Professional Documents

Culture Documents

Ops Summer Project

Uploaded by

Rajiv ChandranOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ops Summer Project

Uploaded by

Rajiv ChandranCopyright:

Available Formats

Dear Friends, This note is intended for those who wish to take up their summer intern ships in operations.

I have appended the key areas where you could look at for a project and also a representative list of specific areas that you could look it. I would advice you to go through this before you start to make your choices on the same. Following guidelines can help you in making your project experience a satisfying one. 1. Be prepared on what you are looking specifically in a project even before you go to an organization and discuss the same. If you do not have this clarity, you might be forced to do some routine mundane project. It would always be good if you prepare on at least 4-5 options so that some of these might find takers in the organization. Preparing this way, will give an impression to the organization that you mean business and that you are professional and focused. 2. While selecting a project topic in your major area, try to do a project that would do some justice to the minor area. For eg if you are specializing in Ops and Marketing, a supply chain project will do justice to both the areas. 3. You should be prepared on the latest trends in the area that you take up for the project. (These apply for goods and services)

Topics Productivity improvement Forecasting Design

Specific projects that you could look at Output enhancement projects Input reduction projects Improving the forecasting process Value engineering projects Mass customization Reliability Improvement

Process improvement

Capacity Layout

Bringing robustness to design Failsafing design Reduction on Non value adding activities Failsafing process Recovery mechanisms Measures for process measurement Standard Operating Procedures Opportunities for concurrent engineering QFD Service Blueprinting Debottlenecking processes and operations Layout changes to manage efficiency variability tradeoff Improving service layouts Product and service profiling Cellular layout design Line balancing and smoothening flow Throughput improvement Scope of enrichment and enlargement Ergonomics Methods analysis Motion study Costs of Quality Variability reduction in process Quality assurance programs Quality circles Root cause analysis Formalizing a framework for problem solving Process control and Process capability SCOR metrics Logistics performance improvement Optimizing supply chain Managing supply chain tradeoffs Procurement policy and effectiveness Supplier performance monitoring Supplier consolidation

Job design

Quality

Supply chain

Service

Improvement in service effectiveness New service development DEA

Inventory

Service blueprinting Service system design Service quality measurement Assurance in service Benchmarking Process control and capability Service facility design Process analysis Demand and capacity management Yield management Optimizing supply chain Service outsourcing Inventory management Inventory policy Inventory rationalization Inventory classification systems Replenishment policies ABC costing Demand management Capacity management Lean operations Waste reduction Lean building blocks Sequencing Improving scheduling effectiveness Scheduling in services Project performance management Project management framework implementation Network implementation Crashing Risk management in project Conflict management in project Resourcing in projects EVA Waiting time reduction Improving utilization Improving availability Reducing break down Increasing uptime

Costing Aggregate planning JIT Scheduling

Project management

Queuing Maintenance

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CT Analyzer Whats New V4 52 ENUDocument6 pagesCT Analyzer Whats New V4 52 ENUSivakumar NatarajanNo ratings yet

- Natural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFDocument508 pagesNatural Law and The Theory of Society 1500 To 1800 (Scan Perso) PDFjcfichte100% (1)

- Chapter-12 Perf Appraisal & Career Strategy (I.m.s)Document4 pagesChapter-12 Perf Appraisal & Career Strategy (I.m.s)Waris KhanNo ratings yet

- How To Install Windows Drivers With Software Applications: August 1, 2006Document12 pagesHow To Install Windows Drivers With Software Applications: August 1, 2006Mohamad Lutfi IsmailNo ratings yet

- Exp#4-Gas TurbineDocument9 pagesExp#4-Gas TurbineLilo17xiNo ratings yet

- CM6 - Mathematics As A Tool - Dispersion and CorrelationDocument18 pagesCM6 - Mathematics As A Tool - Dispersion and CorrelationLoeynahcNo ratings yet

- 1) Two Vectors A, B Are Orthogonal IfDocument9 pages1) Two Vectors A, B Are Orthogonal IfRamesh MallaiNo ratings yet

- Curriculum VitaeDocument4 pagesCurriculum Vitaeapi-200104647No ratings yet

- Community Service - Group 3 - Project 2Document24 pagesCommunity Service - Group 3 - Project 2rofiq wibawantoNo ratings yet

- Finding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveDocument306 pagesFinding The Right Place On The Map: Central and Eastern European Media Change in A Global PerspectiveIntellect BooksNo ratings yet

- Pasig Transparency OrdinanceDocument9 pagesPasig Transparency OrdinanceVico Sotto100% (3)

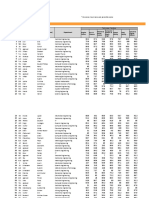

- Innoventure List of Short Listed CandidatesDocument69 pagesInnoventure List of Short Listed CandidatesgovindmalhotraNo ratings yet

- Retail Analysis WalmartDocument18 pagesRetail Analysis WalmartNavin MathadNo ratings yet

- استخدام الشبكة الإدارية في السلوك القيادي بحث محكمDocument22 pagesاستخدام الشبكة الإدارية في السلوك القيادي بحث محكمsalm yasmenNo ratings yet

- DTC Induction Motor DriveDocument13 pagesDTC Induction Motor Drivesarav03100% (2)

- Abstract - Freezing Point Depression Is ADocument5 pagesAbstract - Freezing Point Depression Is AMinahNo ratings yet

- STIers Meeting Industry ProfessionalsDocument4 pagesSTIers Meeting Industry ProfessionalsAdrian Reloj VillanuevaNo ratings yet

- CLOCKSDocument62 pagesCLOCKSdasarajubhavani05No ratings yet

- TM Matematika X IPA 8Document31 pagesTM Matematika X IPA 8Muhammad Ilyas ArradyaNo ratings yet

- Unit 3Document9 pagesUnit 3Estefani ZambranoNo ratings yet

- The FlirterDocument2 pagesThe Flirterdddbbb7No ratings yet

- Airworthiness Officer QuestionDocument1 pageAirworthiness Officer QuestionnanthakumarmaniNo ratings yet

- Zerkle Dalcroze Workshop HandoutDocument2 pagesZerkle Dalcroze Workshop HandoutEricDoCarmoNo ratings yet

- Welspun One Logistics Parks: Hazard Risk AssessmentDocument2 pagesWelspun One Logistics Parks: Hazard Risk AssessmentR. Ayyanuperumal AyyanuperumalNo ratings yet

- Exalted 2e Sheet2 Mortal v0.1Document2 pagesExalted 2e Sheet2 Mortal v0.1Lenice EscadaNo ratings yet

- Session 5 - Marketing ManagementDocument6 pagesSession 5 - Marketing ManagementJames MillsNo ratings yet

- Uvod PDFDocument13 pagesUvod PDFbarbara5153No ratings yet

- Physics WebpackDocument129 pagesPhysics Webpackapi-333910330No ratings yet

- Sidereal TimeDocument6 pagesSidereal TimeBruno LagetNo ratings yet