Professional Documents

Culture Documents

NCC Awasthi 11BM60071

Uploaded by

Abhishek AwasthiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NCC Awasthi 11BM60071

Uploaded by

Abhishek AwasthiCopyright:

Available Formats

VGSOM IIT KHARAGPUR

National Cranberry Cooperative

Case Analysis

Abhishek Awasthi 11BM60071 Section A 1/30/2012

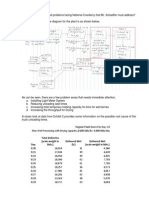

National Cranberry Cooperative is facing problem of overtime and waiting time by its growers while unloading cranberries to Receiving Point 1.

PROCESS DIAGRAM NATIONAL CRANBERRIES CO-OPERATIVE

Receiving

Weighing

Sampling

Colour Sampling

Dumping

Dry

Dry/Wet

Dry

Milling

Drying

Dechaffing

Destoning

1 Bagging Freezer

Finish Processing

Bulk Bin

Bulk Truck

Another Plant

Waste, 5%

Assumptions: We have assumed that: We have not considered per hour operating cost of plant Overtime for both regular and part time worker has been taken to be $ 12 per hour. In calculating the payback time, the same cost saving will occur every day. It is given in case that wet berries will make 70 % of total berries and that normal running hours for plant is 11 (12-1) hours. There is a cost associated with trucks waiting to be unloaded and it is $100 per hour. Throughput: Normal Day: 10000 bbls. Per day Peak Day: 22000 bbls. Per day

Case 1: 10000 bbl/day Berries WB DB Total Time WB Feed DB Feed Minimum processing rate for WB is at dryer, which is Inventory build up rate for WB WB holding bins capacity 10,000 7,000 3,000 11 636 273 bbls./day bbls./day bbls./day hours bbls./hr bbls./hr

600 bbls./hr 36 bbls./hr 3,200 bbls. Which means in normal days trucks don't need to wait, hence no waiting cost 88 hours

No. of hours required to fill the bins

Total accumulation of WB after 11 hours 400 bbls. Overtime 0.7 hours Now, assuming this is not a peak season, we have considered only 27 workers. Since plant is working suboptimal level during overtime , only two-third of the work force will be working on wet berries drying process. =2/3 work force = 20*(2/3) = 12 Savings per day = 12 * 12= 144 Savings for season = 144* 90 = 12960 If we add another dryer, to save overtime cost, cost will be = 40000 Analysis Considering the cost of depreciation and cost of investment in dryer(8-10%) it will not be economical to buy another dryer.

Case 2: 22000 bbls./day Berries WB DB Total Time WB Feed DB Feed Minimum processing rate for WB is at dryer, which is Inventory build up rate for WB WB holding bins capacity No. of hours required to fill the bins 22,000 15,400 6,600 11 1,400 600 600 800 3,200 4 bbls./day bbls./day bbls./day hours bbls./hr bbls./hr bbls./hr bbls./hr bbls. hours

This means after 4 hours there will be a long queue of trucks to unload berries. Total accumulation of WB after 11 hours Daily Overtime Assumming 15 days peak time i.e. 15 days overtime Overtime rate per hour Number of employees working overtime Daily cost of overtime Total cost of overtime WB waiting in truck Average truck capacity Number of trucks waiting Time to clear truck queue Total time spent in waiting by trucks Cost of truck hiring per hour Total waiting cost of trucks Total additional cost 12 18 3,168 47,520 5,600 75 75 9 697 100 69,689 117,209 $ men $ $ bbls. bbls. Trucks hours hours $ $ $ 8,800 bbls. 14.7 hours

Adding 1 Dryer: Berries WB DB Total Time WB Feed DB Feed Minimum processing rate for WB is at dryer, which is Inventory build up rate for WB WB holding bins capacity No. of hours required to fill the bins Total accumulation of WB after 11 hours Daily Overtime Overtime rate per hour Number of employees working overtime Daily cost of overtime Total cost of overtime WB waiting in truck Average truck capacity Number of trucks waiting Time to clear truck queue Total time spent in waiting by trucks Cost of truck hiring per hour Total waiting cost of trucks Total additional cost 22,000 15,400 6,600 11 1,400 600 800 600 3,200 5 6,600 8.3 12 18 1,782 26,730 3,400 75 45 4 193 100 19,267 45,997 bbls./day bbls./day bbls./day hours bbls./hr bbls./hr bbls./hr bbls./hr bbls. hours bbls. hours $ men $ $ bbls. bbls. Trucks hours hours $ $ $

Cost of additional dryer = 60,000 $ Total saving in cost = 117,209-45,997 = 71,212 $ Hence cost saved by adding 1 dryer is 71,212 $ by investing 60,000 i.e. ROI of 119 %.

Adding 2 dryers: Berries WB DB Total Time WB Feed DB Feed Minimum processing rate for WB is at dryer, which is Inventory build up rate for WB WB holding bins capacity No. of hours required to fill the bins Total accumulation of WB after 11 hours Daily Overtime Overtime rate per hour Number of employees working overtime Daily cost of overtime Total cost of overtime WB waiting in truck Average truck capacity Number of trucks waiting Time to clear truck queue Total time spent in waiting by trucks Cost of truck hiring per hour Total waiting cost of trucks Total additional cost 22,000 15,400 6,600 11 1,400 600 1,000 400 3,200 8 4,400 4.4 12 18 950 14,256 1,200 75 16 1 19 100 1,920 16,176 bbls./day bbls./day bbls./day hours bbls./hr bbls./hr bbls./hr bbls./hr bbls. hours bbls. hours $ men $ $ bbls. bbls. Trucks hours hours $ $ $

Cost of additional 2 dryers = 60,000*2=120,000 $ Total saving in overtime = 47,520 14,256 = 33,264 Total saving in cost = 117,209-16,176 = 101,033 $ Hence cost saved by adding 2 dryers is 101,033 $ by investing120,000 $ i.e. ROI of 84 %.

Adding 1 Dryer and converting 4 holding bins Berries WB DB Total Time WB Feed DB Feed Minimum processing rate for WB is at dryer, which is Inventory build up rate for WB WB holding bins capacity No. of hours required to fill the bins Total accumulation of WB after 11 hours Daily Overtime Overtime rate per hour Number of employees working overtime Daily cost of overtime Total cost of overtime WB waiting in truck Average truck capacity Number of trucks waiting Time to clear truck queue Total time spent in waiting by trucks Cost of truck hiring per hour Total waiting cost of trucks Total additional cost 22,000 15,400 6,600 11 1,400 600 800 600 4,200 7 6,600 8.3 12 18 1,782 26,730 2,400 75 32 3 96 100 9,600 36,330 bbls./day bbls./day bbls./day hours bbls./hr bbls./hr bbls./hr bbls./hr bbls. hours bbls. hours $ men $ $ bbls. bbls. Trucks hours hours $ $ $

Cost of adding 1 dryer and converting 4 holding bins= 60,000 + 10,000*4= 100,000 $ Total saving in cost = 117,209-36,330 = 80,879 $ ROI = 67 %

Best Option: By going through and evaluating all the options, best option to be adopted is to add 2 dryers where we can save 33,264 $ in overtime and reduce waiting money loss of growers by 67,769 $.

Note: Complete analysis is done using MS Excel and it can be found at : http://bit.ly/NCC-Simulation-Awasthi

You might also like

- National Cranberry Cooperative - 11BM60070Document3 pagesNational Cranberry Cooperative - 11BM60070Neelesh KhattarNo ratings yet

- National Cranberry Case Report Operations Management - IDocument9 pagesNational Cranberry Case Report Operations Management - IVikash KumarNo ratings yet

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pages11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- National Cranberries CaseDocument7 pagesNational Cranberries CaseHyper Green MindNo ratings yet

- IDS 532 - National Cranberry Case Study - AnswersDocument4 pagesIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiNo ratings yet

- NCC - Case StudyDocument3 pagesNCC - Case StudyDeepika GuptaNo ratings yet

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 pagesNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarNo ratings yet

- National Cranberry Case Report Operations ManagementDocument7 pagesNational Cranberry Case Report Operations ManagementKarthik TirupatiNo ratings yet

- National Cranberry Cooperative 1981Document10 pagesNational Cranberry Cooperative 1981Nicole Dorado0% (1)

- National Cranberry CaseDocument10 pagesNational Cranberry CaseanshumanNo ratings yet

- National Cranberry Part IDocument3 pagesNational Cranberry Part IPrateekRaj167% (3)

- CranberryDocument4 pagesCranberryharshkhambraNo ratings yet

- OPTIMIZED OPERATIONSDocument10 pagesOPTIMIZED OPERATIONSSahil sangwanNo ratings yet

- National Cranberry Cooperative Case AnalysisDocument9 pagesNational Cranberry Cooperative Case AnalysisAudrey Tay100% (3)

- NationalCranberryCooperative CaseAnalysisDocument10 pagesNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriNo ratings yet

- OM WordDocument3 pagesOM WordpulakitNo ratings yet

- Critical Problems and Recommendations for National CranberryDocument5 pagesCritical Problems and Recommendations for National Cranberrymaverick_659No ratings yet

- National Cranberry Case Analysis BottleneckDocument3 pagesNational Cranberry Case Analysis BottleneckHardik SemlaniNo ratings yet

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Document9 pagesAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryNo ratings yet

- Answers NCCDocument2 pagesAnswers NCCAmara Khan0% (1)

- OM - I National Cranberry CooperationDocument7 pagesOM - I National Cranberry Cooperationamritj100% (1)

- National Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsDocument11 pagesNational Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsFabiola SE100% (2)

- OM-I Assignment - Group 1 - Section A - National Cranberry CooperativeDocument8 pagesOM-I Assignment - Group 1 - Section A - National Cranberry Cooperativeaglakshmanan50% (2)

- Essay ReviewDocument11 pagesEssay ReviewMilagros AzparrentNo ratings yet

- National Cranberry Case ReportDocument10 pagesNational Cranberry Case ReportCharles Van Hoorebeke75% (4)

- National Cranberry HBS Case SolutionDocument9 pagesNational Cranberry HBS Case SolutionSandhya Patil100% (1)

- OM - National Cranberry - TemplateDocument3 pagesOM - National Cranberry - Templatebeta alpha gammaNo ratings yet

- National Cranberry Cooperative Case Answer 1Document6 pagesNational Cranberry Cooperative Case Answer 1PRITEENo ratings yet

- National Cranberry Cooperative 1996-1 PDFDocument10 pagesNational Cranberry Cooperative 1996-1 PDFnephielive.cnNo ratings yet

- National Cranberry PDFDocument2 pagesNational Cranberry PDFVarun ChandNo ratings yet

- National Cranberry CooperativeDocument5 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- National Cranberry CaseDocument20 pagesNational Cranberry CaseRicardo David Pareja Baquerizo100% (2)

- National Cranberry Cooperations 1996Document15 pagesNational Cranberry Cooperations 1996Mithilesh Singh67% (3)

- National Cranberry CooperativeDocument3 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- The National Cranberry CooperativeDocument5 pagesThe National Cranberry CooperativeHussein BayramNo ratings yet

- Operations Management National Cranberry CaseDocument12 pagesOperations Management National Cranberry CaseKarthik TirupatiNo ratings yet

- National Cranberry Cooperative Case AnalysisDocument6 pagesNational Cranberry Cooperative Case AnalysisTeja RaoNo ratings yet

- National Cranberry CooperativeDocument15 pagesNational Cranberry CooperativeSaswata Banerjee100% (4)

- Study Group - 2 NCC CaseDocument7 pagesStudy Group - 2 NCC CaseAchin ChatterjeeNo ratings yet

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- National Cranberry CooperativeDocument14 pagesNational Cranberry CooperativeDenisa A86% (7)

- Group 1 Donner Company CaseDocument7 pagesGroup 1 Donner Company CaseAjay Kumar100% (1)

- Inventory Buit Up With Time Inventory Buildup at TruckDocument3 pagesInventory Buit Up With Time Inventory Buildup at TruckdfreNo ratings yet

- Manzana Insurance Fruitvale Branch - Group 6Document6 pagesManzana Insurance Fruitvale Branch - Group 6Puneet AgarwalNo ratings yet

- National Cranberry Cooperative SolutionsDocument2 pagesNational Cranberry Cooperative Solutionsjr_gimp83% (6)

- Answers To Old Midterm QsDocument11 pagesAnswers To Old Midterm QsdarshangoshNo ratings yet

- Midterm Exam AnswersDocument8 pagesMidterm Exam AnswersJ100% (1)

- Group 8 - Donner SolutionDocument4 pagesGroup 8 - Donner SolutionMayank MishraNo ratings yet

- National CranberryDocument2 pagesNational CranberryNripesh PokhrelNo ratings yet

- M2 Capacity For TerraInsureDocument5 pagesM2 Capacity For TerraInsureAniKelbakiani0% (1)

- Guesstimate The Number of COVID Testing Kits Needed by Delhi in OctoberDocument6 pagesGuesstimate The Number of COVID Testing Kits Needed by Delhi in OctobersaiNo ratings yet

- Bacchus, Safraz LE1 - NCCDocument6 pagesBacchus, Safraz LE1 - NCCshaf33zaNo ratings yet

- National Cranberry - Section 4 Group 16Document8 pagesNational Cranberry - Section 4 Group 16milwandaNo ratings yet

- NCCDocument5 pagesNCCDeepika GuptaNo ratings yet

- National Cranberry Cooperative CaseDocument7 pagesNational Cranberry Cooperative CaseMano Ranjani83% (12)

- Xuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpDocument8 pagesXuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpJason zhuNo ratings yet

- A Brief On NCC CaseDocument7 pagesA Brief On NCC CaseMadhurima MagguNo ratings yet

- Case 1 - National Cranberry CooperativeDocument7 pagesCase 1 - National Cranberry Cooperativewhitney100% (1)

- National Cranberry Cooperative Reduces Truck Wait TimesDocument16 pagesNational Cranberry Cooperative Reduces Truck Wait TimesNitish Raj SubarnoNo ratings yet

- NationalCranberryQuestions 12Document1 pageNationalCranberryQuestions 12Umi KhanNo ratings yet

- Conversion of Ordinal Attitudinal ScalesDocument22 pagesConversion of Ordinal Attitudinal ScalesAbhishek AwasthiNo ratings yet

- Project Case StudyDocument10 pagesProject Case StudyAbhishek AwasthiNo ratings yet

- Manufacturing Firms and Hyper Inflation - Survival OptionsDocument23 pagesManufacturing Firms and Hyper Inflation - Survival OptionsAbhishek AwasthiNo ratings yet

- American Connector Company - Abhishek Awasthi - 11BM60071Document11 pagesAmerican Connector Company - Abhishek Awasthi - 11BM60071Abhishek AwasthiNo ratings yet

- 08 Network ModelsDocument2 pages08 Network ModelsJohn Carlo AmodiaNo ratings yet

- JSW Steel Coated Products Test CertificatesDocument10 pagesJSW Steel Coated Products Test CertificatesBernice AkotoNo ratings yet

- Trada 2Document2 pagesTrada 2rdobeidatNo ratings yet

- Practice-1 defining calendarsDocument5 pagesPractice-1 defining calendarspramod nagmotiNo ratings yet

- CAD Specification for Network Rail ProjectsDocument3 pagesCAD Specification for Network Rail ProjectsManoj Kumar MNo ratings yet

- Scrum Online Quiz - Testing ExcellenceDocument16 pagesScrum Online Quiz - Testing ExcellenceKRISHNAPRIYANo ratings yet

- VI Semester Airport and Railway EngineeringDocument2 pagesVI Semester Airport and Railway EngineeringdineshNo ratings yet

- Construction Claims DelaysDocument23 pagesConstruction Claims Delaysgerx11xregNo ratings yet

- V2 I4 Naniwa Newsletter OFFICIALDocument4 pagesV2 I4 Naniwa Newsletter OFFICIALNigelNo ratings yet

- Job planning and process preparationDocument11 pagesJob planning and process preparationNiza JamilNo ratings yet

- Seven Pragmatic Practices To Improve Software QualityDocument10 pagesSeven Pragmatic Practices To Improve Software QualityZeeshan Ahmed KhanNo ratings yet

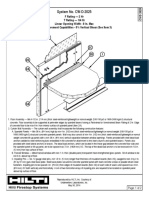

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Document2 pagesSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aNo ratings yet

- The Military Simulation, Modelling, and Virtual Training Market 2013-2023Document28 pagesThe Military Simulation, Modelling, and Virtual Training Market 2013-2023VisiongainGlobal100% (1)

- Cais 0308 - 2021-12 (308, 103S08)Document7 pagesCais 0308 - 2021-12 (308, 103S08)Muhammad UmarNo ratings yet

- Clextra For Project ManagementDocument9 pagesClextra For Project ManagementCasper AbrahamNo ratings yet

- Ten Rs of Efficient PurchasingDocument3 pagesTen Rs of Efficient PurchasingBala FoundMylostNo ratings yet

- Pampanga Rule78 ProblemsDocument63 pagesPampanga Rule78 ProblemsCrizza Joyce CruzNo ratings yet

- Catalog General Kaysun - 2016 Eng SPDocument376 pagesCatalog General Kaysun - 2016 Eng SPAnca JianuNo ratings yet

- NASA Configuration Management (CM) Standard (NASA - STD - 00059Document143 pagesNASA Configuration Management (CM) Standard (NASA - STD - 00059yaseenzaidi5117100% (1)

- Company Profile Prima VistaDocument10 pagesCompany Profile Prima VistaInche Helmi Dori DoriNo ratings yet

- Control Aspects of Netaji Subhash Chandra Bose Airport, KolkataDocument22 pagesControl Aspects of Netaji Subhash Chandra Bose Airport, Kolkatasonu1aNo ratings yet

- Operation ManualDocument9 pagesOperation Manualapi-202718495No ratings yet

- Inventory ControlDocument4 pagesInventory ControlabassalishahNo ratings yet

- Synopsis On CLOUD COMPUTING by Prashant GuptaDocument6 pagesSynopsis On CLOUD COMPUTING by Prashant GuptaPrashant GuptaNo ratings yet

- Arnco FTTX Fiber SolutionsDocument3 pagesArnco FTTX Fiber SolutionsPeterLOW0218No ratings yet

- Thapar Institute of Engineering & Technology, PatialaDocument3 pagesThapar Institute of Engineering & Technology, PatialaMr SamNo ratings yet

- Banner Buffalo BullDocument3 pagesBanner Buffalo Bullanon_579800775No ratings yet

- Lesson 28 DFD and Er DiagramDocument10 pagesLesson 28 DFD and Er DiagramSelect dsouzaNo ratings yet

- Standard Hardwood Pallet SpecsDocument2 pagesStandard Hardwood Pallet SpecsmnnfzNo ratings yet

- Satyam Company ProfileDocument7 pagesSatyam Company ProfileArghya GuhaNo ratings yet