Professional Documents

Culture Documents

Earth Architecture ? Renaissance of An Ancient Technology From The Point of View of The Sustainability

Uploaded by

ayarnaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Architecture ? Renaissance of An Ancient Technology From The Point of View of The Sustainability

Uploaded by

ayarnaCopyright:

Available Formats

EARTH ARCHITECTURE ?

RENAISSANCE OF AN ANCIENT TECHNOLOGY FROM THE POINT OF VIEW OF THE SUSTAINABILITY Pter Medgyasszay Architect, PhD student Technical University of Budapest, Department of Building Constructions

WHY HAVE COME INTO THE LIMELIGHT THE EARTH ARCHITECTURE? During the history of humanity developed rightly an idea about, that the raw materials and energy sources, which are the basis of economy, are boundless and for this reason they are available for free or for very low prize. Of course we could rightly think this way as long as we only used reproducing energy sources and raw materials, which were mostly used in reproducing amounts. But in the 1960's and 70' independent organisations (Roman Club) than in the 80' government organisations (Bruntland Committee) and in the 90' inter-governmental organisations (Rio de Janeiro: Agenda 21) realised that using of energy and raw materials, and changing the environment in the present form of the human life is not sustainable in long term. [1] More and more begin to think that in the future at several parts of life next to questions like "Is it worth?" or "Is it nice?" we have to answer a new fundamental question: "Is it sustainable in long term?" The question of the more and more often mentioned "Sustainability" raised new point of views and requirements at the relation in building materials as well. Some architects and builders realising the ecological, building-physical advantages of the earth building overvalued the traditional preconceptions about the earth architecture, and next to the rebuilding of ancient earth houses built with traditional technology, started to think of the modernisation and alternative adoption of earth architecture. (Explaining this not fully developed terminology, the term "earth building" I mean the traditional mud walls, straw clay walls and houses made out of adobe, and varies of some further developed technologies were the local building materials is used after dried on the sun, without being burnt.) INTERNATIONAL EXPERIENCES In Germany, in France and in the USA they are dealing with updating of different earth building technologies during the past 20 years. In the practices of the overseas countries till now were put a big stress on the reconstruction of monumental type of buildings. In Germany were rebuild the old "Fachwerk" mean woodframe adobe houses so they became suitable for the modern heat standards. In the USA ancient Indian pueblos were rebuilt and turned into touristic attractions.

Next to the reconstruction investments, new earth houses were built in WestEurope and in the USA, where during the architectural conception of these buildings, beyond the ecological and building-physical advantages of the earth, was trying to use the artistical formality of the material. In the desert parts of Australia were minimised the expenses of transport, when the rest-houses besides the highways was built from local earth stabilised with cement. But the most important region of earth architecture researches tends towards to the "countries of the South" trying to solve the problem of lack of houses caused by the demographically exposure. [2] HUNGARIAN EXPERIENCES In Hungary beside the rebuilding of monumental type buildings and building reconstruction (Open Air Museum, Szentendre) from the 1970's even private builders modernised old earth houses mostly as weekend houses. Up to the 1980's new earth houses were built only by the poor, in low quality and insignificant quantity. After the 80's, because of the ecological and building-physical advantages of earth, building of a high standard were built as well out of earth. First of all, because of the static quality of the earth, walls were built but staves, cupolas, slabs-fillings, furniture, heating installations, isolations also were made out of earth (clay). [3] Walls were built, beside the traditional mud, straw clay, and adobe technologies, newly developed technologies like pressed-, pressed and stabilised with cement-, lightened and pressed-, and lightadobe-brick walls. Even using the mentioned technologies we must make it absolutely clear that the optimum use of earth architecture can not be common because of beside other bounds of using the earth suitable as a building material or the place required for the manufacturing of the earth-bricks are not always suitable on the spot, or nearby the spot of the building. ADVANTAGES AND DISADVANTAGES OF EARTH BUILDINGS 1. Advantages 1.1. high thermal storage capacity 1.2. good capacity for conditioning of humidity 1.3. respiration wall construction 1.4. low primer energy content 1.5. low building environment load 1.6. low transport cost and environment load 1.7. using natural materials 1.8. in according the different technologies, different price, and possibility of the market segmentation 1.9. 100 % recyclable__ 2. Disantvantages 2.1. low compressive strength 2.2. unimportant flexural strength 2.3. sensitivity for the biological damage (rodents, insects)

2.4. sensitivity for the humidity 2.5. problems with the plaster strength 2.6 the lingering dry up of the technological humidity 2.7. earthquake sensitivity Sometime mentioned that the earth walls have bad heat-isolation parameters. Plotted against the new developments it is not an evidence already: the overall heat transfer rate of these walls is can be reduced into 0,7 W/m2K or using more supplementary isolation material (reed batten) into 0,35 W/m2K in a case of 45 cm wall thickness. WHAT IS THE MENTIONED "LIGHTADOBE TECHNOLOGY"? This technology was developed in Germany and in Switzerland from the ancient wood-framework "Fachwerk" technology. One element of the technology is the lightadobe-brick, which includes more organic or mineral additive as a traditional adobe brick. 1. chart Some characteristic technical feature of the adobe and usual used bricks 1. 1800 1400 2. 0.91 0.59 3. 50 45+5** 45+5** 38 38 4. 1.39 0.41 0.36 0.49 0.49

traditional earth wall (mud wall) lightadobe wall*

lightadobe wall 900 0.3 (the best from the literature) Porotherm wall (38 S) 800 0.2 (burned brick) Ytong wall (G4-0,6) 750 0.2 (limy quartz sand cellconcrete) * This lightadobe brick was produced in Hungary. ** the thickness of the wall is 45 cm, with 5 cm reed isolation batten [4] [5] [6] 1. density (kg/m3) 2. thermal conduction(W/mK) 3. thickness of the wall (cm) 4. overall heat transfer rate (W/m2K)

KNOW HOW

Because of the low compressive strength of the lightadobe bricks at the usual adoption of the technology it is made only as a fill up wall in between the wood framework. The foundations of the showed earth house was made from compressed concrete. As DP membrane they laid bituminous felt on the floor slab. The load bearing wood framework was built on the water proofing sheet, with the wood slab construction and the roof frame together, at the same time. Before filling up type walling would started, they completed the roof covering to protect the water sensitive lightadobe walls from a possible summer rain. The wall was made from the nearby local prefabricated lightadobe bricks and the local produced adobe mortar in according to the rule of the usual brick walling. Because of the water sensitivity of the earth walls, in the bathrooms and in the kitchen was built a screen wall, from dividing wall brick in 10 cm thickness, in which run the water pipes. CALCULATIONS TO COMPARE THE COSTS OF AN USUAL HOUSE AND AN EARTH HOUSE The principles of the calculations It is possible, using the different technologies, to build walls from the same local earth with significant different quality and prize. As a PhD-student of the Technical University of Budapest, Department of Building Constructions, I was searching at the Naturbau Ltd in August 1996, for the answer of the question: What is the prize of an earth house with the similar technical parameters as an usual house and what from derive the differences? I compared the costs of the building constructions of an earth house (EARTHH), built by the Naturbau Ltd. in Kercaszomor using the straw additive lightadobe technology and wood slab, and an usual house (USUH), which is the same (fictitious) house using the usual Hungarian building methods, plotted against the prize and wages in August 1996. The walls of the USUH was imagined from Ytong (limy quartz sand cellconcrete), which has more ecological advantages as the burned brick Porotherm wall with the same prizes. The slab of the USUH was imagined, printed against the usual Hungarian building methods, from reinforced concrete. The designer of the earth house was Sndor Mezei, who is the leader of the Naturbau Ltd, the original cost calculation was made by Klmn Bn, the building engineer of the Naturbau Ltd. Summery of the costs The constructions differ from each other significant only in their wall-, and slab consrtuctions.

2. chart The costs of the wall-, and slab constructions USUH 933.501 1.182.797 (946.603) 2.116.298 (1.880.104) EARTHH 1.088.894 603.582 1.692.476

Wall Slab Total

The total costs of the EARTHH in according the quotation of the Naturbau Ltd: + VAT

8.480.166 HUF 10.600.207 HUF

The m2-price of the house: In August 1996.

53.563 HUF

The costs of the USUH are, using monolith reinforce concrete slab with 425 tHUF, using prefabricated reinforce concrete slab with 185 tHUF, more expensive than the EARTHH. Considering the total costs of the building it means that the costs are reduced with 5.0 (2.1)%, which is not a significant difference. We have to emphasise that the 80% of the material costs of the adobe-walling and the clay mortaring are during the lightadobe brick manufacturing wage costs, which was paid to the worker. The corrected costs of the lightadobe wall: material 475 814. Ftwage 613 080. Ft-, 1 088 894 Ft material wage 623 210. Ft310 291. Ft-. 933 501 Ft

But the costs of the Ytong wall:

Conclusions from the calculations It is possible to build earth houses in the level of the expectations of the XX. century, as a building for permanent human residence, but the level of the expectations of the XX. century must pay at the prizes of the XX. century. In any case I found it significant advantage of the EARTHH that producing the same ideal and physical value the material costs reduced with the third part by the USUH, which is the consequence of the energy and raw material efficiently as well, and the wages increased to the douple amount of the USUH's. I think it is important because at first twice more money could stay in the local economy, making possible further investments, and second the energie demand of the industrial producing and transport,

covered in the price of the material costs of the USUH, turned to renewable human energy resource. I believe in the future architecture we have to keep in view to a greater extent the principal of the technical subsidiary, which makes possible really significant cost savings in according to the walls and the whole building. I mean, first of all by the seasonal (summer) used building it is possible to build using cheaper, low isulated technologies, because in this case the in winter it is not demanded for the walls but the heavy earth constructions with theire great heat-storage capacity and good capacity for conditioning of humidity could make pleasant inside climate without air-condition. Plotted against the international trends and the above written, I think earth building could have even not much more but higher role in the Hungarian building industry. We should leave our preconceptions and if the building place, the function of the building and the mental ability of the builders make it possible, we consider earth building as a really choice.

BIBLIOGRAPHY [1] Feladatok a XXI. szzadra, Fld Napja Alaptvny, Budapest 1993 [2] Conference: Traditional material in contemporary architecture, UK-Totnes 1996. [3] SZCS, Mikls: Fldptszet 1995. [4] SCHILLBERG, Klaus: Lehm, 1995 [5] Ytong catalogue [6] Porotherm catalogue [7] Photo: MEDGYASSZAY, Pter

You might also like

- Vernacular architecture as a base for contemporary designDocument7 pagesVernacular architecture as a base for contemporary designAnika AgarwalNo ratings yet

- Using Mud Bricks As A Temporary Solution For Gaza ReconstructionDocument5 pagesUsing Mud Bricks As A Temporary Solution For Gaza ReconstructionSerbah hocineNo ratings yet

- Hemcrete, Biobric & Poroton: Sustainable & Solidwall Systems With Ecological MaterialsDocument18 pagesHemcrete, Biobric & Poroton: Sustainable & Solidwall Systems With Ecological MaterialsLucien SteilNo ratings yet

- Building With Hemp and LimeDocument25 pagesBuilding With Hemp and Lime23krneki100% (3)

- Brick Mortar DustDocument31 pagesBrick Mortar DustsellyCanadaNo ratings yet

- Ancient Solutions For Future Sustainability: Building With Adobe, Rammed Earth, and MudDocument10 pagesAncient Solutions For Future Sustainability: Building With Adobe, Rammed Earth, and MudakshayaNo ratings yet

- Neolithic Settlement Vinča - Thermal Aspect: Nenad Miloradović, Dipl. Ing. MechDocument10 pagesNeolithic Settlement Vinča - Thermal Aspect: Nenad Miloradović, Dipl. Ing. Mechancrnobrnja4297No ratings yet

- Acoustic Performance in Raw Earth ConstrDocument10 pagesAcoustic Performance in Raw Earth ConstrPap SyNo ratings yet

- Ceramics and Bricks 1Document13 pagesCeramics and Bricks 1SHAHZAIBNo ratings yet

- Transmitacia TermicaDocument11 pagesTransmitacia TermicaJennipher LizbethNo ratings yet

- Insulating Historic Ground FloorsDocument22 pagesInsulating Historic Ground FloorsgencmetohuNo ratings yet

- Building With Hemp and LimeDocument26 pagesBuilding With Hemp and LimeAdri DiazNo ratings yet

- Quagliarini, E. Stazi, A. Pasqualini, E. Fratalocchi, E. Cob Construction in Italy Some Lessons From The Past. Sustainability 2010, 2, 3291-3308.Document18 pagesQuagliarini, E. Stazi, A. Pasqualini, E. Fratalocchi, E. Cob Construction in Italy Some Lessons From The Past. Sustainability 2010, 2, 3291-3308.Milena Vallone PottNo ratings yet

- Earth As A Material For Construction of Modern Houses: Facta UniversitatisDocument14 pagesEarth As A Material For Construction of Modern Houses: Facta UniversitatisSANI SULEIMANNo ratings yet

- Woodframe housing benefits in cold climatesDocument5 pagesWoodframe housing benefits in cold climatesvalistaNo ratings yet

- Agricultural Residues AnasDocument12 pagesAgricultural Residues AnasHazim MohammedNo ratings yet

- Interlocking Compacted Earth Blocks (ICEB)Document9 pagesInterlocking Compacted Earth Blocks (ICEB)Zarah Ramirez100% (1)

- An Overview of Natural Building TechniquesDocument11 pagesAn Overview of Natural Building TechniquesAlemayehu DargeNo ratings yet

- Architect Laurie BakerDocument116 pagesArchitect Laurie BakerSuvarna456100% (5)

- AMM - Optimized Thermal Performance Design of Filled Ceramic Masonry BlocksDocument9 pagesAMM - Optimized Thermal Performance Design of Filled Ceramic Masonry BlocksNagy BalázsNo ratings yet

- Comparative Analysis of Time and Cost inDocument4 pagesComparative Analysis of Time and Cost inChandra Pramodya GemilangNo ratings yet

- Full Brick, History and Future: IOP Conference Series: Earth and Environmental ScienceDocument7 pagesFull Brick, History and Future: IOP Conference Series: Earth and Environmental ScienceViper SajibNo ratings yet

- Mineral Fiber Insulation Panels Characterized for BuildingsDocument12 pagesMineral Fiber Insulation Panels Characterized for BuildingsFloreaNo ratings yet

- Comparison of concrete blocks and Ruliba bricksDocument52 pagesComparison of concrete blocks and Ruliba bricksKatie SandersNo ratings yet

- Thermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneDocument4 pagesThermal Effect and Cost Estimation of Expanded Polystyrene Insulated Cavity Wall in Buildings of Composite ZoneijsretNo ratings yet

- Places To Live - Ii Houses of The Future: Timber ConcreteDocument39 pagesPlaces To Live - Ii Houses of The Future: Timber ConcreteAnkit SinghNo ratings yet

- Architectural HeritageDocument8 pagesArchitectural HeritageManea SilviuNo ratings yet

- Cob Construction ItalyDocument18 pagesCob Construction ItalyDhamma_StorehouseNo ratings yet

- Innovative Buildings Klosterenga Oslo, NorwayDocument6 pagesInnovative Buildings Klosterenga Oslo, NorwayPranav Kumar ShrivastavaNo ratings yet

- Mud Architecture: I J I R S E TDocument6 pagesMud Architecture: I J I R S E TJazzNo ratings yet

- Applied Clay Science: L. Randazzo, G. Montana, A. Hein, A. Castiglia, G. Rodonò, D.I. DonatoDocument10 pagesApplied Clay Science: L. Randazzo, G. Montana, A. Hein, A. Castiglia, G. Rodonò, D.I. DonatoRayane LimaNo ratings yet

- Clay building products provide sustainable building solutionsDocument13 pagesClay building products provide sustainable building solutionsPaulo AlmeidaNo ratings yet

- Architectural DissertationDocument48 pagesArchitectural Dissertationcandysara67% (3)

- Reviewed - IJCE-Format-The Wall As Architecture SpaceDocument12 pagesReviewed - IJCE-Format-The Wall As Architecture Spaceiaset123No ratings yet

- Construction and Building Materials: Giuseppe Cultrone, Eduardo SebastiánDocument7 pagesConstruction and Building Materials: Giuseppe Cultrone, Eduardo SebastiánAbderrahim BelmJouJNo ratings yet

- Energy Saving Potentiality in Using Fired Bricks in BuildingsDocument7 pagesEnergy Saving Potentiality in Using Fired Bricks in Buildingsm_mukbel8752No ratings yet

- Double Skin Façades and Their Influence On The Form of Contemporary BuildingsDocument7 pagesDouble Skin Façades and Their Influence On The Form of Contemporary BuildingsbsantaceciliaNo ratings yet

- What Makes A Material SustainableDocument8 pagesWhat Makes A Material SustainableshwetaNo ratings yet

- Green Building Materials GuideDocument9 pagesGreen Building Materials GuideRushika KothuruNo ratings yet

- G12 Research 1Document15 pagesG12 Research 1Renz Allen BanaagNo ratings yet

- Sustainable MaterialsDocument4 pagesSustainable Materialsr...No ratings yet

- Rural - Materials & ConstructionDocument12 pagesRural - Materials & ConstructionHaresh Babu PitchaimaniNo ratings yet

- Strawbale Building in Poland - Maciej Jagielak - 0 PDFDocument6 pagesStrawbale Building in Poland - Maciej Jagielak - 0 PDFpacopaNo ratings yet

- Sustaible - The Wall HouseDocument12 pagesSustaible - The Wall HousePrakhar JainNo ratings yet

- 3) Comparing Concrete and WoodDocument27 pages3) Comparing Concrete and WoodKevin Pacho LópezNo ratings yet

- Bamboo's Role in Green Building DesignDocument5 pagesBamboo's Role in Green Building DesignPooja MistryNo ratings yet

- Construction MaterialsDocument4 pagesConstruction MaterialsanmolNo ratings yet

- Press Release / April 2011Document13 pagesPress Release / April 2011Ilaria VanniniNo ratings yet

- Feasibility and Cost Analysis For Locally Produced Interior Walls Using Straw Additive BricksDocument8 pagesFeasibility and Cost Analysis For Locally Produced Interior Walls Using Straw Additive Bricksearn moneyNo ratings yet

- Portola Valley Town Center Goes GreenDocument7 pagesPortola Valley Town Center Goes GreenmymalvernNo ratings yet

- Housing Module 4Document11 pagesHousing Module 4Kyla TiangcoNo ratings yet

- Sanna KUISMANEN• sanna.kuismanen@case.inet.fiDocument35 pagesSanna KUISMANEN• sanna.kuismanen@case.inet.fiDhruval Jignesh PatelNo ratings yet

- Material 1: Straw WorkingDocument3 pagesMaterial 1: Straw Workinggautamsethi999994No ratings yet

- Troubled Times Shelter 2012Document477 pagesTroubled Times Shelter 2012AveksaNo ratings yet

- ENERGY RENEWAL OF INA-CASA HERITAGE: MOISTURE TRANSFERDocument6 pagesENERGY RENEWAL OF INA-CASA HERITAGE: MOISTURE TRANSFERzd zNo ratings yet

- Sandbag House 2Document19 pagesSandbag House 2AhmedBIowar100% (1)

- Ar Bricks-21Document34 pagesAr Bricks-21ManishaChary100% (1)

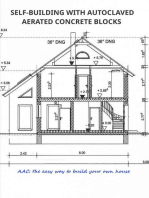

- SELF-BUILDING WITH AUTOCLAVED AERATED CONCRETE BLOCKS: AAC: the easy way to build your own houseFrom EverandSELF-BUILDING WITH AUTOCLAVED AERATED CONCRETE BLOCKS: AAC: the easy way to build your own houseNo ratings yet

- Rammed Earth Building ReviewDocument118 pagesRammed Earth Building ReviewPeter W Gossner100% (2)

- p0089 p0100Document12 pagesp0089 p0100ayarnaNo ratings yet

- Strawberry Production: Overview: ManagementDocument4 pagesStrawberry Production: Overview: ManagementayarnaNo ratings yet

- Wind PumpingDocument9 pagesWind PumpingayarnaNo ratings yet

- Teacher Manual JapanDocument35 pagesTeacher Manual JapanayarnaNo ratings yet

- Wind PumpingDocument9 pagesWind PumpingayarnaNo ratings yet

- Sex CarnivalDocument200 pagesSex Carnivalpaulmaloles55% (44)

- The Significance of Seven in The BibleDocument1 pageThe Significance of Seven in The BibleBot Psalmerna100% (3)

- Kalpataru Serenity Hadapsar PuneDocument36 pagesKalpataru Serenity Hadapsar PuneShamrao ChakaneNo ratings yet

- Flip Book V.2 I.6-SmallDocument92 pagesFlip Book V.2 I.6-SmallHigh CountryNo ratings yet

- W-Faz/A4 W-Faz/Hcr Fixing Anchors: Cracked and Uncracked ConcreteDocument2 pagesW-Faz/A4 W-Faz/Hcr Fixing Anchors: Cracked and Uncracked Concretececa89No ratings yet

- Services Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)Document7 pagesServices Integration With Concrete Buildings Guidance For A Defect Free Interface (Sample)AndRew YNo ratings yet

- Cyclic Loading Behavior of a Perforated URM WallDocument5 pagesCyclic Loading Behavior of a Perforated URM WallCasacasa CasacasalNo ratings yet

- BS en 1999-1-5 - 2007Document8 pagesBS en 1999-1-5 - 2007Wayne ChongNo ratings yet

- R1a GFC FurnitureDocument1 pageR1a GFC FurnitureRACHANA SADANINo ratings yet

- Sagrika DDDocument26 pagesSagrika DDsagrikakhandkaNo ratings yet

- Metal Ceiling Inspection FormDocument1 pageMetal Ceiling Inspection FormAlizamin SalmanovNo ratings yet

- Mad ArchitectsDocument23 pagesMad ArchitectsHok HourhokNo ratings yet

- Fractal Cities: A Case Study of Khargone, Madhya PradeshDocument4 pagesFractal Cities: A Case Study of Khargone, Madhya PradeshJYOTI YADAVNo ratings yet

- Bye-Laws For 5 Star HotelsDocument2 pagesBye-Laws For 5 Star HotelsSaksham Gupta0% (1)

- Prestressing Classification and MaterialsDocument12 pagesPrestressing Classification and MaterialsognjenristicNo ratings yet

- Wellington Indoor Sports Community Centre, New ZealandDocument27 pagesWellington Indoor Sports Community Centre, New ZealandSabita BasnetNo ratings yet

- Design of lifting hook for precast concrete base slab and wallDocument1 pageDesign of lifting hook for precast concrete base slab and walleric bargas100% (5)

- Architectural Anthropology NotationsDocument4 pagesArchitectural Anthropology NotationsSonora GuantánamoNo ratings yet

- PROPOSED MIXED-USE BUILDINGDocument29 pagesPROPOSED MIXED-USE BUILDINGAYSON N. DELA CRUZNo ratings yet

- Quthb17 Courses CIDocument228 pagesQuthb17 Courses CIMeivita Ika NursantiNo ratings yet

- Kitchen Mood BoardDocument9 pagesKitchen Mood BoardKelly CantaraNo ratings yet

- Design BasisDocument4 pagesDesign BasisMohtasim BillahNo ratings yet

- Ground Floor DimensionsDocument1 pageGround Floor DimensionsMEMES HOUSENo ratings yet

- ompadmin,+MOMOWO 01 LOPEZ RODERO LOCK PDFDocument8 pagesompadmin,+MOMOWO 01 LOPEZ RODERO LOCK PDFRaquel SantosNo ratings yet

- Yamuna Apartments: Housing Case StudyDocument39 pagesYamuna Apartments: Housing Case StudyDarshan Bharde100% (1)

- Factory Drawings PDFDocument1 pageFactory Drawings PDFmani rajesh0% (1)

- CPM Lab Assignment-02Document14 pagesCPM Lab Assignment-02Muhammad NomanNo ratings yet

- ELEMENTS OF COMMUNITY STRUCTURESDocument33 pagesELEMENTS OF COMMUNITY STRUCTURESRica RegisNo ratings yet

- Part E DUPADocument2 pagesPart E DUPALuwalhati TomilasNo ratings yet

- GU-628 Civil & Building Standard Drawings Index (Formerly SP 1173)Document46 pagesGU-628 Civil & Building Standard Drawings Index (Formerly SP 1173)Ibrahim NaguibNo ratings yet

- 2C08 Advanced Design of Steel and Composite StructuresDocument4 pages2C08 Advanced Design of Steel and Composite StructuresqutabshNo ratings yet

- AN815 Union Flared Tube SpecificationDocument2 pagesAN815 Union Flared Tube SpecificationJai Bhandari100% (1)