Professional Documents

Culture Documents

Ship Resistance Calculation For A Fishing Vessel

Uploaded by

MahdiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ship Resistance Calculation For A Fishing Vessel

Uploaded by

MahdiCopyright:

Available Formats

CHAPTER ONE

INTRODUCTION

1.1 Background of Research

Naval architecture task is to ensure that, within the bounds of the other design

requirement, the hull form design of propulsion and the procedure will be the most

efficient in terms of hydrodynamics. The final test of the ship will perform at the

required speed with minimum of shaft power, and the problem is to achieve the best

combination of low resistance and high efficiency propulsive. In general, this can

only be achieved by matching precisely the hull and propeller

In general, the basic contractual obligations are placed on the dock that ship

must reach or achieved a certain speed with particular strength in the good weather

on trial and for this reason smooth water performance or calm water is very

important.

1

Forecast resistance vessel is fundamental topics of interest to naval architects.

Hydrodynamics been interested in determining the laws of physics related to the

ship resistance and speed characteristic. Due to the complicated nature of flow

around the ship hull, a satisfactory analytical method relating speed and powering

requirement to hull form has not yet been developed.

Generally, there are many methods can be used to determine the ships resistance.

According to Harvald (1983), these methods can be divided into four groups which

namely:

1) Model experiments

2) Standard series of experiments

3) Statistical methods

4) Diagrams

Model testing is still the most accurate and reliable method but the others may

only be used to predict ship resistance between certain limits or only for a ship that

comparative data on these groups to forecast. Have similar particulars to such group.

For the purpose of this study, only three methods of ship resistance prediction will be

discussed in connection with the three groups are shown above. These methods are:

1) Van Oortmersens method

2) Holtrops and Mennen method

3) Schneekluths method

2

1.2 Project Background

The main objective of this project is to study and research on the ship

resistance for 28.3m single screw fishing trawler. The ship resistance is normally

determined by using model test in a towing tank or circulating water channel.

However it can also be predicted by using, empirical formula or statistical data.

Prediction in the preliminary design stage is one of the important practice and

research in ship design. Several methods can be used in the ship resistance prediction

depends on the type of the ship and the limitation of the methods. Consequently

using existing method, the resistance of 28.3m fishing trawler will be investigated.

1.3 Objective

i. To predict the ship resistance of 28.3 trawler by using methodical series

ii. To calculate manually using the methodical series by means of using

computer tools such as Microsoft Excel and later on making source codes

using MATLAB or MATHCAD.

iii. To compare the result of resistance prediction with model test and sea trial

result.

iv. To make limitation as guidelines for methods used in resistance prediction.

3

1.4 Scope of Research

i. Conduct resistance prediction study in calm water.

ii. Obtain available experimental data and sea trial results.

iii. Conduct resistance prediction based on available methods i.e. Holtrop

and Mennen.

iv. Familiarization of programming language and later on generates source

codes for resistance prediction calculation.

v. Validate prediction result with model experiment.

1.5 Problem Statement

In carrying out prediction using methodical series, several issues will be

addressed as fallow:-

i. How accurate is the present method resistance prediction? It is reliable?

4

ii. If not? Why it is not reliable at first place? What are the factors

contributing to the inaccuracy of these predictions?

iii. What are the limitations?

iv. Which method that can be used and reliable in particular for fishing

trawler?

1.6 Expected Outcome

i. Resistance prediction results of 28.3m fishing trawler using the

Hullspeed software and manual calculation using Microsoft Excel or

programming using MATLAB/MATHCAD.

ii. Identify methods that can be applied to predict trawler resistance.

5

CHAPTER TWO

LITERATURE REVIEW

2.1 General

6

This chapter will give an overview about the methods that will be used to

achieve the objectives of trawler resistance prediction using methodical series.

2.2 Van Oortmersens Method[2]

This method is useful for estimating the resistance of small ships such as

trawlers and tugs. In this method, the derivation of formula by G. Van Ootmerssen is

based on the resistance and propulsion of a ship as a function of the Froude number

and Reynolds number. The constraint of this formula is also based on other general

parameters for small ships such as trawlers and tugs that are collected from random

tank data. The method was developed through a regression analysis of data from 93

models of tugs and trawlers obtained by the Marine Research Institute, Netherlands

(MARIN). Besides, few assumptions were made for predicting resistance and

powering of small craft such as follows:

1. According to the Figure 2.1 there are positive and negative pressure

peak distributions for the hull surface. For the ship hull scope, there

are high pressure at the bow and stern, while in the middle it becomes

a low pressure.

7

Figure 2.1: Pressure distribution around a ship hull [2]

2. Small ship can be said to have a certain characteristics such as the

absence of a parallel middle body, so the regions of low pressure and the

wave system of fore and after shoulder coincide and consequently the

pressure distribution is illustrated as in figure 2.2.

Figure 2.2: Wave system at fore and aft shoulder [2]

3. The summation of viscous resistance and wave-making resistance

representing the components of the total resistance.

The range of parameters for the coefficients of the basic expression is as follow:

8

Table 2.1: Limitations for Van Oortmerssens Method [2]

Van Oortmerssens suggested that the final form of the resistance equation is

represented by the summation of viscous resistance and wave-making resistance as

follow:

9

Parameter Limitations

Length of water line, L

WL

8 to 80 m

Volume, 5 to 3000 m

Length/Breadth, L/B 3 to 6.2

Breadth/Draft, B/T 1.9 to 4.0

Prismatic coefficient, C

P

0.50 to 0.73

Midship coefficient, C

m

0.70 to 0.97

Longitudinal center of buoyancy, LCB -7% L to 2.8% L

entrance angle, i

e

10 to 46

Speed/length, V/L 0 to 1.79

Froude number, F

n

0 to 0.50

( )

( )

( )

( )

1

]

1

+

1

1

]

1

+ + +

2

2

2

4

2

3 2

9 / 1

1

2 l o g 2

0 7 5 . 0

c o s

s i n

2

2 2 2

R n

S V

F n e C

F n e C e C e C

R

m F n

m F n m F n m F n

T

[2.1]

where,

1.

( ) ( ) ( )

m i i i WL i WL i WL i

WL i p i p i i i i i

C d T B d T B d C d C d B L d

B L d C d C d LCB d LCB d d C

+ + + + + +

+ + + + + +

11 ,

2

10 , 9 ,

2

8 , 7 ,

2

6 ,

5 ,

2

4 , 3 ,

2

2 , 1 , 0 ,

3

/ / /

/ 10

[2.2]

2.

( ) 2 /

1

.

b

p

C b m

or for small ships this can be presented by:

( ) 1976 . 2

14347 . 0

p

C m

[2.3]

3.

WL

C

is a parameter for angle of entrance of the load waterline, i

e,

where

( ) B L i C

WL e WL

/

[2.4]

4. Approximation for wetted surface area is represented by:

3 / 1 33 / 2

5402 . 0 223 . 3 V L V S

WL

+

[2.5]

10

Table 2.2 below shows an allowance for frictional resistance and table 2.3 shows the

values of regression coefficient given by Van Oortmerssens.

Table 2.2: Allowance for frictional

resistance [2]

Usually, the Van Oortmerssens methods are useful for estimating the

resistance of small ships such as trawlers and tugs. In general, Malaysian fishing

vessels are short and beamy whilst their draught is relatively low. These kinds of

vessel are normally located in shallow river estuaries. These factors will result in a

relatively low breadth-draught ratio and block coefficient.

11

Allowance for C

F

Roughness of hull 0.00035

Steering resistance 0.00004

Bilge Keel Resistance 0.00004

Air resistance 0.00008

i 1 2 3 4

d

i,0

79.32134 6714.88397 -908.44371 3012.14549

d

i,1

-0.09287 19.83000 2.52704 2.71437

d

i,2

-0.00209 2.66997 -0.35794 0.25521

d

i,3

-246.46896 -19662.02400 755.186600 -9198.80840

d

i4

187.13664 14099.90400 -48.93952 6886.60416

d

i,5

-1.42893 137.33613 -9.86873 -159.92694

d

i,6

0.11898 -13.36938 -0.77652 16.23621

d

i,7

0.15727 -4.49852 3.79020 -0.82014

d

i,8

-0.00064 0.02100 -0.01879 0.00225

d

i,9

-2.52862 216.44923 -9.24399 236.37970

d

i,10

0.50619 -35.07602 1.28571 -44.17820

d

i,11

1.62851 -128.72535 250.64910 207.25580

2.3 Holtrops & Mennens Method [2]

This resistance prediction method is one of the techniques widely used in

prediction of resistance of displacement and semi-displacement vessels. Like all

methods, however, this technique is limited to a suitable range of hull form

parameters. This algorithm is designed for predicting the resistance of tankers,

general cargo ships, fishing vessels, tugs, container ships and frigates. The

algorithms implements are based upon hydrodynamic theory with coefficients

obtained from the regression analysis of the results of 334 ship model tests.

In their approach to establishing their formulas, Holtrop and Mennen

assumed that the non-dimensional coefficient represents the components of

resistance for a hull form. It might be represented by appropriate geometrical

parameters, thus enabling each component to be expressed as a non-dimensional

function of the sealing and the hull form. The range of parameters for which the

coefficients of the basic expressions are valid is shown as following:

Table 2.4: Limitation for Holtrop and Mennens method [2][3]

12

Ship type Max

Froude

no.

Cp L/B B/T

Min Max Min Max Min Max

Tankers, bulk carries 0.24 0.73 0.85 5.1 7.1 2.4 3.2

Trawlers, coasters, tugs 0.38 0.55 0.65 3.9 6.3 2.1 3.0

Containerships, destroyer

types

0.45 0.55 0.67 6.0 9.5 3.0 4.0

Cargo liners 0.30 0.56 0.75 5.3 8.0 2.4 4.0

RORO ships, car ferries 0.35 0.55 0.67 5.3 8.0 3.2 4.0

The step by step procedures are shown below to calculate resistance in order

to predict the ship power.

Calculate:

1. Frictional Resistance,

( ) ( ) ( ) Ca k C SV R

F F

+ + 1 2 / 1

2

[2.6]

2. Wetted Surface,

( )

( )

( )

B B T

W P

M B

M

C A

C T B

C C

C B T L S / 3 8 . 2

3 6 9 6 . 0 / 0 0 3 4 6 7 . 0

2 8 6 2 . 0 4 4 2 5 . 0 4 5 3 0 . 0

2

5 . 0

+

,

_

+

+

+

[2.7]

3. Form Factor

( ) ( ) ( ) ( )

( )

6906 . 0

92497 . 0 22284 . 0

0225 . 0 1 52145 . 0

95 . 0 / / 93 . 0 1

LCB C

C L B L T k

P

P R

+

+ +

[2.8]

where,

( ) 06 . 0 1 +

P R

C L L

[2.9]

4. Correlation Factor,

13

( ) 00205 . 0 100 0006 . 0

16 . 0

+

L Ca

[2.10]

5. Frictional Resistance Coefficient,

( )

2

2

075 . 0

LogRn

C

F

[2.11]

6. Residuary resistance,

( ) ( )

2

2

9 . 0

1

cos

+

Fn m Fn m

R

Ce R

[2.12]

where,

( ) ( ) ( )

3 2

3 / 1

1

984388 . 6 8673 . 13

07981 . 8 / 79323 . 4 / 75254 . 1 / 0140407 . 0

P P

P

C C

C L B L T L m

+

+

[2.13]

( )

2

/ 1 . 0

2

2

69385 . 1

Fn

P

e C m

[2.14]

B L C

P

/ 03 . 0 446 . 1

[2.15]

7. Therefore, total resistances are,

R F T

R R R +

[2.16]

Generally, Holtrop and Mennens method is suitable for a small vessel and

this algorithm is designed for predicting the resistance of fishing vessels and tugs.

14

However, with this method, there are still errors exist. Therefore, all the factors

below are considered to determine the degree of uncertain parameter:

i) Increasing in Froude number which will create a greater residuary

resistance (wave making resistance, eddy resistance, breaking waves and

shoulder wave) is a common phenomenon in small ships. As a result, errors

in total resistance increase.

ii) Small vessels are easily influenced by environmental condition such

as wind and current during operational.

iii) For smaller ship, the form size and ship type have a great difference.

This method is only limited to the Froude number below 0.5, (Fn < 0.5) and

also valid for T

F

/ L

WL

> 0.04. There is correlation allowance factor in model ship that

will affect some 15% difference in the total resistance and the effective power. This

method is also limited to hull form resembling the average ship described by the

main dimension and form coefficients used in the method.

2.4 Cedric Ridgely Nevitts Method [2]

This method is developed for a model test with trawler hull forms having

large volumes for their length. In this method it covers a range of prismatic

coefficients from 0.55 to 0.70 and displacement-length ratios from 200 to 500, their

residuary resistance contours and wetted surface coefficients have been plotted in

15

order to make resistance estimates possible at speed-length ratios from 0.7 to 1.5.

The changing of beam-draft ratio also takes into account the effect on total

resistance.

Table 2.5: Limitations for Cedric Ridgely Nevitts method [2]

This method is applicable to fishing vessels, tugs, fireboats, icebreakers,

oceanographic ships, yachts and other short and beamy ships falling outside the

range of the Taylor Series or Series 60. Procedures of calculating ship resistances

using this method are as follows:

16

Parameter Limitations

Length/Breadth, L/B 3.2 5 .0

Breadth/Draft , B/T 2.0 - 3.5

Vulome/length, ( )

3

01 . 0 / L

200 500

Prismatic coefficient, C

P

0.55 - 0.70

Block coefficient, C

B

0.42 - 0.47

Speed/length, V/L 0.7 - 1.5

Longitudinal center of buoyancy, LCB 0.50% - 0.54% aft of FP

entrance angle ,

e

7.0 - 37.4

Calculate:

i) Parameter of V/L for every speed.

ii) Parameter of /(0.01L)

Residuary resistance coefficient C

R

then can be determined from the

graph / (0.01L) against prismatic C

P

at every V/L.

iii) Parameter of B/T ratio

The wetted surface coefficient, L S / value can be determined

from the graph of wetted surface coefficient against prismatic

coefficient Cp and calculated B/T ratio

iv) The wetted surface area from the wetted surface coefficient,

L S /

[2.17]

v) Reynolds Number,

UL

Rn

[2.18]

vi) Frictional resistance coefficient,

( )

2

2

075 . 0

LogRn

C

F

[2.19]

vii) Total resistance,

( ) ( )

2

2 / SV C C R

F R T

+

[2.20]

After all parameters are calculated, correction needs to be carried out with the

total resistance according to the B/T ratio. The correction can be determined from the

graph B/T correction factor against V/L.

17

viii) Calculate the real total resistance coefficient,

T T

R R

'

x Correction factor [2.21]

In this method, the resistances are base on the limitation of the parameter.

2.5 DJ. Dousts Method [2]

DJ. Dousts Method is used for calculating resistance based on the resistance

tests of about 130 trawler models carried out at the National Laboratory in

Teddington, England. The results of the tests were transformed into a trawler

standard length, between perpendiculars, of 61m (200ft). (Fyson J. 1985) There are

six parameters used in the early stage of design. Those parameters are L/B, B/T, C

M

,

C

P

, LCB and

e.

18

Parameter Limitations

Length/Breadth, L/B 4.4 5.8

Breadth/Draft, B/T 2.0 2.6

Midship coefficient, C

M

0.81 0.91

Prismatic coefficient, C

P

0.6 0.7

Longitudinal center of buoyancy, LCB 0% - 6% aft of midship

entrance angle,

e

5 - 30

Tables 2.6: Limitations for DJ Dousts Method [2]

This method is relevant to be used in predicting the resistance for fishing

vessels. However, correction needs to be taken into consideration for the ships have

different length compared to the standard ship length (200ft). Procedures of

calculation for DJ Dousts Method are as follows:

i) Calculate the parameter required to determine factors used to calculate

residuary resistance for the ship having standard length, 200 ft. These

parameters are L/B, B/T and V/L.

ii) Determine three factors used to calculate residuary resistance using

graph given. These three factors are

( ) T B Cp f F / ,

1

, [2.22]

( ) LCB Cp f F ,

2

and [2.23]

( ) B L Cp f F / , 2 / 1 ,

'

3

[2.24]

iii) Calculate

6

F

using

( ). 875 . 0 100

6

m

C a F

The parameter a is a

function V/L and given by Table 6.7

iv) Calculate residuary resistance,

( ) 6

'

3 2 1 200

F F F F C

R

+ + +

[2.25]

v) Calculate,

3 / 2

1

/ 0935 . 0 S S [2.26]

vi) Calculate, L V L / 05 . 1 ' [2.27]

vii) Calculate Froudes skin friction correction,

19

( )

8

3

' 6

2

' 4 '

175 . 0

'

10 / 22 . 1 10 / 77 . 2 10 / 29 . 0 0196 . 0 L L L SL SFC + +

[2.28]

viii) Calculate,

( )

( )

3 / 1

200 1

/ 5 . 152 SFC x [2.29]

ix) Calculate residuary resistance for new ship,

( ) ( ) 1 200

+

R new R

C C

[2.30]

x) Calculate total resistance,

( )

L

V C

R

new R

T

2

[2.31]

V/L A

0.8 -0.045

0.9 -0.053

1.0 -0.031

1.1 -0.035

Tables 2.7: Values parameter a [2]

20

2.6 Schneekluths Method (Taylor Gertler and Harvald Guldhammer)

This method consists of residuary resistance and Frictional resistance in order

to obtain the total resistance of a ship.

R

T

= R

F

+ R

R

[2.32]

2.6.1 Residuary Resistance

The residuary resistance of a new design is not quite so easy to calculate as its

frictional resistance. The coefficient of residuary resistance (CR) of a merchant ship

having the optimum position of the LCB can be approximated using the following

formula developed by Schneekluth. The formula tends to smooth out the effect of the

humps and hollows of the resistance curves. It is based on the published residuary

resistance curves of Taylor Gertler and Harvald - Guldhammer.

10

3

C

R

= (10Fn - 0.8)

4

(10C

P

- 3.3)

2

(10

3

C

v

+ 4)0.0012 + (10

3

C

v

0.05) +

0.2 + (B/T - 2.5)0.17 [2.33]

where

C

R

is the coefficient of residuary resistance

21

C

v

= Volume/L

3

[2.34]

and the other terms have their usual meanings.

The residuary resistance is then given by

R

R

= 0.5Sv

2

C

R

[2.35]

The limits of validity of the formula are:

0.17 < Fn < 0.30

2.0 < 10

3

C

v

< 11.0

0.50 < C

P

< 0.80

C

B

C

B

(Ayre) + 0.06 (C

B

(Ayre) = 1.08 - 1.68Fn )

5.0 < L/B < 10.0

2.0 < B/T < 4.5

The formula should not be used outside the specified limits.

2.6.2 Frictional Resistance

The International Towing Tank Conference (ITTC) is a body which co-

ordinates research into ship hydrodynamics. By studying a wide range of

experiments in which the resistance of ships, ship models, planks and other objects

was measured and by looking at the underlying scientific principles a consensus was

reached as to the most reliable way of predicting the variation of frictional resistance

of a smooth surface with Length and Speed.

This is normally referred to as the 1957 ITTC Line. The modern method for

calculating the frictional resistance of a ship is to use the 1957 ITTC Line with a

roughness allowance (typically taken as 0.0004) added to take account of the

distinctly unsmooth surface of a real ship: -

C

f

= 0.0004 + 0.075 / (log

10

Rn - 2 )

2

[2.36]

22

where

C

f

is the coefficient of frictional resistance

0.0004 is a roughness allowance

and Rn is Reynolds Number given by

Rn = vL / [2.37]

where

v is the ship's speed in m/s

is the kinematic viscosity which takes the following typical values: -

In Fresh Water at 15 deg C 1.13910

-6

m

2

/s

In Salt Water at 15 deg C 1.18810

-6

m

2

/s

The frictional resistance is then given by

R

F

= 0.5Sv

2

C

f`

[2.38]

where

is the density of water in kg/m

3

S is the wetted surface area in m

2

and may be given by

S = 1.7LT + LBC

B

(The Denny - Mumford formula) [2.39]

L is the ship's length in m

23

CHAPTER THREE

RESEARCH METHODOLOGY

24

3.1 General

This chapter puts emphasis on the using of methodical series to calculate

manually by means of using computer tools such as Microsoft Excel and later on

making source codes using MATHCAD or MATLAB to predict the ship resistance

and compare the results with existing program such as Hullspeed.

3.2 Computer Programs

3.2.1 Hullspeed

Only one computer software is chosen to predict the ship resistance which is

Hullspeed from FormSys. The selected computer program is to determine the ships

resistance which is more accurate than calculating it manually using the selected

methods. The data that been produce by the programs will be used as guidelines and

limitations to help calculating the ships resistance by using methodical series.

25

Hullspeed[6] provides a means of predicting the resistance of a ship hull.

Maxsurf designs may be read in and automatically measured to obtain the required

parameters, or the parameters may be typed by hand without the need for an existing

Maxsurf design file. If the overall efficiency of the propulsion installation is known,

or may be estimated, the power requirements of the design may be predicted.

Given the data required for the resistance prediction algorithms selected for

analysis, Hullspeed will calculate the hull resistance at a range of speeds and will

give results in graphical and tabular formats. These results may be copied to a

spreadsheet or word processor for further analysis and/or formatting.

Hullspeed supports resistance prediction calculations for a wide range of

monohulls and multihull. Many different approaches exist to predict the resistance of

a vessel. Hullspeed implements several different resistance prediction algorithms,

each applicable to various families of hull shapes. For example, some of the

algorithms are useful for estimating the resistance of planning hulls, while others are

useful for estimating the resistance of sailing boat hulls.

Besides resistance prediction calculations, Hullspeed can also be used to

calculate the wave pattern generated by the vessel for a given velocity. It should be

emphasised that resistance prediction is not an exact science and that the algorithms

implemented in this program, while they are useful for estimating the resistance of a

hull, may not provide exact results.

Hullspeed is essentially a resistance prediction program. A number of

regression-based methods and one analytical method can be used to predict the

resistance of the hull form.

It is normal naval architecture practice to break down the resistance into

components which scale according to different laws. Hullspeed can calculate the

resistance components in coefficient form. However, since different methods use

different formulations, not all the resistance components may be available.

26

3.2.2 MathCAD

MathCAD is computer software primarily intended for the verification,

validation, documentation and re-use of engineering calculations. First introduced in

1986 on DOS, it was the first to introduce live editing typeset mathematical notation

combined with its automatic computation. It was also the first to automatically

compute and check consistency of engineering units such as the International System

of Units (SI). MathCAD today includes some of the capabilities of a computer

algebra system but remains oriented towards ease of use and numerical engineering

applications.

27

MathCAD was conceived and originally written by Allen Razdow (of MIT),

co-founder of Mathsoft which is now part of Parametric Technology Corporation.

MathCAD is oriented around a worksheet, in which equations and expression are

displayed graphically, as opposed to a plain text, an approach alter adopted by other

systems such as Mathematica.

Among the capabilities of MathCAD are:

Solving differential equations, with several possible numerical methods

Graphing functions in two or three dimensions

Symbolic calculations including solving systems of equations

Finding roots of polynomials and functions

Statistical functions and probability distributions

Calculations in which units are bound to quantities

Although this program is mostly oriented to non-programming users, it is also

used in more complex projects to visualize results of mathematical modelling using

distributed computing and traditional programming languages.

3.2.3 MATLAB

MATLAB (matrix laboratory) is a numerical computing environment and

fourth-generation programming language. Developed by Mathworks, MATLAB

allows matrix manipulations, plotting of functions and data, implementation of

algorithms, creation of user interfaces, and interfacing with programs written in other

languages, including C, C++ and FORTRAN.

28

Although MATLAB is intended primarily for numerical computing, an

optional toolbox uses MuPAD symbolic engine, allowing access to symbolic

computing capabilities. An additional package, Simulink, adds graphical multi-

domain simulation and Model-Based Design for dynamic and embedded systems.

In 2004, MATLAB had around one million users across industry and

academia. MATLAB users come from various backgrounds of engineering, science

and economics. Among these users are academic and research institutions such as

Georgia Tech, Massachusetts Institute of Technology, NASA, Canterbury University

and RWTH Aachen University as well as industrial enterprises such as ABB Group,

Boeing, Caterpillar Inc., Halliburton, Motorola, Philips, Toyota and UniCredit Bank.

In addition to the usage of MATLAB B being integrated into teaching of

Engineering and Linear Algebra courses, as part as their Continuing Studies

programs, many Community Colleges and Universities are creating stand-alone

MATLAB courses focused on just teaching the MATLAB user interface and script

writing. These courses are especially tailored for returning students going back for a

higher-level degree and for students who graduated many years ago before

MATLAB was integrated into the educational system.

3.3 Methodical Series

There are 3 main methods that will be used when calculating the ships

resistance which are Holtrop and Mennen method, Van Oortmersens method and

Schneekluths method. Using these methods and calculating the resistance using their

formulas in Microsoft Excel, the ships resistance prediction will be obtained. Even

29

though the answer have been obtained, each of the methods came with its own

limitations that need to be consider before the actual results can be compare with the

results that been obtained using Hullspeed.

3.4 Collect Experiment Data

There was a model test have been done in UTM which the result can be used

to compare to the results that obtained by computer programs and methodical series.

It also can be as guidelines so that the results still have the same value but maybe

have a little margin.

3.5 Research Flow Chart

The flow chart mention in the Appendix A.

30

3.6 Research Master Schedule

The Master schedule mention in Appendix B.

CHAPTER FOUR

31

DEVELOPMENT OF COMPUTER PROGRAMMING USING MATLAB

AND MATHCAD

4.1 General

This chapter will explain the software that being used to program the

resistance calculation using the chosen methods. The guidelines that had been set up

using Microsoft Excel and result from Hullspeed will be compared with the program

that will be set.

4.2 MATLAB

MATLAB is a high-level technical computing language and interactive

environment for algorithm development, data visualization, data analysis, and

numeric computation. Using the MATLAB product, it can solve technical

32

computing problems faster than with traditional programming languages, such as C,

C++, and FORTRAN.

MATLAB can be used in a wide range of applications, including signal and

image processing, communications, control design, test and measurement, financial

modelling and analysis, and computational biology. Add-on toolboxes (collections of

special-purpose MATLAB functions, available separately) extend the MATLAB

environment to solve particular classes of problems in these application areas.

MATLAB provides a number of features for documenting and sharing users

work. You can integrate your MATLAB code with other languages and applications,

and distribute your MATLAB algorithms and applications.

Below are the key features:

High-level language for technical computing

Development environment for managing code, files, and data

Interactive tools for iterative exploration, design, and problem solving

Mathematical functions for linear algebra, statistics, Fourier analysis,

filtering, optimization, and numerical integration

2-D and 3-D graphics functions for visualizing data

Tools for building custom graphical user interfaces

Functions for integrating MATLAB based algorithms with external

applications and languages, such as C, C++, Fortran, Java, COM, and

Microsoft Excel

4.3 Source Coding Process Flow

33

Basically, the process of source coding of MATLAB is similar with other

source coding programs such as FORTRAN. Users just need to key in the main

particular or formula that will be used to make the program running as in this case is

to calculate the ship resistance.

First, user need to open the program and create a filename based on the

program that will be set in order for the programmer or other user to use the program.

This process is to distinguish the program that been created so that it will not be

mixed with other similar program but different method or etc.

Next, from the formula that been used before when calculating manually

using Microsoft Excel, programmer have to determine the main particular that will

be change when to calculate other vessels resistance. Then, the velocity of the ship

must be determined so it will automatically calculate the Froude number, for looping

process and for other variables in the formula used.

Further more write the formula that being used to calculate the resistance one

by one and determine what the formula is for so that it will not confused other user

what is that formula for. Make sure that the formula is written according to its

arrangement to prevent from miscalculation or mixed up.

Write until the last variables of the formula and then proceed with running the

program. See whether the program have problem or not. If there wasnt any problem

occur, than the prediction of the total resistance of the ship can be gain from the

program and compared with the formula manually calculated and with other familiar

program been used to calculate ship resistance.

If there were problem, the software will identify which line that is incorrect or

cannot be read by the software. So the problem will be identify by try and error or

search the manual what the causes of the problem and try to rewrite the line and re-

run the program again. If still have problem, identify and rewrite the incorrect line

until the program can produce the appropriate results.

4.4 MathCAD

34

Engineers, scientists and other technical professionals across the world use

MathCAD to perform, document and share calculation and design work. The unique

MathCAD visual format and easy-to-use scratchpad interface integrate standard

mathematical notation, text and graphs in a single worksheet, making MathCAD

ideal for knowledge capture, calculation reuse and collaboration.

MathCAD drives innovation and offers significant personal and process

productivity advantages for product development, engineering design projects and

hundreds of other applications where calculations are key. Unlike proprietary

calculating tools and spreadsheets, MathCAD lets you document, format and present

your work while applying comprehensive mathematical functionality and dynamic,

unit-aware calculations. MathCAD lets you work with updatable, interactive

designs, allowing you to capture the critical methods and values behind each of your

projects.

Benefits:

Easy to learn and use - no special programming skills required

Increases productivity, saving time and reducing errors

Improves verification and validation of critical calculations

Promotes calculation best practices and reuse of calculation content

Complete documentation of calculations supports standards compliance

4.5 Source Coding Process Flow

35

Basically, the process of source coding of MathCAD is similar with other

source coding programs such as FORTRAN. Users just need to key in the main

particular or formula that will be used to make the program running as in this case is

to calculate the ship resistance.

First, user need to open the program and create a filename based on the

program that will be set in order for the programmer or other user to use the program.

This process is to distinguish the program that been created so that it will not be

mixed with other similar program but different method or etc.

Next, from the formula that been used before when calculating manually

using Microsoft Excel, programmer have to determine the main particular that will

be change when to calculate other vessels resistance. Then, the velocity of the ship

must be determined so it will automatically calculate the Froude number, for looping

process and for other variables in the formula used.

Further more write the formula that being used to calculate the resistance one

by one and determine what the formula is for so that it will not confused other user

what is that formula for. Make sure that the formula is written according to its

arrangement to prevent from miscalculation or mixed up.

Write until the last variables of the formula and then proceed with running the

program. See whether the program have problem or not. If there wasnt any problem

occur, than the prediction of the total resistance of the ship can be gain from the

program and compared with the formula manually calculated and with other familiar

program been used to calculate ship resistance.

If there were problem, the software will identify which line that is incorrect or cannot

be read by the software. So the problem will be identify by try and error or search the

manual what the causes of the problem and try to rewrite the line and re-run the

program again. If still have problem, identify and rewrite the incorrect line until the

program can produce the appropriate results.

36

CHAPTER FIVE

EXTRAPOLATION FROM UTM MODEL TEST

5.1 General

This chapter explain the method used to extrapolate the data taken from

model test done in UTM towing tank (Muslim, 2010) and convert the data to RT

s

and

compared it with the result gain from calculations.

37

5.2 Introduction

Extrapolation methods are methods that are being used to convert the results

or data obtained from model tests to full-scale condition. In model powering test, the

results obtained are meant for the specific size of the model and does not present the

actual powering requirement for the full-scale ship. Thus there is a need to

extrapolate the result obtained from model test to full-scale ship.

Model test is an experiment conducted on a small-scale ratio model. Model

testing is meant to estimate the hydrodynamic quantities such as resistance powering

or sea keeping requirement of full-scale ship through the technique of extrapolation

of the data obtained from model test.

5.3 Experiment Data

The data that been collected from UTM Marine Technology Laboratory have

to be extrapolated to get the correct result that needs to calculate and predict the

resistance of the trawler.

Rtm Ctm Vs (m/s)

Vs

(knots)

Fn Rnm

7.10E+00 0.0069505 4.6296 9 0.2779 2767824.561

1.05E+01 0.0083360 5.1440 10 0.3087 3074210.526

1.35E+01 0.0088552 5.6584 11 0.3396 3380596.491

1.81E+01 0.0099539 6.1728 12 0.3705 3689052.632

2.54E+01 0.0119154 6.6872 13 0.4013 3995438.596

3.80E+01 0.0153684 7.2016 14 0.4322 4303894.737

38

Crs Ca Caa Cts Rts(N)

0.0006145

3

0.0004

1

0.000

2

0.004649

6

8406.15496

0.0021281

7

0.0004

1

0.000

2

0.006111

9

13641.97308

0.0027599

6

0.0004

1

0.000

2

0.006698

3

18090.43903

0.0039594

0

0.0004

1

0.000

2

0.007857

1

25253.52860

0.0060108

8

0.0004

1

0.000

2

0.009871

8

37237.62409

0.0095459

2

0.0004

1

0.000

2

0.013373

3

58505.33735

Table 5.3. Extrapolation Data of Fishing Trawler

5.4 Model Test Analysis

From the result that been extrapolated from the model test that being done in

UTM towing tank and compared with the resistance result obtained from Hullspeed,

researcher can see that the total resistance of the model is almost similar pattern of

the graph which is the model test is the most accurate but it has to be done in many

39

Rns Cfm Cfs Fn^4 Fn4/Cfm Ctm/Cfm (1+k)

110098890.8 0.00380 0.00205 0.0059616 1.568507 1.82868 1.667

122332100.8 0.00372 0.00202 0.0090729 2.436333 2.23848 1.667

134565310.9 0.00366 0.00200 0.0132673 3.628481 2.42182 1.667

146798521 0.00360 0.00197 0.0188135 5.231827 2.76807 1.667

159031731.1 0.00354 0.00195 0.0258861 7.308310 3.36402 1.667

171264941.2 0.00349 0.00193 0.0348543 9.978857 4.40002 1.667

runs in order to get most accurate data from the test. But by using this single run test,

we can see that the resistance result is almost the similar to each other but the small

differences may be cause of the limitations of each formula and the machine flaws.

Figure 5.1 Comparison for Trawler Resistance

40

Figure 5.2 Comparison of Hullspeed and Model Test

41

CHAPTER SIX

RESULT COMPARISON AND ANALYSIS

6.1 General

In this chapter will explain the concept of three methods that use in this

project. As the objective of the project is to prove the empirical formulae include 3

methods (Holtrop and Mannen, Van Oortmesen, Schneekluths) are relevant and

validate the result with model test and programmed software by comparing the result.

However, due to parameter limitation we have to come out with 3 difference type of

vessel (fishing trawler, Frigate. Tanker), those have different length, beam, draft and

reliable result according to limitation.

42

6.2 Result Comparison

By creating source code programming software made easier the work using

MATLAB base on the empirical formula come up with result that be compared with

Hullspeed And Model Test.

6.2.1 Trawler Resistance Prediction

To predict the trawler resistance using vessel main input parameter are

enclosed to the MATLAB programming with 3 methods to achieve result. However

result from MATLAB are not the end result, it must be compared with Hullspeed

result and Modal Test. Below is the graph shown the result from empirical formula,

software and model test;

43

Figure 6.2.1: Resistance Prediction for 28.3m Trawler

The result are been plot to the graph above and shown the result from

empirical formula, software and model test. From the result attained that the values

and pattern of the graph almost identical only at the coefficient resistance (CT)

around 5.00E-03 to 1.50E-02. When regardless the limitation ratio, the value start not

coherent and reliable. Limitations of the 3 methods need to be considered, and not all

value is consistent can be used.

It is because the difference of usage of formula between MATLAB coding

and Hullspeed creates the large gaps with the range value. In this case the usage of

the formula which is possibly slightly difference from reciprocally. Bear in mind the

limitation should not be neglected.

44

6.2.2 Frigate Resistance Prediction

The result produce from 2 source coding MATLAB and MathCAD,

illustrated the similar result with programmed software Hullspeed to be compare. But

nevertheless the difference occurs effected in value and graph pattern.

Figure 6.2.2. Resistance Prediction for 80m Frigate

The deviation between the MATLAB source coding and Hullspeed result

almost the similar, but the Frigate data is a remade lines plan to ensure and validate

the empirical method with the program software. So the result between 2 data

Holtrop Mannen almost identical; however without model test for frigate cannot

assume the data as final result. It just imaginary linesplan as a guideline to ensure the

empirical formula and the software data are relevant. Normally, this method is

45

suitable to be used to calculate the resistance for small vessel within 40m to 120m

length range.

6.2.3 Resistance Prediction for Tanker

The method and formula to conduct prediction are the same as the proven

software used. But the data result slightly gave different on value went in goes bigger

froud number and from formulae that been used nowadays. For this type vessel

besides Holtrop and Mannen Formulae, Schneekluth( Taylor Gertler and Harvald

Guldhammer) a modified method also suitable to use.

Below shown the graph of tanker obtained from using Schneekluth formula

compared with Holtrop and Mennen from Hullspeed.

46

Figure 6.2.3. Resistance Prediction for 100m Tanker

47

6.3 Analysis of Selected Methods

There is 5 different method that been found only 3 methods are reliable which

is Van Oortmersen, (Holtrop and Mannen) and Schneekluth( Taylor Gertler and

Harvald Guldhammer). From the chosen methods, there are parameter on limitation

need to be consider before resistance prediction can start. It is because ensure the

parameter of the vessel are not out of the range or less than range that will affected

accuracy of values and results.

From the reseach noticed that for a small vessel such as fishing trawler are

suitable to calculate resistance with Holtrop and Mannen and Van Oortmesen

method. In this case for 28.3m fishing trawler are not reliable to use calculate the

resistance using Holtrop and Mannen method because the vessel parameter are less

the range within the limitation. To estimating resistance for the trawler, the Van

Oortmesen method is useful for predict the resistance.

Due to parameter limitations, reseacher need to expend the reseach on the

others 2 methods and not only focusing on one method that only can calculate for the

small vessel. By adding with 2 differrent type of vessel the research will expand. A

method has been determined to be useful to calculate small vessel resistance but to

calculate medium and large vessel, it is more appropriate to use Schneekluths and

Holtrop and Mennens method respectively

48

Below are the graphs being compared with all the methods being used to

calculate the resistance for frigate and tanker plus with model test result:-

Figure 6.3.3. Resistance Prediction for 80m Frigate

The differences of percentage and the accuracy of the method can be shown

through the bar graph as below.between 2 model data, the method schneekluth is the

most realiable to be used in this method.

however, when using on small vessel and not following the limitation test, they will

be some difficulties on facing with total resisnatce of the modal test, as when using

appropriate method and limitation, we will have a result that is accurate and precise.

49

Figure 6.3.4. Percentage Differences of Fishing Trawler

Figure 6.3.5. Percentage Differences of 100mTanker

50

CHAPTER 7

CONCLUSION AND RECOMMENDATION

7.1 Conclusion

Only one method that can be used to calculate the fishing trawlers resistance

and that is Van Oortmersens method. The other two are not reliable enough due to

their formula limitations but it can be used to calculate the resistance of other type of

vessels such as frigate and tanker.

This program can be used widely for student to calculate and predict their

ships resistance and help them to calculate the powering requirement to propel their

vessel. Even though there is many reliable software or programs that exist nowadays

to calculate and predict the vessels resistance and powering, this program is also

51

reliable and can be used like other existing and well-known program such as

Hullspeed.

This program can calculate the resistance without having the user have to

draw or design the shape of the vessel. This program just need main particulars to

calculate the resistance and can give the result that almost similar to well-known

software.

Even the user is using the well-known program and can get the right values

and results, they still have to recalculate and get the new values that change because

the design process is in spiral and kept repeating/changes again and again until get

the final and satisfied results that meet the owner requirement.

7.2 Recommendation

For future recommendation, to be a naval architecture, they should learn and

know the basic empirical formula to calculate the resistance and other properties so

that they would understand what they are doing. This is because to train them not to

depend on the programming software that only needs clicking to get the results. This

will train them to be more alert and mature to handle and solve any problem occur in

the future.

52

References

1. SV. AA. Harvald, Resistance and Propulsion of Ships

2. Alizam, UTM.

3. Dr. Mohamad Pauzi Abd. Ghani, Ship Resistance, UTM.

4. Rawson and Tupper, Basic Ship Theory Vol.2

5. J. D. van Manen P. van Oossanen, Principle of Naval Architecture Vol.2

6. Hullspeed Manual.

7. Navcad, HydroComp Inc.

8. Mr D.L. Smith. Marine design, Universities of Glassgow& Strathclyde

53

APPENDIX A-

APPENDIX A

Flow Chart

54

START

LITEREATURE

REVIEW

SELF-

PROGRAMMING

SOFTWARE

COLLECT

EXPERIMENT

DATA

ANALYSIS

COMPARISON STUDY

VAN

OORTME

RSEN

HOLTROP

AND

MENNEN

SCHNEEK

LUTH

NAVCAD

2007

HULLSPEED

UTM MODEL

TEST DATA

Resistance

prediction for

single screw ships

ITTC 1978

REPORT

METHODOLOGY

LIMITATION AND

GUIDELINES

APPENDIX B

Master Schedule

55

56

APPENDIX C

57

3D and 2D Modelling

In this appendix to shown the model of the vessel in 2D and 3D view for references.

58

59

60

61

62

APPENDIX D

Programming of Rapid Prediction Resistance Flow Chart

In this appendix, the flow chart of the Rapid Prediction Resistance writen in

MATLAB R2010a. There is 3 method to be program in this programming.

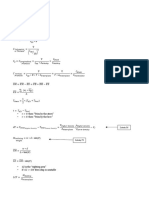

HOLTROP AND MANNEN PROGRAMMING FLOW CHART

OPEN

CREATE FILE

NAME

Velocity =1:1:25

CODE THE

MAIN SHIP

PARTICULAR

PROPERTIES OF

WATER

CRITERIA/

LIMITATION OF

ADDITIONAL

COEFFICIENT

CG

C15

LAMDA

C4

C12

C16

FORM

FACTOR

RTOTAL=(RF*kf

ac)+RW+RtR+R

B+RA

RESULT

END

LOOPING

FOR

VARIOUS

SPEED

63

SCHNEEKLUTH PROGRAMMING FLOW CHART

OPEN

CREATE

FILENAME

Cr = ((((( 10*Fn)-0.8)^4)*(((10*Cp)-

3.3)^2)*(((10^3)*Cvol)+4)*0.0012)+...

(((10^3)*Cvol)*0.05)+0.2+(((B/

T)-2.5)*0.17))/1000;

Rr=0.5*rho*S*(V

^2)*Cr;

mu=1.188E-06;

Rn=((V*L)/

mu);

Cf =

0.0004+(0.0075/

((log10(Rn))-

2)^2);

Rf=0.5*rho*S*(V

^2)*Cf;

CODE THE

MAIN SHIP

PARTICULAR

VOLUME=L*B*T*CB

FROUDE

NUMBER(Fn)

Cvol = Volume /

(L^3);% must be

between 0.002 and

0.011

Velocity =1:1:25

RESULT

ANALYSIS AND

RECOMMENDATION

Rt=Rf+Rr

LOOPING FOR

VARIABLE

SPEED

end

for

`

64

VAN OORTMESSEN PROGRAMMING FLOW CHART

OPEN

CREATE

FILENAME

CODING

SHIP MAIN

PARTICULA

R

Velocity

=1:1:25

ANGLE OF

ENTERANC

E

FROUDE

NUMBER

(Fn)

mu =

%kinematic

viscosity of sea

water in m^2/s

Rn=((Velocity*L)

/mu);

CWL=ie*(3.142/180)*(L/

B);

CWL=ie*(3.1

42/180)*(L/

B);

C1

C2

C3

C4

RRper_displacement=((C1*exp((-

m*(Fn^2))/9))+(C2*exp(-m*(Fn^-

2)))+...

(C3*exp(-

m*(Fn^2)))*(sin((Fn^-2)*(3.142/

180)))+...

(C4*exp(-

m*(Fn^2)))*(cos((Fn^-2)*(3.142/

180))));

m=0.14347*(Cp

^-2.1976);

RFper_displacement=(0.075*rho*S*

(Velocity^2))/(2*(((log10(Rn))-

2)^2)*displacement);

RTper_displace

ment=RRper_di

splacement+RF

per_displaceme

nt;

RT =

RTper_displace

ment

RESULT

ANALYSIS AND

RECOMMENDATION

end

LOOPING FOR

VARIABLE

SPEED

For

65

APPENDIX E

SOURCE CODING AND INPUT DATA

In this appendix. The show the conducting the input data for the program

Rapid Prediction Resistance writen in MATLAB R2010a ,that being develop in this

project.

VAN OORTMESSEN INPUT

66

SCHEEKLUTH INPUT

67

HOLTROP AND MANNEN INPUT

68

69

70

71

72

73

You might also like

- Marine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders and Control Surfaces: Principles, Data, Design and ApplicationsRating: 4.5 out of 5 stars4.5/5 (3)

- Resistance and Powering Prediction For Transom Stern Hull Forms During Early Stage Ship Design S C FungDocument56 pagesResistance and Powering Prediction For Transom Stern Hull Forms During Early Stage Ship Design S C FungGoutam Kumar Saha100% (4)

- Marine Rudders, Hydrofoils and Control Surfaces: Principles, Data, Design and ApplicationsFrom EverandMarine Rudders, Hydrofoils and Control Surfaces: Principles, Data, Design and ApplicationsNo ratings yet

- Modern Tug DesignDocument83 pagesModern Tug DesignJohn Angelo Tuliao100% (1)

- Bow ThrustersDocument15 pagesBow ThrustersJohn Angelo Tuliao100% (1)

- Quasi-Efficiency PropulsionDocument31 pagesQuasi-Efficiency PropulsionWafaà WafaNo ratings yet

- Section Modulus CalculationDocument3 pagesSection Modulus Calculationtejaswi_rao_1No ratings yet

- Methods For Designing ShipDocument60 pagesMethods For Designing Shipbahrul100% (1)

- Inclining Experiment Report of Manzari - 1Document12 pagesInclining Experiment Report of Manzari - 1Hari RamNo ratings yet

- NPTEL Ship Resistance CourseDocument2 pagesNPTEL Ship Resistance CourseMKS3006No ratings yet

- Holtrop & Mennen - An Approximate Power Prediction MethodDocument6 pagesHoltrop & Mennen - An Approximate Power Prediction Methodjimmyy90100% (2)

- Question:-Resistance QuestionsDocument3 pagesQuestion:-Resistance Questionsaimri_cochinNo ratings yet

- HYDRODYNAMIC CHARACTERISTICS OF PROPELLERSDocument46 pagesHYDRODYNAMIC CHARACTERISTICS OF PROPELLERSBishop TariganNo ratings yet

- Bulbous Bow On Ship ResistanceDocument16 pagesBulbous Bow On Ship ResistanceMARIO HUAMANNo ratings yet

- Doc. No. 1-42 18 100 011 - REDocument17 pagesDoc. No. 1-42 18 100 011 - REsidan magnaNo ratings yet

- Stapersma - Matching Propulsion Engine With PropulsorDocument8 pagesStapersma - Matching Propulsion Engine With PropulsorTuan Truong MinhNo ratings yet

- How High Speed Monohulls are Affected in Shallow WaterDocument20 pagesHow High Speed Monohulls are Affected in Shallow WaterStalin ZapataNo ratings yet

- Ship Form Coefficient PDFDocument10 pagesShip Form Coefficient PDFSurendra Kumar SinghNo ratings yet

- Ship Behavior in Shallow WaterDocument20 pagesShip Behavior in Shallow WaterTomas GrigoliusNo ratings yet

- General Arrangement Plan Lecture PDFDocument58 pagesGeneral Arrangement Plan Lecture PDFAktarojjaman Milton100% (2)

- Probabilistic Damage Stability RegulationsDocument54 pagesProbabilistic Damage Stability RegulationsReza BabriNo ratings yet

- Design of Ship RuddersDocument82 pagesDesign of Ship RuddersGerard Sarg100% (1)

- Bulkheads FinalDocument15 pagesBulkheads Finalvikram5211No ratings yet

- 14 Stability TrimDocument37 pages14 Stability TrimDr. Ir. R. Didin Kusdian, MT.100% (1)

- Prop Design ExampleDocument7 pagesProp Design Exampleancamardelli100% (1)

- Naval Architecture Equation Summary SheetDocument11 pagesNaval Architecture Equation Summary SheetAnonymous JSHUTpNo ratings yet

- Calculation (Midship) of ShipDocument24 pagesCalculation (Midship) of ShipSarath Babu S100% (7)

- Ship ResistanceDocument41 pagesShip ResistanceVidoz Diedozz0% (1)

- Rudder DesignDocument11 pagesRudder Designnawan67% (3)

- Ship Stability OOW Load LineDocument34 pagesShip Stability OOW Load LineAmin Al Qawasmeh100% (1)

- Ship Resistance & Propulsion Vol2 PDFDocument622 pagesShip Resistance & Propulsion Vol2 PDFRafee Revaldi100% (1)

- Propeller CalDocument15 pagesPropeller Calbadppl100% (1)

- Stability Data BookletDocument18 pagesStability Data BookletPaul Ashton25% (4)

- 773optimization of Catamaran Demihull Form in Early Stages of The Design Process5-16925-1-Pb - 2Document6 pages773optimization of Catamaran Demihull Form in Early Stages of The Design Process5-16925-1-Pb - 2Muhammad IqbalNo ratings yet

- CatamaranDocument9 pagesCatamaranCornel N. ŞeitanNo ratings yet

- Rudder Calculation PDFDocument8 pagesRudder Calculation PDFeltioferdiNo ratings yet

- Module-1 Part-A: Basic Ship Theory Question Bank 2018Document9 pagesModule-1 Part-A: Basic Ship Theory Question Bank 2018T VigneshwarNo ratings yet

- Ship Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesFrom EverandShip Magnetism and the Magnetic Compass: The Commonwealth and International Library of Science, Technology, Engineering and Liberal Studies: Navigation and Nautical CoursesRating: 5 out of 5 stars5/5 (3)

- Basics of Ship ResistanceDocument44 pagesBasics of Ship Resistanceapi-27176519100% (15)

- Ship Hull DesignDocument66 pagesShip Hull DesignRiyan EsapermanaNo ratings yet

- Naval HidromechanicDocument75 pagesNaval HidromechanicSeptiànAgistà14100% (1)

- LDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceDocument9 pagesLDD 30502 Ship Resistance and Ship Resistance and Propulsion TOPIC 1: Total Hull ResistanceIkram NajihuddinNo ratings yet

- Powering and Propulsion: Lectures ONDocument61 pagesPowering and Propulsion: Lectures ONbovingNo ratings yet

- Chapter Vi Resistance PredictionDocument18 pagesChapter Vi Resistance PredictionAbraham RakuljicNo ratings yet

- Paper Part IIDocument8 pagesPaper Part IIPrasanta Sahoo100% (1)

- Computational and Experimental Works On Ship ResisDocument9 pagesComputational and Experimental Works On Ship ResisKyaw Win TunNo ratings yet

- Catamaran Wave Resistance Prediction Using Regression AnalysisDocument15 pagesCatamaran Wave Resistance Prediction Using Regression AnalysisTihomir MarkovicNo ratings yet

- Hiper04 Paper ADocument13 pagesHiper04 Paper AaspoisdNo ratings yet

- ITTC Calculation Procedures Lab1Document8 pagesITTC Calculation Procedures Lab1Widhana Fajar KussumaNo ratings yet

- Szelangiewicz-Zelazny An Approximate 60-2019Document8 pagesSzelangiewicz-Zelazny An Approximate 60-2019Mohamad JammalNo ratings yet

- Nonlinear Finite Element Analysis of Side Structures Subject To Ice LoadsDocument34 pagesNonlinear Finite Element Analysis of Side Structures Subject To Ice LoadsMahdiNo ratings yet

- List of Certificates and Documents Required On BoardDocument19 pagesList of Certificates and Documents Required On BoardMahdi100% (2)

- Corrosion Protection Strategies For High Speed CraftDocument8 pagesCorrosion Protection Strategies For High Speed CraftMahdiNo ratings yet

- Manuale FRP GB0 6 2014 PDFDocument92 pagesManuale FRP GB0 6 2014 PDFjuli_rad0% (1)

- Strength Analysis of Hull Structures in TankersDocument40 pagesStrength Analysis of Hull Structures in TankersMahdiNo ratings yet

- Theory of Plasticity For Steel StructuresDocument257 pagesTheory of Plasticity For Steel StructuresMahdi100% (2)

- Designing Winches for Dynamic SeasDocument4 pagesDesigning Winches for Dynamic SeasMahdiNo ratings yet

- Application of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersDocument65 pagesApplication of Higher-Strength Hull Structural Thick Steel Plates in Container CarriersMahdiNo ratings yet

- Design Report Agile Surface Combatant, Aluminum (ASCal)Document136 pagesDesign Report Agile Surface Combatant, Aluminum (ASCal)Mahdi100% (2)

- Eurocode Superceded ListDocument5 pagesEurocode Superceded ListLaughlikesiao HeheNo ratings yet

- Failure Defintion For Structural Reliability AssessmentDocument85 pagesFailure Defintion For Structural Reliability AssessmentMahdiNo ratings yet

- Bulb FlatDocument12 pagesBulb FlatMahdiNo ratings yet

- Calculation of Marine PropellersDocument14 pagesCalculation of Marine PropellersMahdiNo ratings yet

- Ship's Survey & Good Maintenance On BoardDocument109 pagesShip's Survey & Good Maintenance On BoardMahdi100% (8)

- Eurocode Superceded ListDocument5 pagesEurocode Superceded ListLaughlikesiao HeheNo ratings yet

- 7500 DWT chemical tanker technical specsDocument118 pages7500 DWT chemical tanker technical specsMahdi100% (1)

- Strength Analysis of Hull Structure in Liquefied Gas Carriers With Membrane TanksDocument30 pagesStrength Analysis of Hull Structure in Liquefied Gas Carriers With Membrane TanksMahdiNo ratings yet

- Guidance For SPMDocument49 pagesGuidance For SPMMahdiNo ratings yet

- Guidance For SPMDocument49 pagesGuidance For SPMMahdiNo ratings yet

- National Standard For Commercial Vessels-StabilityDocument117 pagesNational Standard For Commercial Vessels-StabilityMahdiNo ratings yet

- Bulb FlatDocument12 pagesBulb FlatMahdiNo ratings yet

- National Standard For Commercial Vessels-StabilityDocument117 pagesNational Standard For Commercial Vessels-StabilityMahdiNo ratings yet

- Guidance For SPMDocument49 pagesGuidance For SPMMahdiNo ratings yet

- Marine Proj Uss VarunaDocument187 pagesMarine Proj Uss VarunaDanio JoeNo ratings yet

- Guidance For SPMDocument49 pagesGuidance For SPMMahdiNo ratings yet

- Tonnage 1969 InterpretationDocument27 pagesTonnage 1969 InterpretationMahdiNo ratings yet

- Abs Guide For Passenger Comfort On ShipsDocument106 pagesAbs Guide For Passenger Comfort On ShipsMahdiNo ratings yet

- Maritime Rule, Part 40A. Design, Construction and Equipment - Passenger Ships Which Are Not SOLAS ShipsDocument107 pagesMaritime Rule, Part 40A. Design, Construction and Equipment - Passenger Ships Which Are Not SOLAS ShipsMahdiNo ratings yet

- Design of Double Hull Tankers-GL Presentation May 2005Document42 pagesDesign of Double Hull Tankers-GL Presentation May 2005Mahdi100% (1)

- 01 Dee1012 Topic 1Document52 pages01 Dee1012 Topic 1norzamira100% (1)

- G Code ListDocument3 pagesG Code ListRautoiu AndreiNo ratings yet

- Measuring Inequality: An Introduction to Concepts and MeasuresDocument255 pagesMeasuring Inequality: An Introduction to Concepts and MeasuresNaresh SehdevNo ratings yet

- EE380 LabmanualDocument95 pagesEE380 LabmanualsekinNo ratings yet

- The Gran Plot 8Document5 pagesThe Gran Plot 8Yasmim YamaguchiNo ratings yet

- G (X) F (X, Y) : Marginal Distributions Definition 5Document13 pagesG (X) F (X, Y) : Marginal Distributions Definition 5Kimondo KingNo ratings yet

- Simulation of A Tank Fill by Volume of Fluid Method Using Ansys Fluent - Training, Projects & Research CenterDocument9 pagesSimulation of A Tank Fill by Volume of Fluid Method Using Ansys Fluent - Training, Projects & Research CenterHayderAlSamawiNo ratings yet

- Statistical Non Parametric Mapping ManualDocument47 pagesStatistical Non Parametric Mapping ManualKrishna P. MiyapuramNo ratings yet

- Chapter 3. Drag Force and Its CoefficientDocument47 pagesChapter 3. Drag Force and Its Coefficientsmyeganeh100% (1)

- Sajc 2010 Prelim Math p2Document6 pagesSajc 2010 Prelim Math p2lauyongyiNo ratings yet

- Renormalization Made Easy, BaezDocument11 pagesRenormalization Made Easy, BaezdbranetensionNo ratings yet

- RD Sharma Solutions (Ex - 1. 5, 1.6, 1.7 & 1.8) - Rational Numbers - RD Sharma SolDocument15 pagesRD Sharma Solutions (Ex - 1. 5, 1.6, 1.7 & 1.8) - Rational Numbers - RD Sharma SolSunil AnandNo ratings yet

- Demand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductDocument2 pagesDemand: - Demand (D) Is A Schedule That Shows The Various Amounts of ProductRaymond Phillip Maria DatuonNo ratings yet

- Computed Tomography Notes, Part 1 Challenges With Projection X-Ray SystemsDocument24 pagesComputed Tomography Notes, Part 1 Challenges With Projection X-Ray SystemsBilge MiniskerNo ratings yet

- QuizDocument10 pagesQuizJohanna RullanNo ratings yet

- Subsea Control Systems SXGSSC PDFDocument6 pagesSubsea Control Systems SXGSSC PDFLimuel EspirituNo ratings yet

- Sensex 1Document354 pagesSensex 1raghav4life8724No ratings yet

- Cross Drainage WorksDocument71 pagesCross Drainage Worksjahid shohag100% (2)

- Cast Iron DampingDocument5 pagesCast Iron Dampinggabs88No ratings yet

- ΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorDocument5 pagesΔΣ Modulator with Low power Using Charge- Pump Based Switched-Capacitor IntegratorIPASJNo ratings yet

- Z Score CompiledDocument36 pagesZ Score CompiledKamille Anne Valdez DavidNo ratings yet

- Average Internal Rate of Return and Investment Decisions: A New PerspectiveDocument40 pagesAverage Internal Rate of Return and Investment Decisions: A New PerspectiveBharat MaraiyaNo ratings yet

- 1 Number Bases Student Module 1Document3 pages1 Number Bases Student Module 1X UnknownNo ratings yet

- Determine Beam Deflection Using Integration and Geometric MethodsDocument8 pagesDetermine Beam Deflection Using Integration and Geometric MethodsNadiaNo ratings yet

- Workshop User Guide of GrafcetDocument150 pagesWorkshop User Guide of GrafcetJames HabibNo ratings yet

- Database Systems COMP-213: By: Shahid M HmoodDocument46 pagesDatabase Systems COMP-213: By: Shahid M HmoodTranceNo ratings yet

- Day 2.1 Activity 3 Jemar Wasquin.Document5 pagesDay 2.1 Activity 3 Jemar Wasquin.Jemar WasquinNo ratings yet

- SPUD 604 ManualDocument37 pagesSPUD 604 ManualfbarrazaisaNo ratings yet

- Mathematics Standard 1: NSW Education Standards AuthorityDocument34 pagesMathematics Standard 1: NSW Education Standards AuthorityPoonam SinghNo ratings yet