Professional Documents

Culture Documents

Seligram 2

Uploaded by

Yvette YuanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seligram 2

Uploaded by

Yvette YuanCopyright:

Available Formats

1. What caused the existing system at ETO to fail?

The existing system at ETO began to fail because direct labor hours per lot began to decrease due to vendor certification that allows vendors to do the primary testing. In this way, ETO would only be required to test a small sample of each lot for verification purpose. In addition, as ETO increased its engineering support to enhance customer experience, a shift in labor mix from direct to indirect personnel was prompted. However, the existing system with a single cost pool could not provide such detailed information and therefore could not meet the expectation of the management. Another important factor to be considered is that as expensive equipment were introduced for automated tests, direct labors were reduced, creating a gap between a higher depreciation expense and the less direct labor to absorb it. It is common for a cost system to become obsolete when the process experiences increased automation.

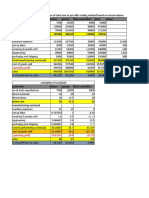

2. Calculate the reported costs of the five components described in Exhibit 6 under: a) The existing cost system b) The system proposed by the accounting manager c) The system proposed by the consultant The cost for the five components described in exhibit 6 can be shown as follows: a) Using the given burden rate of 145%, the calculated costs of the existing system is shown in Exhibit 1. b) Using the managers proposal, the system would be separated by machine hour burden and direct labor burden. The revised labor burden rate would be 21%, while the machine hr burden rate would be $80.1. The relative costs displayed in Exhibit 2. c) If ETO follows the consultants recommendation, the main testing room and the mechanical room would be treated as different cost pools. In this way, the reported burden rates are $63.34/hr for the main testing room and $112.23/hr for the mechanical room. The calculations based on the above referenced data are now shown in Exhibit 3. 3. Which system do you prefer? Why? Among the above cost accounting systems, I prefer the one that was proposed by the consultant. The reason is that through three-burden-pool cost system, the managers in the company could trace the cost down to more detailed level and understand more about the current situation. As a result, better decisions could be made accordingly. In this case, as we learned that the test procedures vary with components provided by the customers. The pricing policy under the existing system caused increased complaints

from the customers. However, such problem could not be resolved by the management because no detailed information was available for a more appropriate method of pricing.

4. Would you recommend any changes to the system you prefer? Why? Yes, I would. The three-cost-pool system can still be further improved by introducing another cost pool that would cover the engineering support costs. One of the factor that causes the existing system to fail is that the cost information provided could not reflect the increased engineering support costs and therefore is considered ineffective in supporting the managements decisions. However, both the systems proposed by the manager and the consultant grouped the support cost and the administrative cost into the same cost pool. Thus, for a better traceability of different cost to different activities, I would consider the single cost pool for engineering support expense is a necessary improvement on the three-cost-pool system.

Exhibit 1 Direct labor and machine hours (under existing system)

Exhibit 2 Direct labor and machine hours (suggested by manager)

Exhibit 3 Direct labor and machine hours (suggested by consultant)

You might also like

- Seligram Case QuestionsDocument2 pagesSeligram Case QuestionsZain Bharwani100% (1)

- Selligram Case Answer KeyDocument3 pagesSelligram Case Answer Keysharkss521No ratings yet

- SUBJECT: Analyses and Recommendations For The Different Cost AccountingDocument4 pagesSUBJECT: Analyses and Recommendations For The Different Cost AccountinglddNo ratings yet

- Process-Oriented Costing System Optimizes Siemens Motor Works ProfitsDocument5 pagesProcess-Oriented Costing System Optimizes Siemens Motor Works ProfitsNikhil Jindal100% (1)

- Seligram Case Cost AccountingDocument3 pagesSeligram Case Cost Accountingsharkss521No ratings yet

- Accounting Seligram CaseDocument2 pagesAccounting Seligram CaseNadia Iqbal100% (1)

- Seligram Summary DetailsDocument6 pagesSeligram Summary DetailsSachin MailareNo ratings yet

- Davey Brothers Watch Co. and Classic Pen Company Case AnalysisDocument4 pagesDavey Brothers Watch Co. and Classic Pen Company Case Analysisabhishek pattanayakNo ratings yet

- DocxDocument3 pagesDocxbilalNo ratings yet

- Shweta Kale Section - B 2019PGP401 Siemens Electric Motor WorksDocument8 pagesShweta Kale Section - B 2019PGP401 Siemens Electric Motor WorksshwetaNo ratings yet

- Manufacturing Cost Analysis ReportDocument5 pagesManufacturing Cost Analysis Reportfelipe.com0% (1)

- MANAGEMENT ACCOUNTING - IIDocument5 pagesMANAGEMENT ACCOUNTING - IIshshank pandeyNo ratings yet

- Dave BrothersDocument6 pagesDave BrothersSangtani PareshNo ratings yet

- Outsourcing Manifold ProductionDocument8 pagesOutsourcing Manifold Productionaliraza100% (2)

- How Does Wilkerson's Existing Cost System Operate? Develop A Diagram To Show How Costs Flow From Factory Expense Accounts To ProductsDocument4 pagesHow Does Wilkerson's Existing Cost System Operate? Develop A Diagram To Show How Costs Flow From Factory Expense Accounts To ProductsKunal DhageNo ratings yet

- 05 Wilkerson Company Solution - StudentsDocument9 pages05 Wilkerson Company Solution - StudentsVinyabhooshan Bajpai PGP 2022-24 Batch100% (1)

- Wilkerson Company Break Even Analysis for Multi-product SituationDocument5 pagesWilkerson Company Break Even Analysis for Multi-product SituationYAKSH DODIANo ratings yet

- Seligram, IncDocument5 pagesSeligram, IncAto SumartoNo ratings yet

- Seimens Electric Motor WorksDocument5 pagesSeimens Electric Motor WorksShrey BhalaNo ratings yet

- Siemens ElectricDocument6 pagesSiemens ElectricUtsavNo ratings yet

- Elwy Melina-Sarah MHCDocument7 pagesElwy Melina-Sarah MHCpalak32No ratings yet

- Wilkerson SpreadsheetDocument6 pagesWilkerson SpreadsheetMandar DeshpandeNo ratings yet

- Case Case:: Colorscope, Colorscope, Inc. IncDocument4 pagesCase Case:: Colorscope, Colorscope, Inc. IncBalvinder SinghNo ratings yet

- John Deere Case Analysis: A A G L I MDocument3 pagesJohn Deere Case Analysis: A A G L I MTavoLixNo ratings yet

- Bridgeton HWDocument3 pagesBridgeton HWravNo ratings yet

- Berkshire Toy CompanyDocument25 pagesBerkshire Toy CompanyrodriguezlavNo ratings yet

- MA Session 6 PDFDocument48 pagesMA Session 6 PDFArkaprabha GhoshNo ratings yet

- Mystic SportsDocument34 pagesMystic SportshelloNo ratings yet

- Costing Systems Reveal True Product MarginsDocument1 pageCosting Systems Reveal True Product Marginsfelipevwa100% (1)

- Destin BrassDocument5 pagesDestin Brassdamanfromiran100% (1)

- 29 Purity Steel Compensation Plan AnalysisDocument7 pages29 Purity Steel Compensation Plan Analysisfajarina ambarasariNo ratings yet

- Group 8Document20 pagesGroup 8nirajNo ratings yet

- Wilkerson - Case Study1 PDFDocument2 pagesWilkerson - Case Study1 PDFPavanNo ratings yet

- Color ScopeDocument10 pagesColor Scopedharti_thakare100% (1)

- Dentin Brass Case Study3Document13 pagesDentin Brass Case Study3Hosein Rahmati100% (2)

- Wilkerson CompanyDocument2 pagesWilkerson CompanyAnkit VermaNo ratings yet

- Siemens CaseDocument4 pagesSiemens Casespaw1108No ratings yet

- Anagene Case StudyDocument1 pageAnagene Case StudySam Man0% (3)

- Siemens Electric Motor WorksAQ PDFDocument3 pagesSiemens Electric Motor WorksAQ PDFHashirama SenjuNo ratings yet

- Wilkerson Company ABCDocument4 pagesWilkerson Company ABCrajyalakshmiNo ratings yet

- Sippican Case ReviewDocument9 pagesSippican Case ReviewDavid KijadaNo ratings yet

- Cost Accounting AssignmentDocument6 pagesCost Accounting AssignmentRamalu Dinesh ReddyNo ratings yet

- Case ReichardDocument23 pagesCase ReichardDesiSelviaNo ratings yet

- MA Session 5 PDFDocument35 pagesMA Session 5 PDFArkaprabha GhoshNo ratings yet

- Ajax Manufacturing Cost AnalysisDocument7 pagesAjax Manufacturing Cost Analysisreva_radhakrish1834No ratings yet

- Prestige Telephone Company SlidesDocument13 pagesPrestige Telephone Company SlidesHarsh MaheshwariNo ratings yet

- SiemensDocument7 pagesSiemensshshank pandeyNo ratings yet

- Final Test Accounting - DestinDocument8 pagesFinal Test Accounting - DestinRandy MarzeindNo ratings yet

- LIFO vs FIFO Impact on Merrimack TractorsDocument3 pagesLIFO vs FIFO Impact on Merrimack TractorsstudvabzNo ratings yet

- EX 1 - WilkersonDocument8 pagesEX 1 - WilkersonDror PazNo ratings yet

- This Study Resource Was: Forner CarpetDocument4 pagesThis Study Resource Was: Forner CarpetLi CarinaNo ratings yet

- Miles High Cycles Katherine Roland and John ConnorsDocument4 pagesMiles High Cycles Katherine Roland and John ConnorsvivekNo ratings yet

- Group 7 - Excel - Destin BrassDocument9 pagesGroup 7 - Excel - Destin BrassSaumya SahaNo ratings yet

- XyberSpace Consulting Inc RahulDocument5 pagesXyberSpace Consulting Inc RahulRatheesh MallayaNo ratings yet

- Bill French Case Submitted By: Sourabh Phanase Section: ADocument2 pagesBill French Case Submitted By: Sourabh Phanase Section: AsourabhphanaseNo ratings yet

- MAC Davey Brothers - AkshatDocument4 pagesMAC Davey Brothers - AkshatPRIKSHIT SAINI IPM 2019-24 BatchNo ratings yet

- Cost ManagementDocument7 pagesCost ManagementSIXIAN JIANGNo ratings yet

- Sigi John DeereDocument2 pagesSigi John DeereJacob Thomas100% (1)

- Destin Brass Products Co.Document5 pagesDestin Brass Products Co.qun100% (1)

- Managerial Accounting Case Study 2: Analyzing ETO's Costing SystemsDocument2 pagesManagerial Accounting Case Study 2: Analyzing ETO's Costing SystemsFaizan Maqsood100% (1)

- Campbell's IQ MealDocument3 pagesCampbell's IQ MealSadia Asif50% (2)

- Fashion Knits Ali VisionDocument4 pagesFashion Knits Ali Visionsalman712100% (1)

- PARTIAL DIFFERENTIATION AND APPLICATIONSDocument15 pagesPARTIAL DIFFERENTIATION AND APPLICATIONSMau-ZyJr.No ratings yet

- Vice President Receivables Manager in Delaware Maryland Resume John TonettiDocument3 pagesVice President Receivables Manager in Delaware Maryland Resume John TonettijohntonettiNo ratings yet

- Qms-thr-Form09 Test Questionnaire. Final ExamDocument11 pagesQms-thr-Form09 Test Questionnaire. Final Examroselle nepomucenoNo ratings yet

- Macro 1Document4 pagesMacro 1Mei Abalos100% (1)

- 22 Steps Successful EntrepreneurshipDocument24 pages22 Steps Successful EntrepreneurshipSomu VenkatNo ratings yet

- Sasha Kate MadfesDocument2 pagesSasha Kate MadfesSasha MadfesNo ratings yet

- BCA Green Mark Assessment Fees For Building Projects in SingaporeDocument4 pagesBCA Green Mark Assessment Fees For Building Projects in SingaporeOoi Wei ShengNo ratings yet

- Business MathematicsDocument6 pagesBusiness MathematicsSharlotAbkarianNo ratings yet

- Case StudyDocument3 pagesCase StudySaba PervezNo ratings yet

- 12 CommerceDocument320 pages12 CommerceNithin VeluNo ratings yet

- Cydney Young Resume 2016Document1 pageCydney Young Resume 2016api-259928044No ratings yet

- Current Focus On Management AccountingDocument3 pagesCurrent Focus On Management AccountingGêmTürÏngånÖ0% (2)

- Consumer Culture Brand Positioning Strategies: An Experimental InvestigationDocument10 pagesConsumer Culture Brand Positioning Strategies: An Experimental InvestigationKrishna MohanNo ratings yet

- 360 AgreementDocument22 pages360 AgreementJef Powell100% (6)

- Factors That Affect Marketing MixDocument11 pagesFactors That Affect Marketing Mixmanjusri lalNo ratings yet

- Groundzero Cyber Cafe: Business ProposalDocument12 pagesGroundzero Cyber Cafe: Business ProposalwensleyNo ratings yet

- FedEx Marketing Plan - Marketing MixxDocument3 pagesFedEx Marketing Plan - Marketing Mixxbrojas35No ratings yet

- Presentation 3Document11 pagesPresentation 3Andre FitriaNo ratings yet

- Columbia HCIA ResumeBook 2010 PDFDocument40 pagesColumbia HCIA ResumeBook 2010 PDFBilly SevernNo ratings yet

- Organization and Management SyllabusDocument8 pagesOrganization and Management SyllabusArianne100% (6)

- Integrated Marketing CommunicationDocument2 pagesIntegrated Marketing CommunicationTHOR -No ratings yet

- Concept PaperDocument8 pagesConcept PaperClarence James GagnaoNo ratings yet

- MakeORBuy NumericalsDocument6 pagesMakeORBuy Numericalsgurjit20No ratings yet

- Himalaya HerbalDocument26 pagesHimalaya HerbalVidit Garg33% (3)

- JK ProjectDocument60 pagesJK Projectmilan77100% (8)

- Thesis Brand AwarenessDocument5 pagesThesis Brand Awarenessamywellsbellevue100% (2)

- Comparing Communication MethodsDocument4 pagesComparing Communication MethodsKenny VillafanaNo ratings yet

- Listing PresentationDocument50 pagesListing PresentationMelissaWegenerNo ratings yet