Professional Documents

Culture Documents

PVM1

Uploaded by

silverfurOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PVM1

Uploaded by

silverfurCopyright:

Available Formats

Automatic Pressure Controller using microcontroller

M. S. Khan, S. B. Bhatt Institute For Plasma Research, Bhat, Gandhinagar-382428 ABSTRACT: The constant total gas pressure require in many industrial application of Vacuum technology such as ion etching, coating, material processing etc. The constant total pressure also require during wall conditioning of the Tokomak vacuum vessel wall to control impurity in high temperature plasma experiment such as GDC, PDC, ECR. For these processes the working gas is introduced in the chamber using gas feed valve and the required gas pressure is maintained by adjusting the gas flow from this gas feed valve. The total gas pressure in the process chamber can vary due to many reasons like desorption of gases during the process, the change of gas flow from the gas feed valve, change in the pumping speed etc. To maintain the constant total gas pressure in side the vacuum vessel, we have developed AUTOMATIC PRESSURE CONTROLLER (APC) using fast response piezo electric gas leave valve and closed loop feedback control unit. APC is an electronic circuit designed to maintain constant gas pressure in a process chamber. Pressure control is accomplished by continuously admitting the correct quantity of gas into a dynamic system to compensate for the variation in the quantity of the gas being removed or introduced in the system during the process. We had designed the APC in 1994 based on operational amplifier [1]. Now we have made some modification and used microcontroller. This paper will describe about it. Keyword: piezo electric valve, ionization gauge, turbomolecular pump, micro-controller 1. INTRODUCTION: There are many industrial applications of vacuum technology such as sputtering, coating, ion etching, material processing etc; which require constant total gas pressure in process chamber. The constant total gas pressure also require during Glow Discharge Cleaning (GDC), Pulse Discharge Cleaning (PDC) and Electron Cyclotron Resonance Discharge Cleaning (ECRDC), conditioning of TOKAMAK vacuum vessel wall for impurity control in high temperature plasma experiments. At present PDC and ECRDC is regularly employed on tokamak ADITYA for wall conditioning and it is necessary to maintain total gas pressure at set level of about 3.0*10-5 torr during this process for optimum result. The APC can be used for slow as well as fast control of the gas. The APC uses electrically operated gas feed valve such as piezo electric valve to adjust the gas flow rate to control the pressure inside the process chambers. The main components required for apc are (a) Pressure monitoring system (b) Feed back control system and (c) electrically operated gas leak valve. Piezo Electric Gas Leak Valve GAS Vacuum Gauge head

Vacuum Chamber

Vacuum Gauge Controller

A. P. C.

Set Pressure Pressure Signal

Figure 1:Layout of main components of Automatic Pressure Controller 2. CLOSED LOOP PROCESS CONTROL: The Schematic of the main components required for automatic pressure control in process chamber is shown in the fig. 1[1]. The ultimate pressure in vacuum chamber will determine by the gas load from the gas leak valve as well as other sources and the pumping speed. The pressure inside the vacuum chamber is monitored using a vacuum gauge during the process. The vacuum gauge gives analog voltage output corresponding to the pressure inside the vacuum chamber. This voltage signal of pressure is used as the feedback signal in the APC circuit and it is compared with the voltage level set for the required pressure in the system. The error signal is generated by this comparison and microcontroller gives the corresponding correction voltage is applied to the gas leak valve. Thus, the pressure control is accomplished by automatically and continuously admitting the controlled quantity of gas to a dynamic system. The response of the APC depends upon the response of the vacuum gauge and piezo electric valve. In APC design presented here, we have used piezo electric gas leak valve (Model PV 10,Make Veeco Inc and Model MV 112,Make Maxtek Inc.) for gas feed due to its fast response and reproducibility & B - A type ionization gauge ( L H make model 210D as it can measure pressure from 1x 10-2 torr to 1x 10-9 torr and provide electrical signals 0 to 10V DC corresponding to pressure value and 3 to 9V DC corresponding to pressure index. 3. BLOCK DIAGRAM AND DESCRIPTION. The two inputs from ion gauge controller corresponding to pressure value (PV) and pressure index (PI) are processed as shown in the block diagram fig. 2, before applying as actual value to the one channel of ADC0809 e.g. let pressure inside the vacuum chamber is 2.0 x 10-7 torr. Here PI = 7 VOLT & PV = 2 VOLT Therefore, the o/p of the second block is

V1 = (7 (2/10))/2 = 3.4 volt This o/p is then applied to channel 0 of ADC0809. The desired pressure in the vacuum chamber is set by two potentiometer provided on the front panel of the unit Here out of two potentiometer, one is to set pressure value and the another is to set pressure index. The two inputs from these potentiometers are processed as shown in the block diagram fig. 2. The output from this block is V2= (PI- (PV/10))/2 This o/p is then applied to channel 1 of the ADC0809. So, in this way the input two the channel 1 is set manually which is nothing but reference value. 3.1 ANALOG TO DIGITAL CONVERTER: We have used IC ADC0809 for A to D conversion, which converts the analog signal given to its input into a digital signal, which is fed to Micro-controller. This ADC contains 8 input channels out of which we are using 2 input channels i.e. CH0 and CH1, while other channels are grounded. The output pins D0 to D7 of the ADC is connected to port1 of Microcontroller 89C51. The channel selection pin A0 is connected to the pin p0.0 of Microcontroller, which can be set or reset as per our requirement by the program to select either of the two channels (CH0 & CH1). When channel CH1 is selected, the feedback signal (actual voltage value corresponding to the pressure inside the vacuum chamber) is converted from analog to digital and fed to Microcontroller, where as channel CH0 is connected to variable voltage, constant current circuit to set the reference voltage corresponding to the desired value of pressure. The Microcontroller is the heart of the feedback control system. Here Microcontroller get the two digitized values from ADC0809 corresponding to the actual pressure value and set pressure valve. Based on these two values, each time microcontroller compare theses values and send some data to digital to analog converter (DAC808). The output pin of the DAC is connected with the operational amplifier. This converts it in to analog voltage. Which is further amplified by 20 gain amplifier. A bias voltage of 1 volt is also applied to 20 gain amplifier. The output of the 20 gain amplifier is given to piezo electric gas leak valve. Throughput of the piezo electric gas leak valve depends upon the voltage applied on it. In this way the pressure inside the chamber, vary. And the ion gauge gives changed voltage signal corresponding to the changed pressure inside the chamber. When both actual and reference signal become equal, voltage to the piezo electric leak valve did not change. Thus piezo electric valve maintain the pressure inside the chamber. Here initially the vacuum chamber is pumped down to 5 x 10-8 torr, so the value of pressure index (in this case 8V) always remains high initially and so the input to the channel 0 which is given by (PI PV/10)/2 = ( 8 5/10 )/2 = 3.75v

POT-1 (SET PV)

POT-1 (SET PI)

Vacuum Gauge

V2=(PI-(PV/10))/2

Ion gauge Controller PV PI

SUPPLY 5V DC

V1=(PI-(PV10))/2

ADC0809 VCC DATA VREF OE CH1 CH0 SEL IP A0 ALE SOC CLK EOC

P1 ATMEL89C51 MICROCONT ROLLER P0.0 P0.1 P0.2 P3.2(INT0) ALE P2

500KHZ CLOCK SIGNAL TWO DFLIPFLOP

DAC808

POWER SUPPLY +100V -100V

I out I to V Converter 0 - 5V o/p

Biasing Voltage

20 Gain Amplifier

To PV-10 Piezo-electric Valve BLOCK DIAGRAM OF APC Figure-2

Lets our desired pressure is 5 x 10-4 torr, which gives input voltage at channel 1 as given by (PI PV/10)/2 = ( 4 5/10 )/2 = 1.75v Initially, always this value is less than the actual value. Now when the actual voltage at the channel 0 of ADC0809 is greater than the reference value at the channel 1 of ADC0809 (which is the initial condition of the system), the voltage to the gas leak valve is increased from 0v step by step after each comparison. The valve start to open and let the gas goes inside the chamber, which increases the pressure inside the chamber gradually by small increment in the valve opening after each comparison. When the desired pressure inside the chamber comes the actual value read by the ADC0809 matches with the reference value and the controller stop the increment of the opening of the valve and the pressure is maintained at that value which is desired pressure. Meanwhile if the pressure increases from the desired value then the condition of the comparison is reversed and the Microcontroller senses the actual value less than the reference value and controller starts to decrement the valve voltage gradually. In this way controller, keep it self busy in marinating the actual. 4. TESTING OF APC: Fig. 3 shows the schematic of the vacuum system used for the testing of the APC. A turbo-molecular pump of 500 ltr/sec pumping speed is connected to UHV chamber of about 5 liters volume giving about 300 ltr/sec net pumping speed at the chamber. A B/A type L-H make IG, Piezo electric gas leak valve (PV-10) and manual gas leak valve with micrometer screw are mounted on the chamber. 4.1 Testing procedure and results: The testing procedure of APC involves the simulation of real gas load variation, monitoring of system pressure and monitoring of the change in the applied voltage to the piezo electric gas feed valve. This described in the following sections. 4.2 Gas Load Calibration: To check the performance of APC, it is essential to simulate the variable gas load using manual gas leak valve. For this the micrometer screw position of manual leak valve was calibrated in terms of gas throughput as follows. The power to the APC was switched off initially, the manual gas leak valve was opened slowly, and air was admitted in the vacuum chamber. For each position of the micrometer screw of the manual leak valve the system pressure was monitored and knowing the pumping speed (300 ltr/sec) of turbo molecular pump gas throughput was calculated. This was repeated for number of times and average valve of gas Manual Leak Valve GAS

Piezo Electric Gas Leak Valve (Operated with APC) GAS

B/A Type IG Turbo Pump (500 ltr./Sec) Pirani Gauge

Rotary Pump (166 ltr./min) Figure 3: Vacuum System for APC Testing. throughput for various micrometer positions of manual leak valve was find out. 4.3 Testing with PV 10 Gas feed Valve: Initially the vacuum chamber was pumped down to 1x10-7 torr, and the air was admitted in the chamber using manual gas leak valve and the system pressure was increased to 1x10-6 torr. Thus, initially the constant gas load of about 3x10-4 torr ltr/sec was adjusted in the system. The o/p of APC was connected to PV-10 gas feed valve. The system pressure was set by potentiometer at 3.0x10-5 torr. As, we switched on APC. It set the said system pressure within one minute. The voltage on the PV-10 valve and the system pressure were recorded. After this, the gas load in the system was gradually increased using manual leak valve and the system pressure as well as the voltage on the PV-10 valve were monitored. Fig. 4 shows the system pressure as well as the in the valve voltage required to control this pressure with varying gas load to the system. It can be seen that pressure in the system is constant for the gas load varying from 3x10-4 torr ltr/sec to 2x10-2 torr ltr/sec. At this valve of the gas load the PV-10 valve, voltage reduced to about 20 volts were it got completely closed. After this the system pressure was basically decided by the gas load from the manual leak valve and hence it started increasing as can see in the fig. 4.

Figure 4: Performance of APC with PV-10 Valve This APC using microcontroller is being successfully tested in the test stand and will now be used with Aditya Tokamak during ECR and PDC discharge cleaning. [1] M. S. Khan, H. A. Pathak, H. D. Pujara, S. B. Bhatt & Y. C. Saxena Design of Automatic Pressure Controller Technical Report, IPR, IPR/TR-51/94, March 1994.

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Plecs FlybackDocument4 pagesPlecs FlybackBhargavNo ratings yet

- Liquid Level Control Using A Pressure Senso R: Application NoteDocument9 pagesLiquid Level Control Using A Pressure Senso R: Application NoteNovian PratamaNo ratings yet

- Measure Pressure and Flow: Install The EMANT300 USB DAQ and Stepper Motor Training KitDocument13 pagesMeasure Pressure and Flow: Install The EMANT300 USB DAQ and Stepper Motor Training KitakashawalkerNo ratings yet

- Indian Institute of Technology (Indian School of Mines) DhanbadDocument10 pagesIndian Institute of Technology (Indian School of Mines) DhanbadSandeep ReddyNo ratings yet

- HPBP Writeup Dadri-IIDocument17 pagesHPBP Writeup Dadri-IIrajan_me083No ratings yet

- Instrumentation Process 2014.12.31 PDFDocument14 pagesInstrumentation Process 2014.12.31 PDFFadlul RamadhanNo ratings yet

- Water Flow Control System V2 PDFDocument12 pagesWater Flow Control System V2 PDFAayushSrivastava100% (1)

- M.tech Lab ManualDocument94 pagesM.tech Lab ManualSHINUMMNo ratings yet

- 27 Appendix D Technical Reference & SpecificationsDocument17 pages27 Appendix D Technical Reference & SpecificationspapipapiiNo ratings yet

- Components For Pneumatic Automation: Five ONEDocument26 pagesComponents For Pneumatic Automation: Five ONEamNo ratings yet

- Vav SystemsDocument4 pagesVav SystemsJesus RoldanNo ratings yet

- Liquid Level Control System V2Document14 pagesLiquid Level Control System V2Shisanu SenNo ratings yet

- A New Control Strategy For Voltage-Type PWM Rectifiers To Realize Zero Steady-State Control Error in Input CurrentDocument7 pagesA New Control Strategy For Voltage-Type PWM Rectifiers To Realize Zero Steady-State Control Error in Input Currentmipanduro7224No ratings yet

- Controllers and Final Control ElementsDocument27 pagesControllers and Final Control Elementsکبری ادریس رسولNo ratings yet

- PB Vs GainDocument6 pagesPB Vs Gainابزار دقیقNo ratings yet

- An Industrial Summer Training Report At: Bachelor of Technology (Engineering.)Document10 pagesAn Industrial Summer Training Report At: Bachelor of Technology (Engineering.)sunilbakoliya786No ratings yet

- Bomba Terracan ElectronicaDocument39 pagesBomba Terracan ElectronicaJenny Mora Leon100% (4)

- 418000E4422 R0 Write Up On Electro Hydraulic ControllerDocument10 pages418000E4422 R0 Write Up On Electro Hydraulic ControllerkoinsuriNo ratings yet

- Barometric Pressure Measurement Using Semiconductor Pressure SensorsDocument12 pagesBarometric Pressure Measurement Using Semiconductor Pressure Sensorssoldadorx01No ratings yet

- LM2907Document21 pagesLM2907leorio88No ratings yet

- IIT Dhanbad Student Paper on Current to Pressure TransducerDocument9 pagesIIT Dhanbad Student Paper on Current to Pressure TransducerSandeep ReddyNo ratings yet

- New EhtcDocument4 pagesNew EhtcRamakrishnan NatarajanNo ratings yet

- PELTON TURBINE EXPERIMENT NOTESDocument5 pagesPELTON TURBINE EXPERIMENT NOTESMj VikneshNo ratings yet

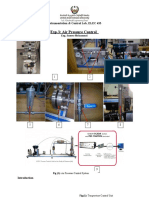

- Exp3 - Air Pressure ControlDocument8 pagesExp3 - Air Pressure ControlDon LawrenceNo ratings yet

- A Nozzle Flapper Electro-Pneumatic Proportional Pressure Valve Driven by Piezoelectric MotorDocument5 pagesA Nozzle Flapper Electro-Pneumatic Proportional Pressure Valve Driven by Piezoelectric MotorSekhar NarayananNo ratings yet

- GTO-Based 48-Pulse STATCOM DynamicsDocument7 pagesGTO-Based 48-Pulse STATCOM DynamicsEngr Imtiaz Hussain GilaniNo ratings yet

- Guidelines For Online ApplicationDocument26 pagesGuidelines For Online ApplicationAnonymous Xf4w0D2cNo ratings yet

- Mech 371 Manual v2010Document38 pagesMech 371 Manual v2010Joe E.No ratings yet

- Electronic WorkshopDocument7 pagesElectronic WorkshopSenthil KumarNo ratings yet

- Process Control Laboratory Equipments: 1. I/P Converter Demonstration System - Model Pc-IpdsDocument19 pagesProcess Control Laboratory Equipments: 1. I/P Converter Demonstration System - Model Pc-IpdscparamesNo ratings yet

- Thyristor Based HVDC SystemDocument5 pagesThyristor Based HVDC SystemAnonymous hzXy93FAE0% (1)

- Nov 2011 Atul1Document10 pagesNov 2011 Atul1Rajeev RawatNo ratings yet

- Synchronous MachineDocument51 pagesSynchronous MachineahmmsayemNo ratings yet

- Axial Piston Pump HydrodynamicsDocument12 pagesAxial Piston Pump HydrodynamicsNur Hidayatul NadhirahNo ratings yet

- Hwange Power Station: November 2022 ReportDocument16 pagesHwange Power Station: November 2022 ReportDennis MuzilaNo ratings yet

- Final PresentationDocument15 pagesFinal PresentationkamalNo ratings yet

- Research Article: Cathodic Protection of Pipeline Using Distributed Control SystemDocument8 pagesResearch Article: Cathodic Protection of Pipeline Using Distributed Control SystemSswahyudiNo ratings yet

- Unit2 MSDocument43 pagesUnit2 MSchandramohan murugan100% (1)

- Mini Project Report-2Document26 pagesMini Project Report-2Remya Ramakrishnan0% (2)

- Dynamics Quick Guide BetaDocument15 pagesDynamics Quick Guide BetaCHANADASNo ratings yet

- An 311Document6 pagesAn 311ayatullah21No ratings yet

- P6..W..EV-BAC 1 0 enDocument10 pagesP6..W..EV-BAC 1 0 enZoran DanilovNo ratings yet

- Project Report On OPDocument13 pagesProject Report On OPVarun PathaniaNo ratings yet

- 270 EHC Sec 2a EHC Actuators and ValvesDocument19 pages270 EHC Sec 2a EHC Actuators and Valvesmendel Santa Fe ArenasNo ratings yet

- Pressure Control TrainerDocument44 pagesPressure Control TrainerAjeet KumarNo ratings yet

- TLE7242G-TLE8242-2L+-Application-Note KP KI V2 0Document13 pagesTLE7242G-TLE8242-2L+-Application-Note KP KI V2 0Larbi_Lakrout_7056No ratings yet

- Top 221-227Document20 pagesTop 221-227Radu MălureanuNo ratings yet

- SGS Technical Note 150 - 40 Industrial Application IdeasDocument32 pagesSGS Technical Note 150 - 40 Industrial Application IdeasPeterNo ratings yet

- Process Control Lab ManualDocument19 pagesProcess Control Lab ManualAnkit Singh100% (1)

- ON-OFF Temperature Control System Using MicroprocessorDocument4 pagesON-OFF Temperature Control System Using Microprocessorsoach123No ratings yet

- Pressure Independent Control ValveDocument16 pagesPressure Independent Control ValverakamechNo ratings yet

- MPX5100Document17 pagesMPX5100Andri PaoNo ratings yet

- Experimental setup for diesel engine emissions testingDocument10 pagesExperimental setup for diesel engine emissions testingprasaad08No ratings yet

- Static Capacitor Banks For Fast Power Factor Compensation Type EckDocument11 pagesStatic Capacitor Banks For Fast Power Factor Compensation Type EckAde WawanNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetRating: 2 out of 5 stars2/5 (1)

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetFrom EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetNo ratings yet

- Gen Func Protek B-810Document25 pagesGen Func Protek B-810scremohentaiNo ratings yet

- CompuRAM RAMinator V2.0.1.12 ReportDocument3 pagesCompuRAM RAMinator V2.0.1.12 ReportJOHN KENNETH JIMENONo ratings yet

- 8085 Microprocessor Architecture and Programming-1Document92 pages8085 Microprocessor Architecture and Programming-1ShubhamNo ratings yet

- PD User Manual InverterDocument60 pagesPD User Manual InverterDwi Bagus JatmikoNo ratings yet

- VolkswagenDocument53 pagesVolkswagenandersonNo ratings yet

- MIMO Technology - Multiple Input Multiple Output - Radio-ElectronicsDocument8 pagesMIMO Technology - Multiple Input Multiple Output - Radio-ElectronicsPrasanth Jayasviji JsNo ratings yet

- Digital Logic Design Course OutcomesDocument1 pageDigital Logic Design Course OutcomesadNo ratings yet

- Audiolab 8000TE AM/FM Stereo Tuner User InstructionsDocument4 pagesAudiolab 8000TE AM/FM Stereo Tuner User Instructionsgorankontic1_4459869No ratings yet

- MotherboardDocument6 pagesMotherboardRadu GavriliuNo ratings yet

- Chapter 11Document51 pagesChapter 11vmspraneethNo ratings yet

- Denison Hydraulics Proportional Directional Valves Cetop 07: Series 4DP03-E/HDocument19 pagesDenison Hydraulics Proportional Directional Valves Cetop 07: Series 4DP03-E/Hpostolache mariusNo ratings yet

- Es 20Document3 pagesEs 20haowiepowerNo ratings yet

- IPT Satellite CommunicationDocument89 pagesIPT Satellite CommunicationKifaru Micro-electronicsNo ratings yet

- TZX-Series: Vishay SemiconductorsDocument7 pagesTZX-Series: Vishay SemiconductorsFABIAN FIGUEROANo ratings yet

- Acceptance Test Optix RTN 900 Series Microwave LinkDocument38 pagesAcceptance Test Optix RTN 900 Series Microwave LinkRonie MarxistNo ratings yet

- MIPI Cadence PresentationDocument55 pagesMIPI Cadence PresentationMohammed Nawaz Shaik100% (1)

- CL 74C Winch Motor: Operation ManualDocument29 pagesCL 74C Winch Motor: Operation Manualionut2007No ratings yet

- Centum VP 7 ENG Advanced Labs - GlobalDocument6 pagesCentum VP 7 ENG Advanced Labs - GlobalNikhilesh Muraleedharan100% (1)

- Tps 51650Document51 pagesTps 51650Qomari Ali MustofaNo ratings yet

- Basics of Computer HardwareDocument73 pagesBasics of Computer HardwareBalaji Rao NNo ratings yet

- 08-Electronics & Comm EnggDocument47 pages08-Electronics & Comm Enggraja2kumariNo ratings yet

- AC107Document1 pageAC107sruNo ratings yet

- Product List (Personas Atms) : IndexDocument38 pagesProduct List (Personas Atms) : IndexMichael BuanNo ratings yet

- 2 - Side Slip TesterDocument3 pages2 - Side Slip TesterTecnicas Reunidas de AutomociónNo ratings yet

- Scout 55Document52 pagesScout 55Catalin Firicel100% (1)

- Uav DesignDocument4 pagesUav DesignLuis Angel SantamariaNo ratings yet

- SH367309 Ev1.2aDocument92 pagesSH367309 Ev1.2aThien Dinh86% (7)

- 7PG21 Solkor RF Technical Manual Chapter 6 Commissioning PDFDocument21 pages7PG21 Solkor RF Technical Manual Chapter 6 Commissioning PDFmarkgaloNo ratings yet

- SAILOCTTDocument15 pagesSAILOCTTpradeepmeena321No ratings yet

- Ladders and BridgesDocument5 pagesLadders and BridgesHamid RajpootNo ratings yet