Professional Documents

Culture Documents

Radioss Crash Seat Presentation v02

Uploaded by

izaafiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radioss Crash Seat Presentation v02

Uploaded by

izaafiCopyright:

Available Formats

Altair Engineering, Inc.

Innovation Intelligence

RADIOSS V4

Seat Modeling For Crash Application V02

Abstract

Target :

The target of this document is to review in detail all necessary RADIOSS options needed to set in the

model in order to perform a seat model analysis. In this example, a front impact sled test is modeled.

Summary :

The different chapters are :

Seat meshing

Model assembling

Materials and properties

Connections

Dummy setting

Loadcase

Engine file

Result analysis

Page

03

07

09

15

16

22

25

26

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Seat Mesh :

The seat is meshed with 4 nodes and 3 nodes thin shell elements. The feet of the seat are modeled with

beam elements. The beams are connected to the shell elements with common nodes. These elements

are set into parts which are linked to isotropic material and property.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PART/1/Seat plate

/PART/1/Seat plate

1

1

1

1

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/SHELL/1

/SHELL/1

#

Id

N1

N2

N3

N4

Thick

#

Id

N1

N2

N3

N4

Thick

1

48

1693

1692

1696

0

1

48

1693

1692

1696

0

2

1181

1694

1692

1693

0

2

1181

1694

1692

1693

0

3

1447

1695

1692

1694

0

3

1447

1695

1692

1694

0

4

788

1696

1692

1695

0

4

788

1696

1692

1695

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PART/3/Feet

/PART/3/Feet

3

3

3

3

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/BEAM/3

/BEAM/3

#

Id

N1

N2

N3

#

Id

N1

N2

N3

12371

531

4

96

12371

531

4

96

12372

2

529

55

12372

2

529

55

12373

3

530

71

12373

3

530

71

12374

1

528

92

12374

1

528

92

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Seat Mesh :

The material for the shell elements is an elasto-plastic one with Johnson-Cooks formulation and damage

(maximum stress). The shell formulation, thickness, number of integration points are defined in the shell

property cards.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/MAT/PLAS_JOHNS/1/STEEL

/MAT/PLAS_JOHNS/1/STEEL

#

Init. dens.

Ref. dens.

#

Init. dens.

Ref. dens.

7.9e-009

0

7.9e-009

0

#

E

Nu

#

E

Nu

210000

0.3

210000

0.3

#

a

b

n

Eps_max

sigma_max

#

a

b

n

Eps_max

sigma_max

200

450

0.5

1e+030

425

200

450

0.5

1e+030

425

#

c

Eps_0

Icc Fsmooth

FCUT

#

c

Eps_0

Icc Fsmooth

FCUT

0

0

0

0

0

0

0

0

0

0

#

m

T_melt

rhoCp

T_i

#

m

T_melt

rhoCp

T_i

0

0

0

0

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SHELL/1/Shell

/PROP/SHELL/1/Shell

# Ishell Ismstr

# Ishell Ismstr

24

0

24

0

#

hm

hf

hr

dm

dn

#

hm

hf

hr

dm

dn

0

0

0

0

0

0

0

0

0

0

#

N Istrain

Thick

Ashear

Ithick

Iplas

#

N Istrain

Thick

Ashear

Ithick

Iplas

5

0

1.5

0

0

0

5

0

1.5

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Seat Mesh :

The material for the feet is the same as the previous one. The beam area, inertias and released DOF

are defined in the beam property cards.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/MAT/PLAS_JOHNS/1/STEEL

/MAT/PLAS_JOHNS/1/STEEL

#

Init. dens.

Ref. dens.

#

Init. dens.

Ref. dens.

7.9e-009

0

7.9e-009

0

#

E

Nu

#

E

Nu

210000

0.3

210000

0.3

#

a

b

n

Eps_max

sigma_max

#

a

b

n

Eps_max

sigma_max

200

450

0.5

1e+030

425

200

450

0.5

1e+030

425

#

c

Eps_0

Icc Fsmooth

FCUT

#

c

Eps_0

Icc Fsmooth

FCUT

0

0

0

0

0

0

0

0

0

0

#

m

T_melt

rhoCp

T_i

#

m

T_melt

rhoCp

T_i

0

0

0

0

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/BEAM/3/BEAM

/PROP/BEAM/3/BEAM

#

Ismstr

#

Ismstr

0

0

#

dm

df

#

dm

df

0

0

0

0

#

Area

Iyy

Izz

Ixx

#

Area

Iyy

Izz

Ixx

130

15000

15000

30000

130

15000

15000

30000

#

Rot Ishear

#

Rot Ishear

000 000

0

000 000

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Seat Mesh :

The backseat structure is linked to the seat itself with two rigid bodies.

The rigid bodies are defined with a set of slave nodes. The parameters are the default ones. The rigid

body is set to the time history.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/RBODY/1/Recliner

/RBODY/1/Recliner

#

RBID

ISENS

NSKEW ISPHER

MASS Gnod_id

IKREM

ICOG Surf_id

#

RBID

ISENS

NSKEW ISPHER

MASS Gnod_id

IKREM

ICOG Surf_id

12109

0

0

0

0

1

0

0

0

12109

0

0

0

0

1

0

0

0

#

Jxx

Jyy

Jzz

#

Jxx

Jyy

Jzz

0

0

0

0

0

0

#

Jxy

Jyz

Jxz

#

Jxy

Jyz

Jxz

0

0

0

0

0

0

/GRNOD/NODE/1/RBODY_group_369_of_NODE

/GRNOD/NODE/1/RBODY_group_369_of_NODE

1

110

211

514

532

598

880

887

1608

1619

1

110

211

514

532

598

880

887

1608

1619

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/TH/RBODY/2/Rigid body

/TH/RBODY/2/Rigid body

#

var1

var2

var3

var4

var5

var6

var7

var8

var9

var10

#

var1

var2

var3

var4

var5

var6

var7

var8

var9

var10

DEF

DEF

#

Obj1

Obj2

Obj3

Obj4

Obj5

Obj6

Obj7

Obj8

Obj9

Obj10

#

Obj1

Obj2

Obj3

Obj4

Obj5

Obj6

Obj7

Obj8

Obj9

Obj10

1

2

1

2

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Model assembling :

On the seat structure, the floor, the seat belt anchorage points and the foam blocks are added.

Tree hierarchy

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Model assembling :

A self impact interface is defined with all the shell element parts. This interface is defined with friction and

variable gap (gap defined according the part thickness).

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/INTER/TYPE7/300003/All self impact

/INTER/TYPE7/300003/All self impact

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

300023 300022

0

1

0

0

0

300023 300022

0

1

0

0

0

#

STFAC

FRIC

GAP

Tstart

Tstop

#

STFAC

FRIC

GAP

Tstart

Tstop

0

0.2

0

0

0

0

0.2

0

0

0

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

000

0

0

0

0

000

0

0

0

0

# Ifric Ifiltr

Xfreq

Iform

# Ifric Ifiltr

Xfreq

Iform

0

0

0

0

0

0

0

0

/GRNOD/SURF/300023/INTER_group_300023_of_SURF

/GRNOD/SURF/300023/INTER_group_300023_of_SURF

300022

300022

/SURF/PART/300022/INTER_group_300022_of_PART

/SURF/PART/300022/INTER_group_300022_of_PART

1

2

4

5 100001 300003 300004

1

2

4

5 100001 300003 300004

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Materials and properties :

The seat foam is defined with isotropic solid elements, HSEPH formulation and linked to a visco-elastic

material. A curve (stress vs strain) defines the material behavior.

Stress

Stress

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/MAT/FOAM_PLAS/300001/Foam

/MAT/FOAM_PLAS/300001/Foam

1.2

#

Init. dens.

Ref. dens.

1.2

#

Init. dens.

Ref. dens.

1e-009

0

1

1e-009

0

1

#

E

Ka

If

#

E

Ka

If

15

0 300001

0.8

15

0 300001

0.8

#

P0

Phi

Gamma_0

#

P0

Phi

Gamma_0

0.6

0

0

0

0.6

0

0

0

#

A

B

C

#

A

B

C

0.4

0

0

0

0.4

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

0.2

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

0.2

/FUNCT/300001/Foam

/FUNCT/300001/Foam

#

X

Y

0

#

X

Y

0

-0.75

1.1

-1

-0.5

0

0.5

-0.75

1.1

-1

-0.5

0

0.5

Strain

0

0

Strain

0

0

1

0.017

1

0.017

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SOLID/300001/Foam

/PROP/SOLID/300001/Foam

# Isolid Ismstr

Iplas

Icpre

Icstr

dn

# Isolid Ismstr

Iplas

Icpre

Icstr

dn

104

0

0

0

0

0

104

0

0

0

0

0

#

q_a

q_b

h

#

q_a

q_b

h

0

0

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

Model building

Materials and properties :

The seat cushions are modeled with orthotropic thick shell elements and linked to the fabric material.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/MAT/FABRI/300002/Fabric

/MAT/FABRI/300002/Fabric

#

Init. dens.

Ref. dens.

#

Init. dens.

Ref. dens.

2e-009

0

2e-009

0

#

E_11

E_22

Nu_12

#

E_11

E_22

Nu_12

2000

2000

0.2

2000

2000

0.2

#

G_12

G_23

G_31

#

G_12

G_23

G_31

500

500

500

500

500

500

#

Re

#

Re

0.001

0.001

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SH_ORTH/300002/Fabric

/PROP/SH_ORTH/300002/Fabric

# Ishell Ismstr

# Ishell Ismstr

24

0

24

0

#

hm

hf

hr

dm

dn

#

hm

hf

hr

dm

dn

0

0

0

0

0

0

0

0

0

0

#

N Istrain

Thick

Ashear

Ithick

Iplas

#

N Istrain

Thick

Ashear

Ithick

Iplas

1

0

0.7

0

0

0

1

0

0.7

0

0

0

#

Vx

Vy

Vz

Phi

#

Vx

Vy

Vz

Phi

1

1

1

0

1

1

1

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

10

Model building

Materials and properties :

The seat belt will be modeled both with 1D elements and shell elements.

The shell elements will be set in front of the dummy in order to manage

correctly the contact and the forces. This 2D meshed seatbelt is linked to

the car (floor) using 1D elements :

Slip-ring

Load limiter

truss (bar)

Load limiter (spring)

Pretentioner (spring)

Slip-ring (pulley type spring)

Pretentioner

Truss

The stiffness of the truss elements used in this model is defined with an

elasto-plastic material (same as the beam elements) and an area set in

the property.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/TRUSS/200001/Wire

/PROP/TRUSS/200001/Wire

#

Area

Gap

#

Area

Gap

50

0

50

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

11

Model building

Materials and properties :

The load limiter is defined with a spring element and a spring type property :

Load limiter

20000

15000

Force

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PART/200003/Limiter

/PART/200003/Limiter

200003

0 200005

200003

0 200005

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/SPRING/200003

/SPRING/200003

#

Id

N1

N2

N3

#

Id

N1

N2

N3

200005 200009 200010

0

200005 200009 200010

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SPRING/200003/Load limiter

/PROP/SPRING/200003/Load limiter

#

Mass

Isensor Isflag

Ileng

#

Mass

Isensor Isflag

Ileng

1e-005

0

0

0

1e-005

0

0

0

#

K

C

A

B

D

#

K

C

A

B

D

10000

0

0

0

0

10000

0

0

0

0

#

N1

H

N2

N3

delta_min

delta_max

#

N1

H

N2

N3

delta_min

delta_max

200001

2

0

0

0

0

200001

2

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/FUNCT/200001/Load limitor

/FUNCT/200001/Load limitor

#

X

Y

#

X

Y

-100

0

-100

0

0

0

0

0

0.6

6000

0.6

6000

100

6000

100

6000

101

16000

101

16000

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10--#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---

10000

5000

0

-100

-50

0

50

Displacement

100

Copyright 2006 Altair Engineering, Inc. All rights reserved.

12

Model building

Materials and properties :

The pretentioner is defined with a spring element and a pretentioner type

property which is activated by a sensor.

Pretentioner

10000

5000

Force

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SPR_PRE/200004/Pretensioner

/PROP/SPR_PRE/200004/Pretensioner

#

spring-mass

Sensor

#

spring-mass

Sensor

1e-005

200001

1e-005

200001

#

Stif0

F1

D1

E1

Stif1

#

Stif0

F1

D1

E1

Stif1

10000

0

0

0

0

10000

0

0

0

0

# Ifunc1 Ifunc2

# Ifunc1 Ifunc2

200002

0

200002

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/SENSOR/TIME/200001/TIME Sensor

/SENSOR/TIME/200001/TIME Sensor

#

Tdelay

#

Tdelay

0.01

0.01

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/FUNCT/200002/Pretensionner

/FUNCT/200002/Pretensionner

#

X

Y

#

X

Y

-121

-10000

-121

-10000

-120

0

-120

0

-50

2500

-50

2500

0

3000

0

3000

1

10000

1

10000

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

-150

0

-100

-50

0

-5000

-10000

Displacement

Copyright 2006 Altair Engineering, Inc. All rights reserved.

13

Model building

Materials and properties :

The slip-ring is defined with a 3 nodes spring element and a pulley type

property.

Slip-ring

The spring will slide around the second node of the spring.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PART/200002/Belt pulley

/PART/200002/Belt pulley

200002

0 200005

200002

0 200005

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/SPRING/200002

/SPRING/200002

#

Id

N1

N2

N3

#

Id

N1

N2

N3

200003 200006 200008 200004

200003 200006 200008 200004

200004 200007 100568 200010

200004 200007 100568 200010

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SPR_PUL/200002/Belt pulley

/PROP/SPR_PUL/200002/Belt pulley

#

Mass

Isensor Isflag

Ileng

Fric

#

Mass

Isensor Isflag

Ileng

Fric

1e-005

0

0

0

0

1e-005

0

0

0

0

#

K

C

A

B

D

#

K

C

A

B

D

10000

0

0

0

0

10000

0

0

0

0

#

N1

H

N2

delta_min

delta_max

#

N1

H

N2

delta_min

delta_max

0

0

0

0

0

0

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

14

Model building

Connections:

Rigid body

The seat feet and the seat belts are merged (red

arrows) to the floor and included in the floor rigid

body.

The cushions are connected to the seat

structure with tied interfaces in order to model

the (strong) glue.

/INTER/TYPE2/300002/Seat - Cushion

/INTER/TYPE2/300002/Seat - Cushion

#Slav_id Surf_id

Spotflag

Level Isearch

Dsearch

#Slav_id Surf_id

Spotflag

Level Isearch

Dsearch

300010 300011

0

0

0

0

0

300010 300011

0

0

0

0

0

/GRNOD/NODE/300010/INTER_group_300010_of_NODE

/GRNOD/NODE/300010/INTER_group_300010_of_NODE

300001 300002 300003 300004 300005 300006 300007 300008 300009 300010

300001 300002 300003 300004 300005 300006 300007 300008 300009 300010

/SURF/SURF/300011/INTER_group_300011_of_SURF

/SURF/SURF/300011/INTER_group_300011_of_SURF

300012 300014

300012 300014

/SURF/GRSHEL/300012/INTER_group_300012_of_GRSHEL

/SURF/GRSHEL/300012/INTER_group_300012_of_GRSHEL

300013

300013

/GRSHEL/SHEL/300013/INTER_group_300013_of_SHELL4N

/GRSHEL/SHEL/300013/INTER_group_300013_of_SHELL4N

181

182

183

184

185

186

187

188

189

190

181

182

183

184

185

186

187

188

189

190

/SURF/PART/300014/INTER_group_300014_of_PART

/SURF/PART/300014/INTER_group_300014_of_PART

1

2

1

2

Tied interface

Copyright 2006 Altair Engineering, Inc. All rights reserved.

15

Model building

Dummy setting :

The dummy is added in the model using the safety position tools. When the

different parts of the dummy model is moved, the joint stiffnesses have to be also

updated.

The dummy is set on its right position even if there is intersection with the seat

cushion. This intersection is removed with the seat deformer of HyperCrash or the

morphing tool of HyperMesh.

Copyright 2006 Altair Engineering, Inc. All rights reserved.

16

Model building

Meshed belt creation :

From the 1D elements of the seat belt and the positioned dummy, the shell

meshed seatbelt is created. The shell meshed seatbelt is defined with fabric

material and orthotropic membrane property.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/MAT/FABRI/500002/Seat belt

/MAT/FABRI/500002/Seat belt

#

Init. dens.

Ref. dens.

#

Init. dens.

Ref. dens.

3e-009

0

3e-009

0

#

E_11

E_22

Nu_12

#

E_11

E_22

Nu_12

10000

10000

0.1

10000

10000

0.1

#

G_12

G_23

G_31

#

G_12

G_23

G_31

5000

5000

5000

5000

5000

5000

#

Re

#

Re

0.001

0.001

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/PROP/SH_ORTH/500195/Belt

/PROP/SH_ORTH/500195/Belt

# Ishell Ismstr

# Ishell Ismstr

24

0

24

0

#

hm

hf

hr

dm

dn

#

hm

hf

hr

dm

dn

0

0

0

0

0

0

0

0

0

0

#

N Istrain

Thick

Ashear

Ithick

Iplas

#

N Istrain

Thick

Ashear

Ithick

Iplas

1

0

1.2

0

0

0

1

0

1.2

0

0

0

#

Vx

Vy

Vz

Phi

#

Vx

Vy

Vz

Phi

0

0

0

0

0

0

0

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

17

Model building

Meshed belt creation :

The shell meshed seatbelt is connected to 1D elements thru rigid bodies (4).

Copyright 2006 Altair Engineering, Inc. All rights reserved.

18

Model building

Contact interfaces :

A contact interface between the dummy and the outside surface of the cushion is

defined.

Because the dummy is defined as rigid body, it should only be defined as master

surface in the interface. In the other case, the friction will be not correctly computed.

The gap of this interface is bigger than the reality in order to have a smooth contact

force during the computation and a good sliding behavior.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/INTER/TYPE7/300006/Seat - Dummy

/INTER/TYPE7/300006/Seat - Dummy

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

500210 500211

0

0

0

0

0

500210 500211

0

0

0

0

0

#

STFAC

FRIC

GAP

Tstart

Tstop

#

STFAC

FRIC

GAP

Tstart

Tstop

0

0.3

3

0

0

0

0.3

3

0

0

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

000

0

0

0

0

000

0

0

0

0

# Ifric Ifiltr

Xfreq

Iform

# Ifric Ifiltr

Xfreq

Iform

0

0

0

2

0

0

0

2

/GRNOD/PART/500210/INTER_group_500210_of_PART

/GRNOD/PART/500210/INTER_group_500210_of_PART

300003 300004

300003 300004

/SURF/PART/500211/INTER_group_500211_of_PART

/SURF/PART/500211/INTER_group_500211_of_PART

500001 500002 500003 500004 500005 500006 500007 500008 500009 500010

500001 500002 500003 500004 500005 500006 500007 500008 500009 500010

500011 500013 500014 500015 500016 500017

500011 500013 500014 500015 500016 500017

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

19

Model building

Contact interfaces :

Upper belt

Contact interface between the dummy and the seatbelt is also defined.

Because the dummy is defined as rigid body, it should only be defined as

master surface in the interface. In the other case, the friction will be not

correctly computed. The gap of this interface is bigger than the reality in

order to have a smooth contact force during the computation and a good

sliding behavior.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/INTER/TYPE7/300004/BELT ID 500038

/INTER/TYPE7/300004/BELT ID 500038

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

#Slav_id Mast_id

Istf

Igap

Multi

Ibag

Idel

500208 300023

0

0

0

0

0

500208 300023

0

0

0

0

0

#

STFAC

FRIC

GAP

Tstart

Tstop

#

STFAC

FRIC

GAP

Tstart

Tstop

0

0.5

5

0

0

0

0.5

5

0

0

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

#

I_BC

INACTI

VIS_S

VIS_F

BUMULT

000

0

0

0

0

000

0

0

0

0

# Ifric Ifiltr

Xfreq

Iform

# Ifric Ifiltr

Xfreq

Iform

0

0

0

0

0

0

0

0

/GRNOD/PART/500208/BELT ID 500038

/GRNOD/PART/500208/BELT ID 500038

500038

500038

/SURF/PART/300023/BELT ID 500038

/SURF/PART/300023/BELT ID 500038

500001 500002 500003 500004 500005 500006 500010 500016

500001 500002 500003 500004 500005 500006 500010 500016

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Lower belt

Copyright 2006 Altair Engineering, Inc. All rights reserved.

20

Model building

Contact interfaces :

A contact interface between the dummy and the floor is also

defined.

In order to take into account the friction (infinite one) between the

floor and the dummy, both defined as rigid bodies, a contact tied

type interface with possible rebound is used.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/INTER/TYPE10/300007/Floor - dummy

/INTER/TYPE10/300007/Floor - dummy

#Slav_id Mast_id

Multimp

#Slav_id Mast_id

Multimp

500212 500213

0

500212 500213

0

#

STFAC

GAP

Tstart

Tstop

#

STFAC

GAP

Tstart

Tstop

0

2

0

0

0

2

0

0

#

I_tied INACTI

VIS_S

BUMULT

#

I_tied INACTI

VIS_S

BUMULT

0

0

0

0

0

0

0

0

/GRNOD/PART/500212/INTER_group_500212_of_PART

/GRNOD/PART/500212/INTER_group_500212_of_PART

500012 500018

500012 500018

/SURF/PART/500213/INTER_group_500213_of_PART

/SURF/PART/500213/INTER_group_500213_of_PART

100001

100001

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

Copyright 2006 Altair Engineering, Inc. All rights reserved.

21

Model building

Loadcase :

On the full model, an initial velocity is applied to the global X direction.

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/INIVEL/TRA/1/All

/INIVEL/TRA/1/All

#

Vx

Vy

Vz Gnod_id Skew_id

#

Vx

Vy

Vz Gnod_id Skew_id

-13000

0

0 500227

0

-13000

0

0 500227

0

/GRNOD/GRNOD/500227/INIVEL_group_500225_of_GRNOD

/GRNOD/GRNOD/500227/INIVEL_group_500225_of_GRNOD

500226 500225

500226 500225

/GRNOD/NODE/500226/INIVEL_group_500226_of_NODE

/GRNOD/NODE/500226/INIVEL_group_500226_of_NODE

12109

12110 100569 300677 300678 300679 300680 300681 300682 300683

12109

12110 100569 300677 300678 300679 300680 300681 300682 300683

300684 300685 300686 300687 300688 300689 300690 300691 300692 300693

300684 300685 300686 300687 300688 300689 300690 300691 300692 300693

GRNOD/PART/500225/INIVEL_group_500227_of_PART

GRNOD/PART/500225/INIVEL_group_500227_of_PART

1

2

3

4

5 100001 100002 200001 200002 200003

1

2

3

4

5 100001 100002 200001 200002 200003

200004 300001 300002 300003 300004 500002 500004 500011 500017 500019

200004 300001 300002 300003 300004 500002 500004 500011 500017 500019

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

The initial velocity has to be applied to any node of the model.

Copyright 2006 Altair Engineering, Inc. All rights reserved.

22

Model building

Loadcase :

On the floor, an imposed velocity (global X direction) is set on the master node of the rigid body in order

to reproduce the car deceleration during the crash.

The other degrees of freedom of the floor rigid body master node are clamped.

12000

10000

8000

6000

4000

2000

0

Velocity

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/IMPVEL/100001/Imposed velocity

/IMPVEL/100001/Imposed velocity

# Ifunct

DIR

Iskew Isensor Gnod_id Iframe

# Ifunct

DIR

Iskew Isensor Gnod_id Iframe

100001

X

0

0 100004

0

100001

X

0

0 100004

0

#

Scale

Tstart

Tstop

#

Scale

Tstart

Tstop

-1

0

0

-1

0

0

/GRNOD/NODE/100004/IMPVEL_group_371_of_NODE

/GRNOD/NODE/100004/IMPVEL_group_371_of_NODE

100569

100569

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/FUNCT/100001/Imposed velocity

/FUNCT/100001/Imposed velocity

#

X

Y

#

X

Y

0

10000

0

10000

0.05

8000

0.05

8000

0.1

0

0.1

0

0.2

0

0.2

0

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/BCS/100001/Floor

/BCS/100001/Floor

011 111

0 100001

011 111

0 100001

/GRNOD/NODE/100001/BCS_group_342_of_NODE

/GRNOD/NODE/100001/BCS_group_342_of_NODE

100569

100569

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

0.05

0.1

Time

0.15

0.2

Copyright 2006 Altair Engineering, Inc. All rights reserved.

23

Model building

Time History data :

In order to analyze the model results, the following items are set in the time history data :

All interfaces

Rigid body master node

of the floor

Rigid body of the floor

All parts

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

/TH/NODE/500001/H350MEF2D00_th_nodes

/TH/NODE/500001/H350MEF2D00_th_nodes

DEF

DEF

505197

0Feet left

505197

0Feet left

505196

0Feet right

505196

0Feet right

/TH/SPRING/500002/TH Spring selection

/TH/SPRING/500002/TH Spring selection

DEF

DEF

506026

Chest_def

506026

Chest_def

/TH/ACCEL/500003/Accelerometers

/TH/ACCEL/500003/Accelerometers

DEF

DEF

500001 500002 500003

500001 500002 500003

/TH/INTER/500004/TH INTER

/TH/INTER/500004/TH INTER

DEF

DEF

300001 300002 300003 300004 300005 300006 300007

300001 300002 300003 300004 300005 300006 300007

/TH/RBODY/500005/Floor

/TH/RBODY/500005/Floor

DEF

DEF

100001

100001

/TH/PART/500007/All

/TH/PART/500007/All

DEF

DEF

1

2

3

4

5 100001 100002 200001 200002 200003

1

2

3

4

5 100001 100002 200001 200002 200003

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

#--1---|---2---|---3---|---4---|---5---|---6---|---7---|---8---|---9---|--10---|

The time history data of the dummy (nodes, springs, accelerometer, rigid bodies) are already defined in

the model.

Copyright 2006 Altair Engineering, Inc. All rights reserved.

24

Model building

Engine file :

Engine file contains all necessary information in order to

compute the model.

Example :

Time step control

Deletion of dummy shell elements

Time computation control

Animation file control

#

#

/TITLE

/TITLE

/VERS/44

/VERS/44

#

#

/DT/NODA/CST

/DT/NODA/CST

6.700000e-001 5.000000e-007

6.700000e-001 5.000000e-007

#

#

/DT/SHELL/DEL

/DT/SHELL/DEL

0.000000e+000 1.000000e-009

0.000000e+000 1.000000e-009

#

#

/RUN/MODEL_00/1

/RUN/MODEL_00/1

1.000100e-001

1.000100e-001

/TFILE

/TFILE

1.000000e-004

1.000000e-004

/PRINT/100

/PRINT/100

#

#

/ANIM/DT

/ANIM/DT

0.000000e+000 5.000000e-003

0.000000e+000 5.000000e-003

/ANIM/ELEM/EPSP

/ANIM/ELEM/EPSP

/ANIM/ELEM/HOURG

/ANIM/ELEM/HOURG

/ANIM/ELEM/VONM

/ANIM/ELEM/VONM

/ANIM/ELEM/ENER

/ANIM/ELEM/ENER

/ANIM/NODA/DMAS

/ANIM/NODA/DMAS

/ANIM/MASS

/ANIM/MASS

#

#

/PARITH/ON

/PARITH/ON

/MON/ON

/MON/ON

Copyright 2006 Altair Engineering, Inc. All rights reserved.

25

Model results

Listing file :

The starter listing file (<root_name>_0000.lis),

shows the RADIOSS analysis of the starter input

deck. .In this file all WARNINGS and ERRORS

have to be checked and corrected.

The total mass, the mass for each part and the time

step need also to be checked.

WARNING id : 432

WARNING id : 432

** WARNING IN SPRING ELEMENT

** WARNING IN SPRING ELEMENT

INERTIA ( = 1) OF SPRING ELT 506011,

INERTIA ( = 1) OF SPRING ELT 506011,

SEEMS TO BE INCONSISTENT WITH MASS AND LENGTH

SEEMS TO BE INCONSISTENT WITH MASS AND LENGTH

( REFERENCE INERTIA = Mass*Length^2 = 2.08001e-16 )

( REFERENCE INERTIA = Mass*Length^2 = 2.08001e-16 )

TERMINATION WITH WARNING

TERMINATION WITH WARNING

----------------------------------------------0 ERROR(S)

0 ERROR(S)

213 WARNING(S)

213 WARNING(S)

NODAL TIME STEP (estimation)

NODAL TIME STEP (estimation)

----------------------------TIME STEP

NODE NUMBER

TIME STEP

NODE NUMBER

8.5352478114788E-07

509728

8.5352478114788E-07

509728

1.1070707124365E-06

509729

1.1070707124365E-06

509729

1.2333282705249E-06

5370

1.2333282705249E-06

5370

1.2333282705249E-06

2628

1.2333282705249E-06

2628

1.2333282705249E-06

2997

1.2333282705249E-06

2997

1.2333282705249E-06

2590

1.2333282705249E-06

2590

1.2333282705249E-06

5423

1.2333282705249E-06

5423

1.2333282705249E-06

2610

1.2333282705249E-06

2610

WARNING id : 430

WARNING id : 430

** WARNING IN SHELL 4N ELEMENT

** WARNING IN SHELL 4N ELEMENT

SHELL With ID 500031 is a 4 Nodes degenerated Shell Element.

SHELL With ID 500031 is a 4 Nodes degenerated Shell Element.

PLEASE USE A SHELL3N FOR BETTER RESULTS

PLEASE USE A SHELL3N FOR BETTER RESULTS

Copyright 2006 Altair Engineering, Inc. All rights reserved.

26

Model results

Listing file :

The engine listing file (<root_name>_0001.lis)

contains the different computation cycles, the deleted

(eroded) elements and the error message.

RADIOSS CRASH-ALE-CFD

RADIOSS CRASH-ALE-CFD

04/27/2007

04/27/2007

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

-- DELETE OF SHELL ELEMENT NUMBER

400001

400001

400002

400002

400003

400003

400004

400004

CYCLE

TIME

TIME-STEP ELEMENT

ERROR I-ENERGY

K-ENERGY T K-ENERGY R EXT-WORK MAS.ERR

CYCLE

TIME

TIME-STEP ELEMENT

ERROR I-ENERGY

K-ENERGY T K-ENERGY R EXT-WORK MAS.ERR

0

0.000

0.4397E-06 NODE

203472

0.0% 0.2856E-33 0.1251E+08

0.000

0.000

0.1003E-04

0

0.000

0.4397E-06 NODE

203472

0.0% 0.2856E-33 0.1251E+08

0.000

0.000

0.1003E-04

ANIMATION FILE: MODEL_01A001 WRITTEN

ANIMATION FILE: MODEL_01A001 WRITTEN

1000 0.5309E-03 0.5311E-06 NODE

408815

0.0%

959.4

0.1251E+08 0.2055

-2800.

0.1003E-04

1000 0.5309E-03 0.5311E-06 NODE

408815

0.0%

959.4

0.1251E+08 0.2055

-2800.

0.1003E-04

2000 0.1062E-02 0.5311E-06 NODE

408815

0.0%

1090.

0.1251E+08 0.1843

-6553.

0.1003E-04

2000 0.1062E-02 0.5311E-06 NODE

408815

0.0%

1090.

0.1251E+08 0.1843

-6553.

0.1003E-04

188000 0.9930E-01 0.5299E-06 NODE

408815 -20.4% 0.3228E+07 0.1512E+06 0.5180E+05 -0.8202E+07 0.1003E-04

188000 0.9930E-01 0.5299E-06 NODE

408815 -20.4% 0.3228E+07 0.1512E+06 0.5180E+05 -0.8202E+07 0.1003E-04

189000 0.9983E-01 0.5299E-06 NODE

408815 -20.4% 0.3227E+07 0.1503E+06 0.5239E+05 -0.8202E+07 0.1003E-04

189000 0.9983E-01 0.5299E-06 NODE

408815 -20.4% 0.3227E+07 0.1503E+06 0.5239E+05 -0.8202E+07 0.1003E-04

ANIMATION FILE: MODEL_01A021 WRITTEN

ANIMATION FILE: MODEL_01A021 WRITTEN

Cycle information

** CPU USER TIME **

** CPU USER TIME **

#PROC CONT.SORT CONT. F

ELEMENT KIN.COND. INTEGR.

I/O

TASK0

ASSEMB.

RESOL

#PROC CONT.SORT CONT. F

ELEMENT KIN.COND. INTEGR.

I/O

TASK0

ASSEMB.

RESOL

1

.2476E+04 .3988E+04 .1543E+05 .7279E+03 .1216E+04 .3486E+02 .1418E+04 .4206E+04 .2865E+05

1

.2476E+04 .3988E+04 .1543E+05 .7279E+03 .1216E+04 .3486E+02 .1418E+04 .4206E+04 .2865E+05

2

.1186E+04 .3797E+04 .1548E+05 .7263E+03 .1218E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

2

.1186E+04 .3797E+04 .1548E+05 .7263E+03 .1218E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

3

.1187E+04 .3694E+04 .1548E+05 .7309E+03 .1184E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

3

.1187E+04 .3694E+04 .1548E+05 .7309E+03 .1184E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

4

.1186E+04 .3829E+04 .1556E+05 .7312E+03 .1238E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

4

.1186E+04 .3829E+04 .1556E+05 .7312E+03 .1238E+04 .0000E+00 .0000E+00 .4206E+04 .2865E+05

RESTART FILE: MODEL_01R01 WRITTEN

RESTART FILE: MODEL_01R01 WRITTEN

------------------------N O R M A L

N O R M A L

T E R M I N A T I O N

T E R M I N A T I O N

Calculation time

TOTAL NUMBER OF CYCLES : 189349

TOTAL NUMBER OF CYCLES : 189349

Copyright 2006 Altair Engineering, Inc. All rights reserved.

27

Model results

Animation file :

With the animation files (<root_name>A001 to <root_name>A021) the motion and model deformations

are available.

Before crash

After crash

Copyright 2006 Altair Engineering, Inc. All rights reserved.

28

Model results

Time history file :

With the time history files (<root_name>T01), 2D plots can be defined in order to check :

Global energies in the model

Mass and mass increase

Dummy parameters and criteria's : HIC, chest deflection, acceleration, upper leg forces,

Seat belt contact forces,

Global energy

Dummy acceleration

Copyright 2006 Altair Engineering, Inc. All rights reserved.

29

Altair Engineering, Inc.

Innovation Intelligence

Contact : emestres@altair.com

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Atec Manual ElectronicDocument73 pagesAtec Manual ElectronicMinaSaeed67% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 2003 Nissan Altima 2.5 Serivce Manual WTDocument6 pages2003 Nissan Altima 2.5 Serivce Manual WTAndy DellingerNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- BiomagnetismDocument30 pagesBiomagnetismapi-19937584100% (4)

- Symmetry and Group TheoryDocument24 pagesSymmetry and Group Theorywicki0007100% (1)

- Calculations For IB ChemistryDocument16 pagesCalculations For IB Chemistryanthor100% (3)

- Control and analyze protein structures with RasmolDocument3 pagesControl and analyze protein structures with RasmolRavi IndraNo ratings yet

- MAGMA How To UseDocument113 pagesMAGMA How To Usepurushothaman1234566No ratings yet

- Damage and Failure For Ductile Metals - Abaqus PDFDocument18 pagesDamage and Failure For Ductile Metals - Abaqus PDFshayan50% (2)

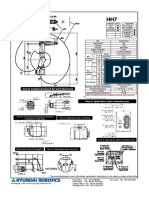

- Hh7 CatalogDocument1 pageHh7 Catalogjitender kumarNo ratings yet

- Using Jmol To Help Students Better Understand Fluxional ProcessesDocument1 pageUsing Jmol To Help Students Better Understand Fluxional Processesdevy ridaNo ratings yet

- Torque and Equilibrium (40 charactersDocument2 pagesTorque and Equilibrium (40 charactersEndai DesuNo ratings yet

- The velocity of propagation gives us the speed of electromagnetic wavesDocument3 pagesThe velocity of propagation gives us the speed of electromagnetic wavesJose Daniel Ochoa MoyaNo ratings yet

- Flexural Strength Tests of Ceramics (SubsTech)Document3 pagesFlexural Strength Tests of Ceramics (SubsTech)mypenta2008No ratings yet

- The UniverseDocument2 pagesThe Universeapi-328735767No ratings yet

- Energy Transfer in Turbomachines ExplainedDocument4 pagesEnergy Transfer in Turbomachines Explainedsachintyagi1No ratings yet

- At-Rest Earth Pressure Comparison BasicsDocument9 pagesAt-Rest Earth Pressure Comparison BasicsDev MitraNo ratings yet

- Numericals on Interference and DiffractionDocument15 pagesNumericals on Interference and DiffractionPratik WalimbeNo ratings yet

- Entalglement - Amir D Aczel PDFDocument4 pagesEntalglement - Amir D Aczel PDFAlejandro LimaNo ratings yet

- Ray Optics MCQDocument8 pagesRay Optics MCQVamsi Vangara100% (1)

- CH 34 - Total SolutionsDocument24 pagesCH 34 - Total SolutionsLemonn LemonnNo ratings yet

- Capacitors PDFDocument84 pagesCapacitors PDFNaseerUddin100% (1)

- Classified Examples of Electrical Engineering 1928Document103 pagesClassified Examples of Electrical Engineering 1928dominicrochford3068No ratings yet

- 55-1-1 Physics Marking Scheme 2020Document18 pages55-1-1 Physics Marking Scheme 2020jyotibhalaNo ratings yet

- SsssDocument17 pagesSsssPhysicsNo ratings yet

- 6 - Francis Turbine PDFDocument39 pages6 - Francis Turbine PDFMohamed YaserNo ratings yet

- Modul 7 MatrikDocument10 pagesModul 7 MatrikAida Nur FadhilahNo ratings yet

- Heat exchanger specification sheetDocument2 pagesHeat exchanger specification sheetDycka Anugerah PuryantoroNo ratings yet

- Trajectories and Radius, Velocity, AccelerationDocument12 pagesTrajectories and Radius, Velocity, AccelerationEpic WinNo ratings yet

- Chapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionDocument5 pagesChapter 12: Vibrations and Waves: 12.1 Simple Harmonic MotionSteven SuNo ratings yet

- Theroretical MesalamineDocument18 pagesTheroretical MesalamineRTTONo ratings yet