Professional Documents

Culture Documents

Allowable Pipe Spans Loads

Uploaded by

Malcolm HuttonOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Allowable Pipe Spans Loads

Uploaded by

Malcolm HuttonCopyright:

Available Formats

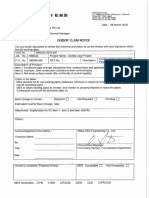

Bechtel Pueblo Team

PROJECT:

CALCULATION COVER SHEET

JOB NO.

Pueblo Chemical Agent-Destruction Pilot Plant (PCAPP) 24852

of Gravity, Wind, and Seismic Spans and Thermal Offset STATUS PRELIMINARY COMMITTED PRELIMINARY

I CALC

NO.

RD-PSC-OOO-POOO1

I ~HEET

SUBJECT Computation

GROUP Plant Design CONFIRMED SUPERSEDED VOIDED

CALCULATION DESIGNATION COMPUTER TYPE

PROGRAM!

I DYes SCP181 No I MAINFRAME I 0

181

PC

181

PROGRAM NO.

I VERSION/RELEASE

NO.

Notes/Comments: Microsoft Excel used as a tool on PC to perform the computations contained in this calculation

DRAFT - Distribution restricted to U.S. Government Agencies and their Contractors. Further release is prohibited. OPSEC review not yet completed.

QUALITY LEVEL:

3

2

[glQ

84 84

Non-Q

12 12 SSC

DN/A

~~

SSC I~SA SA

Issued for Final Design. Corrected Wind Span Calculation Corrected span calculations for SC-II Stainless Steel and Hastelloy piping. Corrected Wind spans. Corrected span calculation for Hastelloy pipe empty Issued for Internal Use, Supersedes Calc. No. PSC-000-P0001, Rev. 2

REASON FOR REVISION

12-18-06 10-27-06

GY

1 0

NO.

84 84

TOTAL NO. OF SHEETS

12 12

LAST SHEET NO.

SSC SSC

SA SA

CHECKED

GY GY

APPROVEDI ACCEPTED

6-6-2006 4-19-2006

DATE

BY

RECORD OF REVISIONS

M:\Span Calculation-Fina~Coversheet_

Calc_RD _PSC _OOO_POOO1_R3.doc

revised 12120/2006

1 of 1

Bechtel Pueblo Team

PROJECT:

PCAPP

CALCULATION

SHEET

JOB NUMBER: CALC NO.:

24852

RD-PSC-OOOPOOO1

2

SUBJECT: BY:

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

SHEET NO.: SHEET REV.:

S. Chitnis

12/14/06

Table of Contents

Page

1 2 3 4 5

6 7

Purpose Design Conditions Assumptions References Calculation 5.1 Gravity Spans and Support Loads 5.2 Seismic Spans and Support Loads 5.3 Wind Spans and Support Loads 5.4 Thermal Offset and Support Loads 5.5 Sample Calculations Conclusions Appendices 7.1 Appendix 'A' Gravity, Wind, and Seismic Spans and Support Loads 7.2 Appendix '8' Thermal Offset and Support Loads (150°F) 7.3 Appendix 'c' Thermal Offset and Support Loads (300°F)

3 3 3 3 4 4 5 7 9 10 12 12 12 12 12

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP 24852

RD-PSC-OOOPOOO1 3 3

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

S. Chitnis

12/14/06

PURPOSE

This calculation is to develop gravity, wind, and seismic spans for pipe support spacing and loads imposed on these supports for piping of nominal diameters W' through 36 ". It also provides computations for determining offset length to accommodate thermal expansion of piping of lengths 10' through 100' at 150°F and 300°F and thermal load imposed on the guide support placed at the offset. This calculation considers piping material of Carbon Steel (CS), Stainless Steel (SS), Titanium (TI), and Hastelloy (HA) for piping of both categories SC-I and SC-II. Piping category SC-I contains fluid with significant chemical release hazard and category SC-II contains fluid with no significant chemical release hazard. This spanloffset and support load data is to be used as general guideline for pipe routing and can also be used for qualification of piping at temperature not greater than 300°F in lieu of detail computer analysis based on stress engineer's judgment.

DESIGN CONDITIONS

The piping is considered simply supported with series of spans and with and without its content. The fluid content is water. An insulation thickness of 2" is considered with density of 12 Ibs/cu. ft for conservatism. These spans and offsets are developed for piping with temperature not greater than 300°F. The limiting stress in pipe for computation of thermal offsets is 20000 psi for all materials. This value provides a 20% or higher design margin. The limiting internal fluid pressure is considered to be 400 psig. Piping schedule STD is considered for Large Bore (> 2" Nom. Dia.) and schedule XS is considered for Small Bore (::;2" Nom. Dia.) piping. The material properties are obtained from standards used in the industries including Internet sources. These properties are as follows: Material Carbon Steel Stainless Steel Titanium Hastelloy Young's Modulus (150° F1300° F)(psi) 28.87/28.1 x 106 27.87/27.0 X 106 15.2/14.6 x 106 29.37/28.6 x 106 Coe. of Ther. Expn. (150°F/300°F)(U/100') 0.61/1.82 0.90/2.61 0.45/1.305 0.678/1.966 Density (lbs/in3 0.283 0.290 0.1625 0.3218

ASSUMPTIONS

None

REFERENCES

1. ASME B31.3 Code, 2004 Edition, ASME Code For Pressure Piping 2. International Building Code (IBC), 2003 Edition

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RO-PSC-OOOPOOO1

4 3

S. Chitnis

12/14/06

3. Army's Technical Instructions TI 809-04, Chapter 10 (UFC 3-310-03A) 4. Design Criteria for Civil/Structural/Architectural facilities, Document NO.24852-RD3DR-000- T0004 5. Formulas for Stress and Strain by R.J.Roark, Fifth Edition 6. Piping Flexibility Basics by Liang-Chuan Peng of Peng Engineering, Houston, Texas, and Tsen-Loong Peng of the M.W.Keilog Co. Houston, Texas. 7. ASCE 7-02, Minimum Design Loads for Buildings and Other Structures, 2002 edition.

CALCULATION

The end condition of a pipe span for a' pipe system under a series of supports is approximately between the fixed end and the simply supported end. Using equations from Formulas for Stress and Strain by R.J.Roark (Ref. 5), the maximum deflection, the maximum bending moment and the support load of the pipe span with these end conditions under uniformly distributed load are as follows: Deflection (L1)

= Y:z [(5wL 4/384EI) + (wL 4/384EI)] = 3wL 4/384EI = Y:z [(wL2/8) + (wL2/12)] = 5wL2/48

(1) (2) (3)

Moment load (M)

Support load (R) = wL where

L = maximum pipe span between two supports I moment of inertia of the pipe E = modulus of elasticity Z section modulus of the pipe

w = pipe weight per unit length

5.1

GRAVITY SPANS AND SUPPORT LOADS The approach used for developing gravity spans is to consider the smaller of the span obtained for the following conditions: a) The maximum deflection of the pipe span is limited to 1/8" b) Pipe stress due to gravity load is limited to 2500 psi L1 3wL 4/384EI :5:1/8 inch, or M

= 5wL2/48:5: crwZ/i

(or IM/Z:5: crw• psi). crw

= 2500

psi

The stress intensification factor (SIF or i) per ASME B31.3 Code (Ref. 1) as follows: SIF (or I) SIF (or I)

= 2.1 for fillet

= 1.0 for butt welds

welds for pipe sizes 2 inch nominal diameter and below for pipe sizes above 2 inch nominal diameter

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

24852

RO-PSC-OOOPOOO1 5

CALCULATION SHEET

Computation of Gravity. Wind. and Seismic Spans and Thermal Offset DATE: 12/14/06

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

S. Chitnis

The gravity span and support load for a simply supported piping with series of spans is determined as follows: L is equal to the less of L1

= (1/8·384EI/3w)1/4

=

or L2

= (crw·48Z15iw)1/2

Therefore Support load (R) wL Note: Weight due to ice and snow is not considered as the small curved surface of pipe will not accumulate significant quantity. 5.2 SEISMIC SPANS AND SUPPORT LOADS The seismic spans are developed based on Army's Technical Instructions TI 809-04, Chapter 10 (Ref. 3) and IBC (Ref. 2) enveloping the results. Reference 2 refers to reference 7 for seismic force computations. The equation for computing lateral seismic force (Fp) per TI and IBC is as follows: Fp

= [(0.4 x ap x Sos x Wp) /Rp/ Ip] (1 + 2z1h)

=

where Sos Spectral acceleration, short period is taken as 0.276 from PCAPP Design criteria for Civil/Structural/Architectural Facilities (Ref. 4) a, Component amplification factor, is taken as 2.5 for flexible piping per Ref. 3, Section 10-3e(4)(c). This is greater than value given in Table 1621-3 of IBC. Rp Component response modification factor, is taken as 3.5 from Table 1621-3 of IBC. It is same as given in TI Table 10-2. Ip the importance factor, is taken as 1.50 for Hazardous facilities from paragraph 10-1d (Ref. 3). This is same as that given in paragraph 1621.1.6 of IBC. z Height in structure of highest point of attachment h Average roof height of Structure relative to grade elevation

= =

For conservatism consider z

=h

Fp = [(0.4 x2.5 x 0.276)/3.5/1.5] (1 + 2) x Wp = 0.355 Wp and F, = 2/3(Fp) = 0.237 Wp Where Wp

= weight

of piping component

Consideration of Vertical loading (Fv) is not required per References 2 and 3. However, it is taken as 2/3rd of Horizontal loading for good engineering practice. The support loads and pipe stresses are calculated as follows:

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity. Wind. and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RO-PSC-OOOPOOO1 6

S. Chitnis

12/14/06

- 5FpL I48 5FvL2/48 FpL FvL = (Mh2+ M/)112

L

= = =

The total pipe stress including longitudinal pressure stress, gravity stress, and seismic stress must comply with the following equations per Reference 1.

M PD + weight stress + i s 1.33 Sh for SC-I piping 4tn Z

The allowable stress for SC-II piping is based on the Faulted allowable for Class 2,3 piping per NC/ND of ASME Section III Code (Ref. 6). If a piping component meets this allowable, it implies that the piping component will not fail, and will maintain the pressure retaining capability. Therefore the equation to check the SC-II piping stress is as follows:

M PD + Weight stress + i s 3.0Sh, but not greater than 2.0Sy for SC-II piping 4tn Z

Therefore the seismic spans for SC-I and SC-II piping are calculated as follows: SC-I Piping: Mh 5FpL2/48 5 x 0.355w x L2/48 Mv = 5FvL2/48 = 5 x 0.237w x L2/48 M (Mh2+ M})112 5L2 [(0. 1822w2)112 ]/48 = 5L 2 w [(0.1822) 112]/48

= =

P . - D + W· ht st ress + /-M ~. 1 33 S h elg 4tn Z i

M

= 1.33 Sh - PD

4tn 4tn

- Weight stress

= Z(1.33

Sh - PD - Weight stress)li

5L2 W [(0.1822)112]/48

= Z(1.33

-

Sh - PD - Weight stress)li

4tn

With 20 % margin on stress for all piping L

= {48(0.8x1.33Sh

- PD/4tn

weight stress).ZI[i.5w(O.1822)

112] }112

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE: 12/14/06

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RD-PSC-OOOPOOO1 7 3

S. Chitnis

L = {48(0.8x1.33Sh - PO/4tn Similarly for SC-II Piping: L

weight stress).ZI[i.5w(0.43)]

}1/2

= {48(0.8x3Sh

- PD/4tn

weight stress)·ZI[i·5w(0.43)]}1/2

Note: 3 Sh is replaced by 2Sy if it is smaller. The longitudinal pressure stress S'P = PD may be determined by the equation

4tn

Pd S/p ---- _d2 - D2

Note: The value of t, in the above equations is nominal pipe thickness minus corrosion allowance as applicable. Using above stated equations, spans and support load tables are developed. These developed pipe spans may result in large pipe displacement causing interference with adjacent pipes or other commodities. Therefore seismic spans are also computed limiting the pipe displacement to 3 inches. The smaller of the seismic span between the span based on allowable pipe stress or the span based on maximum displacement of 3 inches is selected as seismic span to be applied. These spans are contained in tables provided in Appendix 'A'.

5.3

WIND SPANS AND SUPPORT LOADS For calculation of spans and support loads, the design wind pressure is determined per ASCE 7 Section 6.5.13, Equation 6-25 at any height in accordance with the following formula:

where F qz G Cr = = design wind load, (Ib) velocity pressure evaluated at height Exposure C, (Ib/fe) , Equation 6-15

z of the centroid of area using

gust effect factor for rigid structures shall be taken as 0.85 (Section 6.5.8.1) gust force coefficient for round cross-section, moderately smooth and hiD = 25 ft. (h = height of structure in feet and D = diameter of circular cross section) taken as 0.7 (Figure 6-19) projected area normal to the wind, (ft2)

=

=

Ar

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RD-PSC-OOOPOOO1

8 3

S. Chitnis

12/14/06

The pressure velocity, qz, shall be calculated by the following equation (Section 6.5.10, Equation 6-15):

where Kz ~ Kzt V I = = = = = velocity pressure exposure coefficient at height 30 feet above ground level, Z, using Exposure C taken as 0.98 (Table 6-3) of ASCE 7 wind directionality factor for round structure type taken as 0.95 (Table 64) of ASCE 7 topographic factor basic wind speed taken as 90 mph (Figure 6-1) of ASCE 7 importance factor taken as 1.15 (Table 6-1) of ASCE 7

The topographic factor, Kzt, shall be calculated by the following equation: Kzt = (1 + Kl x K2 X

~

)2

where K1, K2 and K3 are given in Figure 6-4 of ASCE 7. Per PCAPP Design Criteria for Civil/Structural/Architectural wind speed is 90 miles per hour, exposure category C. Facilities (Ref.4), the basic

Substituting values for K1 , K2 , K3 from Figure 6-4 (ASCE 7) K1 = 0.32 for H/Lh = 0.30, K2 = 0.33 for xl Lh = 1.0, and K3=0.45 for zI L, = 0.20 Kzt = (1 + K1 x K2 X K3 )2 = (1+ 0.32 x 0.33 x 0.45)2 =(1.04752)2 = 1.0973 Therefore, qz = 0.00256 x Kz x ~ x Kzt X V2 X I (Ib/fe) = 0.00256 x 0.98 x 0.95 x 1.0973 x (90)2 x 1.15 = 24.3612 (Ib/ft2) , (Note: V in mph) The design wind load = F = qz x G X Cf X Af (Ib) = 24.3612 x 0.85 x 0.7 x At (Ib) = 14.4949 x At (Ib) Using the equations in paragraph 5.0, the wind load spans are calculated for maximum deflection of 3 inches and for allowable stress with 20% margin similar to computations of seismic spans. The lower of the deflection and stress span is selected. The wind load for support is computed from equation (3) for the corresponding pipe span.

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP 24852

RD-PSC-OOOPOOO1 9 3

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

S. Chitnis

12/14/06

5.4

THERMAL OFFSET AND SUPPORT LOADS A guided cantilever approach is considered for computation of length of offset required for absorbing the thermal expansion of various lengths (from 10' to 100') of piping at 150°F and 300°F without exceeding the allowable stress limit in piping per Reference 1. The formulas applied are as follows per Piping Flexibility Basics by Liang-Chuan Peng and Tsen-Loong Peng (Ref. 7):

s, = 3ELlDII2

R Where:

= 12EILV,3 =

St Thermal Stress R = Thermal Load on Support E = Modulus of Elasticity Ll Thermal deflection at cantilever end I = Moment of Inertia D = Outside diameter of pipe , = Length of offset

I~

'L' Expansion length

Offset Length

Guide Support

II

Using above stated equations, thermal offsets and support load tables are developed. These tables are contained in Appendices 'B' and 'C'.

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RD-PSC-OOOPOO01 10

S. Chitnis

12/14/06

For computations of all above spans and thermal offsets, the actual thermal stress used is 80% of the allowable thermal stress. This is to provide conservatism in the offset calculations. The thermal stress is derived as follows: St = (1.25x Sc + 0.25 x Sh), where Sc = Allowable stress at room temperature and Sh = Allowable stress at the system operating temperature. Material Carbon Steel Stainless Steel Titanium Hastelloy Thermal Stress (150°F/300°F)(ksi) 30.0/30.0 25.05/25.05 25.05/23.95 40.95/40.95 Thermal stress used for offset calc. (150°F/300°F)(ksi) 24.0/24.0 20.0/20.0 20.0/19.0 32.7/32.7

5.5

SAMPLE CALCULATIONS a) Determine gravity span and support load for 6" nominal diameter CS pipe full with water and has 2 "thick insulation of density 12 Ib/cu.ft. The corrosion allowance = 0.063". Wall thickness = 0.28-0.063= 0.217" For CS material Young's Modulus = E = 28.1 X 106 psi Moment of Inertia for 6" STD Schedule pipe = I = 22.4 in4 Section Modulus for 6" STD Schedule pipe = Z = 6.78 in3 Total Weight of pipe = 36.5 Iblft = 3.04 Iblin (includes weight of content and insulation) Span Length for 118" deflection = L1 = (1/s·384EI/3w)1/4 Hence L1 = (0.125 X 384x28.1x106 x 22.4 I 3 x 3.04)1/4 = (30.213 x 109 I 9.12) 1/4 inches = (33.12829 x 10s ) 1/4 inches = 239.91 in. = 20.0 ft. Span Length for allowable stress limit of 2500 psi = L2 = (O'w·48Z15iw)1/2 inches Hence, L2 = (2500 x 48 x 6.78/5 x 1 x 3.04) 1/2 inches = (813600/15.2) 1/2 inches = 231.36 inches = 19.3 ft. L1 > L2, Therefore, selected gravity span = 19.3 ft. Support Load = R = wL = 36.5 x 19.3 = 704.45 Ibs. b) Determine seismic span and support load for SC-I CS pipe 6 "nominal diameter, full with water and has 2 .. thick insulation of density 12 Ib/cu.ft. The internal fluid pressure is 400 psig. Wall thickness = tc = 0.280-0.063 = 0.217 in. with corrosion allowance Fp = 0.355, F, = 0.237, Resultant seismic factor = [(Fp)2 + (F, )2]1/2 = 0.43 The total pipe weight = w =36.5 Ibs/ft = 3.04 Ibs/in

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP

CALCULATION SHEET

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

JOB NUMBER: CALC NO.: SHEET NO.: SHEET REV.:

24852

RD-PSC-OOOPOOO1 11

S. Chitnis

12/14/06

For SC-I Piping, the seismic span based on allowable stress is

L, = {48(0.8x1.33S - PD/4tn

= {48[0.8x1.33x20000-( 400x6.625/4xO.217)-2500)x6. = {48(21280-3053-2500) 6.78/6.536}1/2 in

384E1I3w]1/4

weight stress).Z/[i.5w(0.43

)] }1/2 78/[1 x5x3.04(0.43)]} 1/2 in

= 884.92 in = 73.7 ft. Seismic span based on 3" pipe displacement is Ld = [~

X

= [3.0 x 384 x 28.1 x 106 x 22.4/3 x 0.355 x3.04] 1/4 Horizontal factor = 0.355 = [2239.6680 x 108 ]1/4 = 687.93 in = 57.3 ft. Ld < L, , therefore seismic span considered is 57.3 ft. Support Load (Horizontal) wL x Fp 36.5 x 57.3 x 0.355 743 Ibs. Support Load (Vertical) wL x Fv 36.5 x 57.3 x 0.237 4961bs.

Total Vertical Load c)

= Seismic

load + Gravity Load

= 496 + 704 = 1200 Ibs.

Determine wind span and support load for CS pipe 6 "nominal diameter, with 2 " thick insulation. From paragraph 5.3, The design wind load = F = 31.180 X At (Ib) At (6.625 + 4) x 12/144 0.89 sq. ft. Hence, F = 31.180 x 0.89 = 27.61 (Ib) per foot of pipe. From equation (1) of paragraph 5.0, for 3 inches of maximum displacement, the allowable span is as follows:

X 10 ]1/4/12 = 569.3137/12 = 47.4 ft. From equation (3), Wind Load

= [(3 x 384 x 28100000 x 22.4) 1(3 x 27.61/12)]114/12 = [7.2511488 x 101111 /6.9024]11 112 ft.

= [1.05052573

= wL = 27.61

x 47.4

= 13091bs.

Hence, L, = {48(21280-3053-2500)6.78/[1x5x2.3)]}1/2 in {48(21280-3053-2500)6. 78/11.5} 112 {48x15727xO.5896} 1/2 667 in 55.59 ft. The wind span for deflection is smaller than for pipe stress and is selected.

= {48(0.8x1.33S - PD/4tn - weight stress).Z/[i.5w Where w = wind load per inch = 27.61/12 = 2.3lb/in

L,

Allowable wind span for stress is calculated as follows: )] }1/2

= = =

Bechtel Pueblo Team

SUBJECT: BY:

PROJECT:

PCAPP 24852

RD-PSC-OOOPOOO1 12

CALCULATION

SHEET

JOB NUMBER: CALC NO.:

Computation of Gravity, Wind, and Seismic Spans and Thermal Offset DATE:

SHEET NO.: SHEET REV.:

S. Chitnis

12/14/06

For exposed piping, the wind span is smaller than the seismic span and is therefore to be applied along with the wind load for supports. d) Determine thermal offset and support load for CS pipe 6 "nominal diameter, at 150°F and 70 ft long. Coefficient of thermal expansion for CS = 0.61 in/100ft at 150°F Consider thermal stress 24000 psi Thermal expansion = L1= 0.61 x 70/100 = 0.427 in

St = 3EL1Dlr Hence I (3EL1DI SI )1/2 (3 x 28.1 x 106 x 0.427 X 6.625/24000)1/2 (9936.42)1/2 in2 99.68 in =8.31 ft.

Support Load

= R = 12EIM

r = 12 x 28.1 x 106 x 28.1 X 0.427/(99.68)3 = 4046 X 106/0.99 X 106 = 40871bs.

CONCLUSIONS

This calculation provides gravity, wind, and seismic spans and support loads for piping from sizes ~ inch through 36-inch nominal diameter for Carbon steel, Stainless Steel, Hastelloy and from sizes ~ inch through 28-inch nominal diameter for Titanium. It also provides length of thermal offset and support load for these pipe sizes and materials for piping ternperatureot 150°F and 300°F. The data contained in Appendices A, B, and C is used in developing a Design Guide for pipe stress analysis and support design for PCAPP project.

APPENDICES 7.1 APPENDIX 'A' GRAVITY, WIND, AND SEISMIC SPANS AND SUPPORT LOADS

(Total number of pages

= 8) = 32)

7.2

APPENDIX 'B' THERMAL OFFSET AND SUPPORT LOADS (150°F)

(Total number of pages

7.3

APPENDIX 'C' THERMAL OFFSET AND SUPPORT LOADS (300°F)

(Total number of pages = 32)

APPENDIX

'A'

GRAVITY,

SEISMIC,

AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK

SHEET FOR SPAN TABLE SC-I AND SC-II PIPING (CARBON

STEEL) WITH CONTENT

Supper! M""'J Gra";ty Stresi Inlen:iilieali on Factor (SIF) 2.10E+oo 2.10E+OO 2,10E+I)O 2,10E..oo 2.10E+OO 1.00E+oo GrlVlly SpIInfOf sUe&a (I..s) (Ft) 3A6E-+OO 4.17E+OO 5.17E-+OO 6.73E+OO 7.83E+oo 1.22E+Ol 1_36E+Ol 1_57E+Ol 1.93E+Ol 2.21E+Ol 2.48E+Ol 2.63E+Ol 2.70E+Ol :U9E-t(Jl 2.87E.ol 2J~3E+Ol 2.99E+Ol 3.04E+Ol 3.09E+OI 3.12E+OI 3.16E+Ol S.19E+Il1 3.2:2E+Ol 3.25E+01 Selected Gravtry Span (Ft) longitudinal Pressure SIre6s [psi) Weight Stress (psi) Seismic Spi!l1IQ1' SC-I (Ft) 1.41E+Ol 1.69E.ol 2,09E+<Il 2.71E+<Il 3,14E+Ol 4.79E+Ol 5.33E+Ol 6.o9E+Ol 7.37E+Ol ~.39E.ol 9.32E+Ol 9.12E+Ol 9.13E+Ol 9.94E+Ol 9.97E+Ol 9-&5E+Ol 9.e8E+Ol 1I,77E+Ol 9.621"'+01 9,44E+Ol 9.23E+Ol 8.99E+Ol ~_12E+OI 8.43E+01 Seismic Insulation Weight [lb'FI)) 1.49E+OO I 1.60E-tOO 1.74E+OO 2.04E+oo 2.29E+OO 2.55E+OO 2.I!BE+oo 3.4(lE+oO 4.52E+OO 5_56E+oo 6.68E+OO 7.72E+OO 8.38E+OO 9.42&00 1,05E+Ol 1.15E+Ol 128E-t(J1 I..36E+Ol 1.47E+Ol 1,571"'+01 1,6IIE+Ol I.78E+DI lIBE+Ol 1.9!:IE+Ol 9.45E+OO 1.38E.ol 2.22E+<l1 4,42E+Ol 6,~SE+Ol 1.29E+02 L89E+02 3.14E+02 7.0:aE+02 1.25E+03 2,03E.o3 2.82E+03 3.33E+03 4.24E+03 5.26E+OS 6.38E+03 7.6OE+03 1I.93E+03 1,00E+04 1.19E+O-$ 1.35£+04 I.53E+04 L71E+04 l.&tE+04 Seismic lood (HoriZQ'ltal) SC-lfLb) I.36E+ol 1.99E+Il1 3,20E+ol 6,31E+Ol 9.75E+Ol 181E+02 2.63E~ 4.33E+02 9_SSE+(l2 1.68E+03 2.72E+03 3.70E+03 4.31E+03 5.S7E+03 8.49E+03 7.6aE+o3 IUllE+03 1.02E+04 1.15E+o4 1,27E+04 1.4OE+04 1.53&04 L65E+04 1.76E+04

,,_

Seismic lood (Verlical) SC-I{Lb) 9.10E+oo 133E+Ol 2,13E+ol 4.21E+Ol 6.51E+Ol 1.21E~ 1.76E-H)2 2_89E+o2 6.37E+02 1.12E+03 1.~IE+03 2.47E+03 2.!IE+03 3.58E+03 4.,34E+03 5.13E+(l3 5.95E+o3 6.79E+03 7,6SE+o3 851E+03 9,36E+03 1.02E+04 l.l0E-+{)4 L17E+04

SUf4JOfl Seismic lood (Horizontal) SC-II(Lb) 216E+Ol 3,16E+Ol 5,07E+Ol 1.00E+02 I.56E+o2 2.91E+02 4.26E+<l2 7,OSE+02 157E+Q3 2.78E+03 4,51E+03 6.20E+(l3 7.J1Et03 9.23E+03 1.131:+04 1.37E+04 1,61E+04 UlBE+04 2,16E+04 2.46E+04 2.nE+Il4 S.10E+04 3.45E+04 3.80E+04

s,_

Sei$lTlic

Allow.

Oeflnfor PIpe spactng (in)

se-t & se-n

Seismic

Span for 1>kHt.0eI1t'l Seismic SpilfVGra"; IySpiln

ErolCorr

WBlIThk

FIowAree.

00

(in)

10 (in)

0.672 0.868 1.083

(tJ(in) 0.084 0.091

Isc;nl

MI(in4) 1.44E-02 3,H!E-02 7.93E-02 2,97E-Ol 1S.6SE·Ol 113E+oo 2.28E+OO 5.54E+oo 2.24t+Ol 5.96E+Ol 1.35E~ 2.36E-t<J2 3.14E+02

Z[in3) 3.44E-02 B,06E-02 1.21E-Ol 3.12E·Ot 5.64E-Ol 7.84E-0I 1.29E+OO 2.46E+oo 6.78E+OO 1.38E+Ol 2.S2E...ol

WI,Lb'Ft

"""

w.k<

WI,Lb'F1 I.53E-Ol 2.56E-OI 3.91lE-01 8.97E-Ol 1,45E+oO 2,28E...oo 3.46E+OO 5.~5E+OO 1.3OE+Ol 2.23E+Ol 3.49E+Ol 4.99E+Ol 6.07E+Ol 8.02E+Ol 1.02E+02 1.27E+02 1.55E+02 I.B5E+02 2.IBE+02 2,54E+02 2.93E+02 3.34E+(l2 378E+02 4.25E+02

SpaniOl" Wllb'Ft

r"""

tcec

(Vertical) SC·II(lb) 1.44E+<l1 2.11E+Ol 3,38E+Ol 6.71E+Ol 1.04E+02 1.95E+02 2.85E+02 4.70E+<l2 1.05E+03 t.e5E+03 3.01E+03 414E+03 4.8BE+03 6.16E+03 7.~E.o3 9.11E+03 I.OSE+04 1.25E+04 1.44.E+04 1,64E+04 185E+04 2,07E+O-$ 2,30E+04 2.54E+(l4

.,Seismic lood (Horiz.) Dellecbo<tfor Be-I Actual Span (In) 1.13E+Ol 1.60E+Ol 2.43E+Ol 4.65E+Ol 7,07E+ol 9.31E+Ol 1,36&02 2.23E~ 4.96E+02 8.78E+o2 1.43E+<I3 2.00E+Ol 2,4OE+oJ 3,IOE+o3 3,90E+o3 4.81E+03 5.I1E+03 6.91E+03 8.13E+o3 9_44E+03 1.0SE+04 1.24E+04 1,41E+04 1.S8E+04 1.27E+OO 1.44E+OO 1.78E+oo 2.03E+oo 2.16E+OO 8.48E+oo 8.51E+OO 8.46E+oo 8.19E+OO 8.01E+oO 7.81E+oo 6.91E+oo 6.26E+oo S.35E+oO 456E+oo 3.~9E+OO 3,3OE+oo 2.IOE+oo 2.38E-t(JO 1.98E+OO 1.65E+OO 1,37E.00 1,12E+oO 9.06E·Ol

Wind Oefle(:lion forSe-II Actual Span (in) 7.95E+oo 9.14E+OO 1,12E+Ol 1.3OE+Ol 1.40E+Ol 5.12E+Ol 5.~4E+Ol 5_94E+CI 5.97E+Ol S.97E+Ol 5.93E+<l1 5,49E+Ol 5.1SE+Ol 4.68E+Ol 4.25E+OI 3.18E+<Il 3.5.5E+Ol 3_25E+Ol 2.99E+Ol 2.7SE+1Jl 2,531"'+01 2.33E+Ol 2,16E+Ol 1.99E+Ol 0,375 0.315 0.375 0,063 0.218 0.203 0.216 0.237 0.063 Nom. Wall Thk (tJ(in)

Selected

d&llection (LU) (Ft} 6.09E-+oo 7.06E+oo 8.32E...oo 1,04E+Ol 1.19E+Ol 1.29E+Ol 1.43E+Ol 1.64E+Ol 2.00E+Ol 2.29E+Ol 2.56E+Ol 2.75E+Ol 2.85E+<l1

Spsnlor

SC-II(FIJ 2.23E.ol

Mechi Erol CaT.

0.063

CrOues

'«Velocity lYes&ure G'Oues Effect 0.85 0.85 force coeflic>en t 0.7

AI"

Projected Area (sq. II) Wind Load (F) (L~t)

Wind SpaniOl' AJIow~G Defl.(Ft) WindL08d lor se-t flb6)

Wind Spanier Slress I (It) 6.31 se

Selected

Wind

SpanIOl'

Stl'6$5SC Ivsc·m (H)

Wind

SpanSClUSC-11i (ft) 10,0 13,0

Wind~~ lorse· II/Se·UI (Lbs) se.es

{ttl

1,7E+Ol

Ratio

Ilbl

1.69E+Ol 2.39E+Ol 3,64E+Ol Ej,96E+Ol 1.06E+02 ',39E~ 2.03E+02 3.34E-t(J2 7.43E.o2 1.31E+03 2.14E...os 3,OQE+o3 3.59E+03 4,65E+03 5,B5E+03 7.20E+03 8.70E+03 I.04E.o4 1.2.2E+04 1.41E+04 1.63E+04 1.86E+04 2,10E+04 2,37E+04

AllCIYI,(inj (Utsq.ft) 24.3612 24.3612 0,063 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612 0.063 0.063 0.063 0,063 0063 ~.3612 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612 0.063 0.063 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612 24.3612

0.840

1,050 1.315

3,55E-Ol 5,92E-Ol 9.21E-Gl

1.01168488 1,4721339 2.1694514 3.627417 5.0IB761~

2.73E+OO 3.32E+oo 4.3OE+OO 6.57E+oo 8.7SE+OO 1.06E+<I1 UiE+Ol

3,46E+oo 4.17E+OO S.17E+OO 6.73E+oo 7,8SS+OO 1.22E+Ol 1.36E+Ol 1.57E+Ol 1.93E+Cl 2.21E+Ol 2.4tiE+Ol 2.63E+Ol 2.70E+Ol 2.79E+al 2.17E+Ol 2_93E+ol 2.99E+Ol 3.04E+Ol 3,09E+ol 3.12E+Ol 3,16E+Ol 3.19E+Ol 3.22E+Ol 3.25E+Ol

1.00E+03 1.15E+03 1. 13E+03 1.39E+<l3 153E-t<l3 2.05E+<I3 2.29E+03 2.59E+03 3.05E+03 3.33E+03 3.56E+03 4.09E+03 4,49E+OJ 5.13E+03 517E+03 6.41E+03 7.05E+03 7.69E+03 B.33E+03 8,97E+03 962E+o3 1,03E+O-$ 1.09E+04 U5E+(l4

2.50E+03 2.5OE+<l3 2,~E+03 2.50E+03 2.5OE+03 2.5OE+<I3 2_50E+03 2.50E+03 2.50E+03 2.50E+OS 2.5OE+03 2,SOE+03 2.SOE+03 2.5OE+03 2.5OE+03 2.50E+03 2.50E+03 2,~E+03 2.50E+03 2,5OE+03 2.5OE+03 2.50E+03 2_5OE+oS 2.50E+03

0.147

0,154 0,179

6."

0.42 6.10 6.42 7.13 22.~ 27.14 3O_35 13.43

2 ,66E-Hl

3.32E+Ol 4,31E+Ol 5.01E+Ol 7.73E+<l1 ~.63E+Ol 9.91E+01 1.21E+02 1.39E+02 1.55&02 1.63Ei'tl2 1.67E+02 1.11E+(l2 1_74E+02 1.77E+02 1.79E+02 180E+02 I,B1Et0.2 I.B2E+02 1.83E+02 1.83E+02 1.83E+02 1.82E+02

"'

3.00

2,OE.ol 2.4E+al 3,OE+Ol 3.4E+<Il

49.81 72.13

..

Span

I(ft)

SC

9."

e.a

11.2 17,0 21.93 21.9 30.3 43,34 55.74 35.3 42.8 57.5 70.3 83.0 &2.4 97,5 10S.2 112.4 119.1 125,6 131.7 131.5 143,2 362..08 317.63 333.63 174.17 217.78 17.81 27.13 35.01

3.00 .:3.00

0.7

0.85 0.85 0.7 0.53

106.98 22.6 27.1 160.91 209.00 252.00

1.900

2.S75 2,875 2.065 2.595

0,137 0.155 0.140 0.153

2.08E+OO 3,35E+oo 5.29E+OO

121.42 188.86 252.00 319.96

7.70

5,78696n

7.5679015 IO_n9094 18.954321 28.523938 40.440632

3,00 3.00

3.7E+Ol 4.1E+Ol 4.7E+Ol

67.30

70.16 90.74

30.3

35.3 428 57.5 70.3 83.0 92.4

e.ora-cc

1.35E+Ol

r.ooa-oo

1.00E+oo 1.ooE+OO 1.00E+OO l.ooE+oo

0.85

9.06

35.32 42.85

4.500

6.625 8.625 10_750 12.750 14.000

4.152 6.191 8.107

a.oce-cr

3.65E+Cl S.64E+Ol 1.20E+Ol 1,07E+<I2 1,24E+02 1.52E+02 1.83E~ 2.17E+02 2.54E+02 2.94E+02 3.36E+02 3.81E+02 4.28E+02 4.78E+02 S.31E+02 5.8'7E-+{)2

0.71 0.7 0.7 1.05

1.23 0.85 0.85 0.7 0.7 1.50 1.67 0.85 0.B5 0.7 0.1 12.83

439.90

737.81 1071.90 1478.69 11168.84 2119.43

0.217

0.259 0.302 0.312 0.312 0.312 0.312

3,01E+Ol S.16E+Ol 8.09E+OI 1.15E+02 1.4IE+02 U8E+02 2.37E+02 2.95E+02 3,59E+02 4.29E+<l2 5.06E+02 5.89E+02 8.18E+02 7,73E~

3.00 3.00

5.7E+Ol 6.6E+Ol 7,3E+Ol

0,280 0.322 0.365

0,375 0.375 0.375 0.375 0.375 0.375 0.375

57.49 70,29 82.99 92.37 97,48

737.81 1011.90 1478.69 1868.94 2119.43 2540.65

'1.51 106.85 131.20 146.63

15.25

17.82

10,146

12.126 13.376 15.376

a.zoe-or

4.49E+Ol

49,510242

54.511276 82.512931 70.514586 71.516242 86.517897 94,519552 102,S2121 110.52286 116.52452 126.52617 134.52783 142.52948

r.ooe-oc

3.00

3.00

7.9E+Ol 82E...ol 8.6E+Ol

20.23

21.74 24.16 26.57

r.coe-cc

1.00E+oo 1.00E+oo I,OOE+OO

153.69

163.53 171.81

260.34

281.22

~7.5

4.73E+02S.92E+Ol 6.7BE+02 9.35E+02 1,25E+03 1.63E+03 2,01lE+03 2.5OE+03 3.21E+03 7.54E.Ol 9.35E+Ol 1.14E+<l2 1.3EiE+C2 1.60E+02 1.86E+02 2,14E+02

a.oce-or

3,13E+Ol 325E+Ol 3,36E+Ol 3.47E+Ol 3_56E+Ol 3.S5E+Ol 3,74E+Ol 3,82E+Ol 389E+Ol 3,96E+Ol

105.2

112,4

254(1.65

2985.82 3453.74 3943.39

18,000 20.000 22-CIOO 24.000 26.000 28.000 30.000 32.000 34.000

17.316

3,00 3.00 3.00 3.00

1I.0E+Ol 9_3E+(l1 9.6E+Ol 1I.S1E+Ol 1,OE+02 1.0E+02

112.36 119,14

.2985.82

0.312

21.376 23.376 25.376 27.376 29.316 31.376 33.376 35,376 0,312 0.l12 0.312 0.312 0.312 0.312 0.312

2.00

2.17

28.99

31.41

3453.74

:ss.J.39

178.68

1804.27 188.68 191.96 194.18

rcos-co

r.cos-oo

l.ooE+oo

0.7 0.7

O.BS

131.119

4453.86 4984.34

5634.11

131.7 137.5

4453.86 4934.34 5534.11

0,375

36.24

137.55

r.ccs-co

1.00E+oo 1.00E+oo 1,00E+OO 1.00E+OO

31."

0.85 0.85 0.7 41.07 43.48 45.90 3.33 48.32 153.82 158.89 163.BO

3.00 3.00

3.00

1,IE~ 1.1E+02 1.1E+C2 1.1E+02

6102.53

6689.01 7293.01 1914.04

195.35 195.48

194.57 '92.61

148.6

153.8 158.9 163.8

386.54

397.49 407.67 417.12

6102.53

3.90E+032.44E+02 4.68E+03 5.57E+03 2.76E+02 3.09E+02

153,8

158.9 163.6 7293.01 7914.04

8.75E+02 91JE+(l2

NOTE: , Gravn span is calculated for a total deflection 2. GravHy stress is limited to 2500 psi of 1/8 inch

3. Seismic span is calculated wHh factor 0,355 for horizontal and 0.237 for vertical to uniform dislributed pipe weight 4 Selected oravily span is the smaller of the span calculated with allowable oetrecton 118 inch ard stress 2500 psQ 5. Seismic span for SC-I pi ing is based on Code allowable stress limij of '.33 x Sh.

9. Insulation thickness 01 2 inches considered with densHy of 12 LblCuft 10. Pipe schedule is 80 fOf piping 2 inch and smaller diameter and 40 (STD) for 2.50 inchdia. and greater rt. S ans for Seismic and Wind loading are calculat8d~fo:;:, m:;;a~~;;:m~u;;m:--;d::;ef;';lecf~io;;-n"'of"'3:C:;nc;;;;;hes~ao;j;;;T-ifo:;;'''''80;c.%~o;fC;a''''Io:';w=a"'ble"',,;;,;;:ess;:;:';a::::o;j"'sm=a:<c.II.::-'C'!"=a:Cn

"'be"',we;;;;;;e"'n

,o.:he""two="C::co;O;ns:;;kIe=,ed",,--+--+----j

1 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK

SHEET FOR SPAN TABLE

EroJCorr. WallThk 00 (In)

..,,"

(0 (in)

0,116

sc-i

AND

se-n PIPING

(CARBON

STEEL) EMPTY

DOn)

-3.55E-01 5.92E-Ol 1I.21E.(II 5.2&E...oo 8.01E+00 5,18E+01

s_

deleclion (Ld)(Ft)

PipII MI(IIl4) "'«E·02 3.UE·02 7.!f3E.Q2 2.97E-01 3.12E-Ol 5.84E·01 3.627417 Z(in3) 3,44E-02 8.08E-02 Wt.Lb'f1 1.086&488

Wl.lbIfl

w....

Total

S""..

(SIf) 2.10E+00

Gra'lity

Gr:wity Span lor SIrDl5 (lsi (A) 3.57E..oo Gravity Spar1 (Ft) 3.57E+00 4.34E+00 Longitudinal Preuure Streu (psi) 1.00E+03 1.15E+03 '_'3E+03 Wei!jjht Slress (PSi) 2.50E+03 2.50E+03 2.5OE+03 SpMllor I (Ft) 1,45E+Ol 1.76E+-Ol 2.20£+01 S~mic: SC- Span lor se II (A) 2.2&E+Ol 2.78E+Ol 3.4.IIE+Ol NIJI.tiOll Weighl (l..blFt)) 1.49E..oo 1,60E+OO 174E..oo 2.04£..00 6.57E+00 L37E+Ol 1.53E+03 2.05E+03 2.29E.03 2.50E+03 2.49E+03 2.4OE+OS 2.3OE+03 3.43E.Ol 5.41E+Ol 6.'7E+Ol 7.28£+01 9.29E+-Ol 2.08E+OS 2.02E+03 2.ooE+03 2.ooE.03 1.!f9E+03 1.9BE.03 1.09E+02 1.25E+02 1.35E+02 14OE+02 1,47E+02 1,53E+02 2.nE.02 1.15£+<11 1.26£+01 1.3&E+Ol 2.35E.02 2.50E+02 8,38£+00 9.42£-+00 1.711E+02 2.05E+02 5,56E+00 6.68E..oo 5.UE+Ol 6.72E+01 9117E.Ol 1.1IIE+02 2,88E+00 3.4OE+oo 2,28E+oo

S.._

Gravity load (Lil) 11.18E+oo 1.33£+01 2.12E.Ot 4.11E.Ol 6.28E+Ol 1.14E+02 1.61E+02 2.53E+02

Seismic Lood (HorilClf'lIaI) SC-I(\..b)

""_

Seismic Lood (V.~) SC-I(L.b) 8.85E+00 1.2&£+01 2.03E+Ol 5.115E+Ol 1.07E+02 '.53E+02 2.45£+02 5.17E+02 8.84E+02 1.40E+03 1.83E+03

Suppm Seismic Lood (Horizonl3l) SC-H(l.b) 2.10E+Ol 3.03E+Ol

S~ Seismic Lood f\lenic3l) SC·II(U:1) 1.4OE+Ol 2.03E+Ol

.Aligw. Delnlar

spacmg (in)

....

SC·I&$C·II Seismic Spanior Allow Deftn (tI) 1,8E+Ol Seismic; SpaNG,,,,,;. ySpan (HOfil·I(Lb) 1,62£+01 2.25E+Ol 2.4E+-01 3.S9E+Ol 6,23E+Ol 9,24E+Ol Supporl

s,_

Stdsmie Lood (VanicalJ

"""'''''

IorSC-1 Span (in)

(Lb'

"''''''

AeNai

:~

Span

Nom. Wall

(in)

Thk,(I,J(injAllow.finj

J ...... .....

J EroJ Con 0.063

At CrGU4ISI ecefllclent p~ Area (sq 11) Wind load (f) (lbsfll) 5.85

Wind 5~br Allowable Deft,(ft) Windloarl lor SC·I (lbs) 36.88

WiN Spanfor SIrdS I(n) SC

Sel~led Wind Span SC 1{1t)

Wind Spanior S .. ess SC· lVsc·m(ft) ~

Wind SpanSCIISC-1Il (ft)

Wind Load forSC· WSC-l~ ~ 58.35

'q'lIe1ocily (UYsq.fI)

,~

O,OOE+oo

2.57£+00

6,16E+00

1.91E+Ol 3.0SE+Ol 5.88£+01 11,91£+01 1.80E+02 229E+02 3.66E+02 7.74E+02

0.1

1.I16E-+oo 4,16£+01 8,17E+()1 2.35E+OO 2.59E+oo 1.68E.Ol 0.&5 1.15E+Ol 1.23E+OI 7,81E+01 B.47E+Ol 0.216 1,24£+01 0,179 24.3612 0.85

0.42 17.81 16.7 106.911

O.OOE+oo

5.67E+00

1.08E+Ol \,24E+Ol

~.10E+OO 2.10E+00

7.~4E+oo &.57E+OO

&.34E+Ol 1.42£+02 2.5IIE+02

8.23E+Ol 9.49£+01 '.72E+02 2.47E+02

3,IE+Ol

17.11-4

0."

7.70

27.14

252.00

2.!75

~.595

1.13E+00 2.26E+00

7.84E·Ol 1.29E+OO 7.S6~0IS O,ooE+OO 1.04E+Ol 1.42£.01 1.79E+01 2.23E+<Il 1.00£+00 1.86E+Ql 2 ..40E+()1

1.16E.027.76E-+Ol 1,64£+02 3.00 $.IE+(ll 1,09E+02 1,72E+02

35.3

10.27 42.65

70.24

1.79E+<Il 2.23E+Ol 2.60E+<Il

2.59£+03 3.05E+03 S.33E+03 3,5eE+03 4.08E+03

5.94£+02 1.26E+03 2.17E+03 3.44E+03 4.58E+03 5.24E+03 6.39E+03 7.59E+03

3.97£+02 8.43E+02

6.625 5.98E+Ol L35E+02 12.750 1.41E+02 2.36E+02 3.14E+02

8.78E+00 1..38E+Ol 2.52E+Ol 3.70E+Ol 4.49E+Ol 4O.44Oe32

O.OS

9,01E+02 6,02E+02 9.42E+02 1.e7E.03 2,16E+V3 1,25E+03 1,44E+03 I.40E+Ol 1.-45E+()1 1.38E+()1 1.32E+Ol 1.22£+()1 3,17E.032.11E+03 3,72E+03 2,48E+03 1,02E+Ol 9.62E+Ol D.375 1,04E+02 1.01E.02 0.15 0.375 1.01E+02 1.06E.02 0.322

~1

70,3 175.74

737.81

o.eoe-cc o.ooe-oo c.oce-oc

O.OOE+OO

3.41E.Ol 4.71E+Ol

2.60£+<11 2,94E+Ol 3.22&01 1,00E...oo 1.ooE+00 3.27E+Ol 3.80E-+Ol

B,B5E.02 l.li£+03

1.32E.03 2.ogE+03

2"~4E+Ol

2.29E+03 3.05E+03

3.00

8.4E.Ol

17.82 O.OS 0.1

21.74 US7 24.111

82.9& 92137 97.5 105.17 2540.65 2INIS.12 319.74 261.9:1

8.211£+01 7.19E+Ol

3.38E+Ol 3.62£+(11 1,ooE.00 4.08E+Ol

3.38E+Ol 3.62E+Ol 3.64E+Ol

4.'8E.03 5,13E+03 5,nE+OJ

2,12E.03 2,6QE+03 3.11E+03 3.115E+03 ~.22E+03 4.B1E+03

313E-+03 3.76E+03

2.09E+03 2.51E+03 2.I114E+03

4.73E+025.92E+Ol 18.000 17,376 2.95E+02 9,35E.02 125E.03 24.000 23.376 4,29E..o2 5,06E+(I2 2,08E+03 9.35E+Ol 1.141:+02 l_38E+02 1.60£+«2 l_eeE+02 2"9,376 6.78E+02 3.21E+03 2.44E+02 8.75E.02 0.312 9.63E+02 4.88E+03 5,57E+03 2.76E+02 3.09E+02 1211,52817 102,52121 78.516242

4.2fiE+03 5.07E+03

3.00

0.1

c.coe-oc

O.ooE+OO O.OOE..oo

s.eee-er

8,91E+Ol 1,06E.02 1,17E+02 4.8SE+Ol 1.00E.00 4.26E+Ol 1.00E+00 4.79E+Ol 5_OtE+Ol 5.22E+Ol 5.43E+Ol ~.&IE+Ol 1,97E+03 1.97E+03 1,&6E+02 -4.26E+Ol 7,05E+03 7.B9E+03 1.97E.03 1.97E.03 1,62E+02 I.B5E+02

5.05E .. 03 5.68E+03 B.32E+03

3.37E+03 3.80E+03 4.22E+03 1.01E+04 1.15E+04 8.5iE+03 6.77E+03

2.88E+02 2.99E.02

2.17E+039.24E+00 4.&oE.OS 5.53E+03 1!I.Il'IE+03 3.27£+03 3.69E+03 7.-«IE+00 9.0BE+Ol 0.375 0.85

2.17 0.1

31.41

125,se 131.7 196.78 137.5 -4453.18

364M

3.19E+02 3.27E.02

I.57E+Ol

1I,07E+03

7.54E+03

5.03E+03

1.43E+04 1.05E .. 04

2.87

5,85E+00 1.25E+Ol 01375 24.3612 0.15

38.65

6102.53 201.54

c.coesce

O.OOE+OO O.ooE+OO

'.35E+02 1.44E+02 1.53E+02

4.98E-+Ol 5.15E+Ol 5131£+01

ooe-oo

562E+Ol S.81E+Ol 5.15E+Ol 1.03E.04 1,9flE+03 1,89E+02

1,ooE+00 1,00E+00

3.35E.02 3.43E+02 1.&&E+Dl 8,14E+03

8.84E+03

s.nE+03

1.72E+G4

1.15E+04 1.25E+04

1.5E.02

7,56E+03 4,42E+00 8.04E+oS 6.03E+03 3,76E+00 7.70E.Ol 7.44E+Ol 0.375 0,063

0.1

163.6

NOTE: 1 Gravity span is calculated lor a total deflection 01 1/8 inch 2 Gravity stress is limited to 2500 psi 3. Seismic span is calculated with factor 0.355 for horizontal and 0,237 tor vetlcattc uniformly distributod pipe weight 4. Selected gravity span is the smaller of the span calculated with allowable deflection (1/8 inch) and stress (2500 psi) 5. Seismic span for SC-I piping is based on Code allowable stress limit of 1.33 x Sh 6. Seismic span for SC-II piping is based on Code allowable stress limit ct a x Sh or 2xSy, whid-,9IIef is smaller 7. Sh '" 20000 psi. SY= 31000 psi, and E: 28100000 psi at 300 dog F lor Carbon Steel. Eighty % of allowable stress considered. 8. These spans are for piping I'Jith fluid temperature not grea.ter than 300 deg. F and fluid pressure no greater than 400 psig 9. Insulation thickness of 2 inches considered with density of 12 Lb/Cuft 10. Pipe schedule is 80 for piping 2 inch and srnener diameler and 40 (STD) for 2.50 inch oe. and greater 11. Spans for Seismic and Wind loading are calculated lor maximum deflection of:3 inches and for 8{)<'k of allowable stress and smaller span between

(he

two

is considered

2 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK SHEET FOR SPAN TABLE SC-l ANO SC-II PIPING (STAlLESS STEEL) WITH CONTENT

G_

Gravity Spaniol' £1re&S{L&.1 (SIF) 2.10£+00 (Ft) 4.10E+oo Gravity Span (R)

MeehJ&oJ CCfT,Wlln 00 (in) D(i,,] Thk.(l.) lin)

FIowAtea (sqin) 2.34£-01 2.01E-02 Z(in3)

Pipo WI.Lb.'Fl 1.113732

w_

WU.b'F! 1.01E-Ol 1.67811 3.11&01

r"",

WtLb'Ft 2.70E+00

5"" .. dfl1Iec1ion {l.d)(FIJ 8,57£ .. 00

alPressu

Sns,(psi} 5.71E+02

·08E-02

5,_

s.ismic Weight Slress(psi) 2.50£+03 Seismic: 5".,,,, SG-I{Ft) 1.52£+01

Support Seismic Load (VII1icaI) SC·I(Lb) 1I.72E+oo 1.43E+Ol

Suppt.ll1 Seismic Load (Horizomal) SC·II(lb)

SLipport Seismic LO<Id (Vertical) SC-I(lbl I.33E+Ol AlIow.Deftn Iorpipe $pacinglin)

SC·j & SC·H Seismic Spaniol" Allow. Deft" (ftl Seismic SpanfGtav itySpan SLipport

..... ~

S"""'"

$ei$mir; Load (Vertiealj (lb) 1.21E+Ol

De1lec1icn fo:)rSC·j A<::Iual Span(ml 1.27E+00 1.46E+00 1.66E.oo

O.lectial JorSC-. At:1Ua1 Span (in) 4.49E+0CI 5.21E+00 8.02E+00 6.89E+00 0.17& Nom. Willi Thk._ (t,.) (in) Q.147

EroJ CaT AIIcw. (in] 'q'Velocity pressure lLblsq,ft) G'Gue,1 E"""I Cf"GLHI5t ProjIeIed

lood

5"",,,, SC-I1(fl) 2.Q8£+01 2.51E+Ol 1,49E .. 00 1.80E+00 1.11E+Ol '.84E+Ol (Horizonlal) SC·I(lb) 1.-46E+<Il 2.14Eflll

Sltismie

Load (HorIz.){UlJ

ron:.

.....a($q e

f'I}

LoadfF) (LboIft)

w'"'

Wind Span !Dr Deft.(FI} WindLoad b SC·I (Lbs) 39.56 WindSpan for Sire$! SC·I(fI) Wind SPM SC·I(fI)

WindSpan faStteu SC·lVSC·nl (ft)

Selecled WindSpan (ft) WindLoad 11(Lbs1 SC-IVSC·MI lor SC·WSC·

4.10£+00

sus

12.1 11.8

4.48E·026.53E·02 1.315 1.06E·Ol 1.81E-Ol 4.12E-Ol 3.7171411

294E+Ol 4.59E+<Il

1.96E+Ol 3.00E+Ol 3.00 25E .. Ol

2.56£+01

1.71E+Ol 2.57E+Ol

427E.00 6.52E+00 4.71E+00

e ere-oc 1.11E+Ol 1.28[+01

2.10E.00 2.10E.00 2.10E.00 7.75E+oO

5.89E+00 7.75E+00

7.35E+02 9.50E+02 1.00E+03

25OE+03 25OE+03 2.50E+03

2.20E+Ol 2.83E+Ol

3.03E+Ol 3.91E+Ol 2.04E.00 5.06E+Ol 7.79E+Ol 6.55E+Ol 1.00E+02 1.92E+02 2.78E+02 4.51E+02 9.73E+02 1.68E+03 4.37E+Ol 8.70E+Ol 1.2IE+02 I.85E+o2 3.otE+02 6.5CE+02 1.12E+03

0.85 24.3812

0.7

12-6,52 7.70 2MII

0.20<1

l.nE+oo

3.91E·Ol

7.63EoOl 1.26E+00

9.04E+Ol '.39E+02 1.7IE+02 3,1I7E+02 1I.31E+02 1.37E+03 2,39E+03 3.&2E+03 9.17E+02 1.59E+03 2.S5E+OS 3.49E+o3 4.11£+03 8.9E.O' 6.3SE+03 1.14E+04 1.34£+04 1.56E+04 1.04E+114 1.0£+02 &.3E+Ol 2.58E+02 5.0e ..Ol 6.0E.Ol lI.ftE+C1 7.6E.O' 8.1E+Ol

735E.Ol 1.11E+02

4.91E+0' 7.43E+Ol 9.69E+Ol 1.44E+02

rece-ec

1.Ii18E+OO 7.25E+00 8.44E+oo 1.34E+OO 8.06E+00 7.37E+00 6.&BE+00 6.42E+00 5.57E+00 .5.02E+00 4.29E+oo 3.85E+oo 3.10E+oo 2.83£+00 2.22£+00 S.ISE.Ol 3.13E+Ol 3.09E.01 2.112E.Ol 2.IOE.Ol 2,88E+Ol 2.43E.Ol 2.26E.Ol 2.03E+Ol '.13E.Ol '.65E+Ol 1.49E+Ol 1.34E+Ol 1.21E+01 1.10E+Ol 9.98E+00 9.05E+00 1I.21E+00 7.45E+00 0.85 0.375 3.17 0.85 0.7 0.375 24.3812 0.15 0.7 2.33 .2<1.3612 2<1.3612 0.36$ 0.85 0.85 0.7 2<1.3612 0.7 24.3612

28.7

a ... a

•. 79E.00 0,216 7.38E+00 1.27E+Ol 2.19E.Ol IU!2S 7.981 5.00E+01 7.89E+Ol 1.,3E.02 14.000 13.250 0.375 1.38E+02 1.83E+02 2.34E.02 20.000 19.250 0.375 2.&IE+02 355E+02 4.25E+02 25.250 0.375 5.01E+02 5.83E+02

'.53E+oo 3.02E+oo 7.23E+00 2.8IE+Ol 7.25E+lll 1.&IE+02 2.79E+02 3.73E+02 5.82E+02 8.07E+02 1.11E+03 I.48E+03 1.94E.03 2.48E+03 3.11E.03

I06E.oo 1.72E+oo 3.21E+00 3.19E+00 5.50E+00 1.99E.Ol 1.53E+Ol 1.74E+Ol 210E+OI 1.68E+Ol 2.99E+Ol 4.38E.Ol 5.33E+Ol 5.96E+III 7.89E+Ol 8.itlE+Ol 1.I1E+02 I.26E+02 I.53E+02 UII2E+02 1.91E+02 2.22E+02 2.9OE+02 129.6558 3.31E+02 3.75E+02 4.28£..02 4.79E+02 5.32E+02 3.87E.Ol 3.95E+Ol 4.03E.Ol 1.00E .. 00 l.ooE+IIO 1.00E+OO 3.45E.Ol 3.49£+01 3.52E+Ol 3.45E.OI 3.49E+Ol 352E+Ol 8.ooE+03 6.53E+03 9.07E+03 25OE.03 2.5OE+03 2.5OE.03 2.16E+02 3.36E+0:2 1.52E+02 1.84E+02 2.18E+02 2.54E+02 3,10E+Ol 3.241;;+01 3.36E+01 3.43E+Ol 3.59E.Ol 3.68E+Ol 3.26E+Ol 3.20E+Ol 3.26E+Ol 5.87E+03 41.44093 2.18E+Ol 3.<llE+01 &.22E+Ol 1.07E.02 2.64E+OI 2.84E+Ol 2.38£+03 1.00E.00 1.80E+OI 1.74E+Ol 1.82E+03 1,90E+03 2.34E.03 2.34E+03

5.12E+Ol 5.66E+Ol 6.37E+Ol

7.11E.Ol 7.8IE+Ol 8.91E+Ol

2.55E.00 2.88E+00

'.46E.02 2.11E+02 3.48E+02

0.85

0.7

0.57

aee.ss

10.21 45.34

52.55

3.52E.02

2.35E+02 5.19E+02 9.'3E+02

4.52E.00 8.4OE+Ol 9.17E+Ol 9.51E+Ol 9.61E+Ol 2.50£+03 250E+03 2.5OE.03 2.50E+03 9.12E+Ol 9.65E+Ol 9.53£+01 1.5OE.02 1.5OE+02 1.3IIE.Ol 1.47£+01 1.57E+0\ 8.98E+Ol 8.73£+01 8.45E+Ol 1.5CE.02 1.49£+02 1.49E+02 1.98E+Ol 1,7&E+Ol 1.48E+02 9.7IE+Ol 1.4ClE+02 L43E+02 1.38£+00 9.42E+00 1.05E.Ol 1.15E+Ol 1.19E+02 1.31[+02 5.56E ..00 8.68E+00

7.64E.02 1.34E+03

117.3"

77U5

105."

r.oce-cc

2.70E+Ol 2_86E.Ol

2.64E+Ol 2.84E+Ol

2.95E+03 34OE+03 3.73E+03

2,4OE+03 2.47E.03

2.21E.03 3.10E+03

I.4&E+03 2.07E+03 248E+03

lIs.n r.eo

150.34 108.70 0.7 1.83 28.57 174.73 129.811 289.03 5157.61 38.85 317.10 6923.91 45.90 169.6 164.5 187.30 251.38 207.50 95.4

1521.22

3.05E.03 3.83£+03

3.82E.03 4.22E+03

2.42E+03 2.82E+o3 3.51E+03

5.23E+03 8.15E ...03 7.75E+oS

2188.86

i.oce-co

3.04£+01

3.04E+Ol

4,27E+03 48OE+03

4.11E+03 6.05E+03

3.21E+03 4.04E+03 4.88£.03

0."

0.15 0.85

5.74E.03 8.~E.03 8.3OE.03

6.36E.03 7.51E+03 8.72E+03

4.24E+II3 5.02E+03 5.82E+03

&.0IE+03

8.01E+03 7. HIE+03

4019.1.2

tcce-cc

3.37E+Ol

3.37E+Ol

6.93E+03

2.50£+03

tiI.3I!E+tIl

1,13E.04

1,12£+04 1.24E.04

7.47E+03

1.79E+04 I.35E..04

1.26E+04 1.47E+0~

8.42E+03 9.78E+03 1.1SE+04

r.eee-cc

I.56E+OO 1.29E+oo 1.06E+oo

57.27 •.25

6.12E+023.83E.032.55E+02 0.375 7,67E+o2 8.68E+<I2 9.76E+II2 4.66E.03 5.60E.03 e.66£+03 2.91E+02 3.29E+02

9.12E+03 1,67£+04 1.48E+04 1.07E+114 2.08E+04 1.70E+04 1.13E+04

2.2IE+04 2.54E+04 2.80E+04 3.01lE+04

1.52E+04 1.119E+04 I.2E+02 2.06E+04 1.92E+04 2,16£+04

1.2&E.04 1.46E+0~ 1.64E.04

e.ete-cr

6.91E·01

7549.71

NOTE: 1 Gravity span is calculated lor a total deflection of 1/8 inch 2. Gravity stress is limited to 2500 psi 3. Seismic span is calculated with factor 0.355 for horizontal and 0.237 for verticalto uniformly distributed pipo weight 4. Selected gravity span is the smaller of the span calculated wilh allowabte deflection (1/8 inch) and stress (2500 psi) 5. Seismic span lor SC·j piping is based on Code allowable stress limit of 1.33 x Sh 6. Seismic span lor SC-U piping is based on Code allowable stress limit of 3 x Sh or 2xSy, whichever is smaller 7. Sh '" 16700 psi, Sy '" 19200 psi, and E", 27000000 psi al300 deg F for Stainless Steel. Eighty % 01 allowable stress considered 8. These spans are for piping with fluid temperature not greater than 300 deg. F and lIuid pressure no greater than 400 psig 9. tnsulation thickness at 2 inches consldered with den!iity of 12 LbJCuft 10. Pipe schedule is 80 lor piping 2 inch and smaller diameler and 40 (STD) lor 2.50 inch dia. and greater 11. Spans for Seismic and Wind loading are calculated lor maximum deflection of 3 inches and lor 80";" 01 allowable stress and smaller span belween the two is considered

3 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK SHEET FOR SPAN TABLE SC-I AND SC-II PIPING (STAJLESS STEEL) EMPTY

MechlEroJ

OD(inJ

orin]

Row .....

Thk.(tJ(irl) (sqin) 2.34E-Ol 4,32E-Ol MI(inA) 2.01E-02 •. oUE-02 1.06£-01 3.91£.01 B,B8E-Ol 4.12E·01 7_31E-Ol 1.06E+oo 0.216 7.39E+00 1.27E+OI 2.19E..ol 0.322 5.ooE+Ol 7.19E+Ol 1.13£+<12 3.02£.00 723£+00 2.11£+01 7.25E+Ol 1.81E+02 2.78E+02 3,73E+02 5,62E+02 1.07E+02 1,I1E+03 1.49E+03 1.72£+00 321E+oo 1.50E+OO 1.68£.01 2.98E+Ol 4.38£+01 5.33£.01 7.03E+Ol 1-"8£+01 1.11E.02 I.35E+02 Z(inJ) 4.7!E-02 B_53E·02

Wtlh'fl

1.113132

~"

w.'" WtU.Ft

O.ooE+OCI

S,...,,,,,

T .. , aefleo::l10!1 (ldl{Ft) 6,63E+OO WI.Lb'Ft UIOE+OO

G_

s....

nFaclor (SIF) 2.10e .. OO

Gravit,' Spano SIrUS(Ls) (FIJ 4.1I!E+OO Gravll)' Span IFI) longilooiMI PrtuUI'I Slre$$(p$i) 5.71E+02 1.82E+02 7.35E+02 Welgllt SIre$$(p$il 2,5OE+03 2.5OE.o8 2.50£..03 2,5(1£+03 2,5OE+03 2.12£+03 2.05£.03 1.i9£+03 181E ..03 U7E..o3 I.UE+03 1.82E+03 1.12E+03 1."E+03 1.10E+03 1.IOE+03 179E+03 1,79E..o3 2.29E-H>1 3,01£+01 3.51E+Ol 5.76£+01 6.52£-H>1 7.SI!E+Ol 9.44£+01 1.~E-H>2 123E+02 1.32E+02 1.37£-H>2 1.44E+02 1.50£+02 1.55E+02 1.59E+02 2,4;!JE+02 1.C14E+02 2,55E+02 2,62E+02 1.66E+02 2,68E+02 1,57E+Ol 1.68E+Ol 1.78E+Ol 1.65£+02 1.63E+02 279E+02 2,13E+02 1.88E+Ol 1.I19E+Ol 1.36£+01 2,31E+02 I.53E+02 1,73E+02 1.19E+02 1,97E+02 2.09E+02 1.36E+oo 9.42E.oo 1.00E..ol 1.15E+Ol 5.5SE+oo 7.&7£+01 &,03£+01 1.05E+02 3.14E+Ol 4,16E.Ol 1.74E+OO 2N·E+OO 2.29E+00 2.55E+oo 2.88E+OO 3.40£.00 Seismic Span lor se span lor se I{FI) I.55E+Ol .{Al 2,12E+Ol nsulabon Weight (LhlFIIJ

s_

GrllYity load (Lb) 1.09E+Ol 2.-«1£+01 7.19E.Ol I.U£.02 1.74E+02 2.72£+02

Support Seismic "'" (Horizontal) SC-I{lb) '.43ft-Ot

Support Seismic lood (Vertcal) SC-I (Lb) 854E .. OO

Suwon $ei$miQ (HcriZonIaI) SC-Q(Lb) t,Me .. Ot (v..rticaI) SC·U(Lb)

0."""

(in)

... ".,,""

Seismic Spanier AIIow,Dell" (ft)

Seismic SpanlGrav itySpan RaJiQ

.._ ..."'" ""'"

s"_

(Chi 1,17E+Ol Seismic l ... (Chi (Horil.) (VerIIcaI) 1.75E+Ol 2.45E+Ol 3.14£+01 6.6&£.01 2 ..&3£+01 4,47£+01 UIOE+Ol &.89£+01 l.n£.02 1.11£.02

O.ftlletion forSC-' Actual Span (in) 1,32E+OO

O,1Iection forSe-II

"""'}

Ero) CQIT Nom. Waf Thk,(U(in) Alk:Jw (in) 'q'V.Ioeit,' pressure (llisq.ft) 24.36'2 14.3612 0,17& 0.7 G'Guest Ct"Guesl forc.e coelkillnt Pro;ecled WinG Load(F) (LbsII'II

Wind SpIIIl fa AI~ Del. 1Ft) Wind Load lor SC-I (lbs) Wind Sp;m lor Streu 5C·1 (fI) Selec\ed Wind Span SCot (ft)

Wind Span Itr ShU SC·WSC-II (ft)

Selecled Wind Span (til

Aelual

Span (in) ,U6E+00 5.53E+00

ArM

(sq.

fI}

ces

'.n ".n

eA2

17.72

•..

sc·wsc-m

WinG LoacI lor SC-WSC II (lbs)

2.10E+OO 3.96E+00 3.7171411 0.00£+00 e.eee-ee 0.00£+00 5.76E.00 7,43E+00 &.4&E+00 1,06£.01 1.113£.01 1,00E+00 114£+01 1.31E+Ol 2.10£+00 210E+00

2,2E+Ol 3.21£+01 8.HIE+Ol 9,27E+Ol 1.74£.02 2,4-5£+02 3,19E+02 ',02E+02 1I.35E+02 1.45£+03 1.93E+o3 2.23E+03 3.7I1E+03 327E.03 3.84E+03 ' ..&3E.03 5.06£.03 4,41E.03 5.05E+03 5,70E+03 1I,34E+03 1I."E+03 1.39E+03 7.09£.03 7.82E+03 9.15£+03 9.34E+03 7.51£+03 1,13E .. 03 2,0IlE+03 2.74E.03 2.14£+01 4.11E+Ol 11,19£+01 1.16£.02 1.84E+02 2.60E+02 5.3!I£+02 8.I19E+02 1,4DE+03 1.13£+03 2.05E+03 2.51E+03 2.94£+03 3.37E+03 3.'IE+03 4.23£+03 '.1I5E+03 Sj)SE+03 5.43E+03 5_18E+03 1I.11E.03 11.40£+03 1.43E+04 I.sSE+04 1.1I7E+04 1.04E+0I 1.6£+02 120£+04 8.01E+03 8.7lIE+C3 1.5E.02 1.4E+02 2,40£+<12 3.~IE+02 5.11£+02 1,12E .. 03 1.89£+03 2.&6E+03 3,&IE .. 03 4.49E+03 5.'8E+03 8.4-5E+03 7.53E+1I3 1.81E..o3 9.72£+03 5.75E.03 1.3E+02 '.32E+03 2.61E+03 7.50E+02 1.26£+03 2.28E+02 5.4£+01 1I.7E+Ol 7.7E+Ol 8.7E+Ol 9,5E+Ol 10E+02 1,IE+02 3.7£+01 4.2£+01 4.~2£+O1 2.95E+Ol 2.6£+01

73.89

1,315

0.&57

0.17&

7.1&E-Ol l,nE+OO

1.82E+00 2.15£+-00 2.32£+00

1I.49E+oo 7.IOE.00 8.48£+00

te.a

8.25£.00

9.88E+00 1.58£+01 1.80£+01 2.11£+01

8.25£.00 11_81E+oo 1_46£+01 1.63£+01 lo86E.Ol 2.33£+01 2.69E.Ol

9,50£+02 1.09E+03 '.42£+03 1.62£.03 1.9(lE+03 2.37£+03 2.68£+03 2.95E+03

,r.

22."

32.42

24.50

170.73

2,875

32.'

....

25

7.75m34

0.00£.00

1,13E+Ol 1,17E+Ol

4,111£+01

0.63

2.nE+02 5.67E+02 9.51E+02 I.41E+03 1.97E+03 227E+03 2.78E+03 3.33E+03 3.1iI1E+03 4.51E+03 5.15&03 5"'£+03 1I.50E+03 7.22E+<I3 7.96E+oo 8.72E+03 9.51E+03 6,35£+03 5.31E+03 2.22£+03 2.61E+03 3.01E+03 3.44E-H>3 3.88E+o3 4.34E+03 3.78E+02 8.35£.02 9089E+02 1,31£+03 I.52E+03

0."

24.3812 ~,72E+Ol '.78£+111 204.381.2 4.61E+Ol 1.50 21.74 602'

c.ece.co

292294n O.ooE+OO

..."

15.25 132.05

64.17

2,39E..ol 3,48£.01

2.33E ..01 2,69E.Ol

l.ooE+oo 1,00e .. 00

2.66E .. Ol 3.11£+01 3.53E+Ol

1.2OE .. Ol 1.20£+01 1.20E+Ol 1.1IE+Ol 1.05£+01 l.ooE+Ol 9.22E+00 8.42£+00 7.84E+00 3.llE+Ol 6.16E+00 3.e4E+Ol 3.4IIE+Ol 4.&3E+00 3.32E+Ol 0,375 0.375 4.3OE.Ol 4.14E+Ol 0.375

I.OS

15U.2

8.8SE+oo

0."

as.ec

e.ece-ee

55,859812 O.ooE+OO

5,85£+01 6.42E+Ol

331E+Ol 3,47E.Ol

1.00E+00 1,00E+00

3.87E .. Ol 4.07£+01

3.31£+01 3.47£.01 3.72E.Ol

3.40E+03 3.73£+03 4.27E+03 '.IOE+03 5,33E+03 5.17E+03

1'7.'3 100.7 164.95

95.4

13.250

0,375

1,36E+02 1.83E+02 2.34E+<12

222.0&

101.7

2188.66

0."

24.3812 l1B,17

72258714 80 .•

e.eca-cc

O,OOE+OO O.IIOE+OO

827E+Ol 9.20E+Ol 1.01E+02 1.IOE..o2

3.95E+<Il 4,17E+OI 4,38E+Ol

l00E+oo 1,00E+00 1.00E+DO

4.65E+Ol 4.92£+01 5.17£+01

3.95£+01 '.17£.01 4.38E+Ol

173.58

_...

1&.250

0,375

2.91EM 3.55£+02

sa34

2.00

28.119

1&6.75 136.2'

.... 23

282.05 136,2

e.es

0.7

2.17

5.01£+02

2, .... £+03

1.91E.02 2.22E+02

105.05707

e.ece-cc O.ooE+OO

1.2OE+02 I.29E+<I2

4.nE+OI 4.95E+<Il

1.00E+OO

5.64E+Ol

'.77E+Ol

6.93£+03

1,79E+03 1.7&£+03

2."

2.17 57:17.25

,ouo

57:17.25 153.8 159,2

0."

6.72E+02

l.UE ..Ol

2.5SE ...02 2.IllE+02

e.ece-co

1..47E.02

6.06E-H>1

5.13£+01

I,OOE+03

1,7IE ..03 1,7I1E+03

41.07

153.t0

lI.e8E+02 303.000 35.250 0,375 9.76£.02

S.$OE+a3 6,66E.03 3,70£+02 ecce-co 1.66E.02 5.63E+Ol 1,00E .. 00

6.48E+Ol 6.68E+Ol

5.47E+Ol 5.63£.01

8,07E+03 &,60£+03

1,7&E..o3 1,78E+03

3.84E+00 3.11E+OO 2.&5E+01

24.3612 41.32

7549.78

199.33

7549.78

NOTE: 1 Gravity span is calculated for a total deflection of lIB inch 2. Gravity stress is limited 10 2500 psi 3. Seismic span is calculated with factor 0.355 for hcrlzonter and 0.237 lor vertical to uniformly distributed pipe weight 4. Selected gravity span is the smaller of Ihe span calculated with allowable deflection (t/B inch) and stress (2500 psi) 5. Seismic span for se-I piping is based on Code allowable stress limit of t.33 x Sh 6. Seismic span for se-It piping is based on Code allowable stress limit of 3 x Sh or 2xSy, whichever is smaller 7. Sh ::: 16700 psi, Sy '" 19200 psi, and E", 27000000 psi at 300 deg F for Stainless Stool, Eighty % 01 allowable stress considered 8. These spans are lor piping with fluid temperature not greater than 300 d09. F and fluid pressure no greater than 400 psig 9. Insulation thickness 01 2 inches considered with density 01 12 LblCuft. 10. Pipe schedule is 80 for piping 2 inch and smaller diameter and 40 (STD) lor 2,50 inch dia. and greater 11. Spans lor Seismic and Wind loading are calculated for maximum deflection of 3 inches and lor BO"k 01 allowable stress and smaller span betWOO1the two is considered.

4 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK

SHEET FOR SPAN TABLE SC I AND

se

II PIPING

(TITANIUM)

WITH CONTENT

Support S_mil: LCIIlfOilLKlinai Gravity Pressure Weight Seismic: SpanlorSC Seismic SI*IIor hsulatioo Weight Support Grmty Load (HoriZOI'1I1l!) Support Sei$m~ l.oiI.d (V1trWcal) Suppon S~mic Load (Hori.tOl'1Ial] SlJpport Seismic Load (Vertic ....) Allow, Oel1n Iorpipe $C-I & se-e SeWnic SIWIIor A11ow.Deln SpanfGra vilySpan SUppttl Seismic Load (Horiz.) Support S.lsmlc LQild jV.rblj

~/ EroJ COlT WaIIThk. AowArea Pipe W" Total

GrsviIy Span br detection

Sires, 1n1l:lnSi1ica~ onf.elor

Gnllvitr Span fa .1re$S{Ls}

D.~eetion Itt SCot AelUal

DeIlKtion for SC-M Nom, Willi ThII;.U.J COlT ....Iow 'q'lIe1oc1~ pressu .. G'Guesl

cr

WiooSpan Guest Prnjecled Areal.q Wind Load lot Allowable lor SC-I Wind Span IgrSnss Seleclltd WindSpM {11) ~

Wind Span lor Stress SC·IrSC·1H

Seleeted Wind Splln SC.IVSC-HI (ft) Wind Load IorsC-lISe

1-:00:;';::",-) I-:":;Ii";:;-)+,::"':;":;-"+,::::::::::::-, r.'~4~14(~::::=) ::"';:'"'::' +W::'::W=A:+-::~$3::'_~~"::-'+::':=~UY:::E.::::+::::.~::::):~::~2:-:::::~:::.oo::-t-:,~!:7::':oo:+:~7:::;,:'!:~~:::'f')-t.:::',-~oo::'::~~,::!." +:' 2::~::::E'!:::;~)t-,,:.!:I;:0:!:,_,f.!;C:::':8~fl~E:R~0:+'~:'::::E.~t:,+:;:~~::'E~~::~+:"::"=·~~"':!..o) +:::::::"I~~~:!.: ~~~b:4!!·"'::::::'' '!l''::')t-,.2.6:~~~,+::R'::::tio,-+:-, ~~,+:+-=:~:::':;~~~;::!:' ~:::,:.'~ 25::=":::' e. "~~E::,b~oo4~:::::E~::!:r:::!:::=E!::::!.j' f--:'~in)=-,~"::,':+-:(lh'oq=:::')+E:::""='~'~:::"'?:=-"i-~o~::;o-+:!..,e,:{",,,,~'1'

1.050 0.868 S,Q2E.(II 9.21E-Ol 2.0BE .. 00 3.nE·02 7.93E-02 6.06E-t12 1.21E-O\ :!I_tZE-Ot 1"5£+00 1.13E+00 2.28£.00 4.500 0.217 1.35E.Ol 3.01E+<Il 224E+<Il 5.IMlE.Ol 10.750 12.12t1 0.312 •. 00E+Ol 1,15£+02 1,41£.02 1.16E+<12 0.312 2.37E+02 '.35E+02 2.3(lE+02 3.14E+02 4.73E+02 6.78£+02 B,35E+02 3.59E+0:2 0.312 4.29£+02 S,OEIE+o2 1.83E+03 1.2457097 3.98E.(II 2_10e ..oo 3.38E+00 5.02E+OO 8.62£.00 8,18E+oo 1.08£.01 1.17E+Ol 8_32E..oo 7.SOE+00 2.10E ..00 2.10E+oo 2.10E+00 2,10£.00 4.62E.OO 5.13E+00 7.e9E+DO 9,01£.00 1,31i1E+Ol 9,01£.00 1,11£.01 153£.03 2,05E+O$ 2,SOE.03 1.78E+03 2,81£.01 4,01E+Ol 4,38£.01 8,78E+Ol 5.83E+00 1,15E+03 1,13E+03 2.5OE+03 2.5OE+03 '.37E+O, 1.73E+Ol 2.27E ..Ol 2.88E+Ol 1.60E..OO 1.74E+00 2.04E+00 2,29E.OO 2.55E+00 1,97E+Ol 3.88E+Ol 5.96E.Ol 8,54E+Ol 1,39E+02 5,8SE+oo 1,3OE+ol 2,23E+(I1 3,49E+Ol 4.1iI9E-t{)1 1,54E+Ol 2,84C+Ol 4,4.2E+01 6,48E+Ol 8.60E+Ol 2.47E.Ol 2.55E+Ol 1,4,E+Ol 1.1I1E+Ol 2.01£+01 1,00E..oo 2,59£+03 2,1IIE+Ol 2,5OE+01 1.81E.Ol 2.07£+01 2,:31E.Ol 2.93£ ..01 2.47£+01 2.55E+Ol 3117E+01 3.13E+Ol 2.67E.Ol 2,7IE+Ol 3,56E+03 4.09E-t{)$ 3,05E.o$ 1.73£.03 1.71E.03 1.71E+03 1,71£.03 l.nE+03 1.112E+03 7.1'11E+Ol 7,51E+Ol 1'I,08E.Ol B.!4£+OI UI5E+Ol 1,05E+02 1,19£+02 1.32£+02 1.3IE+02 1.39£+02 1,40E+02 8.42E+00 1.00E+Ol 1.151:+01 L55E+02 5-4273594 1.85E+02 2.18£+02 2.5<1E.02 2.17E+02 2.53E+02 2.92£+02 3.33E+02 297E+01 :l.05E+01 3.40£+00 4.52E+00 5.5eE+OO 6.88E+00 7.72E+00 2,29E+02 5,14£+02 8.14E+02 1,49E+03 2.12E+03 2,5I5E+03 3.35E+03 4.21E+03 5.30E+03 6."5E+03 1.73E+03 9.14E+03 5.13E+03 S.09E+03 1.31E+01 2.o7E+Ol 4.0IE+DI 6.14E+Ol 1.111E+02 1.71E+02 2.8OE+02 8.13£+0:2 1.07E+03 1.73£+03 2.32E+03 2.SIIE+03 3.25E+03 3.1I1E+03 4.33E+03 1.76E+00 1.38E+Ol 2.66£.01 4.10E.Ol 7.87E+Ol 1.14£+02 1..1I7E.02 4.09£+02 7.17E.02 1.15E+<I3 I.55E+03 1.79E+OS 2_17E+<I3 2.54E+03 2_89£+<13 3.18E+<I3 3.40E+03 3.5OE+<I3 3.42E+03 1,08E+04 1,26E+04 1,44E+04 1.63E+04 B.61E+C:l 1.08£+04 3,00 9.2E+01 1126E+1I3 1.(18E+03 4.IIE+03 5,13E+03 8,11£+113 7.25E+03 8.5£+01 4,20E+03 1.03E+02 1.96E+02 2.117E+02 4.74E+02 1.06E+03 1I17E.03 2.0:l£+O3 2.181£+03 1,92£.02 3.1I1E.02 7.ME+02 52E+Ol 5.9E+<I1 6.6E+Ol 7.1E+Ol 7.3E+<Il 1.7E+Ol 8.0E+Ol 4.34E.03 5.31iIE+03 8.57E+03 7,117£+113 1iI.31E+03 1.0BE+04 2.BO£+03 3,60E+03 4,39E+03 5.26£+03 6,21£+03 7.2B£+03 1.78£+00 1,24£ .. 00 1I.34E-Ol 5.2BE-Ol 3.02E-Ol 1.48E-1I1 2.84E+Ol 2.5(1£+01 2.24£+01 1.9I!E+Ol 1.72E+OI 24.3812 8,8I1E.Ol 2.17E+Ol 3.43E+Ol 1.45E+Ol 3.00 UE+OI 2.2E+Ol 2.7E+Ol 3.IE+Ol 3_4E+Ol 1.74E+Ol 2.58E+Ol 4.83E+Ol 7.28E+OI 9,71E+DI 1.41E+0:2 2.33E+02 5,23E.02 9,3OE+02 1,52E+03 2.16£+03 2,81E..o3 1.18E-t-tl1 &.81E-Ol 1.i'2E-t-tll 3.23f+Ol 4.aeE+Ol L25£+oo 1.43E+OO 1,51E+oo 7,31E+00 9.37E+00 1.11E+Ol '.20£.01 Q.063 201.3812

Actl.al

Iorce

r-"'7.'~'R,-) +-:;~::":-) +.:.'C;-;"::"'--I) SC-I

14.15

I ~:)

87.36

0.8'

7.13

,u.

213.85

5.i7

'.0

19.2 15.9 2e.45 25,6 213.85 271.&5

2.375

2.065

3.3SE+oo 5.29E+00

0.7 24.3612

0.216 29,99

7.84£-01

1.29E.OO 2,46£+00 6.7I1E+00 1.3IIE+Ol 2.52E+<I1 3.70E+Ol 4.49E+Ol 5.92E+Ol 1.54E+Ol 9.35£+01 1.14E+02 I.36E+02 1.60E+02

3.3229055

2.28E+-oo

r.coe-oc

6,48£+016,51£+-005,01£.01 1iI,44C+Ol 1.5&E+02 3,49E+<12 621£+0:2 1.02E+03 144£+03 1.74£+03 6.42£+00 8,20E+oo 5,67E+oo 5.33E+oo 5.02E+00 4.01£+00 3.34E+oo 5,09£+01 5.12E+Ol 5,01EHll 4,93E+Ol 4,83E.01 4.29E.Ol 3.91£.01 0,375 0.322

0.7 24.3812 0.85

0.71

r.cce-cc

.....

SUB

10.5 1586.14 82.76 102.&8

.....

165.80

, o.c

t.ece-oe

1.00E..oo

24.3612 24.3612

0.7 0.85

,..,

".7

910.05

r.cce-oc

I.ODE+OO

t.ooe-oa

e. 00E+Ol

I.02E+02 1.2BE+02 I.53E+02

r.coe-oc

2.1IE+Ol

24.3812

0.7 HO.18

101.15

......

",."

3438.91 101.81 251.18 83.4

HilI.41

r.cce-ce

t.cce-oc r.cce-cc

s.r-e-ce

7.0S€+03 7.aeE+03

lA17E+O:l

6,9Ii1E+Ol

1,41E+02

24.3612

2932.25

323E+Ol 3,27E+Ol 3.31E+Ol

2.97E+Ol 3,OSE.OI 3.13E+Ol

2.11E .. ca 2.17E+03 224E+03

8,18E.Ol 5,61E+Ol

1,41E+02 1,40E+02 1,39E+02

I.26E+Ol 1.36E+Ol t.47E .. ct

0.7

2.17

242.78

e.I1E+Ol

a.tae-ct

320E+Ol

r.oee-cc

ae.ccc

27.376

5,8&£+02

2.BOE+03

1.86E+02

0.85

0.7

"."

.....

116.8

4231.7.

NOTE: 1 Gravity span is celccleted for a lolal deflection of 1/8 inch 2 Gravity stress is limited to 2500 psi 3. Seismic span is calculated with teeter 0.355 lor horizontal and 0.23710r vertical to unilonnly dislributed pipe weight 4 Selected gravity span is the smaller of the span calculated with allowable deflection (1/8 inch) and stress (2500 psi) 5 Seismic span lor SCot piping is based on Code allowable stress limil 01 1.33 x Sh 6, Seismic span lor SC-II piping is based on Code allowable stress limit 013 x Sh or 2xSy, whichever is smaller 7, Sh '" 12300 psi, Sy '" 25600 psi, and E '" 14600000 psi at 300 deg F lor Titanium. Eighty % of aUowable stress considered. B. These spans are for piping with lIuid temperature not 9reater than 300 deg. F and fluid pressure no greater than 400 psig 9. Insulation thickness of 2 inches considered with density of t2 lbICufl 10. Pipe schedule is BO for piping 2 inch and smaller diameter and 40 (STO) for 2.50 inch dia. and grMter 11. Spans for Seismic and Wind loading are calculated for maximum dellection 01 3 inches and for 80% of allowable stress and smallar span belween Ihe two is considered

5 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK SHEET FOR SPAN TABlE

SC-I AND SC-II PIPING (TITANIUM) EMPTY

Support Stlismic Longiludinal Gravity Pressure Weigh! Spanb"SCSpanIorSC Insulation Wei(lt'l, Support Gravity Load (Harizanlal) Support Seilmlc Load (Vartic.al) SUppOI1 Seilimic lOllld (Horizontal) SuppoI1 Seismic Lo;od (Ymcal) Supporl Seismic Load (VericaI) Meehl Ero} Con. Nom.WalI Allow 'q'Veloei~ pr8SIIure G'Guest fDrctI

Gravity MechJEro Cott_WaII fIowArH Pipe WaIJaf Total Spanlor deftecIion

S1reu lnIeni!Iilicati< nFactor

Gravity 5panlor alr1l&S(Ls)

Deftn lor

pipe

It Seismic Spanlor

Seismic Span'Gravi tyS~

S~ Seismic Load

Delleclion brSG-1 Ac1ual

Delleclion forSC·1I AcIu,,1

Wind Span

Wind Span WindLoad torSC-1 WIndSpan IorSIress Seleeled WindSpan forSlress SC-IVSC-III

Selecilld WindSpan WindLO!od SC-WSC·IllIorSC·IVSC·

Ar

Prctacilld Windload

lor Allowable

i~1ng

Allow.

r::OO:::':::.'+::D:::(i":-'

1.0&3

-tT:!h:-k.={\J~(in~'~,:-'.:::!::1~-:-, :!:-' +-::,Z;o~~:::E-02~' ~":!I(i:::"' -f.";:::.6t~::=:=:.,-, =:.OO:;E!:: .:::I1::E.:::OO+S~~.s~~~:~'4-2-.'~::::!."-+-'..!.i:~::'-"'+:~';=:4E~:C!!'~~ 1-' -oo :!.f.!'

5.&2E~1 1I.21E~1 2.08E+00 2,97E-01 1.89E-Ol 3.12E-Ol 5.84e-Ol 784E-Ol 1.211E+00 2.0828808 c.cce-ec 4,12£+00 9.~E+OO 1.15E+Ol 2.10E+00 2.10E+00 8.49£+00 1.02E+Ol 8.49E+oo I.02E+Ol 8_08E-02

.... ~.OO~E.~'~~~)fS~2~:~~~:"~Q;:!I'....''+'..!:~4;":O-' .j.J,~~:!!·E:::!:!!.' -I.-',t~~: ! +=~ood~.":!.!E::!:!..' I-.~~~::!~~.!!::~)+:~:~~t:::!,,!..' ~:.:::!~·~E~Lb::!,;+:~:~~"E.!!::~'+-.!:~i.~:!.'-+~""~"':!'.:!.'+-""~ ... -i!'Hc::,7~:EC;·)~!!:!::!I' ....!!(U>::!'-+~:pan!:!"::..!E~m::!O:-t-=!:.~=.E:!:~)+T~"'~"~.'.!!![in:ll' >~q!!')4-..!E~""'~~~~:-~.7="~' :::."'M=,~.~::!..~"I!:'F!..' ....i!!:,.!..' +1(U>' ~~"""~'~O'OO:: .'::~."'!..' +~sc:::.'!"'.' -i ..<':'A:!.' +-.'

2.5C/E+03 2.5OE ..03 1,39E+03 1.53E+03 asoe ...03 1.84E+Ol 2.48E+Ol 2.96E+Ol 3.04E ..Ol 4.15£..0' .U6E .. t 2.04E+oo 3,SOE+c, 5.27E+Ol 7.'BE+-Ol 1.95E+Ol 3.64E+Ol 5.QE+Dl 1.01E .. 02 8.33E+OO I.30E .. Ol 2.-43E+Ol 3.62E+Ol B.nE+Dl 9.55E+Ol 2.37E+02 3.76E+02 I.51jE+02 251E+02 5.24E"02 1.33E+o3 2.09E+03 '.84E .. 03 3.16E+o3 3.82E+03 2.11E+03 9.&E+Ol 1.59E+03 UlOE..o3 5.22E+03 3.4-9E+03 1.1E.o2 1.2E+02 8,6&E+03 7.43E+03 4.4ElE+D3 4.~E+03 5.4ElE+D3 3.00 1,3E+D2 2,23E+03 2,57E+Cl3 2.93E.03 3,31E+03 3.70E+03 1.06E+03 127E+03 I.49E+03 I.72E..o3 I.~E.o3 2.21E+03 2.47E+03 8.63E.00 7,14E+OO 9.55E+Ol 907E+0\ '.59E+O\ 8,11E+0' 7.e4E+Ol 7,18E+Ol 36.2<1 118.78 0,37.5 101.15 2932.25 8.90E+02 7.1E+Ol 8.0E ...O' 4.1£+01 1.63E+02 3.30E .. 02 5.5OE+02 8.5'E+02 1.t3E+03 5.68E+02 7.53E+02 1.0IlE+0'2 220E+02 2.07E+Ol 3.22E+Ol 8.07E+Ol 9.11E+Ol 1.38E+Ol 2.'5E .. Ol 4.oSE+Ol 2.8E+Ol 1.61E-t-Ol 2.35E .. Ol 4.17E+Ol tI05E+Ol 7.~E ...Ol 1.57E+Ol 2.7!E+Ol 4.04E+D' 5.07£+01 1.DBE..oo 1.42E+OO 1.74E..oo 1.94E+oO 9.58E+oO 1.02E+Ol 1.08E+Ol 1.16E+Ol 1.21E+Dl '.25E+Ol 1,13£+01 1.06E+02 1.05e.02 0.85 118.45 119.84 0.375 9.59E+Ol 0.280 1.35E+Ol I.54E+Ol 7.'IE+Ol 7.71E+0' 0.85 7.13 8.14E+OO 24.3612 5.i7

s:_~(ft) ~

~~~ ~

c.coe.oo

2.44E+OO

6.431:+00

52." us

7.10

1.2'

2.541E+03

2.29E+OD

2.875

e.ses

5..211E+00 8.0'E+00

1.'3E.00 2.26E+oo 5.54E+00

c.cce-cc

oooe-oo

7.23E ..00 9.59E+OO

1.43E+Ol 1.67E+Ol

1.00E .. 00

....

'.7 '.85 '.7

U3

,.

..

ee.ee

213.85 26.83 2S.!

23.0 25.8

r.eee-cc

227f+OI 2_97E+Ol

I.67E.ol 2.1'Eo-(Il

2.59E+03

I.36E+03

6.61E+Ol

1.11E+02

3.40E+OO 4.52E-+OO

1,60E .. 02 3.24E+02 5.40E.02

2.25E+02 4.83E+02

1.SOE+02 3.09E+02 5..21E+02

70.05

6_625

224E+Ol

8.7IE .. 00

60."

SUa

1I.00E+Ol

1.35E+02

2,52E+OI

23221211

O.OOE+oo

2.99E+Ol

2.60£+01

1.00E+00 1.00E+OO

4.10E+OI 4.!'2E+Ol

2.80E+OI 3.06Eo-(Il

3,58E+03

1.16E+03

1.15E+02

1.&7E+02 2.15E+02

6.68E+oo 7.72E-+OO

8,36E+02 1,11E+-03

1.22E+03 I.57E+03

8.11E+02 1.05E+03 1.18E+03

'"

107.20 78.4

167.-47

7C.S

1255.42

12,750

0.312 1,41£+02 1116E+02 '],14E.o2 4.13E+02 8.78E-t<l2 2,95E+02 3.59E+02 4.29E+02 5.06E+02 2,0IE+03 1,60£+02 1.86E.02 58,868184 9.35E+02 125E+03 4.411E+Ol 5.92E+Ol 7.54E+Ol 9.35£.01 1,14E+02 45.014414

18E..o,

e.cce-eo uece-ec

O.ooE+OO

3.111E+Ol 4,53E+Ol 5,10E+Ol 5,66E+Ol 3.87E+Ol 3.45E+Ol

21.74

112.76

t.ece-ec r.ece-ec

1,00E+00

5.11E+Ol

3.4SE+OI

5.13E+03

1.14E+03

I.29E+02

2.38E+02 2.49E+02

9.42E+OO

1,56E.03 1.87E.03

2.07E+03 2.36E+03 2.6.2E+03 2.SSE+03

1.38E+03 1.58E+03 1.15E+03 I.90E+<.I3 2.03E+03

2157.03 OS"

17,m

5.75£.01 8.04E+Ol

:!1_81E+Ol 4.06£+01 7.05£+03

1.13E+03 1.13E+03

1.31E+02 2,&9E..o2

1.15E+Ol 1.2(lE+Ol

2.19£.03 2,53E+03

s.rre-oc

4.54E+00 3.4SE+00 2.5OE+00 1.70E+00

'.85

2.11 117.07

33-47.97

e.oca-oo

O.ooE+oo O.ooE+OO 7,35£+01 4.42E+Ol 1,ooE+00 6.59E+Ol 4.42E+Ol 8.33E+oo 1.12E+03 1.21E+02 U5E+<l2 1.41E+Ol 3.25E+03 3,16E+03

2.11E+03

24.3612

0,85

121.6

NOTE: 1 Gravily span is calculated for a total deflection of 1/8 inch 2. Gravity stress is limited 102500 psi 3. Seismic span is calculated with factor 0.355 for horizontal and 0.237 for vertical 10 uniformly distributed pipe weight 4. Selected gravity span is the smaller of the span calculated with allowable deflection (lIS inch) and stress (25tJO psi) 5. Seismic span for SCot piping is based on Code allowable stress timit of 1.33. Sh. 6. Seismic span for SC-tl piping is based on Code allowabte stress limit 01 3 x Sh or 2xSy, whichever is smaller 7. Sh 12300 psi, Sy 25600 psi, and E 146OO1XX.1 at 300 deg F for Titanium. Eighty % of allowable stress considered psi 8. These spans are lor piping with fluid temperature nol greater than 300 deg. F and fluid pressure no greater than 400 psig 9. Insulation thickness 01 2 inches considered with density of 12 LblCuft. 10 Pipe schedule is 80 lor piping 2 inch and smaller diameter and 40 (STD) lor 2.50 inch dla. and greater 11 Spans for Seismic and Wind laMling erecelcuteteo for maximum deflection 013 inches and lor 80% 01 aUowable stress and smaller span between the

two

is considered.

6 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK

SHEET FOR SPAN TABLE SC-I AND SC·II PIPING

(HASTELLOY)

WITH CONTENT

.... 00 lin) 1O(II1J

lEn> Pipe Iro4I(iN) 2.01E·02 -4.32E-(ll 7.19E·01 U)6E-Ol 3.91E.(l1 U8E-Ol I.53E+oo 3.02E+OO 723E+00 2.81E+Ol 1.72E.00 3.21E+OO 1.S3E·02 H1E·Ol 4.12E-O' U24744& 2 (in3) WLLblFI 1.2358565

Con,WIIII Thk_(t,_J(mJ 0.141

WI,LDlFt 1.01E-Ol

w.'"

, ....

Wt.Lb'FI 3,~E+OO 4.51E+00

dellKlion

s""""

(ld) (Ft)

Gravity

S .... nF"1OI' (SF] 2.10E.00

Gravi\, S".,,, Ilress~) (FU 4.D2E+OO USE+OQ 5.82E+00 7.S2E+OO 8.1181:.00 8,&6E+OO Gravity Span (Ft)

LongitlidiMI Pressure Snss(psl) S.71E.n2 6.82E+02 7.35E.02 ILSOE+D2 I.OQE+03 2.50E+03 U2E+03 1.73E+Ol I.SOE+03 2.49E+03 2.48E+03 Wei¢lt Sire&! (psi) 2.5OE+03 2.SOE+03 2,5OE.03

Seismic Span lor SC-I[Fti 1.97E+Ol

Seismic Span lor SO UtA) 2.60E.Ol

Insulabon W~ (lb'Ft») 1.49E+OO

,_

GrIMly Load(Lb) 1.13E+Ol (HoriZDnlill) SC-I(Lb) 1.IiIIE+Ol 2.63E .. Ol 5.21E+Ol 1.39E+02 2.aSE+02 2.24E .. 02 3.67E+02 8.0IE+02 3.85E.02 6,21E+02 1.3eE+03 2.37E..n3 2,28E+03 3.15E+03 3.nE+03 5.18E+03 6.0IE+03 4.73E+03 7.65E+03 9.3IIE+03

S_

Seismic (Vertical) SC·I{lb)

Suppoo Seismic Load (HrJriZ<:O"1Ial] SC-I(Lb) 2.80E+Ol [Vertical) SC·R(lh) AlIowDe/ln Iorpipe $pacing(lIl)

SC-I&SC-H Seismie Spana AIIow,Ceftn (II) Seismic Span'GrilYi I'I'Span Ratio

L~'

""_

Seismic Lood (lb) 1.8&E+o, I.26E+Ol I.80E+Ol 2.72E+Ol 5.21E.nl 7.91E+Ol l.o5E+02 1..52E+02 2.49E+02 5.49E+02

.... Del\ec:1ion Defleclion Aclual (In) Span (in)

1 At 'q'VeIoc~ pressure (Lblsq_n) G'GUe51 Wind Span lor Wind Load (F) 5~) Allowable D:: 1 Wind LCIa(j Wind Spar1 Saleelld Wind Sp!If1 SC·I{1I:) Wind Span Ia Shin SC·WSC-. 1~~;4 Selecled Wind Spall SC-ItISC-11 (ft) Wind Load for SC·iVSC n~:J cr Gues. Plojecled ArM. (sq n)

tor

Span

50·1

(Hw_l

Iorsc·n

Nom. waa Thk. It) (in)

EroJ COlT. Allow (in)

klual

,...."

Ioru

4,02E+OO 4.85E+OO

7)

Ia SC·I

(Lbs)

for Slress SC-i(fI)

3,58E+00 4,14E.00 4.74E+OO 5.38E+00 S.88E+OO 2.42E+Ol 242E+Ol 2,38E.Ol 2.~E.Ol 1.67E+Ol 1.92&01 220E+Ol 2.33E+Ol l.o1E.02 1.02E.02 1.0IE.02 9.7l!E.01 0.280 0.15 8.21E+Ol 8,51E.Ol I.77E+Ol I.~E+Ol 7.SOE+Ol 11.92E.Ol 1.28E.Ol 1.18E.Ol l.oAE.Ol 8.42E+00 8,51E+00 1.89E+00 1I.9SE+OO 8.2IE+OO 5117E+00 3.91E+Ol 24.3612 5,93E.Ol 5.51E.Ol 5,13E.Ol 4.18E+Ol 4.46E+Ol 0.375 o, 0,375 0.375 0.7 0.203 0.7 0.154 24.3612

7.6SE+oo 1I.81E+OO

z.roa-oc 2.10E+oo

1,9SE+Ol 2.85E+Ol 4,OSE+Ol 2,04E+00 4.22E.Ol 8.&l!E.Ol 9,52E+Ol I.06E+02 1.35E.Ol Il.ieE.Ol 1.12E.02 123E+02 I.62E+02 I.79E+02 1.8I1E+02 1.93E.02 1.IIIIE+02 1.2OE+02 2.291:+00 2.55E+00 2.18E.00 3.40E.OO 4.52E+00 5,56E.OO e.ME.OO 7.72E.00 8.3eE+OO 1I.42E.oo 3.05E+Ol

4.14E+Ol

2,76E+Ol 4,33E+Ol 8.57E.Ol 3.00 3.00 2.5£+01 3.2E+Ol 3.8E+Ol 3.00 3,00 4.4E+O' 5.0E+Ol 3.00 3.00 3.67E+03 (1.8E+Ol 7.8E+Ol 3.00 3,00 7.b3E+OS 12E.Ol 8,5E+Ol 8.9E+Ol 3.00 3.00 9,7E+ol 1.0E+02 3.00 3.00 1.0E+02 l.lE+02 1.1E+02 2,30E+04 3.00 1.1E+02

2l!9E+Ol 4,08E+Ol 7,IOE+Ol 1.18E+02 157E+02 2.28E+02 3,74E.02 l!.23E+02

71.61

11.74

aaa ,

0.'

1.13 29.09 224.02 50.75 173.20

0..,.

0.218

1.77E+OO 2.SSE+00 4.7SE.00 7.39E.oo 0.237 1,27E+ol

7.63E·Ol

1I.93E+00

9.27E+CI' 1.77E+02 2.57E+02 4,19E.02 9.10E+02 1.S8E..n3 2.S3E+03 3.46E+03 4.06E+03 S.11E.03 8.2SE.03 7.4IIE+03

1,&8E+02 3,19E ..02 5.51E+02

1.32E+02 2,53E+02 3.66E+02 6.01E+02

2.07E+00 LII7E+Ol 5.50E+00 1.25E+Ol 1.68E+Ol 2.12E.Ol

1.38E+Ol 1.S3E+Ol 113E ..

1.00E+oo l.00E+OQ

1.38E+Ol I.S3E+Ol 1.74E+CI

'"

38.'

34S.SS

ot

l.ooE ..

-«1.00

472.28 113.18 74.1

2_10E+Ol 2.3&E+Ol

1,97E+03 3.43E+03

1.31E+03

1.625

7.1111 0.365 7.l!"E.Ol 1.13E+02 1.61E+02 2,19E+02

oo

2.37E.Ol 2.63E+Ol 2,1&E+Ol

2.37E+Ol 2.63E+01 2.7I1E+Ol 2.86E+Ol 2.&7E+Ol

288E+03 2.9SE+a3 3.4OE.03 3.7SE.03 4,27E.03

2.5OE+o3

9115E+022.16E.Ol 2.34E+03 3.27E+03 3.90E+D3 S.o4E+03 8.34E+03 7.7&E+03 9.40E.03 1.12E+04 1.31E+04 1.52E+04 1.75E+04 2,ooE+04 1.56E+03 2.16E.03 2.81E+(I3 3,31E+03 4.23E+03 5.20E+03 6.28E+03 7.48E+03 1.76E+03 1,02E+04 1.17E+04 1.33E+04 1.51E+04 1.70E+04 2.07E.Ol

2.99E+Ol

45.985143

3,41E+Ol 4.ISE+Ol

UI7E+Ol 1.13E+02

2.65E+Ol 2.85£+01 2.95E+Ol

17.82

87.02

200.26

11.0 Ge.8 102.2

2.50E.03 2.5OE+03

1.29E+02 1,32E.02 1,35E.02

7.56E+03 B.91E+ll3

5.05E+03

14.000 0,375 1.13E+02 2,34E+02 20,000 18,250 0.375 291E+02 3.SSE+02 5.62E+02 8.07E.02 l.l1E.03 I.4&E+03 1.94E+03 211,000 25,250 5.01E+02 5.83E+02 3,83E+03 2.43E+03

5.33E+Ol 7.03&-(11 7,89E+Ol 1.01E+02 1.11E+02 1.35E+02 1.62E+02 1.91E.02 116.57712 2.S2E+02 2SSE+02 143,67322 3.29E+02 3.70E+02 4.22E+02 3,31E+02 5.47E+02 3.93E+02 4.42E+02 1.26E+02 I.53E+02 1.83E+02 2.64E+02 1.58E.02 1.92E+02

r.oce-oc

2.86E.Ol

0."

0.'

110.27 242.23 117.&

3.11E+Ol 325E+Ol 3.311E+Ol

r.oce-cc

1,ooE+OO

3.06E+OI 3,14E+Ol 320E+Ol

3.06E+Ol

1.39E+04

&.27E+03 1.12E.04 1.32E+04

0.'

131.n

125.0

3.20E+Ol

5.87E+03 6.4OE+03 2,5OE+03

1.4OE+02 1.41E+D2 1.41E.02

2,l1E+02 2,14E+(I2 2.18E+02

1.2tlE+0'

8,46E+o3

1.32E+04

1I.79E+03 1.02E+04 2.31E.04

3.61E+Ol

1.00E.oo

3.26E+Ol 3.31E.Ol

1.54E+04 1.78E+04

W.73

138.2

14-4,4 5232.31

1.47E+Ol 1.57E+Ol

1.1SE+04 I.32E.04 I.50E+04 1,32E+04 3.04E.04

r.oce-oe

3,89E+Ol 1.00E+OO

3.38E+Ol

7.41E+03 lI.ooE+03

2.SOE.03 2.5OE.03 2.5OE+o3

1.41E+02 1.41E.0'2 1.41E+02 2,,9E.02

150.32

5110..27 156.0 471.48 7024.21

30=

7.67E+02 1.66E+02 1I.78E+02

466E+03 S,60E+03

r.oee,oo

4,06E+Ol

3.o44f+Ol

3.«E.Ol 9.07E.03

1.78E+Ol

1.69E+04

2.4SE+04 1,81E+04

3.86E .. 04 4,29E+04 4.75E+04 2.B7E+04 3.00 12E+02 12E.02

2.5OE.03 2.5OE+o3 1,39E.02 2.22E+02 1,99E.Ol

2.26E+04 2.54E+04

, ... .aa

513.81 172.0

t.oce-cc

3.5OE+Ol

3.5OE+Ol

NOTE: 1 Gravity span is calculated lor etotet deflection of 1/8 inch 2. Gravity stress is limited 10 2500 psi 3. Seismic span is calculated with factor 0.355 lor horizontal and 0.237 for.verticalto uniformly distributed pipe weight 4. Selected gravity span is the smaller of Ihe span calculated with allowable deflection (1/8 inch) and stress (2500 psi) 5. Seismic span for SCot piping is based on Code allowable stress limil 01 1.33 X Sh. 6. Seismic span for So-l! piping is based on Code allowable stress limit of 3 x Sh or 2xSy, v.flichaver is smaller 7, Sh '" 27300 psi, Sy = 34500 psi, and E '" 28600000 psi al 300 deg F for Hastelloy. Eighty % of allowable stress COf1sidered a These spans are lor piping with fluid temperature not greater than 300 deg. F and fluid pressure no greater than 400 psig 9 Insulation thickness 012 inches considered with density 01 12lb/Cuit to. Pipe schedule is eo lor piping 2 inch and smaller diameter and 40 (STD) for 2.50 inch dla. and greater 11. Spans for Seismic and Wind loading are celccieted for maximum dellection 013 inches and lor 80% of allowable stress and smaller span between

Ihe

two

is considered.

7 of 8

APPENDIX 'A'

GRAVITY, SEISMIC, AND WIND SPANS AND LOADS

24852-RD-PSC-OOO-P0001,

Rev. 3

WORK

SHEET

FOA SPAN TABLE

SC-j AND SC-II PIPING

(HASTELLOY)

EMPTY

S,_

00(00, [)Iin)

-'''''

Con. Wall Thk. (l) (in)

S ....

Gl1IviIy

A~_

(sqin) MI(in4) 2.01E-02 Z(in3) 418E.(I2 8.S3E-02 1.111£-01 412E.(I1 5.7045949 2.4668886 4.32£-01 7.19E-Ol 4.48£·02 1.06E-Ol

Waler WUMO WU.trF!

nF1IC1oI'

(SF) 2.10E .. 00 7.76£ .. 00 9.03E .. 00 2.10e .. 00 2,10e+00 2.10E+00

",,""

slnm(L.$) (R,

Selecled Gr .... 1y Span (Ft)