Professional Documents

Culture Documents

TS200-20 Hires

Uploaded by

wolfsterzOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TS200-20 Hires

Uploaded by

wolfsterzCopyright:

Available Formats

T H E R M O S PA N

200-20

WAY N E - DA LTO N C O M M E R C I A L D O O R S Y S T E M S

T HERMOSPAN 200-20

SECTIONAL DOOR SYSTEMS

INSULATED SECTIONAL STEEL DOORS CUT YOUR TOTAL COST

Wayne-Dalton Thermospan 200-20 offers premium thermal efficiency combined with a heavy-duty 20-gauge flush exterior surface. Featuring continuous foamed-in-place insulation and a non-conductive thermal break between the inner and outer skins, the Thermospan 200-20 provides a U-value of .057 and an R-value of 17.50, making it the ideal door for energy-conscious architects, engineers, contractors, and building owners. The Wayne-Dalton Thermospan Series doors are the only doors in the industry with patented, roll-formed integral struts on each section, making them the most rigid doors available.

PREMIUMTHERMAL QUALITIES (R-VALUE = 17.50, U-VALUE = 0.057) STANDARD SIZES UPTO 24 2WIDE AND 16 1 HIGH INDUSTRIAL/COMMERCIAL DURABILITY INTEGRAL STEEL STRUTS FOR SUPERIOR STRENGTH

SMOOTH, FLUSH EXTERIOR FINISH 25K CYCLE SPRINGS STANDARD

SECTIONAL DOOR SYSTEMS

T H E R M O S PA N 2 0 0 - 2 0

The Thermospan 200-20 outperforms other conventional insulated steel doors in the area of energy efficiency. The Thermospan 200-20 offers a U-Value of .057 (R-value of 17.5) a dramatic improvement over most conventional insulated steel doors, which typically have U-values between .33 and .51. At the heart of the Thermospan 200-20s excellent insulation qualities is a patented manufacturing process during which the polyurethane core is continuously foamed-inplace between the outer and inner skins, forming a homogenous sandwich of steel/polyurethane/steel. This process creates outstanding thermal, strength, and bonding characteristics which combine to make the Thermospan 200-20 an ideal choice for commercial and industrial applications. Additionally, a non-conductive thermal break virtually stops hot or cold outside temperatures from being transmitted to the inside.

Joint seal prevents air infiltration and saves energy. Thermal break separates inner and outer skins so virtually no heat or cold is conducted through section. Prepainted inner and outer skins for added corrosion-resistance. NOTE: Both skins are also hot-dipped galvanized steel for further protection against corrosion. Solid polyurethane core provides maximum thermal efficiency and adds to quiet operation and strength. Integral struts Two 1 3/4" roll-formed struts per section increases rigidity and strength.

Materials & Construction TheThermospan 200-20 also features two patented 1 3/4" integral roll-formed struts per section providing the highest strength-to-weight ratio.

Two-inch nominal thickness. Rugged 20-gauge smooth, flush exterior skin gives the Thermospan 200-20 excellent strength qualities, ideal for large openings. Extended Limited Warranty

Part of what makes the Thermospan 200-20 virtually maintenance free is the pre-painted flush exterior surface. This outer skin of hot-dipped galvanized, structural quality steel is factory finished with baked-on corrosion-resistant primer and a white polyester finish coat. The inner skin is also hot-dipped galvanized steel factory finished with the same corrosion-resistant primer and polyester finish coat. The Thermospan 200-20 features an innovative thermal break that keeps the interior skin at room temperature, preventing condensation and frost and thereby resisting corrosion. A flexible vinyl bulb seal and non-corrosive polymer retainer prevent water and air filtration at the bottom of the door. Reinforcement plates are located at all hardware attachment locations, and industry standard commercial-grade, heavy-duty, hot-dipped galvanized hardware also contribute to the Thermospan 200-20s long service life. For the same energy efficiency with a pinstriped, pebbled outer skin, see Wayne-Daltons Thermospan 200. Contact Wayne-Dalton for additional sizes and colors. Color Options

TEN (10) YEARS against cracking, splitting or deterioration due to rust.

SEVEN (7) YEARS against separation of polyurethane from the steel skin of the panel.

Operation Options

Chain Hoist Operation Motor Operation Performance Options High Cycle Spring (50K, 100K) 3"Track Option Windload Window Options

Safety Options

Broken Cable Devices Safety Edges Safety Photo Eyes Special Application Options SpecialTrack Designs Pass Doors Mullions

White Smooth Flush Finish

www.wayne-dalton.com/commercial

Vision Lites allow for visibility while maintaining security

Aluminum full view sections all for maximum natural light and visibility

STANDARD SIZES UP TO: 24 2 WIDE & 16 1 HIGH ENERGY EFFICIENCY VALUES: U = 0.057 R = 17.50 WINDLOAD: MEET OR EXCEED ANSI/DASMA 102-2003 IN ACCORDANCE WITH ASTM E-330-70. BEST APPLICATIONS: Extra Heavy-Duty Applications Where High Insulation Value Is Desired U.S. Patent Nos. 4238544 and 4339487

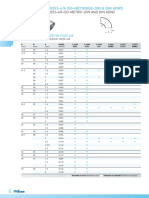

General Operating Clearances

Headroom*** Sideroom** Depth Into Room Type 2" track 3" track 2" track 3" track 2" & 3" track Standard Lift Manual12"R 1212-17" NA Opening Height +18" Standard Lift Manual15"R 1412-20" 1512-21" Standard Lift Motor Oper. 12"R 15-1912" NA 412" 512" Opening Height +66" 1 1 Standard Lift Motor Oper. 15"R 15-19 2" 18-23 2" High Lift Manual Door Height Opening Height Lift +30" +12" High Lift Motor Oper. 24" One Side Door Height Vertical Lift Manual 12"R 412" 512" Opening Height +18" +20" Vertical Lift Motor Oper. 12"R 24" One Side Low Headroom Manual* 6-1412" 6-1412" Opening Height +20" - 26" 6" 9" 1 Low Headroom Motor Oper.* 8 2-17" 812-17" Opening Height +66" Door Section and Lite Selection Door Width No. Panels Max. No.Windows Up to 9'2" 2 2 9'3" to 12'2" 3 3 12'3" to 16'2" 4 4 16'3" to 19'2" 5 5 19'3" to 24'2" 6 7 24'3" & up Call Factory Door Height and Section Selection Door Height No. Sections Up thru 8'1" 4 8'2" thru 10'1" 5 10'2" thru 12'1" 6 12'2" thru 14'1" 7 14'2" thru 16'1" 8 16'2" & up Call Factory

Center Line of Springs 2" track 3" track Opening Height +12" NA Opening Height +13" Opening Height +14" Opening Height +12" NA Opening Height +13" Opening Height +14" Opening Height Opening Height +Lift +612" +Lift +712" Double Door Height +13" Does Not Apply

Panel/Section Selection Guide

*Note: Rear mount torsion requirements shown on chart. See drawings for front mount torsion clearances. **Note: 8 sideroom required, one sidefor doors having chain hoist. 24" side room required, one side for doors having jackshaft operators. ***Note: Clear headroom is based on cable size so please contact factory for specific headroom for your door.

Track Selection Guide

Standard Lift

www.wayne-dalton.com/commercial

High Lift (break-away is standard, straight incline is available)

Roof Pitch (standard or high lift)

Vertical Lift

Low Headroom (rear mount torsion)

Low Headroom (front mount torsion)

SECTIONAL DOOR SYSTEMS

Note to specifiers: Words in parentheses indicate frequently specified and highly recommended options.

PART I GENERAL 1.01 Section Includes A. Sectional overhead doors [manually] [motor] operated with accessories and components. 1.02 Related Work A. Opening preparation, miscellaneous or structural steel work, access panels finish or field painting are in the scope of work of other trades and divisions of these specifications. 1.03 Reference Standards A. ANSI/DASMA 102 American National Standards Institute [A216.1] Specifications for sectional overhead doors published by Door & Access Systems Manufacturers Association, International in bulletin 102-1990. B. ASTM A123 Zinc [hot-dipped galvanized] coatings on iron and steel products. C. ASTM A216 Specifications for sectional overhead type doors. D. ASTM A229 Steel wire, oil-tempered for mechanical springs. E. ASTM A-653-94 Steel sheet, zinc-coated [galvanized] by the hot-dipped process, commercial quality. F. ASTM D1929 Ignition temperature test to determine flash and ignition temperature of foamed plastics. G. ASTM E84-91A Tunnel test for flame spread and smoke developed index. H. ASTM E330 Structural performance of exterior windows, curtain walls, and doors by uniform static air pressure difference. I. ASTM E413-87 Sound transmission class. Acoustical performance value = 23 J. ASTM E1332-90 Outdoor-indoor transmission class. Acoustical performance value = 22. K. ASTM E283 Air infiltration for = .07CFM/FT 2 at 15 MPH. 1.04 Quality Assurance A. Sectional overhead doors and all accessories and components required for complete and secure installations shall be manufactured as a system from one manufacturer. B. Sectional overhead doors shall be tested and labeled certifying compliance with ASTM D1929 and ASTM E84-91A standards. 1.05 Systems Description A. Sectional Overhead Door:Type: Thermospan 200-20 B. Mounting: Continuous angle mounting for [steel] [wood] jambs C. Operation: [manual push-up] [chain hoist] [motor] [motor with chain hoist] D. Material: Galvanized steel with polyester finish paint E. Insulation: Polyurethane 1.06 Submittals A. Shop Drawings: Clearly indicate the following: 1. Design and installation details to withstand standard windload. 2. All details required for complete operation and installation. 3. Hardware locations. 4. Type of metal and finish for door sections. 5. Finish for miscellaneous components and accessories. B. Product Data:Indicating manufacturers product data,and installation instructions. 1.07 Delivery, Handling, Storage A. Deliver products in manufacturers original containers, dry, undamaged, seals and labels intact. B. Store and protect products in accordance with manufacturers recommendations. 1.08 Warranty A. Provide manufacturers standard SEVENYEAR warranty against separation/degradation of the polyurethane foam from the steel skin of the panel under provisions of Section 01700. Standard manufacturers TENYEAR warranty against cracking, splitting or deterioration due to rust-through.TEN YEARS on insulation value.

T H E R M O S PA N 2 0 0 - 2 0

D. Counterbalance: 1. Springs shall be torsion type, low-stress, helical wound, oil-tempered spring wire to provide minimum [25,000 standard] [50,000] [100,000] cycles of use, on continuous steel [solid]. 2. Spring fittings and drums made of die cast, high strength aluminum. 3. Pre-formed galvanized steel aircraft cable shall provide a minimum of a 5:1 safety factor. 2.03 Operation A. Operation shall be [manual push-up] [chain hoist] [motor] [motor with chain hoist]. Manufacturer does not recommend chain hoists or jack shaft operators on the following track applications. 15" radius standard lift with roof pitch less than 2:12 Hi-lift less than 24" Hi-lift between 12" 23" with roof pitch less than 1:12 Low headroom track Special chain hoist assemblies (using a trolley rail) are available for the above track systems. 2.04 Locks A. Locks shall engage the right-hand vertical track and utilize [an interior side lock] [standard size rim cylinder]. 2.05 Weatherstripping A. Doors shall be equipped with top and side seals to seal against header, co-polymer joint seals between sections, and vinyl bulb shaped astragal provided on the bottom section. 2.06 Glazing A. Optional. 2.07 Windload A. Windload per DASMA 102-2003 and as required by local codes.

PART I I PRODUCTS 2.01 Manufacturer A. Wayne-Dalton or approved equal Thermospan 200-20 insulated sectional overhead doors of steel construction complete as specified in this section and as manufactured by Wayne-Dalton Corp.,Mt. Hope,Ohio. 2.02 Materials A. Door Sections: Shall be of steel/polyurethane/steel sandwich type construction with thermal break and calculated materials R- value of 17.50, in accordance with industry guidelines. 1. Exterior Skin:Structural quality,hot-dipped galvanized steel, 20 gauge white flush smooth. 2. Interior Skin:Structural quality,hot-dipped,galvanized steel, factory finished with a polyester primer and white finish coat. Interior skin shall have two 13/4" roll-formed integral struts sealed with polypropylene rib caps per section. 3. Ends of section shall be sealed with 18 or 16 [14 GA.] gauge hot-dipped galvanized steel full height end caps. 4. Insulation: Cavity shall be filled with foamed-in-place CFC free polyurethane core separated by a factory extruded thermal break. 5. Insulated sections shall be tested by an I.C.B.O. certified laboratory in accordance with ASTM E-8491A and shall achieve a Flamespread Index of 10 or less,and a Smoke Developed Index of 210 or less. 6. Insulation material shall be tested by an I.C.B.O. certified laboratory in accordance with ASTM D-1929 and shall achieve a minimum Flash Ignition temperature of 734 degrees F, and a minimum Self Ignition temperature of 950 degrees F. 7. Insulated sections shall be tested and meet all requirements of the UBC 17-5 corner burn. B. Track:Track design shall be [standard lift] [high lift] [vertical lift] [low headroom].Vertical mounting angles shall be hot-dipped galvanized.Track size shall be [2"] [3"].Vertical track shall be graduated to provide wedge type weathertight closing with continuous angle mounting for [steel] [wood] jambs, and shall be fully adjustable to seal door at jambs. Horizontal track shall be reinforced with continuous angle of adequate length and gauge to minimize deflection. Note: Horizontal track applies to standard lift,high lift, low headroom and follow-the-roof designs only. C. Hardware: Hinge and Roller Assembly: 1. Hinges and brackets shall be made from hot-dipped galvanized steel. 2. Track rollers shall be case-hardened inner steel races with 10-ball [2"] [3"] rollers. 3. All factory authorized attachments shall be made at locations indicated and reinforced with backup plates.

PART III EXECUTION 3.01 Installation A. General: 1. Install doors in accordance with manufacturers instructions and standards. Installation shall be by an authorized Wayne-Dalton representative. 2. Verify that existing conditions are ready to receive sectional overhead door work. 3. Beginning of sectional overhead door work means acceptance of existing conditions. B. Install door complete with necessary hardware,jamb and head mold strips, anchors, inserts, hangers, and equipment supports in accordance with final shop drawings, manufacturers instructions, and as specified herein. C. Fit, align and adjust sectional overhead door assemblies level and plumb for smooth operation. D. Upon completion of final installation, lubricate, test and adjust doors to operate easily, free from warp, twist or distortion and fitting for entire perimeter. Note:Architect may consider providing a schedule when more than one sectional overhead door or opening type is required. 3.02 Materials (See note above.)

Distributed By:

Specifications and technical information also available at www.arcat.com, SpecWizard, and Sweets.com.

www.wayne-dalton.com/commercial

For technical information, visit:

2007 Wayne-Dalton Corp. One Door Drive Mt. Hope, Ohio 44660 800-764-1457 Mt. Hope, OH Dalton, OH Trail, OH Pensacola, FL Portland, OR

Printed in U.S.A. Item #332537 Revised 9/2007

You might also like

- 6664 GeneratorProtection MD 20140911 WebDocument10 pages6664 GeneratorProtection MD 20140911 WebwolfsterzNo ratings yet

- Asus p5rd2 VMDocument0 pagesAsus p5rd2 VMwolfsterzNo ratings yet

- IBC Span Tables for Floors, Roofs and WallsDocument37 pagesIBC Span Tables for Floors, Roofs and WallsSharon KolbekNo ratings yet

- P45T-A v2Document76 pagesP45T-A v2wolfsterzNo ratings yet

- Sa vz. 58 manualDocument43 pagesSa vz. 58 manualMonteiro Antonio100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Corrosion Raccords Proform 2018 PDFDocument34 pagesCorrosion Raccords Proform 2018 PDFDiegoNo ratings yet

- Aqua Shield 4Document2 pagesAqua Shield 4aneeshp_4No ratings yet

- FP03Document718 pagesFP03John Tejada IIINo ratings yet

- Line Designation TableDocument2 pagesLine Designation TableKarthikNo ratings yet

- Selection of NodularizersDocument2 pagesSelection of Nodularizersarnaldorcr8646100% (2)

- Chapter 2 - Water TransportDocument18 pagesChapter 2 - Water Transportsheil.cogayNo ratings yet

- Astm C 617Document6 pagesAstm C 617ArunselvanNo ratings yet

- Pengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMDocument15 pagesPengantar Dfki Pipa: Ediman Hotman Ir. MMBAT., DPL - SMMulYadi100% (1)

- Tech Specs BrickDocument53 pagesTech Specs BrickCumhur MalgilNo ratings yet

- Summary of Specifications: 1.1 Schedule of Exterior FinishesDocument2 pagesSummary of Specifications: 1.1 Schedule of Exterior FinishesanaNo ratings yet

- Technical Note on BugholesDocument2 pagesTechnical Note on BugholescesarNo ratings yet

- Espol 38.00 Revised 07032016Document2 pagesEspol 38.00 Revised 07032016Vinay YadavNo ratings yet

- TYPICAL ROAD SECTION-ModelDocument1 pageTYPICAL ROAD SECTION-ModelEmmanuel Simangon AgudaNo ratings yet

- Dilli Haat JanakpuriDocument19 pagesDilli Haat JanakpuriApeksha Sethi81% (21)

- Sample Test Certificate en 10204Document1 pageSample Test Certificate en 10204api-3703379100% (2)

- Acknowledging Support for Inplant TrainingDocument36 pagesAcknowledging Support for Inplant Trainingyogesh vNo ratings yet

- Plastering Techniques and MethodsDocument6 pagesPlastering Techniques and MethodsYazhisai SelviNo ratings yet

- 22A Wright RD Builder's ReportDocument13 pages22A Wright RD Builder's ReportAriel LevinNo ratings yet

- Manual On Pavement Design PDFDocument31 pagesManual On Pavement Design PDFAnil Kumsr T B100% (3)

- 04 MASONRY HandoutDocument9 pages04 MASONRY HandoutZabeth villalonNo ratings yet

- Chap 1 - Injection MouldingDocument31 pagesChap 1 - Injection MouldingVikas MishraNo ratings yet

- Valve Repair Kits GuideDocument16 pagesValve Repair Kits GuideOswaldo LeónNo ratings yet

- Wall Panel SystemsDocument95 pagesWall Panel SystemsAthrun Pure54% (13)

- Ps BallDocument5 pagesPs BallChristopher LloydNo ratings yet

- 2022 E-Z Line Product Catalog PDFDocument35 pages2022 E-Z Line Product Catalog PDFKyle Shepard100% (3)

- Design of RC StructuresDocument1 pageDesign of RC Structureskamalnitrr0% (3)

- tHORO STRUCTURITE PRIMER - v3Document2 pagestHORO STRUCTURITE PRIMER - v3Ankita Baban GavadeNo ratings yet

- Data Sheet Lockshield Valve Type RLV - With Facility For Connection To Drain TapDocument4 pagesData Sheet Lockshield Valve Type RLV - With Facility For Connection To Drain TapZeljko RisticNo ratings yet

- ABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersDocument72 pagesABS Guide For Application of Higher-Strength Hull Structural Thick Steel Plates in Container Carriersamin_corporationNo ratings yet

- +GF+ Harvel PVC - CPVC-1Document174 pages+GF+ Harvel PVC - CPVC-1Mauricio CarestiaNo ratings yet