, including laboratories not following the test method precisely, not doing frequent enough calibrations,

not correcting for test method interferences, and/or not having satisfactory quality control in the laboratory operations. These are not mere speculations, but are based on actual laboratory experience. On the other hand, it has been observed that sets of laboratories that are well managed in terms of test method adherence, appropriate calibration, and strict quality control obtain precisions equal to if not better than the ones espoused in the ASTM test methods. It is illuminating to look at the three major studies done to review the analytical performance of some major test methods used in the laboratories testing petroleum products.

ASTM Research Report D.02-1456

In a very thorough research study done at the Southwest Research Institute (SWRI, San Antonio, TX), three sulfur methods were compared for fitness for use. 5 The three methods studied were D 2622 wavelength-dispersive X-ray fluorescence (WDXRF), D 4294 ene rgy-dis pers ive X-ray fluorescence (EDXRF), and D 5453 UV-uorescence for the analysis of fuels at <500 mg/kg sulfur. All three were found to be equivalent for measurements in the 150500 mg/kg range. D 5453 and D 2622 demonstrated equivalent fitness for use down to 20 mg/kg. Strong evidence was found that the D 5453 method can be fit for use in multilaboratory situations down to the 1-mg/kg sulfur level. A single isooctane matrix was used to minimize the well-known carbon to hydrogen ratio interference in the XRF test methods. All three test methods were then evaluated for any bias with respect to 24 commonly occurring organosulfur compounds. No bias was found and the accuracy was within the precision limits for each of the test methods. Of these three test methods, the best low-level precision and accuracy were found in methods D 2622 and D 5453. Of these two, D 5453 was found to generate better data in the low (<50 mg/kg) sulfur regime. This work suggests that the D 5453 method can be routinely used for the determination of sulfur in liquid hydrocarbons at levels below 1 mg/kg.

European sulfur cross-check

In a very recently completed, very large roundrobin study in Europe, 69 laboratories from nine countries participated in the determination of sulfur at levels between 5.0 and 500 mg/kg in eight gasoline and seven diesel samples.6 Five methods were principally

20

NOVEMBER 2000

Table 3

Precision obtained in the Center for European Normalization round-robin study

Method WDXRF EDXRF UV-uorescence Microcoulometry Wickbold WDXRF EDXRF UV-uorescence Microcoulometry Wickbold Repeatability 0.048X+ 0.0002 NA 0.0417X + 0.0001 0.043X + 0.0003 NA 0.0293X+ 0.0003 NA 0.0285X + 0.0002 0.043X + 0.0003 NA Reproducibility 0.147X + 0.0003 0.0838X + 0.002 0.1573X + 0.0002 0.1679X+ 0.0008 NA 0.0725X+ 0.0005 0.0289X+ 0.0016 0.1088X+ 0.0002 0.1679X+ 0.0008 NA

Gasoline

Diesel

Table 4

Comparison of reproducibility obtained in the European crosscheck with ASTM test method reproducibility*

European cross-check ASTM method Method reproducibility reproducibility WDXRF 10 12.8 (D 2622) EDXRF 37 74 (D 4294) UV-uorescence 10 8.1 (D 5453) Microcoulometry 16 19 (D 3120) Wickbold 17 101 (D 1266) *All precision estimates are at 50 mg/kg sulfur in gasoline.

tested: WDXRF (ISO14596, i.e., ASTM D 2622), EDXRF (IP PM CX/00, i.e., ASTM D 4294), UV-fluorescence (MO7-059, i.e., ASTM D 5453), microcoulometry (ISO CD 16591, i.e., ASTM D 3120), and Wickbold combustion (EN 24260, i.e., D 1266). At these levels, all ve test methods were found to produce essentially equivalent results, but the precision of different methods varied considerably (Table 3). The best reproducibility was obtained for WDXRF and UV-fluorescence methods. Table 4 compares the reproducibility obtained in this cross-check with those suggested in their equivalent ASTM methods. The best reproducibility appears to be those of the D 2622 and D 5453 test methods. As an outcome of this European round-robin study, it is proposed that the Wickbold and EDXRF methods be dropped from further consideration for analyzing fuels at the 30mg/kg sulfur level for the year 2005. Only the UVuorescence method was considered suitable for the determination of sulfur at less than 10 mg/kg content required in future European fuels.

ASTM interlaboratory cross-check programs

For nearly a decade, the ASTM DO2 Petroleum Products and Lubricants Committee through its Coordinating Subcommittee 92 has instituted a voluntary proficiency testing program. 7 This program has proved highly successful in the oil industry worldwide. At present, 11 product lines are analyzed among a total of over 1400 laboratory units, nearly 35% of these being non-U.S. laboratories. Most products are

AMERICANLABORATORY

21

SULFUR DETERMINATION continued

Table 5

Alternate methods precision for sulfur determination in petroleum products

Analysis method Robust mean robust SD (#valid results) Motor gasoline (MG9904) mg/kg D 1266 115 38 (5) D 2622 96 8.7 (30) D 3120 69 36 (13) D 4045 82.8 8.7 (4) D 4294 105 34 (49) D 5453 78.7 14.2 (15) Reformulated gasoline (RFG9906) mg/kg D 2622 16.7 6.0 (66) D 3120 14.3 3.7 (5) D 4045 13.6 3.5 (5) D 4294 29 21 (31) D 5453 13.9 1.6 (22) Diesel fuel (DL9902)mg/kg D 129 614 222 (10) D 1266 360 (1) D 2622 466 19 (64) D 4045 422 152 (4) D 4294 487 27 (142) D 5453 471 55 (20) Figure 2 Box and whisker graph for methods used for sul fur determination of automotive lubricant additive 9910.

Figure 1 Box and whisker graph for methods used for sul fur determination of motor gasoline sample 9908.

analyzed three times per year. Since only a single analysis using ASTM DO2 methods is carried out, only an estimate of reproducibility (which ASTM defines as the agreement between two laboratories analyzing the same sample using the same test method) can be calculated. As can be imagined, a vast database exists

through this program regarding the reproducibility of various test methods used for a multitude of analyses. A survey among the participating laboratories conducted in August 1999 found that the most commonly used test methods for sulfur determination in motor gasoline, #2 diesel fuel, reformulated gasoline (RFG), and aviation turbine fuel were D 2622 WDXRF, D 4294 EDXRF, and D 5453 UV-fluorescence. Other test methods, D 1266 lamp, D 3120 microcoulometry, D 4045 hydrogeneolysis rateometry, and D 6344 WDXRF, were used to a much lesser extent.8 Table 5 gives typical analyses obtained in these cross-checks using alternative sulfur methods in different matrices. There is a vast amount of data available, but only the typical data from 1999 cross-checks are included to illustrate the point. Overall, there appears to be good agreement between the mean results obtained by alternative methods for a particular product. However, sometimes there is considerable difference between the precisions obtained associated with the individual test methods. This point is more vividly illustrated in the box and whisker graphs plotted for two products, motor gasoline and automotive lubricant additive, in Figures 1 and 2 respectively. These graphs provide a cross-reference of test data generated from different methods that determine the same parameter. The graph separates the data by standard with the shaded box representing the middle 50% of test data centered around the median. The horizontal lines within the box represent the median of the reported data. Data points above or below the whisker are included, unless

22

NOVEMBER 2000

Table 6

Comparison of reproducibility of cross-checks and test method for sulfur determination

Sample RFG 9910 RFG 9910 RFG9910 MOGAS9912 MOGAS 9912 MOGAS 9912 MOGAS 9912 MOGAS 9912 DL 9910 DL 9910 Robust mean 18.0 mg/kg 16.3 mg/kg 16.8 mg/kg 0.0158 M% 0.01741 M% 0.01559 M% 0.0166 M% 0.01475 M% 69.1 mg/kg 55.3 mg/kg Reproducibility Cross-check Test method 16.3 8.4 7.0 6.2 5.5 3.0 0.0122 0.0104 0.00396 0.00208 0.00517 0.00593 0.0114 0.0088 0.0061 0.0022 16.9 10.4 47 8.9

Method D2622 D3120 D5453 D1266 D2622 D3120 D4294 D5453 D2622 D5453

the data are off the y-axis scale, in which case the data, which would be off the graph, are indicated with an arrow. The y-axis scale represents the absolute value and the x-axis scale provides an identification of the test method and number of reporting data points. The sulfur concentrations in these two products differ almost by a factor of 100. Even though the mean values of each product are reasonably close among different test methods, the range of results and thus the reproducibility of the analysis varies widely from unacceptable (e.g., D 4927A in Figure 2) to very precise (e.g., D 1552 in Figure 2). Thus, great care must be exercised in making decisions regarding product quality among buyers and sellers and by the regulatory agencies. The precision of the analysis is perhaps even more important than the average value in cases of dispute. In spite of the resounding success of the ASTM DO2 Committees interlaboratory crosscheck program (ILCP) project, the precisions calculated from these round-robin studies were generally found to be inferior to those required in the standard test methods. This situation was somewhat improved after the extreme outlier rejection routine was included in the statistical calculations. However, the round-robin precision was still found to be better than the one given in the standard test method only in a small numer of cases. Typical data on cross-check and test method reproducibility are compared in Table 6. As noted earlier in this article, a lack of strict adherence to test method details, inadequate calibration, and probable lack of quality control in the laboratory are the suspected reasons for this discrepancy. The original reproducibility value in the standard test methods resulted from w ell-controlled cross -checks among a limited number of leading industry laboratories. Hence, it would not be judicious to replace the current reproducibility limits given in the standard test methods with those from these crosschecks among laboratories that may or may not be technically well controlled.

continued

AMERICAN LABORATORY

23

SULFUR DETERMINATION continued

Regulatory aspects of sulfur in gasoline

Reduction of sulfur levels in gasoline and diesel with a view toward signicantly reducing damage to vehicular pollution control devices is an ongoing goal of the U.S. EPA. The U.S. EPA targets gasoline to have an average sulfur level reduced to 30 mg/kg by the year 2004 from the current average of more than 300 mg/kg. It also proposes that sulfur levels in diesel will be reduced by 97% to 15 mg/kg by the year 2006. To this end, the U.S. EPA recently promulgated its Tier 2 motor vehicle emission standards and gasoline sulfur control requirements in the Federal Register.9,10 These new laws are significant in that they for the rst time treat automobiles and their fuel as a single system. Included in these current and proposed regulations is the requirement that only a single test method for the determination of low levels of sulfur in gasoline, RFG, and diesel fuels be used.11 There is little disagreement among automotive manufacturers and the environmental community with the U.S. EPAs overall goal of reducing sulfur to near-zero levels in the next decade. However, the refiners and importers have engaged in serious debate about levels of sulfur reduction and timing. While not as high profile, other discussion has revolved around the appropriate test methods for measuring these low levels of sulfur fuels of the not-too-distant future. In its nal Tier 2 gasoline rulemaking, the U.S. EPA has mandated the use of D 2622 WDXRF as the sole regulatory sulfur test method for this analysis. However, it is questionable whether this indeed is the best choice of test methods. Based on its precision, the UV-fluorescence test method D 5453 would be a better choice rather than the D 2622 WDXRF method for the measurement of low sulfur level fuels. Indeed, some years back, the California Air Resources Board (CARB) mandated D 5453 as the sulfur test method for the analysis of gasoline containing <10 mg/kg. It was designated as an alternative to the D 2622 method for sulfur levels of >10 mg/kg; for diesel fuels, D 5453 was established as an equivalent test method to the D 2622 test method.12 In its notice, the U.S. EPA also seems to recognize that in certain situations D 2622 has limitations. As an example, in the range required for California fuels, the U.S. EPA agreed to recognize the test methods allowed by the California EPA.10 The ASTM CS 92 cross-checks clearly indicate that for gasoline types of sample below the 10-mg/kg sulfur level, D 2622 has extremely poor precision. At around 30 mg/kg, D 2622 has improved reproducibility, but D 5453 still has superior reproducibility at this level (see Table 7 for this comparison). At sulfur levels over and above 50 mg/kg, however, both D 2622 and D 5453 produce equivalent results in RFG, motor gasoline, diesel, and jet fuels based on ASTM cross-checks between June 1996 and December 1998 (Figure 3). Based on the precision of analysis, D 5453 appears to be much superior to D 2622 at less than a 50-

Table 7

Precision of test methods as related to sulfur concentration levels

ASTM D 5453 D 2622 sample* Mean SD % RSD Mean SD % RSD Below 10-mg/kg level RFG9810 2.5 1 40 6.5 5.5 85 RFG9907 2.2 0.9 40 6 5.7 95 JF 9711 3.5 1.8 51 13.9 13.3 96 RFG9806 4.5 1.4 31 9 7.1 79 RFG 9706 5 1.5 30 7.4 5.2 70 RFG 9712 5 1 20 8.8 5.3 60 RFG9612 8.7 1.9 22 12.2 5.7 47 Between 10 and 30 mg/kg level MG 9612 10 2 20 14 10 71 RFG9807 11 2 18 13 6 46 RFG 9709 13 3 23 14 6 43 RFG 9910 17 2 12 18 6 33 RFG 9609 14 3 21 15 6 40 RFG 9906 14 2 14 17 6 35 RFG 9703 27 5 19 28 6 22 RFG 9901 29 2 7 30 7 23 RFG 9803 30 4 13 34 10 29 RFG 9904 23 2 9 24 8 33 *RFG = reformulated gasoline; JF = jet fuel; MG = motor gasoline.

Figure 3 D 5453 vs D 2622. mg/kg sulfur level and equivalent at above this level. Thus, there is no technical reason w hy D 5 4 5 3 should not be the primary method of analysis for sulfur in gasoline-type products. The cost of instrumentation and maintenance of D 5453 equipment is also about three times lower than that needed for the D 2622 method.

Reliability of EDXRF Test Method D 4294

Although per its scope this method is not meant for the analysis of samples containing less than 150 mg/kg sulfur, it appears to be widely used in the oil industry in spite of its poor reproducibility, as seen in the ASTM cross-checks. The reason for its widespread use is probably the low cost of purchase and mainte-

24

NOVEMBER 2000

Table 8

Comparison of three major test methods used in oil industr for sulfur analysis; values expressed as mean reproducibility (number of valid results)

D 2622 ASTM sample* (WDXRF) JF9811 6.1 15.8 (34) MG9812 184 39 (27) MG 9904 96 24 (30) RFG 9811 218 39 (69) RFG9902 67 24 (73) RFG 9904 30 19 (71) RFG 9905 99 27 (74) RFG 9906 17 17 (66) DL 9810 441 52 (63) DL 9902 466 53 (64) *DL = diesel fuel.

D 4294 D 5453 (EDXRF) (UV-uorescence) 34 83 (81) 2.85 1.8 (16) 195 111 (52) 165 68 (16) 105 94 (49) 79 39 (15) 235 75 (42) 214 68 (20) 72 66 (39) 65 20 (25) 42 69 (39) 29 7 (24) 114 100 (44) 89 22 (25) 29 58 (31) 14 4 (22) 456 102 (143) 440 91 (16) 487 75 (142) 471 152 (20)

5. Kohl K. ASTM Research Report DO2-1456. ASTM, West Conshohocken, PA, 1999. 6. Tittarelli P. Round Robin Exercise for Sulfur Test Methods for EN 228 and EN 590 Fuel Specications. CEN/TC 19/WG 27, Apr 2000. 7. Bover WJ. ASTM Standardization News 1994; June:56 63. 8. Bradley D. (ASTM). Private communication to EPA, Sep 20, 1999. 9. U.S. EPA. Federal Register, 62(133), 40 CFR Part 80, Part II, p. 37337. Jul 11, 1997. 10. U.S. EPA. Federal Register, 64(92), 40 CFR Parts 80, 85, and 86, p. 26055, May 13, 1999. 11. U.S. EPA. Federal Register, 65(28), pp. 675274. Feb 10, 2000. 12. Title 13, California Code of Regulations. Sections 2281 and 2282, Sep 1992.

nance of the instrumentation used in this test method. Table 8 compares the results obtained on several typical samples of petroleum products analyzed by three major methods used in the oil industry: D 2622 WDXRF, D 4294 EDXRF, and D 5453 UV-uorescence. In spite of the large number of laboratories using the D 4294 method, poor reproducibility, sometimes approaching 100% or more of the mean value, makes this analysis of very little use, particularly in settling product quality disputes between buyer and seller. Again, at below a 30-mg/kg sulfur level, D5453 has the best precision among the three test methods compared.

Dr. Nadkarni is President, Millennium Analytics, Inc., 47 Helena St., East Brunswick, NJ 08816, U.S.A.; tel.: 732613-8710; e-mail: knadkarni@aol.com. Dr. Nadkarni is Chairman of the ISO/TC 28 Committee on Petroleum Prod ucts and Lubricants, Chairman of the ASTM DO2 SubCommittee 3 on Elemental Analysis, and Vice-Chairman of the ASTM DO2 Sub-Committee 92 on Inter- L a b o r a t o ry Cross-Check Programs.

Concluding remarks

There are over a dozen test methods available for the determination of sulfur in petroleum products and lubricants. Each method has its advantages and drawbacks. An intelligent choice must be made based on the methods accuracy and precision before deciding which method to use for a specic product. Since the method precision is dependent on the sulfur concentration level, this is a critical decision. Arbitrarily using a test method without taking these considerations into account can only result in producing data that are unreliable, which does not help in settling disputes in commercial transactions or in regulatory affairs.

References

1. Boldt K, Hall BR, eds. Signicance of Tests for Petroleum Products. STP 7C. ASTM, Philadelphia, PA, 1977. 2. Dyroff GV, ed. Manual on Signicance of Tests for Petroleum Products. 5th ed. MNL 1. ASTM, Philadelphia, PA, 1989. 3. Nadkarni RA. Modern Instrumental Methods of Elemental Analysis of Petroleum Products and Lubricants. STP 1109. ASTM, Philadelphia, PA, 1991. 4. Nadkarni RA. Guide for the Analysis of Petroleum Products and Lubricants. MNL 44. ASTM, West Conshohocken, PA, 2000.

AMERICANLABORATORY

25

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FM-23-85 60mm Mortar M19 1967Document174 pagesFM-23-85 60mm Mortar M19 1967rigal849No ratings yet

- Organic Chemistry Lab Prepares HydrocarbonsDocument6 pagesOrganic Chemistry Lab Prepares HydrocarbonsJhei Mesina AfableNo ratings yet

- Project Report FinalDocument22 pagesProject Report FinalAshishThomasChempolil0% (1)

- Liquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidDocument10 pagesLiquid-Liquid Equilibria For The Systems Water-Alcohols-Acetic AcidAleska Guzman SantamariaNo ratings yet

- M20Document54 pagesM20Mijail Pérez Miranda100% (1)

- Especificacion Tecnica Tanques FRP CANATUREDocument3 pagesEspecificacion Tecnica Tanques FRP CANATURETomasae1980No ratings yet

- Process Ventilation Design RequirementsDocument4 pagesProcess Ventilation Design RequirementsMehman NasibovNo ratings yet

- Reforming 2Document15 pagesReforming 2HAFIZ IMRAN AKHTERNo ratings yet

- Lecture Planner - Chemistry PDF OnlyDocument1 pageLecture Planner - Chemistry PDF OnlyJai ChandNo ratings yet

- Heat gain loads in air conditioning designDocument18 pagesHeat gain loads in air conditioning designNg Swee Loong Steven100% (2)

- NEET-2021 (Paper Analysis) FinalDocument32 pagesNEET-2021 (Paper Analysis) FinalMahasina BegumNo ratings yet

- Phase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsDocument8 pagesPhase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsAsshole FuckerNo ratings yet

- Lighting Techniques TVDocument29 pagesLighting Techniques TVMireya FernandezNo ratings yet

- Operation and Maintenance ManualDocument39 pagesOperation and Maintenance Manualhdf17No ratings yet

- MSDS - Robond L-330 - ISS130910Document7 pagesMSDS - Robond L-330 - ISS130910Anonymous pXU4tefJNo ratings yet

- SF 6Document16 pagesSF 6dennyyusuf100% (1)

- Syllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsDocument9 pagesSyllabus:-Biomolecules, Cell: The Unit of Life, Structural Organisation in AnimalsEXCEPTIONAL FOCUSNo ratings yet

- ELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinDocument2 pagesELITE™ AT 6900: The Dow Chemical Company - Enhanced Polyethylene ResinLeductoan LeNo ratings yet

- Antioxidant Enzyme EvaluationDocument14 pagesAntioxidant Enzyme EvaluationArpit JainNo ratings yet

- Deep Cryogenic Treatment of A D2 Cold-Work Tool Steel PDFDocument4 pagesDeep Cryogenic Treatment of A D2 Cold-Work Tool Steel PDFBinh Thanh LeNo ratings yet

- Sodium Alginate TestingDocument2 pagesSodium Alginate TestingImran Anwar0% (1)

- Patrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossDocument9 pagesPatrick Biller, Brajendra K. Sharma, Bidhya Kunwar, Andrew B. RossBrahian Alexander RinconNo ratings yet

- ΔL, SIF, Hoop Stress, API StandardsDocument3 pagesΔL, SIF, Hoop Stress, API StandardsVijay KumarNo ratings yet

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokNo ratings yet

- Fluid Flow Pressure Drop and Friction LossDocument148 pagesFluid Flow Pressure Drop and Friction Losslkjasdf8879100% (1)

- 3404 10153 1 PBDocument6 pages3404 10153 1 PBSergio Fabian NavarroNo ratings yet

- Refinery Wastewater Treatment TrainingDocument27 pagesRefinery Wastewater Treatment TrainingHariajahNo ratings yet

- Effect of Concentration in Rate of ReactionDocument3 pagesEffect of Concentration in Rate of ReactionblablaNo ratings yet

- Non-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementDocument7 pagesNon-Destructive Pressure Detection in Sealed Containers Using Strain MeasurementstevensurandomNo ratings yet