Professional Documents

Culture Documents

Bunker Ing Safety Checklist

Uploaded by

metinarukOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bunker Ing Safety Checklist

Uploaded by

metinarukCopyright:

Available Formats

BUNKERING OPERATIONS

25.4.3

Bunkering Safety Check-List

Port Ship Master Date Barge Master

1. Bunkers to be Transferred

Grade Fuel Oil Gas Oil/Diesel Lub. Oil in Bulk Tonnes Volume at Loading Temp Loading Temperature Maximum Maximum Line Transfer Rate Pressure

2. Bunker Tanks to be Loaded

Tank No. Volume of Tank @ ____% Vol. of Oil in Tank before Loading Available Volume Volume to be Loaded Total Volumes Grade

Grade

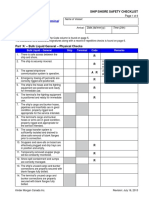

3. Checks by Barge Prior to Berthing

Bunkering 1. The barge has obtained the necessary permissions to go alongside receiving ship. 2. The fenders have been checked, are in good order and there is no possibility of metal to metal contact. 3. Adequate electrical insulating means are in place in the barge-to-ship connection. (34) 4. All bunker hoses are in good condition and are appropriate for the service intended. (7) R Ship Barge Code Remarks

ICS/OCIMF/IAPH 2006

359

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

4. Checks Prior to Transfer

Bunkering 5. The barge is securely moored. (2) 6. There is a safe means of access between the ship and barge. (1) 7. Effective communications have been established between Responsible Officers. (3) A Ship Barge Code R R Remarks

(VHF/UHF Ch ..........).

Primary System: Backup System: Emergency Stop Signal:

8. There is an effective watch on board the barge and on the ship receiving bunkers. (22) 9. Fire hoses and fire-fighting equipment on board the barge and ship are ready for immediate use. (5) 10. All scuppers are effectively plugged. Temporarily removed scupper plugs will be monitored at all times. Drip trays are in position on decks around connections and bunker tank vents. (10) (11) 11. Initial line up has been checked and unused bunker connections are blanked and fully bolted. (13) 12. The transfer hose is properly rigged and fully bolted and secured to manifolds on ship and barge. (7) 13. Overboard valves connected to the cargo system, engine room bilges and bunker lines are closed and sealed. (16) 14. All cargo and bunker tank hatch lids are closed. (15) 15. Bunker tank contents will be monitored at regular intervals. 16. There is a supply of oil spill clean-up material readily available for immediate use. 17. The main radio transmitter aerials are earthed and radars are switched off. (42) 18. Fixed VHF/UHF transceivers and AIS equipment are on the correct power mode or switched off. (40) 19. Smoking rooms have been identified and smoking restrictions are being observed. (36) A R

Nominated Smoking Rooms Tanker: Barge:

at intervals not exceeding . minutes

360

ICS/OCIMF/IAPH 2006

BUNKERING OPERATIONS

Bunkering 20. Naked light regulations are being observed. (37) 21. All external doors and ports in the accommodation are closed. (17) 22. Material Safety Data Sheets (MSDS) for the bunker transfer have been exchanged where requested. (26) 23. The hazards associated with toxic substances in the bunkers being handled have been identified and understood. (27)

Ship

Barge

Code R

Remarks

H2S Content ..................... Benzene Content .............

ICS/OCIMF/IAPH 2006

361

INTERNATIONAL SAFETY GUIDE FOR OIL TANKERS AND TERMINALS

DECLARATION We have checked, where appropriate jointly, the items of the Check-List in accordance with the instructions and have satisfied ourselves that the entries we have made are correct to the best of our knowledge. We have also made arrangements to carry out repetitive checks as necessary and agreed that those items coded R in the Check-List should be re-checked at intervals not exceeding _____ hours. If, to our knowledge, the status of any item changes, we will immediately inform the other party.

For Ship Name Rank Signature Date Time Name Rank Signature Date Time

For Barge

Record of repetitive checks:

Date:

Time:

Initials for Ship:

Initials for Barge:

362

ICS/OCIMF/IAPH 2006

You might also like

- I5 Bunkering Safety Checklist InteractiveDocument4 pagesI5 Bunkering Safety Checklist InteractiveshamratNo ratings yet

- ECL6 Bunkering Safety ChecklistDocument3 pagesECL6 Bunkering Safety Checklistyvonne22No ratings yet

- Ship Shore Safety Check List For Tankers PDF FreeDocument6 pagesShip Shore Safety Check List For Tankers PDF FreeAZWAR SIDINo ratings yet

- Ship-Shore Safety Check List For TankersDocument6 pagesShip-Shore Safety Check List For TankersMedha Jog Katdare67% (3)

- Bunkering Safety ChecklistDocument3 pagesBunkering Safety ChecklisttomiNo ratings yet

- Bunkering Safety Checklist and GuidelinesDocument6 pagesBunkering Safety Checklist and GuidelinesvaaliNo ratings yet

- Ship Shore Safety Checklist-TankersDocument6 pagesShip Shore Safety Checklist-TankersJoe Smith100% (1)

- SHIP SHORE SAFETY CHECKLISTDocument8 pagesSHIP SHORE SAFETY CHECKLISTTayfur KarabelaNo ratings yet

- Chemical cargo safety precautionsDocument6 pagesChemical cargo safety precautionsHoàng Anh PhạmNo ratings yet

- Hanafi Assasment VDocument6 pagesHanafi Assasment VGhaniyatul Ulum JemberNo ratings yet

- Regulation 12:-Ozone Depleting Substances (ODS) : A. Verify VOC Return System Certification and BDocument47 pagesRegulation 12:-Ozone Depleting Substances (ODS) : A. Verify VOC Return System Certification and BParesh Redkar100% (1)

- Port State Control in The USA ChecklistDocument3 pagesPort State Control in The USA Checklistrabi4457No ratings yet

- FN 3Document75 pagesFN 3tiyiti1926No ratings yet

- Capt Deepak Kapoor Oral Questions Mar 18 To Feb 19 PDFDocument62 pagesCapt Deepak Kapoor Oral Questions Mar 18 To Feb 19 PDFManoj Kumar Kalamegam100% (1)

- Safe stay at terminal checklist for oil tankersDocument22 pagesSafe stay at terminal checklist for oil tankersMohd AkifNo ratings yet

- A. Checklist Cargo Ops OKDocument44 pagesA. Checklist Cargo Ops OKIhwan Asrul100% (1)

- Jan 2012 To Aug 2014 Ques and Ans SafetyDocument224 pagesJan 2012 To Aug 2014 Ques and Ans SafetyAnonymous E33XbE100% (2)

- Seam 4 Cargo Handling Stowage DG ILODocument55 pagesSeam 4 Cargo Handling Stowage DG ILORay Ray100% (2)

- Ship Shore Safety Check ListDocument6 pagesShip Shore Safety Check ListMaktrukNo ratings yet

- Grab Hopper DredgerDocument40 pagesGrab Hopper DredgerPeter John Packiaraj100% (1)

- MGN 224 (F)Document4 pagesMGN 224 (F)aakash9090No ratings yet

- E23a ISGOTT Bunker ChklistDocument4 pagesE23a ISGOTT Bunker Chklistvic.barca2012100% (1)

- 14.0-Ship Shore Safety Check List and GuidelinesDocument15 pages14.0-Ship Shore Safety Check List and GuidelinesAZWAR SIDINo ratings yet

- Checklist - Pre-Transfer of BunkersDocument1 pageChecklist - Pre-Transfer of BunkersednsmnNo ratings yet

- SQA Stability Section B AnswersDocument50 pagesSQA Stability Section B AnswersMandy Conquers93% (14)

- Q & A GekDocument16 pagesQ & A GekLagon AinNo ratings yet

- Pc23 06 MPA Singapore Bunkering Checklist 2023-03-22Document7 pagesPc23 06 MPA Singapore Bunkering Checklist 2023-03-22kyaw zin tun TunNo ratings yet

- P01 2017 OilPolPrev FormDocument4 pagesP01 2017 OilPolPrev FormMade PutraNo ratings yet

- Understanding SolasDocument22 pagesUnderstanding Solas21amrikamaharajNo ratings yet

- Pemeriksaan Kecelakaan Kapal Imdg & MarpolDocument35 pagesPemeriksaan Kecelakaan Kapal Imdg & MarpolVino Telo100% (1)

- Bunker checklist 40Document3 pagesBunker checklist 40Roshan PandeyNo ratings yet

- Enc Encoded d6nefXfqEKmR8bB17jGY8V4Wzma9HgYKpN6Uoefmk2k49oCluDsDocument5 pagesEnc Encoded d6nefXfqEKmR8bB17jGY8V4Wzma9HgYKpN6Uoefmk2k49oCluDsParas ThakurNo ratings yet

- Guide passenger ship tendersDocument13 pagesGuide passenger ship tendersKTVNo ratings yet

- ReviewerDocument4 pagesReviewerALEX ANTHONY ULEPNo ratings yet

- Capt AnamDocument29 pagesCapt AnamLynton MenezesNo ratings yet

- Bunker ProcedureDocument24 pagesBunker ProcedureDimas Bangkit100% (2)

- Fire FightingDocument30 pagesFire FightingkisiaNo ratings yet

- Questions On Marine OperationDocument10 pagesQuestions On Marine OperationMahdi Bordbar100% (1)

- B118-14 - Trans Mountain Response To City Burnaby IR No.1.22.03e-Attachment1 - A3Y2F9Document6 pagesB118-14 - Trans Mountain Response To City Burnaby IR No.1.22.03e-Attachment1 - A3Y2F9ye100% (1)

- Test I: Identification and Enumeration For The Following QuestionsDocument4 pagesTest I: Identification and Enumeration For The Following QuestionsRuleen Y. BerezoNo ratings yet

- Amsa-229 2023Document36 pagesAmsa-229 2023pattuabinNo ratings yet

- Dry Docking PDFDocument3 pagesDry Docking PDFDeepakNo ratings yet

- Vetting Inspectors.Document5 pagesVetting Inspectors.Pavel ViktorNo ratings yet

- Cargo Handling and Stowage RegulationsDocument23 pagesCargo Handling and Stowage RegulationsVibhav KumarNo ratings yet

- The Ship/Shore Safety Check-List: Al Shaheen TerminalDocument6 pagesThe Ship/Shore Safety Check-List: Al Shaheen TerminalSunil TauroNo ratings yet

- Ship To Ship (STS) Operations Plan:: ArrivalDocument3 pagesShip To Ship (STS) Operations Plan:: ArrivalBehendu PereraNo ratings yet

- SBO 11 Set QuestionsDocument11 pagesSBO 11 Set QuestionsMamunNo ratings yet

- Q1.a Describe The Legal Status and Purpose of The IMDG CodeDocument4 pagesQ1.a Describe The Legal Status and Purpose of The IMDG CodeSujeet sharmaNo ratings yet

- Notice To Shipmasters Loading Coal CargoesDocument18 pagesNotice To Shipmasters Loading Coal CargoesDujeKnezevic67% (3)

- Ship SafetyDocument36 pagesShip SafetyQOBITNo ratings yet

- Tank Inspection HandbookDocument148 pagesTank Inspection HandbookThanapong UsupanNo ratings yet

- Meo Oral AnsDocument17 pagesMeo Oral AnsKapil Verma100% (4)

- Performance of Engine Room Watch Keeping DutiesDocument17 pagesPerformance of Engine Room Watch Keeping DutiesMike Bunoan Dumangeng83% (6)

- Oil Record Book InstructionsDocument3 pagesOil Record Book InstructionsRutvikNo ratings yet

- Contractor Safety-OMR 2017 PDFDocument13 pagesContractor Safety-OMR 2017 PDFvaibhavharigarh100% (1)

- Safety of Ships in YardDocument63 pagesSafety of Ships in YardPetar Aleksandrov100% (1)

- Scupper PlugDocument21 pagesScupper PlugMcrislb100% (3)

- Survey ChecklistDocument17 pagesSurvey ChecklistSamuel Blandes Rwegasira100% (1)

- Commercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysFrom EverandCommercial Ship Surveying: On/Off Hire Condition Surveys and Bunker SurveysRating: 4.5 out of 5 stars4.5/5 (6)

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Instrument SymbolşsDocument1 pageInstrument SymbolşsmetinarukNo ratings yet

- SS 09Document3 pagesSS 09Ajaykumar TiwariNo ratings yet

- CHEMICAL ENGINEERING OBJECTIVE TYPE QUESTIONSDocument15 pagesCHEMICAL ENGINEERING OBJECTIVE TYPE QUESTIONSmetinaruk0% (1)

- Bechtel - PPT (1) - Foundation Fieldbus Technology PDFDocument31 pagesBechtel - PPT (1) - Foundation Fieldbus Technology PDFmetinarukNo ratings yet

- Process control modes and tuning methodsDocument23 pagesProcess control modes and tuning methodsMuhammad Ibad AlamNo ratings yet

- Lessons Learned From Texas City Refinery ExplosionDocument20 pagesLessons Learned From Texas City Refinery ExplosionAmal A.No ratings yet

- Annubar Installation Straight Run Requirements PDFDocument1 pageAnnubar Installation Straight Run Requirements PDFmetinarukNo ratings yet

- Specification SheetDocument108 pagesSpecification SheetGunaseelanvr67% (3)

- RP 7401Document26 pagesRP 7401metinarukNo ratings yet

- All AS F331 QuestionsDocument116 pagesAll AS F331 QuestionsSalvador__DaliNo ratings yet

- CPR0517 30Document16 pagesCPR0517 30Jamie MiddletonNo ratings yet

- Measure Volume Irregular ObjectsDocument4 pagesMeasure Volume Irregular ObjectsCheng NieNo ratings yet

- Midstream 101: Oil and Gas Processing, Transportation, and Storage ExplainedDocument3 pagesMidstream 101: Oil and Gas Processing, Transportation, and Storage ExplainedFaizal IrsyadNo ratings yet

- Battery and ChargerDocument72 pagesBattery and ChargerlrpatraNo ratings yet

- Presentation ON Fired HeatersDocument98 pagesPresentation ON Fired HeatersKrishanu Saha100% (1)

- Coursework: Name: Student Number: DateDocument7 pagesCoursework: Name: Student Number: DateACHIENG REBECCANo ratings yet

- Deepwater Advanced 1 PDFDocument8 pagesDeepwater Advanced 1 PDFYadiiraaSagreeroNo ratings yet

- Talos PDFDocument9 pagesTalos PDFAdmin KCEngineerslimitedNo ratings yet

- 06-2 Data Sheet Oil FilterDocument2 pages06-2 Data Sheet Oil FilterAnonymous 9WNqHZNo ratings yet

- Shoreline Cleanup Methods GuideDocument3 pagesShoreline Cleanup Methods GuideTdukeresolveNo ratings yet

- The Carburetor Works On BernoulliDocument2 pagesThe Carburetor Works On BernoulliManoj ManujNo ratings yet

- Project Feasibility ReportDocument8 pagesProject Feasibility ReportKarthik SrinivasNo ratings yet

- Fire Safety Training Course OutlineDocument53 pagesFire Safety Training Course OutlineRichard R M ThodéNo ratings yet

- SJ 9 PDFDocument52 pagesSJ 9 PDFNicolas X FloresNo ratings yet

- PRODUCTION OF PROPYLENE FROM PROPANE VIA DEHYDROGENATIONDocument4 pagesPRODUCTION OF PROPYLENE FROM PROPANE VIA DEHYDROGENATIONBihina HamanNo ratings yet

- Astm D7152 - 2011Document9 pagesAstm D7152 - 2011Everardo Bracamontes DíazNo ratings yet

- Define fuel and classify based on origin and stateDocument22 pagesDefine fuel and classify based on origin and stateGautam GambhirNo ratings yet

- This File Is A Part of The Rhodium Site ArchiveDocument7 pagesThis File Is A Part of The Rhodium Site Archiveimharsh1992No ratings yet

- Field Operator: Diploma in Mechanical EngineeringDocument5 pagesField Operator: Diploma in Mechanical Engineeringjohn MNo ratings yet

- MFL67783505 - Eng-15.8 PDFDocument30 pagesMFL67783505 - Eng-15.8 PDFcooldamageNo ratings yet

- CNG SMDocument10 pagesCNG SMSovan MangarajNo ratings yet

- Preparation of Zeolite Y Catalyst for Petroleum CrackingDocument7 pagesPreparation of Zeolite Y Catalyst for Petroleum CrackingMustafa Abbas MustafaNo ratings yet

- Part 1:choose The World Whose Underlined Part Is Pronounced Differently From That of The RestDocument3 pagesPart 1:choose The World Whose Underlined Part Is Pronounced Differently From That of The RestTuan Nguyen ManhNo ratings yet

- Cessna ChecklistDocument3 pagesCessna ChecklistbnolascoNo ratings yet

- The Solar PV Landscape in IndiaDocument20 pagesThe Solar PV Landscape in IndiaAbhinav MishraNo ratings yet

- UniSim Design Clean Fuels PPKG User GuideDocument54 pagesUniSim Design Clean Fuels PPKG User Guideapi-3750488No ratings yet

- Vogel Zang Stove Kit BK 150 eDocument16 pagesVogel Zang Stove Kit BK 150 eLovely GreenNo ratings yet

- Acid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilDocument3 pagesAcid-Catalyzed Preparation of Biodiesel From Waste Vegetable OilRommelGalvanNo ratings yet

- Civil Engineer Job at MEDGULF Construction CompanyDocument2 pagesCivil Engineer Job at MEDGULF Construction CompanysyedAtifNo ratings yet