Professional Documents

Culture Documents

VLSI Design Style

Uploaded by

Praneeth VasanthamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VLSI Design Style

Uploaded by

Praneeth VasanthamCopyright:

Available Formats

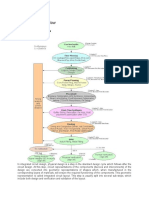

VLSI Design Styles VLSI design styles are primarily classified as full custom and semi custom design

styles. In the former case, the functional and physical designs are fully customized, requiring an extensive effort of a design team to optimize each detailed feature of the circuit. In this case, the design effort and cost are high, often compensated by the achievement of high quality circuits. It is obvious that the cost has to be amortized over large volume production (as in the case of processor design) or borne in full (as in case of specialized processor design). In case of semi-custom VLSI design, some part of the design is already being made and put in the library. The designer is required to define the interconnections between those modules. The reduction of the possible number of implementation choices makes it easier to develop CAD tools for design and optimization and also reducing the design time. Semi-custom design may be further classified into two subclasses: cell based design and array based design. Cell based design make use of library cells. Library cells are designed once and stored. Cell based designs are further classified as cell library (standard cell) based design and macro cell based design. In standard cell based designs, cells are designed once but updates are required as progress in semiconductor technology allows for smaller geometries. Every cell needs to be parameterized in terms of area and delay, over ranges of temperatures and operating voltages. Macro cell based design consists of combining building blocks that can be synthesized by computer programs called cell generators. Originally the macro cell generators targeted the automated synthesis of memory arrays and programmable logic arrays. The recent macro cell generators start with the functional description of the circuits and are able to synthesize the layout of those circuits that closely match their optimized full custom counterpart. Array based designs are further classified as pre-diffused and pre-wired, also called mask programmable gate arrays and field programmable gate arrays. MPGA consists of batches of wafers with array of sites being manufactured. The fabrication process entails programming the sites by contacting them to wires, i.e. by contacting them to routing wires. FPGA, in contrast, is programmed on field, i.e. by applying electrical pulses. They consist of arrays of programmable modules capable of implementing logic functions connected by switched wires. Programming is achieved in two ways. Wires, already present in the form of segments can be connected by programming anti-fuses. Alternatively, memory elements inside the array can be programmed to store information that relates to the module configuration and interconnection.

You might also like

- Standard CellDocument53 pagesStandard CellShwethNo ratings yet

- Mips Fpga LabDocument10 pagesMips Fpga LabBiloKhanNo ratings yet

- Answer 4Document6 pagesAnswer 4Mohit SinghNo ratings yet

- VLSI Design Methodology OverviewDocument26 pagesVLSI Design Methodology OverviewkripaNo ratings yet

- VLSI Assignment TitleDocument10 pagesVLSI Assignment TitleApoorva JainNo ratings yet

- Rohini 55102868036Document18 pagesRohini 55102868036عليNo ratings yet

- System On Chip (SOC)Document9 pagesSystem On Chip (SOC)jravi154No ratings yet

- Fpga ArchitectureDocument98 pagesFpga ArchitectureKavya Vimal100% (1)

- VLSI DesignDocument55 pagesVLSI DesignClique for Applied Research in Electronic TechnologyNo ratings yet

- Standard Cell Library Design and Characterization Using 45nm TechnologyDocument5 pagesStandard Cell Library Design and Characterization Using 45nm TechnologyTitan FredNo ratings yet

- SOC - System On Chip SeminarDocument8 pagesSOC - System On Chip SeminarUlhas N. GangjiNo ratings yet

- Many Core Processor ArchitectureDocument36 pagesMany Core Processor ArchitectureSiddhasen PatilNo ratings yet

- Soc System On Chip SeminarDocument8 pagesSoc System On Chip SeminarTHE HERALDSNo ratings yet

- VLSI DesignDocument19 pagesVLSI DesignEr Deepak GargNo ratings yet

- Dagatan Nino PRDocument12 pagesDagatan Nino PRdagatan.ninoNo ratings yet

- Introduction To ASIC TechnologyDocument6 pagesIntroduction To ASIC Technologyrpa projectNo ratings yet

- Asic CH1Document16 pagesAsic CH1Anonymous eWMnRr70qNo ratings yet

- Automation of Standard Cell Library Characterization for 180nm, 90nm and 45nm TechnologiesDocument4 pagesAutomation of Standard Cell Library Characterization for 180nm, 90nm and 45nm TechnologiesShraddha MaheshwariNo ratings yet

- Project ReportDocument15 pagesProject ReportAnuj Kalra100% (1)

- Introduction To AsicsDocument14 pagesIntroduction To AsicsmuralitejasNo ratings yet

- ASIC Cell Library ComponentsDocument2 pagesASIC Cell Library Componentsrpa projectNo ratings yet

- VLSI Physical Design andDocument23 pagesVLSI Physical Design andRajesh BathijaNo ratings yet

- Application-Specific Integrated Circuits (ASICs)Document5 pagesApplication-Specific Integrated Circuits (ASICs)ijeteeditor100% (1)

- Vlsi Design - Ec - 701 - Unit - IDocument37 pagesVlsi Design - Ec - 701 - Unit - Iangelcrystl4774No ratings yet

- VLSI Design Flow: The 8 Step Process for Creating Integrated CircuitsDocument3 pagesVLSI Design Flow: The 8 Step Process for Creating Integrated CircuitsSaurabh PorwalNo ratings yet

- ASic DesignDocument14 pagesASic DesignManpreet SinghNo ratings yet

- VLSI Design Quick GuideDocument68 pagesVLSI Design Quick GuideMayur AgarwalNo ratings yet

- An Efficient Heuristic Procedure For Partitioning GraphsDocument93 pagesAn Efficient Heuristic Procedure For Partitioning Graphsmhmd_saadNo ratings yet

- Study On Column Wise Design Compaction For Reconfigurable SystemsDocument4 pagesStudy On Column Wise Design Compaction For Reconfigurable Systemsyame asfiaNo ratings yet

- Chapter 5: Asics vs. PldsDocument13 pagesChapter 5: Asics vs. PldsLaxmanaa GajendiranNo ratings yet

- A Multicore Reconfigurable Processor Platform For Energy and Throughput Aware ApplicationsDocument3 pagesA Multicore Reconfigurable Processor Platform For Energy and Throughput Aware Applicationslovelyosmile253No ratings yet

- Vlsiphysicaldesign 150621074440 Lva1 App6891Document16 pagesVlsiphysicaldesign 150621074440 Lva1 App6891Æshok IncreĐible KingNo ratings yet

- A Brief Study of Reconfigurable Computation Systems With A Focus of FPGA Based DevicesDocument11 pagesA Brief Study of Reconfigurable Computation Systems With A Focus of FPGA Based DevicesMeToolNo ratings yet

- PD FlowDocument6 pagesPD FlowUTtNo ratings yet

- Chapter 1 IntroductionDocument21 pagesChapter 1 IntroductionIshrak AhmedNo ratings yet

- Physical DesignDocument12 pagesPhysical DesignPallavi ChNo ratings yet

- Application - Specific.IC DesignFlowDocument8 pagesApplication - Specific.IC DesignFlowNandagopal SivakumarNo ratings yet

- Deming Chen: Chapter 38, Design Automation For Microelectronics, Springer Handbook of AutomationDocument15 pagesDeming Chen: Chapter 38, Design Automation For Microelectronics, Springer Handbook of AutomationanilariNo ratings yet

- Basic VLSI Design ConceptDocument18 pagesBasic VLSI Design ConceptMoon Sadia DiptheeNo ratings yet

- VLSI Design Abstraction LectureDocument58 pagesVLSI Design Abstraction LecturebhawnaNo ratings yet

- Cad Vlsi DesignDocument39 pagesCad Vlsi DesignKunwar Abhimanyu SinghNo ratings yet

- SYNTHESIS-sparc by RajeshDocument20 pagesSYNTHESIS-sparc by RajeshRajesh PerlaNo ratings yet

- Introduction to Digital VLSI Design ChaptersDocument1 pageIntroduction to Digital VLSI Design ChaptersCarlos SaavedraNo ratings yet

- Efficient Reconfigurable On-ChipDocument11 pagesEfficient Reconfigurable On-ChipsuganyaNo ratings yet

- Vlsi Design StyleDocument15 pagesVlsi Design StyleSubir MaityNo ratings yet

- FPGA Vs ASICDocument9 pagesFPGA Vs ASICKamleshNo ratings yet

- UntitledDocument4 pagesUntitled291SWAYAM BEHERANo ratings yet

- FPGA Based Multi Core ProcessorDocument16 pagesFPGA Based Multi Core ProcessorvinayNo ratings yet

- Digital VLSI Chip Design With Cadence and Synopsys CAD ToolsDocument366 pagesDigital VLSI Chip Design With Cadence and Synopsys CAD ToolsMacy Yuan80% (5)

- NileshDocument22 pagesNileshNilesh VermaNo ratings yet

- Guide To TannerEDA For VLSIDocument32 pagesGuide To TannerEDA For VLSIPratik SinghNo ratings yet

- Physical Design FlowDocument42 pagesPhysical Design Flowelumalaianitha100% (1)

- Embedded Systems Design with Platform FPGAs: Principles and PracticesFrom EverandEmbedded Systems Design with Platform FPGAs: Principles and PracticesRating: 5 out of 5 stars5/5 (1)

- IET Computers Digital Tech - 2023 - Cao - Multi Objective Digital Circuit Block Optimisation Based On Cell Mapping in AnDocument15 pagesIET Computers Digital Tech - 2023 - Cao - Multi Objective Digital Circuit Block Optimisation Based On Cell Mapping in Anabel belaNo ratings yet

- ASIC Design: Introduction to Application Specific Integrated CircuitsDocument41 pagesASIC Design: Introduction to Application Specific Integrated CircuitsChandan TkNo ratings yet

- Vlsi Assingnment 1Document26 pagesVlsi Assingnment 1Info StudioNo ratings yet

- Cad For Vlsi 1Document284 pagesCad For Vlsi 1shekhartitNo ratings yet

- Cse2001 - Computer Architecture and Organization Name - Rushil Mehtani REG. NO.-16BCE2134 Digital Assignment - 2 Topic - Multi-Core ProcessorsDocument2 pagesCse2001 - Computer Architecture and Organization Name - Rushil Mehtani REG. NO.-16BCE2134 Digital Assignment - 2 Topic - Multi-Core ProcessorsRushil MehtaniNo ratings yet

- 5 Implementation Srategies of Digital ICDocument22 pages5 Implementation Srategies of Digital ICapi-19772070No ratings yet

- Design Abstraction and Validation VLSI MEDC 104Document90 pagesDesign Abstraction and Validation VLSI MEDC 104maheshsamanapally0% (1)

- Assgn 3Document95 pagesAssgn 3Praneeth VasanthamNo ratings yet

- CMOS Logic DesignDocument35 pagesCMOS Logic DesignsomosreeNo ratings yet

- Load Any Track of Your Choice Onto Your AudacityDocument9 pagesLoad Any Track of Your Choice Onto Your AudacityPraneeth VasanthamNo ratings yet

- DG-WN3150N User ManualDocument37 pagesDG-WN3150N User ManualPraneeth VasanthamNo ratings yet

- Ion Beam MachiningDocument58 pagesIon Beam MachiningPranav Madaan50% (2)

- DP LAN Realtek 15036 DriversDocument7,242 pagesDP LAN Realtek 15036 DriversJuan Carlos Gonzalez LNo ratings yet

- Atlas98-V1 Users PDFDocument318 pagesAtlas98-V1 Users PDFLOKESH SHARMANo ratings yet

- A Stable Radio Microphone With Loop AntennaDocument6 pagesA Stable Radio Microphone With Loop AntennaAdi FadillahNo ratings yet

- LZQJ ManualDocument54 pagesLZQJ Manualthomaswangkoro100% (3)

- LG 19Document36 pagesLG 19Walter AlvarengaNo ratings yet

- Integration of The General Network Theorem in ADE and ADE XLDocument36 pagesIntegration of The General Network Theorem in ADE and ADE XLosewoudtNo ratings yet

- 74HC73Document19 pages74HC73S. ChavesNo ratings yet

- Optics AssignmentDocument2 pagesOptics Assignmentbaffianforlife2113No ratings yet

- LADD SeminarDocument26 pagesLADD SeminarMusic MusicNo ratings yet

- Pha MGW Rfman 10Document81 pagesPha MGW Rfman 10BogdanNo ratings yet

- Main Memory CharacteristicsDocument48 pagesMain Memory CharacteristicsSet Emp100% (1)

- Voltage Source Inverter Control of Induction MotorsDocument34 pagesVoltage Source Inverter Control of Induction MotorsPrem SagarNo ratings yet

- LM340Document17 pagesLM340Lucas Diego Rodrigues FerreiraNo ratings yet

- Ipad Charger Teardown - Inside Apple's Charger and A Risky PhonyDocument39 pagesIpad Charger Teardown - Inside Apple's Charger and A Risky PhonyJorge Cruz MancillaNo ratings yet

- 0-30V 20A High Power Supply With LM338Document5 pages0-30V 20A High Power Supply With LM338Antonio José Montaña Pérez de Cristo100% (3)

- Sinamics G130 / G150 / S150: MotorsDocument14 pagesSinamics G130 / G150 / S150: MotorsANDRES CISTERNASNo ratings yet

- When Capability Is Critical PDFDocument5 pagesWhen Capability Is Critical PDFkrechbaNo ratings yet

- Compact smart relay data sheetDocument6 pagesCompact smart relay data sheetMircea MurarNo ratings yet

- 3800 IndicatorDocument3 pages3800 IndicatorP Shashidhar Chavan0% (1)

- World Skills 2011 enDocument11 pagesWorld Skills 2011 enS.i. FairusNo ratings yet

- CMOS Readout Interfaces for MEMS Capacitive MicrophonesDocument123 pagesCMOS Readout Interfaces for MEMS Capacitive MicrophonesKhaled AggourNo ratings yet

- Experimental Report on the Behaviour of Zener Diodes in Forward and Reverse BiasDocument9 pagesExperimental Report on the Behaviour of Zener Diodes in Forward and Reverse BiasDadNo ratings yet

- MPPT Power PsocDocument14 pagesMPPT Power PsocgubiliNo ratings yet

- 3-Channel Constant Current LED Drivers Chip DatasheetDocument18 pages3-Channel Constant Current LED Drivers Chip Datasheetastral projectNo ratings yet

- Datasheet 2Document2 pagesDatasheet 2Dung TranNo ratings yet

- Optical Characterisation of La0 7Sr0 3MnDocument5 pagesOptical Characterisation of La0 7Sr0 3MnbjsimardNo ratings yet

- Imex Rotating Lasers Operating Manual: 77R 88R and 88GDocument20 pagesImex Rotating Lasers Operating Manual: 77R 88R and 88GRobert SiraschNo ratings yet

- Rrrintel 3Document2 pagesRrrintel 3meghna vNo ratings yet

- Change LogDocument87 pagesChange Logoscar7890No ratings yet