Professional Documents

Culture Documents

Driving IN-9 Neon Displays: Fe in Be Be

Uploaded by

slawek_kedra3218Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Driving IN-9 Neon Displays: Fe in Be Be

Uploaded by

slawek_kedra3218Copyright:

Available Formats

Driving IN-9 Neon Displays Russian IN-9 neon bargraph indicator tubes are readily available on eBay and

from a number of commercial sources. However, there seem to be no detailed characteristics or circuits for driving this tube published on web. The designs in this document are not particularly sophisticated, but should serve as a basis for experimenting with these interesting displays. Although these circuits were designed for the IN-9, they will also work for the similar IN-13 with changes as noted below. The IN-9 is a current driven indicator. The length of the glowing bar is directly proportional to tube current over a most of the device's range (Figure A). Linearity is very good between 0 and 8mA with a fit constant of 10.3mm/mA. Sensitivity decreases rapidly for currents above 8mA. Once the cathode is saturated at 103mm, the glow brightness increases with increasing current. As shown by the V-I diagram (Figure B), the tube voltage drop remains nearly constant when the glow is expanding. This characteristic allows the IN-9 and a series resistor to be used as a voltage indicator. Once the cathode glow is fully expanded, the tube behaves as a resistance of approximately 400 ohms. The maximum recommended current for an IN-9 is 12mA. Those ratings were exceeded somewhat to produce these plots. One of the simplest possible drivers for this tube is a single transistor current sink (Figure C). This circuit requires only two parts. If the transistor base current is neglected (good assumption, hfe of a MJE340 is >200), the tube current is approximately i = (Vin - Vbe) / R. Vbe is typically a little over 0.6V for a silicon transistor. Thus, with R = 330 ohms, an input voltage of +0.6V to +5.0V will sweep the IN-9 through its entire normal operating range. (I do not have an IN-13, but with a design current range of 0 to 5mA, R = 820 or 1K ohm would be appropriate). For an easy test circuit, Vin can come from a 10k potentiometer connected between ground and +5V. Different high voltage transistors can substitute for Q1, but I wouldn't recommend the popular MPSA42. At full current, this circuit is too close to that part's maximum dissipation for my comfort. The MJE340 is inexpensive and widely available from Digikey, Jameco, Farnell and many others. Q1 will be warm to the touch in normal operation. If you intend to operate any of these circuits from a higher supply voltage than +150V (for example, the 170-190V typically available in a nixie clock), I would add a 2.2k or 3.3k resistor in series with the IN-9 to prevent excess power from being burnt off in the transistor. A simple seconds indicator for an MCU based clock is given in Figure D. The TLV5625 is small (SMD) 8-bit D/A converter I happened to have on hand. The reference voltage is set so that the MCU can sweep the D/A from a count of 24 (0.6V) to a count of 144 (3.7V) incrementing at a rate of 2 counts per second. This produces a nice jump in the glow bar each second. Figure E shows an equivalent circuit that uses discrete counter ICs, a parallel D/A converter and an op amp. The NAND circuit causes the counters to reset at a count of 60 instead of 256. In a nixie clock, this circuit can directly replace the counters used to scale the 1Hz timebase input to the 1/60Hz minute signal. The diode in the op amp feedback path introduces a 0.6V offset in the output to offset the Vbe drop. The op amp and diode types are not critical. The supply voltage requirements of this circuit are somewhat inconvenient; a possible modification would be to change the +12V supply to +5V and use a rail-to-rail op amp, and to generate the negative supply using one of the many LM555-based inverter circuits available on the web. The main short-coming of the simple current sink is the Vbe drop subtracted from the input voltage. Vbe is not constant; it varies with both collector current and junction temperature. Luckily, the collector current effect is negligible at the operating point used and even if the whole assembly was moved from the Sahara to the Arctic, Vbe temperature dependence would only shift the bar length by a few millimeters (changes in tube gas pressure would likely have a much greater effect under those circumstances). In many cases, however, it is useful to have an indicator that starts at 0V. The circuit in Figure F uses an op amp to remove the Vbe offset and compensate for any temperature dependent effects. Current through the indicator tube is simply i = Vin / R, with no offset adjustment needed. Questions are welcome. Copyright 2004, Jeff Malins [jmalins@gmail.com]. This document may be redistributed verbatim in any form provided that this message is retained. Do not build any circuit presented here unless you understand the dangers of working with high voltages. Special thanks to the members of the NEONIXIE-L@yahoo.com mailing list for the feedback I received on these circuits.

Figure A. Bar length as a function of tube current.

Figure B. V-I characteristics.

Figure C. Single transistor current sink.

Figure D. MCU driven D/A driver circuit.

Figure E. TTL discrete IC driver.

Figure F. Op amp based driver with zero offset voltage.

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 1.5v Battery ChargerDocument25 pages1.5v Battery ChargerJOHN BRICCO A. MATACSILNo ratings yet

- Easy(er) Electrical Principles for General Class Ham License (2015-2019)From EverandEasy(er) Electrical Principles for General Class Ham License (2015-2019)Rating: 5 out of 5 stars5/5 (1)

- 13.8v Power Supply PS HighCurrentDocument17 pages13.8v Power Supply PS HighCurrentMadumathi BulumullaNo ratings yet

- Relaxation OscillatorsDocument9 pagesRelaxation OscillatorsJoseGarciaRuizNo ratings yet

- A Bipolar Junction TransistorDocument29 pagesA Bipolar Junction Transistor76697669No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- DiyAudio Tube Constant Current Source BoardDocument7 pagesDiyAudio Tube Constant Current Source Boardjimmy67musicNo ratings yet

- Microcontroller-Based Potentiostat Supporting InformationDocument15 pagesMicrocontroller-Based Potentiostat Supporting InformationJesús Munayco FloresNo ratings yet

- 1707 An253 Power Supply Design Basics ImpDocument6 pages1707 An253 Power Supply Design Basics ImpbmmostefaNo ratings yet

- Power Supply Design Basics: Figure 3: Full Wave Rectified Output From TheDocument6 pagesPower Supply Design Basics: Figure 3: Full Wave Rectified Output From Theprotesto06No ratings yet

- Variable Power Supply Using LM317Document12 pagesVariable Power Supply Using LM317Víctor FaucheretNo ratings yet

- Lm723 Linear Power Supply: GeneralDocument9 pagesLm723 Linear Power Supply: Generalsyed_hafeez_2No ratings yet

- 2 038 PDFDocument11 pages2 038 PDFAmit GauravNo ratings yet

- Basic Electronics L2Document17 pagesBasic Electronics L2msellereneNo ratings yet

- Valve Curve TracerDocument7 pagesValve Curve TracerIsa Campos100% (1)

- Opamp Linear Device 1300847494 PDFDocument12 pagesOpamp Linear Device 1300847494 PDFNini FarribasNo ratings yet

- Smart Voltage Stabilizer Using PIC16F877ADocument8 pagesSmart Voltage Stabilizer Using PIC16F877AAswathy CjNo ratings yet

- E330 Electronic System Design Lab 2 Design of A Current Mirror Continuity Tester 1Document3 pagesE330 Electronic System Design Lab 2 Design of A Current Mirror Continuity Tester 1egaupc2123No ratings yet

- Electronics Lab: Part I. Operational AmplifiersDocument8 pagesElectronics Lab: Part I. Operational AmplifiersToMNo ratings yet

- Power SupplyDocument5 pagesPower SupplyJaphetRayModestoCanaNo ratings yet

- Op Amps BasicsDocument10 pagesOp Amps BasicsinformagicNo ratings yet

- Question of EE ProjectDocument5 pagesQuestion of EE ProjectANJALI KUMARINo ratings yet

- 400W Rms Hexfet Mosfet Symmetrical AmplifierDocument10 pages400W Rms Hexfet Mosfet Symmetrical Amplifieralbedo367No ratings yet

- It Would Be Useful To Be Able To Run A Motor in Either Direction Using H BridgeDocument51 pagesIt Would Be Useful To Be Able To Run A Motor in Either Direction Using H BridgeatulhinduNo ratings yet

- IC Questions With Ans AnilsirDocument22 pagesIC Questions With Ans AnilsirAniil J Kumaar50% (2)

- E 987002Document2 pagesE 987002dugamdugonjaNo ratings yet

- Variable DC Power Supply, 1.2V To 30V 1A Using LM317Document20 pagesVariable DC Power Supply, 1.2V To 30V 1A Using LM317ferdinandNo ratings yet

- Transformer: Rapid ElectronicsDocument5 pagesTransformer: Rapid ElectronicsMayaa KhanNo ratings yet

- 3 Best Transformerless Inverters With Circuit DiagramsDocument35 pages3 Best Transformerless Inverters With Circuit Diagramswinkyi100% (1)

- Circuito LED VUmeter FacilDocument6 pagesCircuito LED VUmeter FacilEnya Andrea Ribba HernandezNo ratings yet

- Automatic IR Tap ControllerDocument67 pagesAutomatic IR Tap ControllerAnkit88% (16)

- 4 Zener Voltage Regulator Diode Clippers ClampersDocument7 pages4 Zener Voltage Regulator Diode Clippers ClampersmakreloadedNo ratings yet

- Power Supply NotesDocument48 pagesPower Supply NotespugazhendiraNo ratings yet

- Clock GeneratorDocument11 pagesClock GeneratorswathipushpaNo ratings yet

- Analog Sensor InterfacingDocument5 pagesAnalog Sensor Interfacingkokolanski100% (1)

- Car Battery MonitorDocument39 pagesCar Battery MonitorroopavennelaNo ratings yet

- How To Linearize Wheatstone-Bridge Circuit For Better PerformanceDocument11 pagesHow To Linearize Wheatstone-Bridge Circuit For Better Performancecoper123No ratings yet

- UJTTDocument8 pagesUJTTJagdeep SinghNo ratings yet

- XP 620Document8 pagesXP 620Far PilonNo ratings yet

- ICL7107 Assembly GuideDocument9 pagesICL7107 Assembly GuideLaurentiu IacobNo ratings yet

- Specialized Circuit Drives 150-V Piezoelectric Motor Using Low-Voltage Op AmpDocument8 pagesSpecialized Circuit Drives 150-V Piezoelectric Motor Using Low-Voltage Op AmpCARLOSNo ratings yet

- Chapter 3 Signal Conditioning CircuitDocument30 pagesChapter 3 Signal Conditioning CircuittcsNo ratings yet

- Ecler Pam2000 Pam2600 Power Amplifier Service ManualDocument107 pagesEcler Pam2000 Pam2600 Power Amplifier Service Manuallluissb92% (12)

- 12V DC To 220V AC Converter DesignDocument7 pages12V DC To 220V AC Converter DesigntintuvrNo ratings yet

- Building Recommendations EL34 Amplifier 27 Jan 2018Document6 pagesBuilding Recommendations EL34 Amplifier 27 Jan 2018senthilnathan100% (1)

- 12V DC To 220V AC ConverterDocument7 pages12V DC To 220V AC ConverterAedrian M LopezNo ratings yet

- 8-Bit Digital To Analog Converter (DAC)Document5 pages8-Bit Digital To Analog Converter (DAC)Yaman GargNo ratings yet

- LM3886 ChipAmp GuideDocument11 pagesLM3886 ChipAmp Guideeleceng1979No ratings yet

- Op Amp Circuits GuideDocument11 pagesOp Amp Circuits Guidelibrian_30005821No ratings yet

- Amplificador Final de VálvulasDocument6 pagesAmplificador Final de VálvulasTammy WashingtonNo ratings yet

- Exercise On Analog Circuits: PHYS 331: Junior Physics Laboratory IDocument6 pagesExercise On Analog Circuits: PHYS 331: Junior Physics Laboratory Iviso167No ratings yet

- DAC ConceptDocument6 pagesDAC ConceptMuhammad Isfan TauhidNo ratings yet

- SSHV2 regulator Build Guide: "TITLE SSHV2 Regulator Build Guide: A Constant Current High Voltage ShuntDocument3 pagesSSHV2 regulator Build Guide: "TITLE SSHV2 Regulator Build Guide: A Constant Current High Voltage ShuntCalsonic CMGNo ratings yet

- This Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentDocument14 pagesThis Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentJc LastaNo ratings yet

- Chapter No 1Document6 pagesChapter No 1rajamudasarjavedNo ratings yet

- Operational Transconductance Amplifiers GuideDocument20 pagesOperational Transconductance Amplifiers Guidem1dasNo ratings yet

- BJT AC Analysis: re, Hybrid Models, Gain, ImpedanceDocument30 pagesBJT AC Analysis: re, Hybrid Models, Gain, ImpedanceKazi TanvirNo ratings yet

- Behringer Micromix Mx400: Welcome To Behringer ApplicationsDocument2 pagesBehringer Micromix Mx400: Welcome To Behringer ApplicationsArama0% (1)

- Pulse Oximeter Repair and TroubleshootingPulse Oximeter Repair and TroubleshootingDocument4 pagesPulse Oximeter Repair and TroubleshootingPulse Oximeter Repair and TroubleshootingLarry CalubagNo ratings yet

- General Description: Plug Fan ER..C With Standard MotorDocument7 pagesGeneral Description: Plug Fan ER..C With Standard MotorwildanNo ratings yet

- M.SC Physics Sem 1-2 2020-21Document13 pagesM.SC Physics Sem 1-2 2020-21Dixit VajaparaNo ratings yet

- NEC Article 620: Elevators, Part 1: Continuing Education: Codes & StandardsDocument10 pagesNEC Article 620: Elevators, Part 1: Continuing Education: Codes & StandardsMenaNo ratings yet

- Integrated Electrical ProtectionDocument44 pagesIntegrated Electrical ProtectionRodrigoNo ratings yet

- Unit 2 CDocument58 pagesUnit 2 CShaleva SinghNo ratings yet

- Robotic Solar EaterDocument16 pagesRobotic Solar EatersorecietyNo ratings yet

- SFRA Testing On Two Winding TransformerDocument4 pagesSFRA Testing On Two Winding TransformerNithya GowdaNo ratings yet

- Nanni Diesel Manual N2.10-N2.14-N3.21 ENG - 970316081Document68 pagesNanni Diesel Manual N2.10-N2.14-N3.21 ENG - 970316081thomasbranley100% (2)

- Solar Energy Storage MethodDocument11 pagesSolar Energy Storage MethodĐặng HuyNo ratings yet

- 12V Battery Charger-cum-Variable Power SupplyDocument11 pages12V Battery Charger-cum-Variable Power SupplyLOLO ISMUNASIBNo ratings yet

- 4-Sistem Kontrol Generator SinkronDocument140 pages4-Sistem Kontrol Generator SinkronUsman FadillahNo ratings yet

- LMV51Document157 pagesLMV51camus1125No ratings yet

- PWM Controller For ZVS Half Bridge: EaturesDocument41 pagesPWM Controller For ZVS Half Bridge: Eaturesalex castroNo ratings yet

- AEG Energy Storage AS-BSL1-8000 12000 Installation Instructions ENDocument32 pagesAEG Energy Storage AS-BSL1-8000 12000 Installation Instructions ENSxplanetNo ratings yet

- Diagrama Electrico Exc.Document2 pagesDiagrama Electrico Exc.Becker Orlando Perez FIallos100% (1)

- Distribution VoltageDocument10 pagesDistribution VoltageIsagani Madrid100% (1)

- ME-447 Lab Final Exam Paper BDocument7 pagesME-447 Lab Final Exam Paper BSaad RasheedNo ratings yet

- Injector Wiring - SpeeduinoDocument3 pagesInjector Wiring - SpeeduinoCristián QuirozNo ratings yet

- SFM With Binlevel MeasuringiDocument7 pagesSFM With Binlevel Measuringiayaskant751001No ratings yet

- RC Circuits: Electrical EngineeringDocument3 pagesRC Circuits: Electrical Engineeringiraj shaikhNo ratings yet

- Repairing The Electronic Devices: Laica Olvida Nichaela Jane D. TerribleDocument16 pagesRepairing The Electronic Devices: Laica Olvida Nichaela Jane D. Terribleanon_493312229No ratings yet

- Ee 211Document37 pagesEe 211Muhammad OsamaNo ratings yet

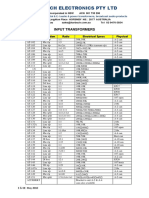

- Harbuch Electronics Pty LTD: Input TransformersDocument4 pagesHarbuch Electronics Pty LTD: Input Transformersattapapa100% (1)

- K739630Document2 pagesK739630Ari Santoso100% (2)

- Lab 3 TheveninDocument2 pagesLab 3 TheveninLê MinhNo ratings yet

- FTR p1Document7 pagesFTR p1José María Paredes LorenzoNo ratings yet

- 6.Single-Sideband Communications SystemsDocument22 pages6.Single-Sideband Communications SystemsEjazullahkhan EjazNo ratings yet