Professional Documents

Culture Documents

Thermometer Liquid in Glass Calibrationvvs102

Uploaded by

juncar25Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermometer Liquid in Glass Calibrationvvs102

Uploaded by

juncar25Copyright:

Available Formats

1(10)

THERMOMETERS, LlQUID-lN-GLASS: CALIBRATION

Key words: Calibration, test method, liquid-in-glass thermometers

UDC 536.5:53.088

CONTENTS

1. 2. 3. 4. SCOPE FIELD OF APPLICATION REFERENCES DEFINITIONS 4.1 GENERAL DEFINITIONS 4.2 DEFINITIONS FOR LIQUID-IN-GLASS THERMOMETERS 5. SAMPLING 6. METHOD OF TEST 6.1 PRINCIPLE 6.2 APPARATUS 6.2.1 Reference thermometer 6.2.2 Thermostat 6.2.2.1 Baths 6.2.2.2 Temperature calibrators 6.2.3 Equalising blocks 6.3 PREPARATION OF TEST SAMPLES 6.3.1 Cleaning 6.3.2 Visual inspection 6.3.3 Rejoining of separated columns 6.4 PROCEDURE 6.4.1 Selection of calibration temperatures 6.4.2 Mounting 6.4.2.1 Immersion 6.4.3 Readings 6.4.3.1 Parallax errors 6.4.3.2 Sequence of calibration temperatures 6.4.3.3 Readings at a calibration temperature 6.4.4 Correction for emergent stem 6.5 EXPRESSION OF RESULTS 6.6 UNCERTAINTY 6.7 TEST REPORT 1 1 1 2 2 2 3 3 3 3 3 3 3 4 5 5 5 5 5 6 6 6 6 6 6 7 7 7 8 9 10

1.

SCOPE

The scope of this method is to function as a guideline for the calibration of liquid-in-glass thermometers by means of the comparison technique.

2.

FIELD OF APPLICATION

The method can be applied for the calibration of liquid-in-glass thermometers in the approximate range of -100C to 500C. The method does not apply to minimum and maximum thermometers. For the purpose of this method it is important to distinguish between the 3 types: total-immersion thermometer, partialimmersion thermometer and complete-immersion thermometer. (See chapter 4.2 Definitions for liquid-in-glass thermometers.)

3.

REFERENCES

1. The International Temperature Scale of 1990 (ITS-90), H. Preston-Thomas, Metrologia 27, pages 3-10 (1990). 2. Standard Practise for Preparation and Use of Freezing Point Reference Baths, ASTM E 563-76. 3. Precautions in the Use of Nitrate Salt Baths, Health and Safety Executive, Her Majesty's Stationery Office. 4. International Vocabulary of Basic and General Terms in Metrology, BIPM, IEC, ISO and OIML, 1984. 5. Bureau International de Poids et Mesures. Proces-Verbeaux de sances du ClPM 49, 26 (1981). Version in English published in Metrologia 18, page 44 (1982). 6. Guidelines for the Expression of the Uncertainty of Measurement in Calibrations, WECC Doc. 19-1990. 7. Kaufman, Alvin B., Temperature Calibration Baths, Measurements & Control, April 1990, page 121. 8. Wise, Jacquelyn, Liquid-in-Glass Thermometer Calibration Service, NlST Special Publication Service 250-23, 1988, U.S. Government Printing Office, Washington, 1988.

Published by NORDTEST ISSN 0283-7226

Tekniikantie 12 FIN-02150 Espoo FINLAND Proj. 951-90

Tel + 358 9 455 4600 Fax + 358 9 455 4272 www.nordtest.org

NORDTEST METHOD

NT VVS 102 2

9.

Liquid-in-glass Laboratory Thermometers - Principles of Design, Construction and Use, ISO 386.

4.2

Definitions for liquid-in-glass thermometers

Auxiliary scale

A short scale including a reference temperature, such as the ice point, to provide a means for checking the thermometer for a change in calibration with time. This scale is added when a suitable reference temperature is not included in the range of the main scale.

10. Standard Specifications for ASTM Thermometers, ASTM E 1. 11. Standard Test Method for Inspection and Verification of Liquid-in-Glass Thermometers, ASTM E 77.

4. 4.1

DEFINITIONS General definitions

The general definitions are mainly taken from [4].

I&+&

Bulb

Bulb r

Stem

Auxiliary Scale

Expansion Chamber

Contraction Chamber

Immersion Line

Main Scale

Calibration

The set of operations which establish, under specified conditions, the relationship between values indicated by a measuring instrument or measuring system, or values represented by a material measure, and the corresponding known values of a measurand. Notes

1. The result of a calibration permits the estimation of errors of indication of the measuring instrument, measuring system or material measure, or the assignment of values to marks on arbitrary scales.

Fig. 1. A solid-stem liquid-in-glass thermometer.

The reservoir for the thermometer liquid.

Contraction chamber

An enlargement of the capillary bore which serves to reduce a long length of capillary or to prevent contraction of the entire liquid into the bulb. This chamber is introduced below the main scale or between the main scale and the auxiliary scale.

2. A calibration may also determine other metrological properties.

3. The result of a calibration may be recorded in a document, sometimes called a calibration certificate or a calibration report.

4. The result of a calibration is sometimes expressed as a calibration factor, or as a series of calibration factors in the form of a calibration curve.

Expansion chamber

An enlargement at the top of the capillary to provide protection in case of overheating.

Enclosed-scale thermometer

A thermometer having a capillary stem adjacent to a separate strip bearing the scale, both being enclosed in a protective sheath.

Conventional true value (of a quantity)

A value of a quantity which, for a given purpose, may be substituted for the true value. Note A conventional true value is, in general, regarded as sufficiently close to the true value for the difference to be insignificant for the given purpose. Within an organisation the value assigned to a reference standard may be taken as the conventional true value of the quantity realised by the standard.

Solid-stem thermometer

A thermometer having a thick-walled capillary stem on which the scale is etched or marked.

Example

Complete-immersion thermometer

A thermometer designed to indicate temperatures correctly when the whole thermometer, including the expansion chamber, is subjected to the temperatures being measured.

TraceabiIity

The property of a result of a measurement whereby it can be related to appropriate standards, generally international or national standards, through an unbroken chain of comparisons.

Partial-immersion thermometer

A thermometer designed to indicate temperatures correctly when the bulb and a specified part of the stem are exposed to

NORDTEST METHOD

NT VVS 102 3

Used with a good measuring bridge and a stable standard resistor, uncertainties in the range of millikelvins can be obtained. A stable Pt-100 probe with a measuring bridge and a standard resistor or with a good digital thermometer or with an ohmmeter can be a useful reference thermometer. Uncertainties of a few millikelvin have been reported. Liquid-in-glass and other direct-reading thermometers of sufficient accuracy and stability are convenient due to their ease of use.

Complete

6.2.2

Thermostat

The requirements for the thermostat are:

Fig, 2. Liquid-in-glass thermometer types of immersion.

Sufficient dimensions to contain both the thermometer and the reference thermometer. Sufficient stability compared with calibration time and the uncertainty requirements. Good temperature uniformity so that the temperature difference between the thermometer and the reference thermometer is small compared with the uncertainty requirements.

the temperature being measured. The remaining part of the stem, referred to as the emergent stem, will be at the ambient temperature, usually different from the temperature being measured. Such thermometers are generally marked with an immersion line to indicate the proper depth of immersion.

Total-immersion thermometer

A thermometer designed to indicate temperatures correctly when the bulb and just the portion of the thermometer containing the liquid are exposed to the temperature being measured.

6.2.2.1

Baths

For the most demanding calibration work the stirred liquid bath is preferred. The liquid and the stirring ensure good temperature uniformity in the bath and good thermal contact with the thermometers. Special calibration baths are commercially available. They have the necessary depth, and the liquid to air surface is small. Some general purpose baths can also be used, but the larger the liquid to air surface area the higher is the risk of instability, and the larger the bath the higher is usually the "from corner to corner" temperature difference. A bath with a large amount of liquid is usually very stable, but it takes a long time to change the calibration temperature, while a small volume bath changes calibration temperature fast but requires a better control system to be stable. Different liquids are used depending on the temperature range: Ethyl Alcohol Methyl Alcohol Ethylene Glycol/Water 1:1 Ice point bath Water Vegetable oils Silicone oils Petroleum oils Potassium Nitratel Sodium Nitrite, approx. 1:1 mixture -112 C to 23 C -97 C to 23C -30 C to 110 C 0 C +1 C to 95 C up to approx. 200 C -50 C to 300 C 100 C to 300 C 170 C to 550 C

5.

SAMPLING

Not applicable.

6.

6.1

METHOD OF TEST

Principle

The thermometer is placed in a thermostat together with a reference thermometer. The indication of the thermometer is compared with the reference temperature which is measured with the reference thermometer.

6.2

6.2.1

Apparatus

Reference thermometer

Any type of thermometer can be used as reference thermometer provided that it covers the required temperature range and that its calibration is traceable to a national standard. Further the calibration and reading uncertainty of the reference thermometer must be small compared with the desired calibration uncertainty. Standard Platinum Resistance Thermometers (SPRT) fulfilling the requirements in [1] are used for the most demanding work.

The temperature range of the alcohols can be extended upwards, but care has to be taken as the fumes are toxic and explosive.

NORDTEST METHOD

NT VVS 102 4

Different grades of petroleum and silicone oils must be used to cover the stated ranges. The oils must not have flash points below the highest calibration temperature nor must they be too viscous to prevent adequate stirring at the lowest calibration temperature. At the high end of the temperature range, the fumes can be rather unpleasant. Experience with the use of vegetable oils for calibration baths is limited. [7] gives some examples of flash points and experience gained with oils such as olive, corn, soybean, peanut, rape seed and others. Use of the salt bath with Potassium Nitrate and Sodium Nitrite requires some precautions. The nitrate salt alone cannot be made to burn or explode. It is, however, a powerful oxidizing agent and combustible material coming into contact with molten nitrate is readily ignited and often burns with explosive violence. The molten nitrate should therefore never come into contact with organic materials such as oil, grease, cottonwaste, rags, sacking, paper, wood, clothing, food and graphite. Water introduced accidentally into molten salt baths will give rise to a 'steam explosion'. In several instances the injuries have proven fatal. Due to fast oxidation, aluminium or aluminium alloys should not come into direct contact with molten nitrate. Further information about precautions and the use of salt baths can be found in [3].

At lower temperatures the liquid-in-glass thermometers may be immersed directly in the salt, but at higher temperatures above approx. 400 C attack of the glass may occur. This can be avoided by placing the thermometers in steel wells immersed in the molten salt. Thin-walled steel tubes closed at one end are suitable for this purpose. Neither should quartz encapsulated thermometers come into contact with molten nitrate as the quartz will be matted due to the start of a devitrification process. The ice point (Fig. 3) is the equilibrium between ice and air saturated water, and it was once a defining point on the temperature scale. Today it still plays a major role in thermometry as a secondary fixed point that can be readily achieved by almost any laboratory with a minimum of resources. In its simplest form it consists of a dewar with a mixture of demineralised or distilled water and crushed or shaved ice made from demineralised or distilled water. As the ice is melting continuously and as water has its maximum density at 4 C, one has to make sure that there is ice and not only water around and below the tip of the thermometer. Such a bath can give the temperature 0 C with an uncertainty better than 0.01 C. The more sophisticated ice points contain a stirring mechanism constructed in such a way that it keeps the water saturated with air. The uncertainty in these baths can be better than 0.002 C. A description of the preparation and use of the ice point bath can be found in [2]. 6.2.2.2 Temperature calibrators

The thermostat and the reference thermometer can be combined into one instrument, by different manufacturers called a temperature calibrator or a dry well calibrator. The temperature is maintained in a chamber in which interchangeable temperature equalising blocks can be fitted one at a time. The block contains one or more bores for the thermometers to be calibrated. The probe (the temperature sensitive part) of the reference thermometer is located in the chamber but outside the block and it is connected to a built-in digital instrument. The resolution of these instruments is often 0.1 C, but 0.01 C has also been seen. The stability of these calibrators is often better than 0.1 C, but the lack of a stirred liquid can cause problems with the temperature difference between the reference thermometer and the thermometer to be calibrated. To improve thermal contact it is important that the bore in the block fits closely the thermometer to be calibrated. The depth of the bore is limited, and this often makes the calibrator less suitable for long liquid-inglass thermometers. Further there is a time lag between the probe of the reference thermometer and the thermometer to be calibrated. After changing to a new temperature, the built-in instrument will show that the temperature is stable before the temperature of the thermometer to be calibrated is stable. It is recommended that the user establishes a thorough base of experience of his calibrator before using it for demanding calibrations.

Fig. 3. Ice point.

NORDTEST METHOD

NT VVS 102 5

6.2.3

Equalising blocks

The advantage of an equalising block in a bath is primarily its ability to smoothe the small temperature fluctuations to a few millikelvins. The temperature differences are usually small in a stirred bath provided that the distances between the thermometers are small. This extremely good stability should not make one forget about other sources of error. If the equalising block is touching a cold wall in the bath, errors greater than the fluctuations can easily arise due to gradients. And when a resistance thermometer (reference thermometer) is used in an equalising block, the error due to self-heating is generally greater than when the thermometer is used directly in the stirred liquid and this may impair the advantage of the equalising block. A drawback of using equalising blocks is that they make the change to a new temperature slowly. The temperature at the beginning of the change quickly approaches the set point, but final stabilisation takes time. For any equalising block as well as the bore in the block of a temperature calibrator, it is important that the bores fit closely both the thermometer under calibration and the reference thermometer to ensure good thermal contact.

d) Broken capillary tube or broken scale can be seen in enclosed scale thermometers. Such thermometers must be rejected.

6.3.3

Rejoining of separated columns

Separation of the liquid column is common particularly after shipment. With care it is often possible to rejoin the column. Various joining methods can be tried: a) Ligthly tap the thermometer against the palm of your hand, a block of paper or a rubber stopper. b) Apply centrifugal force, but not a flick, and be careful to avoid striking anything. This can best be done by holding the bulb alongside the thumb, protecting it with the fingers and with the stem along the arm. Raise the arm above the head and bring it down quickly to alongside the leg. c) If the separated part of the column is small and the thermometer has a contraction chamber, cooling can be applied to bring the separated part into the contraction chamber. By ligthly tapping the thermometer, the separated part is brought into a position where it only has contact with one side of the contraction chamber. If the bulb is then heated, the separated part should remain in the contraction chamber and be rejoined with the rest of the liquid when it enters the contraction chamber. d) If none of the above methods have been successful or the thermometer did not have a contraction chamber, another cooling method may be tried. Cool the bulb so that all the liquid enters the bulb leaving none in the stem. The above methods may need to be applied to assist this. The column may rejoin when it is warmed to room temperature. Cooling can be done in various ways using: either the ice point, calibration bath with alcohol, dry ice or liquid nitrogen. Since the last two methods and perhaps the calibration bath give temperatures below the freezing point of mercury, special care has to be taken. Cool only the bulb and never the stem or mercury column. Care must be taken to warm the top of the bulb first, so that pressures in the bulb due to expanding mercury may be relieved. The warming can be done by rolling the thermometer between two fingers around the top of the bulb. e) Should none of the above methods give the desired result, a more drastic method is to apply some heating to allow the rejoining to occur in the expansion chamber at the top. Great care is necessary to avoid filling the expansion chamber to more than 2/3, otherwise a pressure large enough to burst the bulb might build up. This method should not be applied if it requires the thermometer to be heated above 250 C, and the bulb should never be heated in an open flame. The methods mentioned above are the most important. [8] gives some additional methods especially for thermometers containing organic liquid. After rejoining, the thermometer should again be visually inspected for bubbles and small separations.

6.3

6.3.1

PREPARATION OF TEST SAMPLES

Cleaning

If necessary, the thermometer is cleaned with water, water and soap or alcohol and rinsed with demineralised water in order to avoid contamination of the liquid in the baths and of the other calibration equipment.

6.3.2

Visual inspection

The thermometer is viewed under a microscope or magnifying glass with 8 to 15 times magnification. It is not possible to make a complete list of all possible defects, but below are listed some of the most important to look for: a) Separated columns. Try one of the methods described in 6.3.3 to rejoin the liquid. b) Gas bubbles in the bulb or in the liquid column. Try one of the cooling methods in 6.3.3 in order to place the gas above the column. c) Foreign matter in the capillary or in the bulb might tend to make the thermometer readings erratic. If glass chips or mercury oxide are found in the capillary or bulb, they can cause the thermometer to give different readings at different periods of time. Such a thermometer should be rejected. If the foreign matter is in the top end of the scale, the thermometer may be calibrated to a maximum temperature below the position of the foreign matter, but information of the position and the type of the foreign matter observed should be given in the certificate so that the user is warned and can be observant of any change in its position.

NORDTEST METHOD

NT VVS 102 6

6.4

6.4.1

PROCEDURE

Selection of calibration temperatures

Sometimes exceptions are made to the main rules. If the calibration equipment does not permit the main rules to be followed, the temperature of the emergent stem must be determined with an auxiliary thermometer and a stem temperature correction must be applied. (See Subclause 6.4.4 Correction for emergent stem.) If the user has given information about how the thermometer is used, this measurement situation is simulated as far as possible during the calibration measurements, and corrections to the readings are applied where necessary. (See Subclause 6.4.4 Correction for emergent stem.) The attempted depth of immersion is indicated on the certificate.

Calibration is performed at the temperatures selected by the user. If the measuring range or the auxiliary scale of the thermometer includes 0 C, the user is advised to have a calibration performed at the ice point as this point can be easily reproduced by the user and serve as a future check point. When the user requests a calibration covering the total range of the thermometer, the number of calibration points should be chosen based on the required uncertainty between the calibration points. In order to obtain these uncertainties, the user must use the corrections in the certificate. For normal accuracy 5 calibration points or points at every 100 scale divisions covering at least 80% of the range of the thermometer are recommended. For the highest accuracy, points at each 50 scale divisions should be chosen [9]. In [8] the recommendations are also dependent on the range. For thermometers graduated below 200 C and when an uncertainty of approximately one-half of a scale division is requested, the interval between calibration points should not exceed 100 scale divisions. If uncertainties of one or twotenths of a scale division are desired, the calibration interval should be reduced to 40 to 50 scale divisions. For thermometers graduated above 200 C, a 40 to 50 scale division calibration interval is required to obtain corrected temperature values with uncertainties of approximately one-half scale division. And a 20 to 25 scale division calibration interval is necessary for accuracies of approximately one or two-tenths of a scale division. The recommendations in [11] are consistent with the above.

6.4.3

Readings

Good lighting is required when reading a thermometer. Interpolation should be carried out between the centres of the graduation lines. Interpolation between the edges will give erroneous results.

6.4.3.1

Parallax errors

Parallax errors will arise if the line of sight is not perpendicular to the liquid column. Using a binocular or a monocular with a close-up lens placed on a heavy stand and set at the same height as the top of the liquid column will ease the readings and help to avoid parallax errors. The existence of parallax errors can be checked as follows. In case of an enclosed-scale thermometer the graduation line immediately above the meniscus can be seen through the capillary tube. If parallax errors exist, the graduation line seems to be broken by the capillary tube. The liquid column on the left side of Fig. 4 has no parallax error. For solid-stem thermometers the graduation lines are placed in front of the liquid column. If the thermometer liquid is mercury, a reflected picture of the graduation lines can be seen in the mercury. By looking at the graduation line immediately below the meniscus and adjusting the line of sight until the

6.4.2

Mounting

The thermometer is placed in the thermostat close to the probe of the reference thermometer. Several thermometers can often be calibrated at a time.

6.4.2.1

Immersion

The main rule is that thermometers are immersed according to their type, which means:

Partial-immersion thermometers are immersed to their immersion line or as otherwise indicated on the thermometer. Total-immersion thermometers are immersed so that just a small length of the liquid column is left emergent from the bath to allow reading of the position of the meniscus. Complete-immersion thermometers are immersed completely in the bath liquid. Readings are taken through a window in the bath. Should the type of thermometer not be obvious from its construction, it is calibrated as a total-immersion thermometer, and this is indicated on the certificate.

Fig. 4. Enclosed-scale thermometer.

NORDTEST METHOD

NT VVS 102 7

The mean of the three readings of the reference thermometer is the basis for the average calibration temperature. The mean of the pairwise readings of the thermometers to be calibrated is used as their reading at the average temperature. By taking readings in this sequence, the risk of a slight drift in temperature is minimised. When calibrating in the ice point, readings of the reference thermometer are not necessary.

6.4.4

Correction for emergent stem

Fig. 5. Solid-stem thermometers.

graduation line covers its own reflection, the parallax is avoided. The liquid column on the left side of Fig. 5 has no parallax error.

When it is necessary to calibrate or use a total-immersion thermometer partially immersed or a partial-immersion thermometer totally immersed, a correction should be made for the difference of the temperature of the emergent stem from that which is appropriate for the specified immersion cond it ion. The immersion conditions for partial-immersion thermometers can be specified by the user or e.g. by a standard [10] and include both the depth of immersion and in some cases the emergent-stem temperature. The correction c1 should be evaluated from the formula:

6.4.3.2

Sequence of calibration temperatures

Calibration is generally performed by starting with a measurement at the ice point then continuing with the other temperatures starting with the lowest calibration temperature and advancing to the higher calibration temperatures. Finally the ice point is measured once more to give an idea of a possible drift of readings.

where

k

6.4.3.3

Readings at a calibration temperature

N

is the apparent thermal expansion coefficient of the liquid in the particular type of glass from which the stem is made; for purposes of evaluation, the value of k may be considered to be dependent on the arithmetic mean of t 1 and t; is the number of C equivalent to the length of the emergent-stem and is the difference between the thermometer indication and the actual or extrapolated scale value corresponding to the specified immersion level; is the average temperature of the N degrees of the thermometer stem;

When the temperature is sufficiently stable, the reference thermometer (R) and the thermometers to be calibrated (Xi) are read in the following order (Fig. 6) at constant time intervals: R, X1, X2 .... Xn, R', Xn' .... X2', X1', R" The thermometers are gently tapped before reading to prevent sticking of a falling meniscus.

t1 is the temperature of the thermometer bulb.

When total-immersion thermometers are partially immersed, the correction c1 is added to the indication of the thermometer when the mean emergent-stem temperature is lower than the bulb temperature and subtracted when it is higher. When partial-immersion thermometers are totally immersed, the correction c1 is subtracted from the indication of the thermometer when the mean emergent-stem temperature is higher than the specified ambient temperature of the emergent stem and added when it is lower. When partial-immersion thermometers are used at the prescribed depth of immersion in the medium, there may be a difference between the actual and the specified temperature of the emergent stem. In this case a correction to the indication c2 should be evaluated from the formula: Fig. 6. Sequence of readings.

c2 = k * N * (ts - tf)

NORDTEST METHOD

NT VVS 102 8

where k is the apparent thermal expansion coefficient of the liquid in the particular type of glass from which the stem is made; for purposes of evaluation, the value of k may be considered to be dependent on the arithmetic mean of ts and tf ;

,Faden

N is the number of C equivalent to the length of the emergent stem, and is the difference between the thermometer indication and the actual or extrapolated scale value corresponding to the specified immersion level;

tf

ruxf

thermometers

immersion level

Llquld column of thermometer

1

(B) (C)

is the average emergent-stem temperature in use during Cali bration;

(A)

ts is the specified average emergent-stem temperature.

The corrections are considered to be correct within 10 %. For thermometers graduated in C, most types of glass and over the common temperature ranges, the following values of k are to be used: Mercury k = 0.00016 C -1 Organic liquids k = 0.001 C -1 More information about the dependence of k on temperature and the type of glass can be found in [8] and [9]. Complete-immersion thermometers are mainly used for meteorological purposes i.e. indoor and outdoor air temperatures. If they are gas-filled, there will be a significant difference between complete and partial-immersion as a result of the effect of the temperature on the gas pressure in the thermometer. The difference in readings under the two conditions is particularly significant at high temperatures. Corrections are difficult to apply due to lack of knowledge of the internal pressure. [8] gives some advice. Before any correction can be applied, the average temperature of the emergent column has to be determined. A traditional method for measuring the emergent-stem temperature is to use a Faden thermometer with the correct bulb length. Faden thermometers have long bulbs and they are attached alongside the stem of the thermometer and overlap the emergent column length. The top of the Faden thermometer bulb should be at the same height as the meniscus in the thermometer to be calibrated. Thus, the Faden thermometer does the averaging. When a Faden thermometer is used, the number N is determined as the length in C parallel to the bulb of the Faden thermometer. Fig. 7 (A) and (B) show a total-immersion thermometer partially immersed. The bulb of a Faden thermometer measures the average temperature t over N degrees of the main thermometer. Fig. 7 (B) can also be interpreted as a partial-immersion thermometer being immersed to the correct length, but a Faden thermometer measures the average of the emergent-stem temperature tf, thus corrections can be made if the temperature is different from the specified emergentstem temperature ts. If the bulb of the Faden thermometer is too short or no Faden thermometer is available, place two or three mercury-in-glass

Fig. 7. Determination of emergent column temperature.

thermometers along the stem and average their readings by weighting them for the length along the emergent stem in order to determine t or tf. If for example two thermometers are used of which one covers n1 degrees on the thermometer to be calibrated and its reading is t1 C, and the second thermometer covers n2 degrees and its reading is t2, the weighted average temperature of the emergent stem is then found as:

6.5

EXPRESSION OF RESULTS

The result is stated in a table in which all numbers are rounded to the same number of decimals as the uncertainty d). The table has 4 columns. a) Temperature t (C)

t is the conventional true value of the temperature and is calculated as the mean of the 3 readings R of the reference thermometer corrected for all known systematic errors.

b) Reading tf (C)

tf is the reading of the thermometer. It is calculated as the mean of the 2 readings Xi and Xi', and corrected for emergent-stem temperature if required.

c) Correction tc (C)

tc is calculated from the following equation:

tc = t - tr When the thermometer is used after calibration, the correction tc can be added to the reading tf of the thermometer to give the best estimate of the true temperature: t = tr - tc

NORDTEST METHOD

NT VVS 102 9

A. Those which are evaluated by applying statistical methods to a series of repeated determinations. B. Those which are evaluated by other means. The WECC guideline treats all components as random variables even the influence quantities which may affect the measured value in a systematic way. The results of using the WECC guideline are consistent with the results of using the BIPM recommendation. In the short description below, we do not distinguish between category A and B, and as for the WECC guidelines we treat all components as random variables. The principle of the combination method is that the size of each uncertainty component s i is evaluated at a 1 sigma level. The 1 sigma values are then combined by means of the following equation:

st =

Temperature C

0.00 100.57 230.9

Reading C

0.20 100.25 228.5

Correction C

-0.20 +0.32 +2.4

Uncertainty C

0.10 0.16 1.o

6.6

UNCERTAINTY

There are at least 4 main sources of uncertainty for the total calibration uncertainty. Each source can have several uncertainty components involved. a) The calibration uncertainty of the reference thermometer as stated on its certificate. b) The uncertainty of determination of the reference temperature. This is very dependent on the type of instrumentation used. In case of a direct-reading thermometer, the components are the reading uncertainty and the drift since last calibration. In case of a Pt-100 with an ohmmeter, the drifts of the Pt-100, the ohmmeter, the reading uncertainty and the calibration uncertainty of the ohmmeter must be considered. In case of a SPRT measured at the triple point of water or ice point for determination of its W at the temperature, its drift can be neglected, but contributions from the triple or ice point, the measuring bridge and the standard resistor have to be considered. c) The uncertainty of the thermostat (instability and gradients). d) The reading uncertainty of the thermometer to be calibrated.

+ -

--+3

ut is then found from: ut = k * st

For this Nordtest method k = 2 is used. An example of the calculation of uncertainty is given below. Each component is listed with an estimate of its size. The distribution factor for each component is then estimated and the 1 sigma value is found by dividing the component's size with its distribution factor. a) The calibration certificate for the reference thermometer states the uncertainty to be 0.02 C. The calibration laboratory also uses k = 2, thus the 1 sigma value becomes 0.01 C. b) The reading uncertainty of the reference thermometer is equal to its resolution 0.01 C. The distribution is estimated to be rectangular, thus the distribution factor is 3. The history of the reference thermometer shows that the drift between two calibrations has never exceeded 0.02 C. Again the distribution is estimated to be rectangular. c) Temperature fluctuations in the thermostat have an amplitude not exceeding 0.01 C. The variations follow approximately a sine function. In such a case the distribution is U-shaped and the distribution factor is 2. The type A uncertainty is strongly related to this component and is estimated to be included in it. The temperature gradients in the thermostat have a limit of 0.005 C with a rectangular distribution. d) The graduation of the thermometer to be calibrated is 0.1 C. Interpolation to 1/5 of the graduation (0.02 C) is carried out. The distribution is assumed to be rectangular. The correction for the emergent-stem temperature was 0.2 C assumed to be accurate within 10 %.

The reading uncertainty is normally 20 % (1/5) of the smallest graduation. In the case of coarse graduation lines, the reading uncertainty may be greater. Use of a monocular and good lighting may give smaller reading uncertainties. The uncertainty components are combined to a total uncertainty as described by BIPM in [5] or WECC in [6]. Both descriptions assume that corrections have been made for all known systematic errors. The BIPM recommendation defines two categories of uncertainty according to the way in which their numerical values are estimated:

NORDTEST METHOD

NT VVS 102 10

Component

Value

C

Factor

1 sigma

a) Name and address of the issuing calibration laboratory. b) Accreditation number of the laboratory if the laboratory is accredited by the national accreditation body. c) (Unique) identification number of the calibration certificate.

value C

2 1.73 1.73

a) Ref. therm. calibration b) Reading uncertainty of reference thermometer Drift of ref.therm. c) Thermostat instability Thermostat gradients d) Reading of thermometer to be calibrated

Correction for emergentstem temperature

Root of sum of squares

0.02

0.01

0.006

0.01

0.02 0.01

0.005

0.02

0.012

0.007 0.003

d) Date of receipt of the instrument or device calibrated, date(s) on which the calibration was carried out and date of issue of the certificate. e) Number of pages comprising the certificate. f) Statement by the accreditation body if the laboratory is accredited by the national accreditation body. g) Name(s) and signature(s) of authorized person(s).

1.41

1.73 1.73

1

0.012 0.02

0.02

h) Suitable identification of the client.

st= 0.029

i) Identification of the instrument or device calibrated. j) The conditions (e.g. environmental) under which the Calibrations were performed. k) Identification of this and any other procedure employed and of any deviation from the procedures. I) Statement of the traceability of the calibration results. m) Calibration results and the associated uncertainty of the calibrations.

The uncertainty is then calculated as:

ut = 2 * st = 0.059 C

6.7

TEST REPORT

The Test Report called a Calibration Certificate must, if relevant, include the following information:

You might also like

- DKD Guidance - Calibration of Liquid WaterDocument14 pagesDKD Guidance - Calibration of Liquid WatergustavoesanchezNo ratings yet

- Ea 10-08 PDFDocument16 pagesEa 10-08 PDFAna Safranec VasicNo ratings yet

- R135 E04Document48 pagesR135 E04naranjocarlosNo ratings yet

- Astm E145 1994 OVENDocument4 pagesAstm E145 1994 OVENNinit MiyuNo ratings yet

- Calibration Defelsko Certified ShimsDocument6 pagesCalibration Defelsko Certified ShimsPubcrawlNo ratings yet

- Certificate IPT 501Document3 pagesCertificate IPT 501Guilherme DiasNo ratings yet

- Iec TS 62492-1 - 2008Document24 pagesIec TS 62492-1 - 2008mrkNo ratings yet

- Calibration Lab MagazineDocument48 pagesCalibration Lab MagazineNizar Alif100% (1)

- DKD R 6 2 t5 e PDFDocument9 pagesDKD R 6 2 t5 e PDFDragan Ilic100% (1)

- EURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01Document29 pagesEURAMET Cg-19 V 2.0 Guidelines in Uncertainty Volume 01Daniel AlvesNo ratings yet

- FAS146en - Electrical Temperature MeasurementDocument164 pagesFAS146en - Electrical Temperature MeasurementShiva Sai BuraNo ratings yet

- 2012 Calibrations in Process Control and AutomationDocument11 pages2012 Calibrations in Process Control and AutomationLALIT RAAZPOOTNo ratings yet

- Coca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselDocument30 pagesCoca-Cola Femsa Philippines, Inc.: Report On The Result of Inspection of Pressure VesselEphraim John Tangelon AquinoNo ratings yet

- EURAMET-cg-08 V 2.1 ChangesDocument18 pagesEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoNo ratings yet

- Coir Moisture MeterDocument4 pagesCoir Moisture Metersaurabh_acmasNo ratings yet

- Semi Automatic Polarimeter: MODEL NO. - ACM-SAP-2644Document4 pagesSemi Automatic Polarimeter: MODEL NO. - ACM-SAP-2644saurabh_acmasNo ratings yet

- Lab3 Temperature and Calibration - FINALrrDocument6 pagesLab3 Temperature and Calibration - FINALrrDerrick SheeNo ratings yet

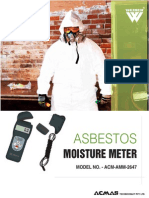

- Asbestos Moisture MeterDocument6 pagesAsbestos Moisture Metersaurabh_acmasNo ratings yet

- Calibration at HBMDocument8 pagesCalibration at HBMlelixNo ratings yet

- EPA Method 21-DETERMINATION OF VOLATILE ORGANIC COMPOUND LEAKSDocument17 pagesEPA Method 21-DETERMINATION OF VOLATILE ORGANIC COMPOUND LEAKSwholenumberNo ratings yet

- Certificate of Analysis ListDocument3 pagesCertificate of Analysis ListJorge Luis ParraNo ratings yet

- E 1965 - 98 - Rte5njutotgDocument16 pagesE 1965 - 98 - Rte5njutotgPrakash MakadiaNo ratings yet

- Microcoulomb AnalyzerDocument4 pagesMicrocoulomb Analyzersaurabh_acmasNo ratings yet

- Balance Ohaus AS200Document89 pagesBalance Ohaus AS200Abraham Farias ANo ratings yet

- National University of Singapore: Faculty of Engineering Department of Mechanical & Production EngineeringDocument9 pagesNational University of Singapore: Faculty of Engineering Department of Mechanical & Production EngineeringDelroy JqNo ratings yet

- Uncertainty Budget TablesDocument11 pagesUncertainty Budget TablesJepri PurwantoNo ratings yet

- Confidence in MeasurementDocument8 pagesConfidence in MeasurementloleNo ratings yet

- Improving The Video Totalized Method of Stopwatch CalibrationDocument32 pagesImproving The Video Totalized Method of Stopwatch Calibrationjulian mora100% (1)

- Form MetrologyDocument67 pagesForm Metrologymrbalaji88No ratings yet

- DKD R 6 2 t5 eDocument9 pagesDKD R 6 2 t5 eSebas BuitragoNo ratings yet

- Viscosity Cup Astm d1200 Ford Vf2029 d44Document3 pagesViscosity Cup Astm d1200 Ford Vf2029 d44RodrigoNo ratings yet

- Homework 1 ME 531 2018 WebDocument4 pagesHomework 1 ME 531 2018 WebEhab WilsonNo ratings yet

- USP Certificate: Caffeine Melting Point StandardDocument2 pagesUSP Certificate: Caffeine Melting Point StandardKimia AsikNo ratings yet

- Crack Depth GaugeDocument4 pagesCrack Depth Gaugesaurabh_acmasNo ratings yet

- Microprocessor Based COD Analysis ColorimeterDocument4 pagesMicroprocessor Based COD Analysis Colorimetersaurabh_acmasNo ratings yet

- OIML and ASTM Calibration WeightsDocument28 pagesOIML and ASTM Calibration WeightsScott TylerNo ratings yet

- Specifying and Verifying The Performance of Color-Measuring InstrumentsDocument11 pagesSpecifying and Verifying The Performance of Color-Measuring InstrumentsEnriqueVeNo ratings yet

- Certificate of Analysis ListDocument3 pagesCertificate of Analysis ListFabian GarciaNo ratings yet

- Manual UN-01-260 Rev. E Sypris Test & Measurement All Rights ReservedDocument59 pagesManual UN-01-260 Rev. E Sypris Test & Measurement All Rights ReservedChin Lung LeeNo ratings yet

- Sound and Vibration IsulationDocument9 pagesSound and Vibration Isulationferdinand laiNo ratings yet

- Liquid-in-Glass Thermometer Calibration: Principle of Operation Traceability ChartDocument1 pageLiquid-in-Glass Thermometer Calibration: Principle of Operation Traceability ChartbasdownloadNo ratings yet

- Uncertainty Presentation Digital MultimeterDocument76 pagesUncertainty Presentation Digital MultimeterAHMAD YAGHI100% (1)

- Sylvac Catalogue 2014 en WebDocument221 pagesSylvac Catalogue 2014 en Websava88No ratings yet

- KippZonen ISO9847 Calibration StatementDocument1 pageKippZonen ISO9847 Calibration Statementmoro1381No ratings yet

- Measurement Uncertainty: 7 Steps To CalculateDocument14 pagesMeasurement Uncertainty: 7 Steps To Calculateerwinch100% (1)

- TDS X-RAY Calibration Standards 952-025 EnBIGDocument40 pagesTDS X-RAY Calibration Standards 952-025 EnBIGPO Hsien YUNo ratings yet

- EURAMET Cg-18 V 3.0 Non-Automatic Weighing Instruments 01Document84 pagesEURAMET Cg-18 V 3.0 Non-Automatic Weighing Instruments 01Dragana Srdic100% (1)

- Coffee Moisture MeterDocument4 pagesCoffee Moisture Metersaurabh_acmasNo ratings yet

- Calibration TechnicianDocument4 pagesCalibration TechnicianRolando DaclanNo ratings yet

- D445 15Document15 pagesD445 15Melissa MartinezNo ratings yet

- Mitutoyo Bore Gauge PDFDocument12 pagesMitutoyo Bore Gauge PDFAnonymous 8rb48tZSNo ratings yet

- EURAMET cg-15 V 2.0 Guidelines Calibration Digital Multimeters 01 PDFDocument18 pagesEURAMET cg-15 V 2.0 Guidelines Calibration Digital Multimeters 01 PDFVallik TadNo ratings yet

- T205 - Uncertainty Analysis For Hydrometer Calibration at NMISADocument22 pagesT205 - Uncertainty Analysis For Hydrometer Calibration at NMISApanjang snsuNo ratings yet

- ISO-4064-2-2014 PreviewDocument15 pagesISO-4064-2-2014 PreviewLingeshwar Baskaran100% (1)

- Thread GaugesDocument8 pagesThread GaugesJohn MuellerNo ratings yet

- LWS Technical Paper - Impaction Technology and ISO 14698Document11 pagesLWS Technical Paper - Impaction Technology and ISO 14698BLUEPRINT Integrated Engineering ServicesNo ratings yet

- Coulometric Sulfur AnalyzerDocument4 pagesCoulometric Sulfur Analyzersaurabh_acmasNo ratings yet

- G&B Calibration BrochureDocument45 pagesG&B Calibration Brochureanon_521111922No ratings yet

- Expression of Uncertainty in MeasurementDocument1 pageExpression of Uncertainty in MeasurementamishraiocNo ratings yet

- Lista de Partes 700HTP-2Document1 pageLista de Partes 700HTP-2juncar25No ratings yet

- Recommended Calibration Interval-NISTDocument1 pageRecommended Calibration Interval-NISTjuncar25No ratings yet

- Fluke 101 Digital Multimeter: The FIRST-CHOICE Multimeter For Electrical ProfessionalsDocument2 pagesFluke 101 Digital Multimeter: The FIRST-CHOICE Multimeter For Electrical Professionalsjuncar25No ratings yet

- Making The Right Choice For Your Temperature ReadoutDocument2 pagesMaking The Right Choice For Your Temperature Readoutjuncar25No ratings yet

- Distribuciones para La Estimacion de La IncertidumbreDocument1 pageDistribuciones para La Estimacion de La Incertidumbrejuncar25No ratings yet

- Asch 2Document2 pagesAsch 2juncar25No ratings yet

- CapstoneDocument23 pagesCapstoneA - CAYAGA, Kirby, C 12 - HermonNo ratings yet

- HCPL 316J 000eDocument34 pagesHCPL 316J 000eElyes MbarekNo ratings yet

- DOC-20161226-WA0009 DiagramaDocument61 pagesDOC-20161226-WA0009 DiagramaPedroNo ratings yet

- SP Essay 1Document14 pagesSP Essay 1api-511870420No ratings yet

- Arbor APS STT Unit 01 Design Basics 25 Jan2018Document31 pagesArbor APS STT Unit 01 Design Basics 25 Jan2018masterlinh2008No ratings yet

- JC Series Jaw Crusher PDFDocument8 pagesJC Series Jaw Crusher PDFgarrybieber100% (1)

- Column, Slab, Footing and Wall Footing Foundations: Class A MixingDocument47 pagesColumn, Slab, Footing and Wall Footing Foundations: Class A MixingGioharry Nul PanambulanNo ratings yet

- VBAC MCQsDocument3 pagesVBAC MCQsHanaNo ratings yet

- 12 Key Principles On Bhava AnalysisDocument28 pages12 Key Principles On Bhava AnalysisDhineshNo ratings yet

- Bhil Tribal Mobilisation in AlirajpurDocument14 pagesBhil Tribal Mobilisation in Alirajpurrahul banerjeeNo ratings yet

- Someone Who Believes in YouDocument1 pageSomeone Who Believes in YouMANOLO C. LUCENECIONo ratings yet

- Managing Diabetic Foot Ulcers ReadingDocument21 pagesManaging Diabetic Foot Ulcers Readinghimanshugupta811997No ratings yet

- Bảng giá FLUKEDocument18 pagesBảng giá FLUKEVăn Long NguyênNo ratings yet

- Percent by VolumeDocument19 pagesPercent by VolumeSabrina LavegaNo ratings yet

- Technical Information: Range-Free Controller FA-M3 System Upgrade GuideDocument33 pagesTechnical Information: Range-Free Controller FA-M3 System Upgrade GuideAddaNo ratings yet

- De Vault 1996Document22 pagesDe Vault 1996Harumi OONo ratings yet

- Dusta ManaDocument16 pagesDusta ManamahaphalaNo ratings yet

- SPL Lab Report3Document49 pagesSPL Lab Report3nadif hasan purnoNo ratings yet

- Recipes From The Perfect Scoop by David LebovitzDocument10 pagesRecipes From The Perfect Scoop by David LebovitzThe Recipe Club100% (7)

- Reviews: The Global Epidemiology of HypertensionDocument15 pagesReviews: The Global Epidemiology of Hypertensionrifa iNo ratings yet

- JRC JFE-680 Instruct ManualDocument86 pagesJRC JFE-680 Instruct ManualMark Dominic FedericoNo ratings yet

- The Passion For Cacti and Other Succulents: June 2017Document140 pagesThe Passion For Cacti and Other Succulents: June 2017golf2010No ratings yet

- SSDsDocument3 pagesSSDsDiki Tri IndartaNo ratings yet

- EXP4 The Diels Alder ReactionsDocument3 pagesEXP4 The Diels Alder ReactionsLaura GuidoNo ratings yet

- C.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)Document1 pageC.Abdul Hakeem College of Engineering and Technology, Melvisharam Department of Aeronautical Engineering Academic Year 2020-2021 (ODD)shabeerNo ratings yet

- Runyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechDocument28 pagesRunyankore-Rukiga Dictionary Launch: President Yoweri Museveni's SpeechThe New Vision50% (2)

- User'S Guide: Tm4C Series Tm4C129E Crypto Connected Launchpad Evaluation KitDocument36 pagesUser'S Guide: Tm4C Series Tm4C129E Crypto Connected Launchpad Evaluation KitLương Văn HưởngNo ratings yet

- Lecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Document1 pageLecture Planner - Inorganic Chemistry (Legend) - Yakeen NEET 2.0 2024Dipendra KumarNo ratings yet

- Dawn of Solar PV CookingDocument5 pagesDawn of Solar PV CookingAbhinav AgrawalNo ratings yet

- Process Costing Exercises Series 1Document23 pagesProcess Costing Exercises Series 1sarahbeeNo ratings yet