Professional Documents

Culture Documents

Rifling Machine

Uploaded by

kcwelderOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rifling Machine

Uploaded by

kcwelderCopyright:

Available Formats

MuZZ6l0d06I

Barel Machine

by Gerald R. Hunter

Georgia

There are several gunshops in this country which can

turn out an excellent rifle barrel or rechoke a shotgun

tube to your preferred percentage, but for many muzzle

loaders this is not enough. It wasn't enough for me, when

I bought bucketful of flintlock parts from Dixie Gun

Works, induding an unrifled barrel blank.

Of course, many a muzzleloader who would give his

eyeteeth to be shooting a rifle barrel he had built himself,

may be well heeled, but there are also many poverty

stricken ones who cannot afford such custom work. The

barrel machine described and pictured here, of my own

design, is versatile, accurate, minimal in cost, and small

enough to fit into the tiniest home workshop.

Among the many operations which can be performed

on the device are rifling, overboring, finish reaming to

land size, chambering, throating and muzzle-relieving of

rifle barrels, as well as choke cutting, chambering, lap

ping and polishing of shotgun bores.

The rifling rig cuts any number of grooves from I to 12

(including the awkward 7 and II) and any pitch from I

turn in I foot to infinity in a straight twist (and with U

arched cam bar, the gain twist).

While the device could be used for deep-hole drlg in

solid blanks, it is intended for overboring shot-out rifle bar

rels, or increasing the bore size of useless calibers to larger

conversions like . 357 and .4 magnum, or muz eloaders.

The same unit that does the borng is utilized also for finish

reaming after the borng, preparator to rifljng. In smooth

bore barrels it can be used to remove pitting when thickness

of barrel walls allows, to ream out choke, and to rechamber.

This same unit is used for all work on rifle barrels except for

lapping and cutting the liOing. Shotgun bore work is done

on the third unit of the device.

A single motor transmits power through a series of V-belts

and pulleys to operate the devices at proper relative speeds.

the rifling head is hand-operated, as is the shotgun barrel

carriage_ The barrel boring carriage may be hand-operated

or powered by cables, pulleys and weights.

Overall size of the composite machine is only 24 I wide

by 42' high by 96" long, but it could be smaUer. The ri

fling platform may be swung out about 450 during the

brief time when actual ri fling is being done, to make it

more comfortable for the operator, and also so the cam

bar (which determines twist) has additional room when

severe rates of twist are being cut.

Expense "f the machine can vary widely. For instance,

the .frame can be made of welded I-beams; expensive

thrust bearings can take the loads; highly tempered rack

and pinion gears can turn the cutter rod, and so on, to a

very staggering figure. To shave costs severely without

sacrificing efficiency, my machine is constructed from

materials you would classify as junk. It cost less than $50,

excluding the motor.

The most important ingredient is the entire operation is

that of proper perspective. You must first understand

just what you are doing, what the parts of the machine

are to do, and how you are going to make the machine do

them. Once you have this' 'big picture" you are in a posi

tion to economize most on construction.

Few of the tolerances are critical. You can vary the di

meions of the parts to fit whatever supply of materials

you can acquire at least cost. If you can find a cam bar of

somewhat different thickness than specified, for in

stance, at a substantially cheaper cost, by all means sub

stitute it. Further savings can be effected by utilizing used

materials. Superficial rust on a rail or bar from a scrap

yard may make that material available for JO per pound

instead of several dollars per pound for some newly al

loyed metals, either of which would do the job. In the

case of rods, use hot or cold rolled steel instead of drill

rod, at vast savings. For the hollow boring rods, use

seamless steel tubing instead of the more expensive air

craft qUality. For chucks, borrow those already on hand

fr

c.

m some of your other appliances or machines.

To begin a[ual construction of the machine, cut the

Act;urau indexing of the r barrd vcm be done by using

a compo

llnd

bubble protractor temporaily ci1ped to pipe that w

be the vise,

Compltlld r/ling barrel vlst. insldt Induing head.

4x4's to Ingth for the main frame, then the 2x2's for the

scondary part. Mortise the joints Or half-lap them. and

as you join the parts apply glue, true them with a square,

clamp them, drill pilot holes, and bolt or screw them to

gether. Allow the glue to dry thoroughly before proceed

ing farther. The machine will be subject to vibration,

which will wreck your structure unless it is soundly made.

Do not permanently install th bed for the lapping!

choking device until you have found, by actual xperi

ment, where it must go to align properly with the chuck.

Rifling

Rig

B

e

gn with the platform, a 2 7 10 7 96 inch straight,

we

ll

seasoned plank, and bolt or screw the tracks on one end of

it. Any track that is substantial and reasonably true wldo.

Make up the carriage block; and rabbet, dado, or oth

erwise, make it a clean sliding fit in the channels of the

track. Length must be provided to give room for the pi

nion gear, rack gear bar, bearings and hand grip.

The ball bearings (roIler skate wheels) must be firmly

bolted to the carriage with V-straps, or something simi

lar. Between the bearings, at right angle, bolt the chan

nel iron guide for the rck gear. The rack gear isa bicycle

chain bolted to a flat steel bar that will slide snugly in the

greased guide channel.

Anchor the rack gear to the rack gear bar with a stout

machine screw at either end, for the bicycle chain must be

very taut. The rack should be long enough to all ow two

! more complete revolutions of the pinion gear (a bicycle

rear sprocket) when assembled and meshed.

The largest rod that will pass through the hole in the

sprocket acts as the pinion axle. Turn down ends of the

rod to fit through each bearing (the skate wheels), leaving

shoulders turned on the rod as natural end stops, and

braze the rod true in the sprocket. Before assembling the

ale, adapt the longer end of it to hold the rifling rod. A

common threaded joint, which allows twisting, wiII not

suffice. You can cut a lap-and-hook joint, held together

with a movable sleeve. or a small chuck.

Assemble the sprocket-mounted axle into the bearings,

mesh sprocket with the rack gear, then bolt down the

bearing housings.

Camming

The cam bar, by the angle it forms with the spacing bar,

determines the bore distance per revolution of pitch to be

cut, and must be four feet long if you want to cut barrels up

to 42". This proportion may be used for shorter lengths. The

pivot end is attached to the platform with a bolt; the opera

tor's end is anchored to the spacing bar with any movable

device which wlsecurely hold it to the index. Dogleg bends

raise the cam and spacing bars up to the level of the rack gear

guide so they'll operate in the same plane.

The cam end of the rack is drilled to accept two bolts.

A short under bar, 8" long, is drilled and mated to that

end of the cam bar, and a ball bearing skate wheel i s per

manently bolted under the rack bar and inside the cam

bar. The outer holes are elongated to allow adjustment

(fast twists cramp the cam), and a second skate wheel is

mounted on a wing nut adjustment bolt through the

routed holes. The skate wheels must embrace and snugly

roll along the cam bar; the wing nut adjustment is neces

sary because the space between the wheels increases as the

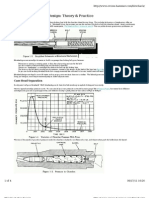

. .. OilLinc

::

-

_

.

O

il

S

e

a

!

Healing

TranSrerpulle)

.

___

_

I

f --_." DrivcPulley

Drive. ______ " .

-

Mandrel. ______ __

Chuck. ___________ --

Track. ____ ____ ---

Skate Whed ___ _ _

Carriage_________

-3"

Frame _________ ._

. _ . __ Chuck

_. __ Track

____ , ... Oil Pan

_ _ ___ .. Barre

l

Vise

___ ._Ca

riage

BORE RA LAP

R0nRod_

` .

3mct

.

_

_

Chuck.

Skate WhcI

Pinion Gear

,

,

:, :.

Handle PuIl

,

,

Lzrtiayc

`

Handle "

`~-

.^

Pict

Bolt

*

Platrorm

Ballc\Vis

.

*

,5:opCcIIat

_~,

'

. lode.ingHead

..

,/:.

Inde.

Pn

<:

^

M

ount

H1LH

SetScrews

Cam 83r Pvct

CamTar

5katcWhccI

AdJutment

stop collar for

h end which wlkep the small pip from

fore-a

nd-aft driftlIlg. Bolt the outer QIQc firmly on

the plat

fonn

to line up

with 1DCQgaxle and rod. .

Cut

the

smaller pipe,

.

which is your

barrel vise,

enough

longer than the outer plpe so that you cau have room for

opposed set screws which will hold the gun barrel. Insert

the small pipe into the larger and drill a small hole

through both pipes; this is your first basic index refer

ence. Whh these holes firmly aligned (by a temporary

pin), affix the stop collars. To index the barrel vise, space

the circumference of the vise into the number of divisions

(grooves) you may want to cut. You can set up 0 12-

groove index with just one outer index hole, and with

it

cut 12, 6, 4, 3 or 2 equally spaced grooves. But you must

drillS additional outer indices to cut 5, 10,7. 8, 9 and J

grooves. Ends of the barrel vise should be drilled and

tapped at right angles for two sets of set screws each to

grip the gun barrel.

Barrel Boring, Reaming

First step i the oil pan. Ol a wooden template, 7' x 8" x

2", clamp the sheet metal over it, and bend the oil pan into

shape. A drain hole for the cutting oil is cut through a lower

corer of the pan. Solder a cup under this hole, with its own

exit hole below, to hold some loose packing a a filter for the

oil. For gravity feed you need a catch pan, and a reseroir

mounted above the machine. A oil line connects the reer

voir to the hollow driveshaft so cutting oil wlbe fed to the

work. Mount the oil pan with self-threading screws, through

neoprene washers, into the oil pan platfonn.

Borng Head

Thread one end of the driveshaft to take a chuck that

will hold the boring rod. True and polish the outer end of

the driveshaft to take the pressure-snug oil line. Install

the shaft in the 1 pulley and through the mou nted

thrust bearings. JD boring track should be as long as the

Rifling rods and

cutter head. Fore and aJt, carriage

guides.

Rile

barr;1

udamped In ILre wllh

machine screws. Cutler

in top

center oj

hell ,

woodtn shim In pilce below.

Rifling carriage. Fore and aft, guide rails. Right, wooden o

p

erating

handle. Background, cam bar. Center, bicycle sprocht is actuated by

bicycle chain mounted on bar which slides in channel iron as carriage

move.I. Note ball bearing skate wheels (bearings) in moun/so Rifling rod

at left ctnter.

longest barrel you will bore plus cnglhof the longest bit

or reamer you will use, fastened firmly through Ihe bot

tom of !bcoil pan to Ihe oil pan plalform.

The boring barrel vise is made from a Z thickwall

pipe, with opposed set screws to grip the barrel. This vise

U firmly mounted to the carriage, which can be made of

either wood or metal. Depending on the scrap available,

make guides that will force the carriage to slide accurately

down the track. Criteria for mating of the carriage and

track is that they be an easy sliding fit, free of wobble, so

the cutter won't chatter. Centerline of the vise must cor

respond to centerline of the drive chuck.

One end of the hollow boring rod is held Ithe chuck. The

other end V brazed or threaded 10 the cuUer, with a bleed

hole through the rod wall at the cutter so cutting oil c

reach the work, 6!the tube and be caught in the oil pan.

Lapping, Choking

The device for rechoking, internal polishing, bore lap

ping and removing rust from barrel chambers is mounted

paraUed to the boring tool, and nearer the operator since

. the carriage is hand-fed.

Begin with 'the track. a simple strip of hardwood 1

long, Z" wide and I deep, nailed to its platform. The

wooden carriage must be wide enough to handle the wid

est double barrel guns and drillings with which you will

work. as well 8 single barrels and barrels having awk

ward integral lumps or mounts. The carriage cover is

clamped to its base with four opposed wing nut machine

bolts, 80when the cover is screwed down tightly on a bar

rel. the barrel is firmly held in the carriage. The carriage

moves on ball bearing roUer skate wheels to allow eas).

consistent carriage movement alan, its track_

Mount the ball bearing mandrel so the shaft aligns with

the track. If barrel-widths of the guns you are working

with

is extreme, instead of nailing the track to its plat

form, you will have to provide lateral adjustment. On lhe

outer driving end of the mandrel put a b drive pulley

then a 2`pulley that will transfer power \0 Ihe cutting de:

vice. The inside end of the mandrel takes the chuck. ^

lJ motor, with the pulleys specified. will give

proper speeds for most operations. The malar should be

al least k h.p., and a full 1 h.p. wi\\ be less likely to stall

and leave a cutter stuck :La high-priced shotgun tube.

OH Seals

Culling oil is gravity fed to the O0/|n[ drive shaft by a cop

per oil line, bent to shape so it exerts pressurc against the end

oflhe hollow mandrel. The two pasages arc mated against a

hollow neoprene "button" (which you can shape with a little

experiment), and the oil itself provides ample locallubrica

lion as the mandrel turs against it.

To seal the joint wherc cutting oil lcavcs the mandrel and

passes through the centerless chuck to the hollow boring rod,

a simple, flat, flexible neoprene or plastic washer inside the

chuck prevents escape of the oil. Hold the borng rod tightly

againsl this washer while locking the chuck.

Rifling

The main essentials in rifling are these: (a) make sure

the gun barrel cannot slip in the barrel vise; (b) double

check before starting to make sure the bore is reamed to

land, not groove, diameter; (c) keep a sharp cutter, with

enough relief not to bind; (d) never stop the cutter during

a stroke; (e) never change the relationship of the rifler to

the bore until the job is completed.

To rifle. mount the barrel, muzle toward the cariage.

M]betwen the set screws. Slip the rifling ro through the

barrel and moun

l

1{1Dthe chuck. 7lthe cutler head ad

adjust the shims for the first cut, which should be ver lht,

lor .Jkthe indexng head. Ancor the O

Son, Gerald, Jr. operates riftr. Below, center, carriage of boring/

rramlng machinr

In oil pan.

Etrrme below, Shotgun barrel In carlolt

of shotgun tool.

` Pulley

On Motor

--10"

--

-

DRIVE

.

6" Pulley

/

on the spacing bar for the required amount of twist.

h0 Cut is made on a pustroke. Make the fIs! cut with a

dry bore. After the cut, inspect the bore to make sure the cut

Gean and consistent. Now remove !h0shims from the {-

ter head, put 8|8!Chwet wilh CuUnoil on the head bulton,

and push the head through 1he bore in reverse, thus cleaning

out the chip ad lubOca!mg for Ihe n0xt Cut.

Shim up the cutter for about a .UJCut (thickness of a

brown paper bag). Pu\l the indexing pin, rolate the barrel

vise to !hcnext hole, and replace the pin. Squirt mOre c|-

ting oil in the bore and take a new cut. When you h

ave

been all the way around the index, add anothcr paper

shim and repeat un!! !h0 d0J0d d0!h of grouve is cut.

About .012isusual.

Choke Cutting

To remove choke, or to cut a recess choke in a cylinder

bore barrel, lock an ordinary brake cylinder hone, avail

able from most auto supply houses, in the shotgun chuck.

Lubricate with cutting O!. h0D Cut!ng recess choke,

provide carriage stops so the cutter will cut only the

cW!h of choke you want. Don't slop the carriage In niid

track; hep a steady back-and-forth motion. Stop the

motor and remove the barrel frequently for inspection.

Lapping, Internal Polishing

As diagrammed, the power shaft of this tool turns at

approximately 800 RPM, ideal for most such work. 1!

this speed it exerts a lot of bulldog power - enough to

wrench

the carriage out of your hands if it

gets

away

from you, possibly severely injuring you. 1!is wise 10pro

'vide 8foot or knee cutoff switch so you can instantly stop

the motor if necessary. Faster speeds build up too much

heat and burnish rather than cut; slower speeds tend t

gal! and may freeze the cutter in the work.

The

chuck

on the driveshaft should be large

enough

to

hold

up to

V" cutter rods. You wl need Yz /

down to 1/"

rods

to

cover JO

down to .410 bore tube,

each a little longer

than the longest gun barrel to be worked on. The end of each

rod should be slit with a hacksaw or mlfor 4" to I " depth

depending on rod dianleter, to accept part of a sheet of

emery doth. Coarse grits are best; flne grits may polish a bit

prettier, but have been found not to have enough friction to

control shot well.

You will also need some rubber to shim up the emery as

the cut proceeds and wears the grit down. Use plenty of

cutting oil.

In practice, tear off a piece of emery cloth, slip it into

the slit of the rod, and wind it so it will follow the direc

tion of rotation. Use as much winding as you can force

into the bore as the rod begins rotating. In full-length

bore polishing, keep the carriage moving full-length back

and forth, with no stopping, and with considerable pres

sure being needed to hold the carriage and to make it

move back and forth. When the resistance becomes easy,

slide the carriage off the cutter, stop the motor, and add

shimming or more emery; fe-lube and cut again.

Never let the emery stop in the tube or it may stick and

give you fits removing it without damage. To help pre

vent such a catastrophe, keep drive belts and chuck very

tight, and use a motor you can't stall.

M0IH

}

, MuH1H

}

The eselltia1s Othese operations are to have al\ ade

quate 1OW O cutting oil; to make sure the cutting rod

OOcsD't slip in the chuck; and to have the carriage free of

all undue wobble that would cause the cutter to chatter.

Boring is best done OD a pull stroke, because the entire

!OOW rOO aets as a pilot, and the emire bore behind the

In

P

rlht hand, chuck j<hlch hold bo,;n,l"gm( rods; ;1ule!t,

cult/n, oft/ttd lint, In IeJ| hllnd, chuck which holds shottun lapp'''

rod, Nou wooden slide at lowtr 't/I, /0 adjusl b,'t /tns/on, Top, rift'

mreI0e

Ano

lh

"

vi

.

..

of

sh

Olg

"

n

b

a

rr

"

vis

e!

c

a

rr

ia

g

'

(r

o

nl)

;

re

ar,

b

a

rin

,

!

rea

m

ing

ch

uck

.

bil is available !0 take the chips. Keep thc bit going and

the carriage moving or your stopping will show up as a

ripple in thc bore.

Reaming is usually done immediately after the boring,

and can be done on either a pull or a push stroke. 1n the

instant machine, sct up for boring on a pull stroke, ream

ing should bc done likewise. The weight-pulley-cable ap

Dlication will result in much smoothcr reaming than is

,)Ossible by hand.

An dfective rcamer can be made by grinding down

a

wornou! square file of applicable site, which automati

cally provides a feeding taper and a soft iron end to braze

to the rod. It should be ground so that the first cut is very

shallow. For succecding cuts, place a long wooden shim

between one side of it and thc bore, so the shim will force

the opposite cutting corner to ream. Add paper shims g

necessary. as in rining.

Excellcnt reamers also can be made of lathe tool bilS,

particularly cobalt or tungsten carbide bils. In silver sol

dering or brazing the bits to the rods, use 8 little heat as

possible and a heat sink, to prevent drawing the temper.

Use the automatic gravity oiler if at 8 possible, and

]0n!)of cutting oil. .

Tlengthy volume could be written on the techniques o' f

rifling, choking, boring, reaming, lapping and the other

potentials of this maching. You will enjoy lurnin. these

things you operate your Own homemade machine.

Construction Procedure:

The main frame must be built first. Joinls musl be

bolted and glued to prevent looseness from working vi

brations. Flooring over the bottom is optional, but pro

vides a

place for accessories. Solid boards must be

used

for the rifling mechanism and the lapping bed. A mid

levelshelfmwt be provided for the molor, its height de

ltndent upon size of the molor and length of the mQ(a

minimum of 1 h.p. motor, because you don', want a lap

to get stuck midway of a bore, which might ruin the

whole job). Above the motor pulley, a sliding mount

must be provided for the lapping arbor and pulley and

behind it, a mandrell on which to mount the chuck and

puUey for the boring and reaming device.

After installation of the above, a track must be made

on which the cradle for the lapped (bore polished barrel)

will run. Recommended size is 2 V2" by Y I depth to

whatever length barrel you expect to process. The cradle,

running on four rolter skate wheels, is made of oak, with

a cover to hold the barrel, of the same material. The

cover is clamped by four wingnut bolts to hold the barrel

tight when being lapped or polished as it is passed to and

fro for application of the rod which is held in the chuck.

Behind the lapping polishing track is the part for bor

ing and reaming.

A

sheet metal pan is mounted here, with

neoprene washers so it won't leak the cutting oil which is

fed in through the chuck holding the reamer or drill. This

oil is fed from a I-gallon can mounted head-high above

the far end of the machine, as a gravity feed. The oil

flows down through the chuck into the hollow rod to

which the drill Of reamer is attached, and escapes through

a hole drilled in the rod just behind the cutler. A drain

hole is provided for the pan. :

The rifng device could b made separate from the rest of

the machine, but is mounted atop it for practical working usc.

The whole thing is mounted on a 2 x 6 board, pivoted at the

far end Vth a bolt so it Cbe swung to the left to give more

room for working it. Guide ras (of whatever material is

available) are attached to either edge, so the rifing index wl

move in a straight line. A blok of wood is made so it has

flange which follow the guide rails. To this is bolted a half

square steel beam, which seres as a channel for the index

chain to run back and forh. The chain, fastened solid at both

ends, is a common bicycle chain. This chain actuates a com

mon bicycle sprocket (from the same scrap bike, in this case)

which is fastened to a chuck which holds the rifling cutter

rod. The sprocket is mounted i pillow blocks, so it L tum

as the head is slid back and forth. The progession of the tum

(pitch) is regulated by a cam bar. The bar is anchored at the

near end of the guide rails, the far end being able to swing i

and out depnding on the rifling pitch deired. The far right

end of the chain mount has a bracket which s lides along the

L bar, so that as the rig is pulled (this is a pull CUller), the

L makes the chain move rght or left which, in tum, re

volves the sprocket, that tums the culler rod.

The barrel vi se is a hollow steel tube also mounted on

the same board; it has four big headed set screws to hold

the barrel firm for rifling. This tube goes inside the index

tube. The index tube is pre-indexed with 6 holes (more if

you want more than 6 turns to the length). You put a steel

pin through the index into a matching hole in the barrel

vise; make a pass with the cutter; pull the pin, rotate the

vise until the pin drops into the next hole; then make an

oter pa

s with

_

the cutter, and so on.

In iing, after you cfamp the barrel in the vise, you

damp the cuUer rod in the chuck, run it through the bar

rel so it comes out the far side, screw the cutter head to it

and crosspin the cutter so t won't unscrew. Put a shim

(common brown paper is about .UU3" under the elev, tor,

squirt culting oil in the bore, and pull one pass. Rem' ove

the shim, push the rod back through the bore, rotate the

barrel one hole, and rcpeat. When you have finished all

grooves (or however many you wish to index), add an

other thickness of papcr (or whatever) under the first

shim, and repeat the cutting process. Usually this is done

four times, for a groove depth of .Oll". Push a tight

patch through the finished rined bore; if it i s too rough,

lap it smooth with a poured lead slug and valve grinding

compound, or a grit of your choice.

To operate the lapping/polishing devce, clamp the gun

barrel flT y in the carriage, so the bore lines up with the rod

held in the chuck. Hold the carriagejirmly .. . . ith both hands

or the torque may take I! away from you and make a gand

mes. To leave both hands free, it Vbest to install a motor

s"itth that you can K with a motion o your X=. T Y

diameter longer than the n Dattc should be hacksawed

sptit about thIee inches at the working end to accept a wind

D of emery cloth. T more slender rod may whip and be

dangerous - even fatal -- as it revolves without a center rest.

The emery cloth should be wound to follow the diection of

the turg rod. It should be as tight as you can comfortably

control; a backing of a piece of bicycle inner tube W pro

vide the fit and also allow nexibility. Cutting oil should 0

squirted into the bore and onto the emery cloth, and the

emery slowly fitted to start into the bore. With hand pre

sure, the cloth is passed back and forth slowly through the

bore. Tfiner grit should be used lofinish the job. Never Jet

the turg rod stop with the emery doth in the DCIc.

In using the drilling device, or the reamer, also do not

let the culler stop in the Dutc.hcdrill or reamer is Qf0

Detail of all comer joints. Frame is of finished 2x4's, which of course

actually measure q 0 I, Longitudinal members are through boiled to

upright Unon; cross members extend across tenon and upright and are

0screwed

into logitudinal member. All joints, before fnal

takeup of

the bolts and screws, are glued with eXlerlor Weldwood glue, available

i small amounts/rom almost any hardware store or craft shop.

All other wooden connections are simple lap joints secured with double

through bolts and glue.

No'e of the dimensions aTe critical. They may be varied, depending

upon materials a'ailabJe to whomever is constructing the machine.

pelled by a gravi!y weight, through a pulley; l it balks

add a DIof propulsion by hand but never force it rapi0ly:

Barrel Machine--Materials required

Frame

lineal feet 4 x 4" lumber (mlin frame); 28 lineal feet

2" x 2" lumber (secondary frame); 24 !\Bc t0I Z"Xb"

lumber (main platforms); 1V square feet of flooring; 4

square feel of Zmaterial (for motor mount) I pint glue;

machine bolts, or lagscrews, with washers, to pin joints.

Rifling Rig

Jmk

8|Otm- WC00XZX (included in frame above);

Tracks - preferably steel, two 5 ' sections of channel iron

(old garage door hanger tracks will do).

u06u_Head

Indexing sleeve - iron p;pe "to Ilong, Z Y" , Stop

collars - 2" sections of above piece of pipe; Stop collar set

screws - 1 ar setscrews in each collar; Induing sleeve

mount-wood, l' x 4" x 4"; Barrel vise - iron pipe longer

than sleeve, 2 7 LL, Barrel vise lock screws - two sets

of Out opposed machine screws; Indexing stop - sma!!

tapered eel pin to match index holes.

l0Inuex

Cam bar - iron, 54" x I Y" x */t, L3 bar pivot - short'

V`section cut from same stock, plus bolI; Spacing bar -

iron, 42", cuI from same stock; Spacing bar pivot - bolt,

through DatinlO platform.

RifiiD&Head

Rifling rod(s) - slightly under bore size(s); Riins rod

chuck - simple lap CuIjoint plus steel sleeve Jock; Rifling

rod cutter * steel rod, length and diameter to suit; Rifling

CuItct

-

"7t" piece of old file, lathe Dit, elc.

Carriage

Carriage block - wood, 12" x 6" x 2";

Carage gips - wood, 20" x 3" X I";

Thrust bearings - two ball bearing

roller skate wheels; Bearings mounts -

bent iron straps, bolted down; Rack

gear - bicycle chain securely screwed to

rack gear bar; Rack gear ba - iron,

42" x 1 Y" x Y 1; Ca roller bar - 8"

section of same stock; Ca roller

bolts - short bolts to fasten skate

wheel s to ca bar; Rack gear bar

guide - channel iron, slip fit for bar;

Pinion geai - rear sprocket from bicy

cle, matched to chain; Pinion gear

shaft - shaft through pinion and bear

ings, 6" long.

M0IB@~ M88D1D@

Power pulley - standard V, 10 di

ameter, ! II bore; Drive belt - stan

dard V to match, 40 I length; Shaft

hollow seamless steel tube ! NOD,

12" long; Bearings - matches pair

standard mounted ball bearings, YII

bore; Oil tank - I, 3, or 5 gallon can

(for cutting oil); Oil feeder line -

standard

t

/8" copper tubing 36"

long, with cock; Oil seal - neoprene

or vinyl button between shaft and

line; Oil pan - strip of galvanized

roofing (flashing) 96" X 12 "; Oil

sump - small tin cup, plus filter ma

terial; Track - inverted channel iron

60" x 2"; Track bolts - four anchor

bolts hold track to bed.

Carriage

Barrel vise - iron pipe 24" X 2" 1,

plus lock machine screws; Carriage

block - wood, 18" X 2 VI" 7, Car

riage guide - iron straps, screwed to

block

-

; Boring bars - hollow steel,

length and diameter to suit; Cutters

_ bits, reamers to suit, machine or

handmade; Chuck - stout 3-jaw,

centerless, to accept t" slock; Oil

seal- neoprene or vinyl washer to fit

inside chuck against heel.

pggn_- 1D0XD@

Power pulley - standard V, 6", with

y"D0f8, Transmission pulley - stan

dard V, 2", Ybore; Main drive belt

standard V, , Bearing unit -

standard bal bearing mandrel, DE

V " shaft; Chuck - cheap hand tight

3-jaw to take VI" stock; Track - wood,

84" X2" X 7; Carriage - two wooden

boards 16 I x 4 ; clamp bolts to grp

barrel between boards, 9 skate wheels;

Carrage stops - wooden pegs, spaced

Htrack as work requires; Lapping rod

- steel, maximum diameter to suit bore

and job; Cutters - wound emery cloth,

abrasive coated felt bobs, or automo

tive brake cylinder hone.

Power

. Motor - heavy duty 3/ or 1 h.p., 220

volts, 1750 RPM preferred; Motor

pulley - standard V. 3 ' diameter, to ft

motor shaft; Motor mount - wood (in

cluded in frame materals); Motor

switch - foot or knee switch, for emer

gency cutoff.

Miscellaneous

Cutting oil - at least 1 @alon; Do not

Uf lubrcating oil to cut; Hardware -

asorment of bolts. Jag screws, D

chine screws as neeed; Pat - vyl,

epoxy or

p

olyeurethane enamel wil

hel

p

keep machine easy to clean, and

wl

p

rotect against oi l rot; Solder - for

oil

p

an and sump.

`''=9^".i,, Ih. -0'1'''1' f"r r;rIi,, II ,.,,,,,, \,,,,I

h

., _,,, ,

"

II". b:..l:."hid"II,,.II

'

j

h

Il

n".r "r,;.", .

.

i tI. .,,t,..(,(; . ,I . -,.

,

. i_ 1'"II,oJ ,,

1

""1'

L |. Kuehn, obcve, rifling 0 muule.loodu, borrel with equipment

and tool. of hi. Own de.ign ond moovtoct,, righ', onorher viow

|'he home'mode rifling equipmen'. Skill olld pu'ie"ce o-

o 'equired

on atloching 'he wooden .plin". '0 'he cylinde . It 'qu"e teom

ing

ond

bending

:bio .triPI o( o, oo@ ollaching

wi,h ,crew .

At top, above, two views of rifing heads.

Under the scale is a wedge for adjust

Ing the cutters; second from the bottom

Is a foat used for clearing the barrel of

the old rifing; at bottom is an adjust

ing device. Right, close-up view of the

head of the rifling guide, the index

boards and their method of attachment.

Uniform TwIst Rllllng

Study the diagra on lhe lefl Jfyou want to

make a rifling cyUnder that has one tum

36, you c start with a cylinder that m36

long where lhe grooves a to be cut. A0c-

Ible metal wire Is attachcd to one end of the

wooden cylinder at poInt l. It Is then stretched

Sllnght away from the cylinder to a point tmt

Is equal to the circumference {dIstance around

lhe cylinder!. poim2 From point 2the WIre

Is stretched to i poInt l3mathe other end

of tie cylinder mat Ise.nctly 36from point .

It Is best 1the cyUnder tslying flat on atable

or workbench. Point 2 shouldbe stapled or

lacked to lhe nch so U:utIt do<:s nOI move. Now roll the cylinder toward poInt 2. ^the cyllnder

Is rolled. the wIre from pOUl I Will roll around one ndoIthe cylinder. When you have fnished

rolling the cylinder POints I an(t 2ltouIucome together Now the wire from po:nt2. 3 make one

spiral arou.nd t he cylll1der ii+|ic36"length.

DEEP HOLE DRILLS

Li us wlk 11iltlc <hcml the Deep HIlle Drill. Sizes. and thl' Grimling

of the orill. What U Deep Hole Drill look like. and "111111 of the

terminology of Ihe rarhitlc drill.

I will nUl

g

(1 inlt) thcgrimJing ttl much of the Deep 1-1t)1t; Bils. as m{l1

will buy lhe sizes that they need. When you have III huy the 'V' luhe.

am Ihclirililips, plus insHllIlhc tlrilillrivcr, ind tip. il isjll1 a"uul as

cheap to huy the completed drill. Ifyuu want tll griml your tlrililips.

the various makers if Glrhidc lools will he able tll supply ynu wilh Ihe

scvcrotl izcs (If Carhide deep helle drill tips Ihal you \\ill ncell. Te

gnuJc()f t.:;lrhidc u!.ua IlyslIp*

plied ror deep hole lip:. is

IK1.

GRINDING TIPS

Tu set up for grinding the

deep hole tips. all Ihal is

necessary is 1 tur 2 short

pieces of drill rod, ahoul I

inch long, center one end of

Deep Hole Drill Tips

each piece, The drill rod

shuuld be the same size as

the drill tip that you are

planning to grind. Gel a

small V way, or'a piece of

finish angle. Lay the tip and the 2 pieces of drill rod, with the cenlers

out Uclh end of tile lip. Get some low melting silvcrs()ldcr and j()in

the 3 picces.

and

C

D

E

IIVEl

AS DEG.

0

I'OEG.

_ -

FL

20 DEG.

0

20DEG.

PosnON CHISLE

PRIMARY CLEARANCE

POINT AT

' ` |

.19JXDIA.

' I

SECON?

?

J

--\ :SS

CLEARANCE THAN ,020

i-

L-

DRILL TIP CLEARANCE

Usc Ihe lowesl name possihlc 10 melt I he silver solder, as 10 much heat

will OGin (ra(k Ihe GHhillc lip. Whcn donc lei (001 in the fixture.

When cool set up hetwccn centers of the lathe. set tail stock over so

u1Ove1CeLL*

g

o

o

e'

rt1uF

NO"rNCL . Tunr or cuN .. .. ,

you wi l l have U I lkgrcc i ndudcu taper per inch rrom the front or

(ulling edge or t i p t o t he hark.

After this. grind the primary land. This will have to he ground U

ahsolutcrcntl'r. AJkr lhi s is done. hcaL Ihedri ll t i p lip and remove the

:

l

DRILL

TUBING

CUTG EDGE

.

.

HOLE

DRILL liP

THROGH

TP

k 1 1Ubb

ceOiered ends. Grind lhe remainingsilvcr solder from lhecarbidc li

p

.

iflheholc>are pl ugged, dri l l lhcm oul. I have found lhal welders chalk

rubbed inlO Ihe holes of I he l i p will help H keep the solder from

plugging i l . The drill can now be moun led O the drill lubing.

IMfLL lf #M$5 lN CNWCWM

The V luhing can he purchase from High Sianoun!. l Donjon.

address arc in the hack of the hook under suppliers. 1 would rCllffi

mend Ihal Y()U huy Ihe firsl (ie from Ihe suppliers. This will save you

some head aches on your first harre!. The urill will last for several

humlrcd harrcls if you have no m.dtlcn(, ami you take (arc of them.

DRILLING THE RI FLE BARREL

In Ihi. dmp't'rwc \\ i l l cm'(:r I he pron: Suf makin)! lhl' I i l ll: 11;1 1 ' 1: 1 . 1y

II\IWyou kIll 1\\ III 1\\ 1 hI. ' 1< II\: l l l' !'II' lUIIU. 0UU ha\'t' " l'!`ilka of

hnw t he ri l l e har l c! l

lIIadc. I \\ i l l nnw ll'll you "h :p 11\ "'\'P hl l\\' 10 _O

"hOlll rakill,! 01 III1 h;mel.

Firs! I woul d SI I I 1 \\ j I ll :1 ` i urh X 2(, inch IIltl.! ]lic 01 `UI\I

Sfl\"Sprnnf. Thi <,Iccl VIII dri l l . 1""::1111 . ., nll riflc h(' , 1 1 I 1 i l l l l . :IIHI ;,111I111

IICl(,1 .Iiw, al l Y " ! l l l hk. Thv nrq Illill! In th. i I n ] 1 1 1 1 1 1 1 i .. I >: 1 I il 1 l lH:

1:" ll l `

lt1111 01 1 l' .:nd. and (cnlel dri l l l . On Ihl' , . , h, ' , l"lld i . I bl:sl

In lact" i. ni l :thl '

rj akcsl l I t I hal I l i e ' , ' nd I hal \IHI 1 1. 111(' 1 d I i l l ed J1 1 : 1 1 : 1 1 1 0 1 "1 1 1 1 " I I li AI I !f

I I H' 1I:l I l d I I.ItUI . 1 1 . IVii l l':-ll' ndl'll. I rtlJ l l l hl: clwd; : 1 1 ' 1 ' 1 1 1 !

,

i mhc'i.

If lIlhand i" .1 i{'k i Illl l I (1111 I hl' cnd (l r I hl' 1<11 lie. 111:1 kl a wllar. \\ il

h

SCi Sl'rl\' . lilt' hanl'l clIl he l'l'!Hl'ICUHI lU I i,!i d. Al lhl' l1ieh ~pccl

1 11;1 1 I iiI. 11;1 I 1 tl I til i lled. I he end ni l he harTl'1 wi l l ... 1 : 1 1 1 1 1 1 r1l1l 1 1 1 1 1 and

vihr;I1t.'

.

The rhi p box i S in' ,Jalled wi r l l r he sr arh :r hll"ihill! ill pla(,l', ;11111 r he

slarlel' hll:hill i ~ H'I

.

(" ; udul l y nusIil'u lIJl H!ainSI I lll' h:l l i d hl ank.

(:Ol1I1CCI :111 1 (shields

,

UIIII'I I"I IrLCI :

t

hOUl l ht: C lIH' Pll lhc: t' nd nr , hc

l.l lhe Ihal wi ll rCll1 l l1 l ilt: Clil whel; you ,!o IIHOII!,h th(' haHt'1 \'jlll the

lIrill. 8011 ihe II i 1 l 1lrivcI holder.ccntering it ViI h Ihe renter I I I he lail

stuck. 11 would he 111111(' fll:llr<lIC if II would he dnll<` \\Oh a 5han

dlUdcc ill till: II.!ad tuLk, t hrough t he opening t hat hullis the drill

drivJ:f,

Sct lhl: lle(p lit Ill' drill ill I he dril l drivlr (11 11) Iilrriage, l(mnel:l the

hylll allli, huse I n I Ill! l i l l illg. IIW\,try c.iHcfully Iafl I he drill I ip illio

the l ul l Il hll!hing. I kI t H'c. yllil 1111"11 1111 Ihe I i l lll Il!sl II (1I I l , lIllUhlc

dld Ihe !et Llew that hilids Ille drill ill, I fYlll l l ur 1I11 1hc oil iIHI

m1 6cw6 1OR

cn1mINu Bumt.

lATHE WITII COLLETS

FOR 1I0LDlNG BARREl,

t ur II p r I l l: P 1"(. "'.' U!v, Y It, wi l l llIW Ol l r 1 1 1.: OI i l l ili ld

I

' 1

ihk chip I hl:

l i p, <lml iIlt g.1 all i l i l hi l i l l

Tur UII I I I ..: oi l . hUI bdl lre \t III \l I l l wk. II I ": I hal l ile vidvl' is ()PI\ al l

I he way..t1 I l lere i" J I ll pl ':"'11 rc i I I I he I i II":.

I

I cwryl hi ng i U K you ,He

pumping I hL' oil h.II:" 1 l 1 1 he l ank, wi t l i very l i l l lc oil gl l ing t hrough Ihe

drill. N, IW dllc tile valve l( )wly. watching t lie pn; .... urL' (I l l the ,'ilIge.

when i l geb lip I I I l\ I I I liJIJ 111 ..

which is ahout I he righl pressure fu

3D calihtr h'IHeb.

Lei il lUHfor ,I JJl illllle IJIo It H:her" h II' leak .... l .utI" ami l'C IHI\\' much

oil i: cllming OUI {II I Ill: l i p. Theh l1ollld he qui l L a hi t . Thb i ...

iI1lPlll l ; I I I I .. wlhlI yt) I I ;l I cdl i l l i llg l hi: l OIlt wily t hat yl l il watdl to

sec i t your dl i l l b pl l l ggLtl Up. ;l I y l i llll: I he nllw slow: 111 1\,11, I I I ttlP.

Ol pn':","lIfc goe ... II p . .h II 1 (jOWl! Illc kcd fa"' l . Ill' you wi 1 / l ui n I he dri l l .

I wi l l ,IS:lIl11e t l l at Y' I II have :t l h'"dv I' llilllgl'll l l l c qui rk (' !lange gcarssil

you cln get Bslower feetl. A goot , I<lrl i ng poinl woultl he .OO{)X feetl

per revi liul iOIl.

PRESSURE AND VISCOSIT

MATERIAL . 1 56 .250 .5fHI

LOW

VIS. - I'.S.1. 100 - HOO 100 - HOO 125 - 700

ALLOY

IIIGII

VIS. - 1'.S.1. 1 fI0 - HOO 1 00 - HOO

125 - Hon

ALLOY

I 1 1 GI I

VIS. - I'.S.I. 10f) - HOO

100 - HOO

1 25 - Hilil

SI't.)

300

VIS - I'.S.I.

1fI0 - HOO

STAINIJo;SS

Nowifyuu lre reatly. haveall thcshicltls up. no leaks. tur Dn I he lalhe.

Bcme you tlo t his make sure Ihal Ihe tlrill lip is no\ tllut:hing the

h<fn: 1 . The l athc!'hllUld he funni ng ahnut 4000 rpm. hul you LU\run

it at jts rl:gul <rspcctl. It will take longer hH.lrill the harrel. and the dril l

mi ght tcnll l owlInlier a l i t l l eon the slower RPM. Nowwil h the oil on,

feed the dril l ililO the harrd hlank ver slowly hy hand. The dri l l and

tubing will prob.bly challer. Unless the drill tube starts O buckle,

keep reeding i t i n. an<l after i l goes jn 1/8 in or so it wil l Slt)P chattering.

Once i t SlOpS chaltering engage the reed. I t hhQuld start drilling with

no

chatter. I wouh.l recommend thai you keep your hand lin t hetl ri l l

IUhi ng ror two re.sons; ( I ) - J ryour hand is on Ihe luhingyou wil

l

he

able to nil what is going 011 i n th

e harre!. There is B tertain rill U the

tubing when the dril l is culling right. (2) Your hand will act as a

vibration damper ror the lIrili.

Rememher lu keel' your hand on Ihe drill all the lime to reel Ihe

vihralio,,'s on Ihe drill. Aner " short while you will he able l lell

cxacUy how Ihe drill is (Ioing. Aner a few harrels you will he ahle O

lell when I hedrill is uull, Ol it gels (hipped. Under normal comJitions

the drill should he sharpened ahout every two barrels. To sharpen i t

i s only necessary to just touch the t:utting surf<l:c wilh the silicon

caroilc (green wheel), l diamoml wheel, ralhcnhan grimlingtlll i l ic

surfaces.

SPEEDS AND FEEDS

MATEIUAL

'I'll .250 TO .SIHI TO .750

LOW IU'M 6700 4.l1l0 21 1HI

ALLOY 1 . 1'.11. .IHHI. .IHII .IHII

I I I GI I IU'M .1400 Will 15111

ALLOY 1 . 1'. 11. .001 .0111 .IHII

I I IG I I IU'M 2910 ZIOII I HIMI

SPEEIJ 1 . 1'.11. .1111114 .IIOO .1I(HI5

JOII

I(I'M J4011 ZIOII I HIMI

STAI NLESS 1 . 1'.11. .11110.\ .IHHI.\ .1HH14

41HI0

IU'M .l4tHl 2 100 IHIHI

STAINU.:SS

1. 1'. 11 .11110] .IHHI. .IHH1

The angles on [h face of the lIrill is fai rly l:ritit:al, as [hey will change.

There my hcSp(l[S ruhhing thcllrill hccause lack (lfdcarance, may cut

turvcd holes. O m<y [ urn oul rihhon thi ps. These prohlcms LBhe

usual ly he t rLcl H an i mproperly sharpcm:ll dril l. You shouldn't

have ny rrouh1c on the l1rilling if you have followcl1 inst ructions. By

now you will have pn)hahly 1H1Iicell I hat as t he pressure (lfthc ()it goes,

so docs the temperature.

On mall ca/ihcrs the Lril 1 tUhing get rcal warm. This is IltJrJmtl. By

nowVlIushould hC<lhout till thcwCy through the harrel. When thcdrill

coms through lhe end of the harrel. your now of oi l in Ihe rhi p hox

will SlOp ahruptly. Open the valve on the hypass line ttl dmp I he oil

pressure. Let t he drill travel ahoul l tnol hcr 1/4 inrh allLl Llisengagc lhe

rccdlcveranll hack nut thedrill. when it all the wayout ShUL C\,crthing

tuwn.

Well you have done it. You have drilled your rirsl harrel. The rest

should he cCisy now. /l' e\'erythi ng Vd5Llone right the harrel should he

perfectly sl r:i

g

hl . Leave I he harrel i n the lathe as the 1 1f.xt operation

will he reaming the lIrillc( harrel.

THE DEEP HOLE

DRILLING LTHE

CONVERTING THE LTHE

You will nced lathe with hole t hrough the hcalJ I\ld: 01 al least I

114 inLh. Thi is so you can l<ike the 2( inch Itln!cr halTl'i D\0HK

Ihrouh thcspimllc. You wi l l :1Io Ilced to gel a ,carl rai n"o yt\u

LH

rcUU.:c til: Iccl \l r l llL l al hl. ' lIuwl1 l oal llaSI .OO{) L`L`Il PCI Il: \nhlli nn

.

THIS SLOW FEED IS NECESSARY TO BE ,181.1: TO IJRII.I.

THE 1 7 CAL. BARRELS. FRUM TlE I lelL BARREl.S TIlE

FEED WILL BE SPEEDED UP AS THE L4. GETS BIGGER.

Alsu ifylIu have rliln llr make lluilC a few tI;'lrn..ls it wtlUlLI he wise Il)

gCl lhe right size pullc)! ltl he utile H:inl:c<l!c t hl. ' spcctJ \l rl hcpinc.lh.!

up lu 300 RPM. Now you mi

g

ht sa

y

. <lnu some or the people who

manufacture I he

h

eri ngs fo Ihe \alhe. lh"l lhe hearings wi\\ ntll l"kc

this kiml of spccll.

My Urllling !uhe was a Hilll:h Clausing. 36 im:h hcl1, whidl I usclJ t-

9 hoursaday. Sumetimes 7 d<lYs a week for almost 5 YCCrs hchHl: I had

lo change the bearings.

The Key 10 this is (;OOD 011. AND PLENlY OF IT. Tere i little

pressure on the bearings when drilling or reaming. just a light push or

pull on Ihe spindle.

Also if you ha\e plHs Hmake quite a few harrels using cut rining. it

would he wise 10 gel Ihe righl Sil pUlleys 10 he ahle O increase the

sped of Ihe spindle up 10 2(XX) RPM to handle the smaller clibers

such d 30 caliber. My drilling lathe for reboring was a older South

BeHd wilh a 6 inch hcd, which I used H9 hOllrs a day. This lalhe ws

excellent for rehuring and liner making. and proved excellent for cut

rining. Somelimes 7 days a week for aimosl 5 years before I had to

change the bearings.

SATR BUSHG

CH BOX

BR

DRL

LT CHCK

DRLIG SETU

If your lathe doesn't have an oil tray or chip pan underneath, you wll

have to construct one. The tray needs 10 extend a few inches past the

head stock spindle. I f i t does not it won't be to much of a problem to

huild a LYLl thai will faslen ll1the lalhe or lray 10 caldt l ile llil frm

Ihcbarrcl anti return i l lo the tray. This cover needs to he high enough

10cOvcrthespindie hole with a piece of canvas with a hllic in II III keep

Ihe oil from splallering all over everything.

COOLANT VOLUME REQUI REMENTS

VOLUME

DEI'TH OF HOLE

6" 1 2"

1 8" 2

9

" 36"

HOLE nIA.

INCHES

3/1 6 - 1/4" 2 3 3 3 3

5/1 6 - 1 /8" 4 4 5 66 6

1 5/32 - 1/2" 5

6 8 1 0 "

1 7/32 - 3/4" 7 8 1 0 1 3 1 7

CHUCK COVER

You will need a tIlVCt thaI wtll gu liver the jaw thutk. o vrl!cI.

there will hC4uilc a hil ofuiJ Ihnlwn 'Iul lhcrc. Thbcl)'crtan h0m8c

urai scstraighl up 8ndthe tn,n! there should hculong \Iu' h. dcar

thctlrill ur rC<lmer luhc. `IIuwill alsu need anuit \untaincr tl al 1c<M

oogallon!. This c<n he the oil drum thaI the oil !Imes in.

Thcrcwillalsu ncell 10 Ilea (unlilincrtJI al lea!>! U;,II'J/t_, h! ';ttth the

oil and t:hips herllrC il reI urns Iu lhe mun:IctmIatntt. Yt uwil] need

some kim.! ul O<rCS whirh (an hc I im:h angle inll1 I"iu 11;11 tnlhc lray

in Ihe J'!hc. Thb. i to help SC

]

uIJlc [hc (hips frum Ille uil. "nd help

III settle lhc fine (hips. From there il goes 1uu I 1/2 iudl return pipe

un lhc lr<y. down [0 ahoul iJ foot off lhe nullom ul lht: =IlgalJun

cCJntaincr. This is uiIIc l:hClpscparate the chips InUll Ihct.iI. nm

this cunlaincr the oil over now. through a I 1/4 inch pipe luthc 55

gall"n urum, which i laying un rI illc.

In rrunl urlhcovcrllow pipe is a lar!c magnci which wlil lrap lhcvcry

finc melal Thai lliull'\ have lmc Inscille. This will prolong lhl. life "f

yuur pump.

HYDRAULIC PUMP

Yuu will ncell a hydwuli( pump that w!l lurnlIut :rI \c,I' 54l l !lf

rrc.urc. and a gtxKl now ralc. You will nced the hi,!h IHC\UrC rur

drilling to gCl lhc rcquircu now lurt'movc the chips. In thl' rC;lming

operation. you wi l l also ncctl il large volume uIUl! Itktpthe nutes

dear. Nol cnuugh oil now anu the I1UIC of Ihe Il'amcr 11111 1 uin Ic

reamer and hiHn:1.

COOLNT VISCOSIT

L1u!anIviscl)sily ftnllrillsi1.t 1/ tll.VXinchhtIUld hcX!)/115 Sayl,1t

Secunds al Ddegrees.

PUI a barrel blank i n Ihelalhe Ihal has theendsquared and trued, press

Ihe unhardened Slaner bushing into Ihe bearing. Then very carefully

move Ihe chip box wi l h Ihe slarter bushing and bearing up flush with

Ihe end of the harTel. Make sure that the hushing is Oush with the

barrel, and not canted. Tighten down the chip hox, turn on the

machi ne Umakesurc all is running true. Ifeverthingis running true,

set in the deep hole dril l the size you are making Ihe hushing for, turn

on the uil. SCI for low pressure. The drill point will just be Slaned in

the hushing.

Turn on the lathe, and slowly feed the drill tip into the hushing, and

into Ihch,lrrcl fori dcplhtlfaht)ul a 1/4 inch. Rack(JUI when lhistlcplh

is reached, shut off the oil, and (urn off the machine. This method can

he used ira (orren size reamer cannot he ohtaincd. This mClhno will

not give you the dosesl ft, hul if starting the drill very carefully will

almost always giVe you a straigh hole.

BUSHING (HEAT TREATI NG)

After the hand is drilltc. !size iI can mstamped for size, amI heal

treated. Bring up the temperature in the furnace ttl proper lempcrd.

lun:. UI:llhl.! nushingwilh 8CtlmpuuntJ [hal willsHJpScaling,and put

in the furnace. l have used a surface hardening compound for this

purpt)sc wilhcxcdlcnl results. Hardand Tuffisvcr gOixl. AsStlilfl as

Ihchushing has rClchcd the proper temperature. rcmOVCllnd qllcnl'il

in i gmxl 4ucnchingoil. You will not nced hdraw the \cmpcron [he

hushing uwe need all lhcllinJncss we l<ln get.

Th;shushingwi!l lasl Iuta manyl'tarrds, anuwhcn ilslan, !OWC<.r, you

will kllt)w as yruwill start uigcI cHluked urrccnlCr hl)Ic...

Uimensions for the starter nushin I lule

CuliitCl'

U"iII Uiametcl'

1 72 . 1 64

224 .2 1 2

244 .2ZX

257 .244

O1meDe1co Ioz tUe 2M .2511

BL1Le1 EuoD1DQ

2711 .2M

284 .2711

.lOX .2Y3

.(). .2Y7

32. .304

3]8 322

350 34.

375 3(1

44 .41 5

457 .443

DEEP HOLE DRILLING

Normally in lnytlccp hulctlrillingllpcratiun, the h:.rrcJ tur . , IntJ Ihe

urill isstalinnary. The rCaStlO riiT IhisL"an he secn in. YIIU will notic

thai with Ihcsinglc lipgundrill lha\ ilunlyculsun nncctlgc. ^S il tlrills

in thcbarrcl it only cuts nn unccugt.and as it drill it drills in Ihe !lmel

ils makes ilsllwn ,-"nler. Duc \ulhe high RPM urlhe h:.rrcl, it makes

its on (cnler as il drills. This is Ihe rcasun why an ;u:loralc !Harler

hushing is so impunanl.

Thc tlritling Ilfa rilk harrel is actually thcsimptcsi und mlIS\ trlluh!e

frecuperaLion orall. When Ihcdrill is nut Maned waigh! iI will try lu

pick up the center IJf rulatiun. and the hlile is lme !clOg Lurvc.

We nurmally turned out IOUur murcmmplclctJ rille Ilrrcls pcrwcek.

and in lhetlrillingupcralion we L'Ould mlowskill help. Ali lhal was

.

n

.

"

.

Ca

.

ry was for Ihe uperalurs WIu8cIup Ihe ma..hine. lurn it on.

They had 10 walch so Ihe drill wouldn'l plug up with chip shul il of

when done, and Ihen reload i t and slarl again. When you gel

everylhing sel up righl. you will be able U turn oul 3-4 compleled

barrels a day with no problem on ONE lalhe. This is a compleled

harrel lhal is drilled. reamed and rilled.

Now aboul lhe laSl lhing lhal will be needed is a special Sleady R1

SUPPOI lhe drill lubing as il drills. This will help CU down tile

vlhrauons thai will some ti mes start in the tlrill.

You CAN NOT allow t hese vihrations to slart. If it uocs it l:an l::use

the carhide drill tip l1chip. and if you do not catch it in time it can also

cause the drill to plug upand twiSi the ti poff. Will give you a good idea

ofwhal " Deep Hole Drill looks like.

I want to point out Ih:l this drilling setup is not li mi lcd lo just barrels.

It ('n he uscll for 4uitc a hit df other imJuslriul opcral ions. where

extremely accurate holes arc neeued. Also with carhide drill tips. ver

hard sleel can he drilled. Fo odd shaped items whereyuu are unohle

PRESSURE AND VSCOSIT

MATEIUAL .156 .250

.500

LOW

VIS. - I'.S.1. IIH. - HlHl 100 - 800 125 - 7lN'

ALI.OY

1111; II

VIS. - 1'.S.1. 1110 - 8lH. 100 - 8lN. 125 - IMHI

AI.LY

111(;11

VIS. - I'.S.I. 1 110 - 800

11". - 8lH.

125 - IMH'

SI'I':":1l

:N.

VIS - I'.S.I. I OO - 8lH'

STAIN I.I'"S

OrOlale the drill. you can set u

p

the operation where the drill can l

rotatcd using special tooling.

PRESSURE AND VISCOSITY CHART.

Thcscwill givc)uu thc prc.sureand Visl;osily ("fYl/urOH Cuolarll !Il

dilferent Iypes of materials. Do nut furget luput the shield liver the

end uf the harrel, so when you tlr[ll lhruugh Ihe harrcl the nil will nul

he sprayed uver the enlire shup.

TOOL F OR G U N SMI T HS - AN D OTH ERS

W. o. MEK oullincs an old mClhod of drilling barrels

.Host readers are familiar with

D-bits, which are used as substitutes

for reamers in many model workshops,

alld hare been referred to in several

}'1E constructional articles. But recent

qlleries suggest that the D-bit is not

as well known as it should be, even to

professional engineers. This article

describes one of the first and most

important applications of D-bits in

deep drilling and boring operations.

Dcc !um $oIder !obl!

t

<",II" ....

! .

0 W

W

HILE the Dbit is pr!marily

a gunsmith's 1001. l could

be very useful to model

and general engineers if its mcthod

were more generally known. It is

often confused wi t h the nat bil for

opening out cored holes !H iron

castings.

When guns were firsl iDt rOduLed.the

nalUm1 cOlc to build them Wcre the

armourers and sword-l1l;lkcrs. They

had developed a high St0nUurU of skill

in smith's work. but they did not lise

lHc laIht to any extent. 1 was found

possi blC to make serviceable gun

barrel s by hammer-welding bundles of

wrought iron wires and ! \isling them

at the same time. When the barrels

were fnish fled. they had a DC0U1I!U

I8!D, running in spirals like a wire

IO. They were morc resistant to

bursting than an ordinary bnr.

At frst thC bore was rormed by

oIin on B mandrel. By 1 60 , gooU

quality bOIes VcIC |IOUuLcU WH!LH

must have beCn dr!lled. The UD

drill, as we know it. has the advantage

of beiDg able to drill u HOle accurately

without the need lOt an accurate beU.

The drill bit i1selis the accurate part.

!course, moder deephole UIlS are

highly accurate, multi-s

.

indle, DODt-

0tlV6D,highspemachUlcs-but they

I MRL l96{

are stil l the linear descendants of these

old devices.

Before Hitler alterd th,e 5

CUDC]

there was a quaner I n Bmllllll!ham

where many onelllan businesses l11adc

gun pans

There I saw and sketched

a dCphole gun dri l l reputed to have

been mUde in the 1 8105. The b\d.

about 10 ft long. \\ as said to have

been chipped, filed :\nd scraped by

hand.

There \\-as a headstock. \\ hieh had

a hollow mandrel. a tailstock. with a

hollow spindle. and U carriage \\i th a

screw feed and a drill holder mounted

on the saddle. Connected to the drill

holder was a telecopic brass lUbe

running to a high-pressure oil pump.

which drew irs oil from the chip pan.

through U filter. \Vhale oils were

traditionally used, but cutting oils

are also suitUble.

The barrel O be drilled was swung

between hollow centres, with large

cones in each end. The drill was fed

through a bush in the tailstock spindle,

which acted as a guide bush as it was

a good sliding fl.

To the bit proper, which was about

four inches long, was soldered a

length or D-scction tubc. Thc pump

forced oil at several hundred pounds

pressure through the lube and the oi l

hole i n the bi t. Such a force was

enough to wash away the chips.

The point of the bit was made

out-Dr-centre, usually about fivc

eighths or the radius of the hole. It

was, of course. cut only on one side.

The tube was flexible enough to allow

the drill to fnd its own centrc. 1f it

was ground right (there was a mystique

about the grinding) it would produce

perrect ly straight hole. The speed

would be about 800 to 1 ,00 r.p.m.

and the feed about hal f . a thou a

revolution.

Once started, the drill was not

stopped until the hole was finished;

the operator could tell, by placing his

finger on the dril l tube and feel ing the

vi brations, and by examining the

swarf, how tbe drill was cutting.

Correctly, it would come away in a

crinkled ribbon: not in curls, as these

would tend to jam up the hole.

Of course, that was not thc end:

the fnal beautiful fni sh of the bore

was obtained by spill boring, another

old method now hardly used. [

You might also like

- Barrel Fitting by Harold HoffmanDocument114 pagesBarrel Fitting by Harold HoffmanNorm100% (6)

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheFrom EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheRating: 4.5 out of 5 stars4.5/5 (2)

- SGN22 1 PDFDocument3 pagesSGN22 1 PDFgalak12001100% (4)

- Manufacturing World-Famous Colt 45 PistolDocument14 pagesManufacturing World-Famous Colt 45 PistolJesus Cortez100% (1)

- 1F7BZ MR Singleshot's Book of Rifle Plans Part5Document12 pages1F7BZ MR Singleshot's Book of Rifle Plans Part5angelines123100% (6)

- Making Chamber ReamersDocument3 pagesMaking Chamber Reamersfmchuck100% (7)

- Professor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor ParabellumDocument23 pagesProfessor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor Parabellumzaid hashem100% (2)

- Military Musket Wheel Lock, CA. 1600Document40 pagesMilitary Musket Wheel Lock, CA. 1600NO2NWO100% (1)

- Bolt Action 3Document10 pagesBolt Action 3browar444100% (2)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- Blowback Bolt WeightsDocument4 pagesBlowback Bolt Weightsorions_hammer100% (1)

- How To Drill A Rifle BarrelDocument6 pagesHow To Drill A Rifle BarrelMaria Donoghue50% (2)

- A History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityFrom EverandA History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityRating: 4 out of 5 stars4/5 (1)

- 50 Cal PlansDocument24 pages50 Cal PlansClint Muldoon100% (10)

- Building A Button Rifling Machine by Harold HoffmanDocument15 pagesBuilding A Button Rifling Machine by Harold HoffmanNorm100% (18)

- Antique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsFrom EverandAntique Firearms Assembly/Disassembly: The comprehensive guide to pistols, rifles & shotgunsRating: 4.5 out of 5 stars4.5/5 (2)

- The English Sten Sub Machine Gun ExplainedDocument11 pagesThe English Sten Sub Machine Gun Explainedknockelflies100% (3)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Patent Summary: Single Shot Falling Block Rifle ActionDocument11 pagesPatent Summary: Single Shot Falling Block Rifle ActionE Makinen100% (1)

- Handloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesFrom EverandHandloader's Manual - A Treatise on Modern Cartridge Components and Their Assembly by the Individual Shooter Into Accurate Ammunition to Best Suit his Various PurposesNo ratings yet

- DP Series Build SheetDocument49 pagesDP Series Build SheetJoe CreoleNo ratings yet

- 1858 Remington ConversionDocument6 pages1858 Remington Conversionwienslaw5804No ratings yet

- The Basics of How A Lever Action Works PDFDocument5 pagesThe Basics of How A Lever Action Works PDFtwinscrewcanoeNo ratings yet

- Rifling by Flow FormingDocument6 pagesRifling by Flow FormingOzkar Pirata100% (2)

- Ruger Mark IDocument7 pagesRuger Mark IAdam OrionNo ratings yet

- MAC .45 ACP ReceiverDocument3 pagesMAC .45 ACP Receiverbrowar444100% (5)

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (5)

- How I Make A Chamber ReamerDocument17 pagesHow I Make A Chamber ReamerGhazali Zuberi100% (30)

- Holmes 50Document65 pagesHolmes 50The_Desolator100% (15)

- Overall Length 6Document6 pagesOverall Length 6angelines12350% (2)

- Handgun Firing Mechanism with Independent Sear ReleaseDocument5 pagesHandgun Firing Mechanism with Independent Sear Releaseyuehan0% (1)

- Darcy Falling Block Study PlansDocument12 pagesDarcy Falling Block Study Plansangelines123100% (19)

- Darcy's Falling Block Single Shot PlansDocument12 pagesDarcy's Falling Block Single Shot Plansmk35100% (3)

- Gas OperatedDocument5 pagesGas OperatedZararian Ali0% (1)

- The New SW 76 Submachine Gun (Small Arms Review)Document3 pagesThe New SW 76 Submachine Gun (Small Arms Review)antermv86% (7)

- Collection of Rifle and Shotgun ManualsDocument29 pagesCollection of Rifle and Shotgun ManualsNO2NWO100% (4)

- Thompson M1A1, MK1 Lanchester Model 37 SMGS, UD-M42 Pistol - BlueprintDocument7 pagesThompson M1A1, MK1 Lanchester Model 37 SMGS, UD-M42 Pistol - BlueprintAride4ever100% (1)

- Sten Building BookletDocument22 pagesSten Building Bookletpamrick100% (1)

- Stinger Rifles FamilyDocument7 pagesStinger Rifles Familybrowar44467% (9)

- Kommando RCVRDocument1 pageKommando RCVRMike Nichlos100% (1)

- Single Shot Rifle Action Safety MechanismDocument6 pagesSingle Shot Rifle Action Safety MechanismE MakinenNo ratings yet

- Blowback (Firearms)Document13 pagesBlowback (Firearms)Escribir4TPNo ratings yet

- Wheellock PlansDocument59 pagesWheellock PlansPuturrú De Fuá100% (2)

- Blueprints PPSH41 Yugo49-57 American180 Browning1919Document7 pagesBlueprints PPSH41 Yugo49-57 American180 Browning1919Mika100% (2)

- D66C5 MR Singleshot's Book of Rifle Plans Part1 PDFDocument18 pagesD66C5 MR Singleshot's Book of Rifle Plans Part1 PDFMainAvel100% (7)

- D-Bit Chambering Reamer MakingDocument5 pagesD-Bit Chambering Reamer MakingEadNo ratings yet

- Stevens Favorite Info & Exploded ViewsDocument4 pagesStevens Favorite Info & Exploded Viewsmichaelj49684619389% (9)

- Colt Revolvers Workshop Manual Vol 1 - Jerry Kuhnhausen PDFDocument221 pagesColt Revolvers Workshop Manual Vol 1 - Jerry Kuhnhausen PDFDavid Stone100% (19)

- AK Bolt Gap SetupDocument22 pagesAK Bolt Gap SetupAdam Hemsley100% (2)

- Turkish Mauser InfoDocument2 pagesTurkish Mauser Infoguytr2100% (4)

- Mauser Model 45 ENGLISH PDFDocument19 pagesMauser Model 45 ENGLISH PDFIM_JohnnyV100% (1)

- Welcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"Document5 pagesWelcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"GasMaskBob50% (2)

- Mel Tappan On SurvivalDocument91 pagesMel Tappan On Survivaljim100abNo ratings yet

- Welcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"Document5 pagesWelcome To (Removed) 'S Page of "Maglite Flashlight Conversions!"GasMaskBob50% (2)

- Mel Tappan On SurvivalDocument91 pagesMel Tappan On Survivaljim100abNo ratings yet

- Above Ground Fallout ShelterDocument8 pagesAbove Ground Fallout Shelteragabatti100% (1)

- Converting A Portable Cordless Drill To A Hand Crank DC GenDocument8 pagesConverting A Portable Cordless Drill To A Hand Crank DC GenkcwelderNo ratings yet

- Built of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland SawickiDocument13 pagesBuilt of A Rattan Indian Style Bow: Author: Rolf Gerschwinat Translation and Drawing: Roland SawickikcwelderNo ratings yet

- 25 Telephone Tips For InvestigatorsDocument11 pages25 Telephone Tips For InvestigatorskcwelderNo ratings yet

- Unintended ConsequencesDocument749 pagesUnintended ConsequencesTazman1602100% (3)

- Firearms - McLean, Don - Do-It-Yourself Gunpowder CookbookDocument72 pagesFirearms - McLean, Don - Do-It-Yourself Gunpowder Cookbookkcwelder100% (3)

- Business PlanDocument9 pagesBusiness PlanRico DejesusNo ratings yet

- Nmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesDocument2 pagesNmea Components: NMEA 2000® Signal Supply Cable NMEA 2000® Gauges, Gauge Kits, HarnessesNuty IonutNo ratings yet

- IT support tips for non-tech colleaguesDocument7 pagesIT support tips for non-tech colleaguesLeo KrekNo ratings yet

- Perbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraDocument9 pagesPerbandingan Sistem Pemerintahan Dalam Hal Pemilihan Kepala Negara Di Indonesia Dan SingapuraRendy SuryaNo ratings yet

- SABIC Ethanolamines RDS Global enDocument10 pagesSABIC Ethanolamines RDS Global enmohamedmaher4ever2No ratings yet

- SC invalidates Ordinance allowing oil depots in Pandacan due to population densityDocument2 pagesSC invalidates Ordinance allowing oil depots in Pandacan due to population densityMigs Raymundo100% (1)

- PHASE 2 - Chapter 6 Object ModellingDocument28 pagesPHASE 2 - Chapter 6 Object Modellingscm39No ratings yet

- 2011 Mid America - WebDocument156 pages2011 Mid America - WebFaronNo ratings yet

- Sec of Finance Purisima Vs Philippine Tobacco Institute IncDocument2 pagesSec of Finance Purisima Vs Philippine Tobacco Institute IncCharlotte100% (1)

- VSP-12Way - Is Rev.03Document55 pagesVSP-12Way - Is Rev.03Marcelo AlmeidaNo ratings yet

- Telangana Budget 2014-2015 Full TextDocument28 pagesTelangana Budget 2014-2015 Full TextRavi Krishna MettaNo ratings yet

- Part 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentDocument12 pagesPart 9. Wireless Communication Towers and Antennas 908.01 Purpose and IntentjosethompsonNo ratings yet

- For-tea Tea Parlour Marketing Strategy Targets 40+ DemographicDocument7 pagesFor-tea Tea Parlour Marketing Strategy Targets 40+ Demographicprynk_cool2702No ratings yet

- ATmega32 SummaryDocument18 pagesATmega32 SummaryRajesh KumarNo ratings yet

- Recommended lubricants and refill capacitiesDocument2 pagesRecommended lubricants and refill capacitiestele123No ratings yet

- Enhancing reliability of CRA piping welds with PAUTDocument10 pagesEnhancing reliability of CRA piping welds with PAUTMohsin IamNo ratings yet

- 63db2cf62042802 Budget Eco SurveyDocument125 pages63db2cf62042802 Budget Eco SurveyNehaNo ratings yet

- Vallance - Sistema Do VolvoDocument15 pagesVallance - Sistema Do VolvoNuno PachecoNo ratings yet

- Sap Fi/Co: Transaction CodesDocument51 pagesSap Fi/Co: Transaction CodesReddaveni NagarajuNo ratings yet

- Tutorial Manual Safi PDFDocument53 pagesTutorial Manual Safi PDFrustamriyadiNo ratings yet

- QDA Miner 3.2 (With WordStat & Simstat)Document6 pagesQDA Miner 3.2 (With WordStat & Simstat)ztanga7@yahoo.comNo ratings yet

- Illustrator CourseDocument101 pagesIllustrator CourseGreivanNo ratings yet

- Verificare Bujii IncandescenteDocument1 pageVerificare Bujii IncandescentemihaimartonNo ratings yet

- Programming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurDocument4 pagesProgramming in Java Assignment 8: NPTEL Online Certification Courses Indian Institute of Technology KharagpurPawan NaniNo ratings yet

- Forms of Business Organization: Sole Proprietorship, Partnership, Corporation, CooperativesDocument17 pagesForms of Business Organization: Sole Proprietorship, Partnership, Corporation, CooperativesSanti BuliachNo ratings yet

- Pass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppDocument1 pagePass Issuance Receipt: Now You Can Also Buy This Pass On Paytm AppAnoop SharmaNo ratings yet

- Critical Values For The Dickey-Fuller Unit Root T-Test StatisticsDocument1 pageCritical Values For The Dickey-Fuller Unit Root T-Test Statisticswjimenez1938No ratings yet

- Assignment 2 - p1 p2 p3Document16 pagesAssignment 2 - p1 p2 p3api-31192579150% (2)

- Namal College Admissions FAQsDocument3 pagesNamal College Admissions FAQsSauban AhmedNo ratings yet

- ASM Architecture ASM Disk Group AdministrationDocument135 pagesASM Architecture ASM Disk Group AdministrationVamsi ChowdaryNo ratings yet