Professional Documents

Culture Documents

National Cranberry Cooperative - 11BM60070

Uploaded by

Neelesh KhattarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

National Cranberry Cooperative - 11BM60070

Uploaded by

Neelesh KhattarCopyright:

Available Formats

NATIONAL CRANBERRY COOPERATIVE- A CASE STUDY

By Neelesh Khattar,11BM60070

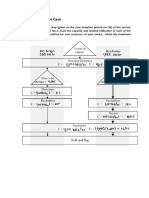

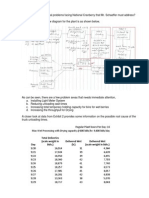

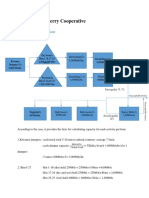

The National Cranberry Cooperative has to change the operational format of receiving plant #1 to meet production requirements during the high volume period of the cranberry harvest while reducing the costs of trucks waiting, overtime and inaccuracy of the grading process. The two types of harvesting techniques are water (wet) and dry which require different procedures to process them. The specific issues that have to be evaluated are the current maximum capacity the plant can handle at this time, the cost of labour (including overtime), the wait time to unload trucks as well as the benefits/cost of capital investments for the fifth Kiwanee dumper that was installed the past winter, installation of 2 new dryers, conversion of the holding bins to wet/dry units as well as a light meter for color grading. Based on the average busy day having 16,700 barrels (bbls) delivered a day, 70% would be wet berries (11,690 bbls) and 30% would be dry berries (5010 bbls). To achieve this operational level the following evaluations were made. The dry berry process starts with the receiving of the berries, the dumping to the Kiwanee dumpers, to the temporary holding, destoning, dechaffing, separation and the bulking and bagging. There is no issue with this process as the maximum output is 600 barrels per hour at the present time. The wet berry process starts with the receiving of the berries, the dumping to the Kiwanee dumpers, to the temporary holding, dechaffing, drying, separation and the bulking and bagging. This process is limited by the capacity of the dryers which are capable of processing 600 barrels per hour and the second limiting factor is the milling process which is shared with the dry processing berries resulting in the capacity being approximately 800 bbls per hour. As the daily requirement during the high volume period is 11,690 barrels it creates a backlog in inventory levels throughout the day and requires the dryer to operate for 20 hours a day during this time. Inventory levels build and with the current configuration of the holding tanks there is not the capacity to keep up with the levels created. With the increase in the wet berry inventory it is necessary to make some changes. The first recommendation is to purchase a light meter system for the plant. The annual loss of $168,750.00 on grading quality errors can be solved easily with the $20,000 capital investment and the additional annual wages of $15,600 which will result in a savings in the first year of over $133,000. The second recommendation is to convert the 16 dry holding bins to handle either wet or dry berries at a capital cost of $120,000. The dryer capacity creates a backlog of wet berry inventories within 3 hours and once the holding tanks are full it is only possible for an average of 8 trucks to unload an

hour based on only 600 barrels moving an hour. This investment will reduce waiting times for trucks during the high volume period (3 weeks in September) from an average of 410 hours a day ($4100 day or $86,000 for 3 weeks) to less than 20 hours a day ($200 day or $4,200 for 3 weeks) wait time which will result in a labour savings of $82,000 the first year. When looking at the usage of overtime it is clear that the volume levels of wet berries during high volume period are not able to be processed in a 12 hour shift. With the daily volume of 11,690 bbls and the dryer capacity only at 600 bbls/hour it is necessary for the plant to operate over 19.5 hours a day. With the current staffing and scheduling the additional 7.5 hours a day would be covered in overtime. On solution to this is to operate the plant during high volume periods with a crew of 89 employees on based on a 20 hour day and 2 shifts per day which will reduce overtime. The cost for this 3 week period with a 53 employee crew will be $44,606 and with a 89 employee crew $37,376 which will save $7,230 a week and $21,690 in the high volume period. Another solution would be to operate on a 16 hour day with 2 shifts. This would require a capital investment to purchase one additional dryer unit at a cost of $40,000 to increase the capacity to 800 bbls per hour. A second dryer unit should not be considered at this time as the milling can only handle a capacity of 1200 bbls/hr which is shared with the dry berry process leaving approximately 800 bbls/hr available for the wet berry process. By operating on a 16 hour day with 2 shifts the weekly wage expense would be reduced 2,457 for a total of $7,371 for the high volume season. The dryer expense would take roughly 5.5 years to recapture the wage reduction costs so it is an option that can be looked at and determined what the life expectancy would be on this asset before the final decision could be made

You might also like

- NCC Awasthi 11BM60071Document8 pagesNCC Awasthi 11BM60071Abhishek AwasthiNo ratings yet

- National Cranberry Case Report Operations Management - IDocument9 pagesNational Cranberry Case Report Operations Management - IVikash KumarNo ratings yet

- National Cranberries CaseDocument7 pagesNational Cranberries CaseHyper Green MindNo ratings yet

- OPTIMIZED OPERATIONSDocument10 pagesOPTIMIZED OPERATIONSSahil sangwanNo ratings yet

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 pagesNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarNo ratings yet

- National Cranberry Case Report Operations ManagementDocument7 pagesNational Cranberry Case Report Operations ManagementKarthik TirupatiNo ratings yet

- National Cranberry Cooperative 1981Document10 pagesNational Cranberry Cooperative 1981Nicole Dorado0% (1)

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pages11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- National Cranberry CaseDocument10 pagesNational Cranberry CaseanshumanNo ratings yet

- NationalCranberryCooperative CaseAnalysisDocument10 pagesNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriNo ratings yet

- Critical Problems and Recommendations for National CranberryDocument5 pagesCritical Problems and Recommendations for National Cranberrymaverick_659No ratings yet

- OM - National Cranberry - TemplateDocument3 pagesOM - National Cranberry - Templatebeta alpha gammaNo ratings yet

- National Cranberry Case ReportDocument10 pagesNational Cranberry Case ReportCharles Van Hoorebeke75% (4)

- Bacchus, Safraz LE1 - NCCDocument6 pagesBacchus, Safraz LE1 - NCCshaf33zaNo ratings yet

- National Cranberry HBS Case SolutionDocument9 pagesNational Cranberry HBS Case SolutionSandhya Patil100% (1)

- National Cranberry Cooperative Case AnalysisDocument9 pagesNational Cranberry Cooperative Case AnalysisAudrey Tay100% (3)

- Operations Management National Cranberry CaseDocument12 pagesOperations Management National Cranberry CaseKarthik TirupatiNo ratings yet

- Answers NCCDocument2 pagesAnswers NCCAmara Khan0% (1)

- National Cranberry Cooperative CaseDocument7 pagesNational Cranberry Cooperative CaseMano Ranjani83% (12)

- National Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsDocument11 pagesNational Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsFabiola SE100% (2)

- National Cranberry Cooperative 1996-1 PDFDocument10 pagesNational Cranberry Cooperative 1996-1 PDFnephielive.cnNo ratings yet

- National Cranberry Case Analysis BottleneckDocument3 pagesNational Cranberry Case Analysis BottleneckHardik SemlaniNo ratings yet

- National Cranberry Cooperative Case AnalysisDocument6 pagesNational Cranberry Cooperative Case AnalysisTeja RaoNo ratings yet

- IDS 532 - National Cranberry Case Study - AnswersDocument4 pagesIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiNo ratings yet

- OM - I National Cranberry CooperationDocument7 pagesOM - I National Cranberry Cooperationamritj100% (1)

- NCC - Case StudyDocument3 pagesNCC - Case StudyDeepika GuptaNo ratings yet

- M2 Capacity For TerraInsureDocument5 pagesM2 Capacity For TerraInsureAniKelbakiani0% (1)

- National Cranberry Cooperations 1996Document15 pagesNational Cranberry Cooperations 1996Mithilesh Singh67% (3)

- National Cranberry CaseDocument20 pagesNational Cranberry CaseRicardo David Pareja Baquerizo100% (2)

- OM WordDocument3 pagesOM WordpulakitNo ratings yet

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Document9 pagesAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryNo ratings yet

- Group 1 Donner Company CaseDocument7 pagesGroup 1 Donner Company CaseAjay Kumar100% (1)

- National Cranberry CooperativeDocument3 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- The National Cranberry CooperativeDocument5 pagesThe National Cranberry CooperativeHussein BayramNo ratings yet

- CranberryDocument4 pagesCranberryharshkhambraNo ratings yet

- National Cranberry Part IDocument3 pagesNational Cranberry Part IPrateekRaj167% (3)

- OM Group 5, National Cranberry CooperativeDocument10 pagesOM Group 5, National Cranberry Cooperativesudip2003No ratings yet

- National Cranberry Cooperative Reduces Truck Wait TimesDocument16 pagesNational Cranberry Cooperative Reduces Truck Wait TimesNitish Raj SubarnoNo ratings yet

- National Cranberry CooperativeDocument15 pagesNational Cranberry CooperativeSaswata Banerjee100% (4)

- National Cranberry CooperativeDocument5 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- National Cranberry PDFDocument2 pagesNational Cranberry PDFVarun ChandNo ratings yet

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- Operations Management at Donner CompanyDocument27 pagesOperations Management at Donner CompanymuruganandammNo ratings yet

- Inventory Buit Up With Time Inventory Buildup at TruckDocument3 pagesInventory Buit Up With Time Inventory Buildup at TruckdfreNo ratings yet

- National Cranberry Cooperative Case Answer 1Document6 pagesNational Cranberry Cooperative Case Answer 1PRITEENo ratings yet

- NCC-Case-Writeup-2021 - Sec D - Group D15Document9 pagesNCC-Case-Writeup-2021 - Sec D - Group D15dfreNo ratings yet

- OM-I Assignment - Group 1 - Section A - National Cranberry CooperativeDocument8 pagesOM-I Assignment - Group 1 - Section A - National Cranberry Cooperativeaglakshmanan50% (2)

- National Cranberry Cooperative: Revised Apr 09Document16 pagesNational Cranberry Cooperative: Revised Apr 09Varun ChandNo ratings yet

- National Cranberry Cooperative SolutionsDocument2 pagesNational Cranberry Cooperative Solutionsjr_gimp83% (6)

- National Cranberry - Section 4 Group 16Document8 pagesNational Cranberry - Section 4 Group 16milwandaNo ratings yet

- NCC Case Writeup 2020Document7 pagesNCC Case Writeup 2020rajuNo ratings yet

- Xuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpDocument8 pagesXuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpJason zhuNo ratings yet

- NCC RP-1 Cranberry Processing BottlenecksDocument11 pagesNCC RP-1 Cranberry Processing BottlenecksUday Raj RastogiNo ratings yet

- 4c. Full ProceedingDocument626 pages4c. Full ProceedingRato Petani Bandeng SilamonNo ratings yet

- National Cranberry CooperativeDocument14 pagesNational Cranberry CooperativeDenisa A86% (7)

- A Rice Husk Fuelled Paddy Dryer For Trader-MillerDocument3 pagesA Rice Husk Fuelled Paddy Dryer For Trader-MilleranhthynhanNo ratings yet

- Synopsis: 2.1 Work DoneDocument5 pagesSynopsis: 2.1 Work DoneKetan BhoreNo ratings yet

- NationalCranberryQuestions 12Document1 pageNationalCranberryQuestions 12Umi KhanNo ratings yet

- Banana Stem Waste to Paper and BoardsDocument4 pagesBanana Stem Waste to Paper and BoardsSanjeeva YedavalliNo ratings yet

- Additional Exportable Energy From BagasseDocument7 pagesAdditional Exportable Energy From BagasseMarco Antonio Polo FuentesNo ratings yet