Professional Documents

Culture Documents

CW Sample

Uploaded by

Laurence SarmientoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CW Sample

Uploaded by

Laurence SarmientoCopyright:

Available Formats

1.

CW-2A/CW-2

For CW-2a and CW-2 the difference lies on the size of middle glass panel. The bigger glass size is considered on the verification for CW-2A/CW-2.

SA

PL

ES

IG

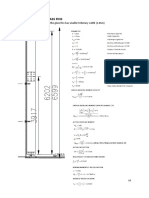

1.1. MULLION DESIGN 1.1.1.FORCE DISTRIBUTION

SA

PL

AXIAL FORCES ON MULLION

CURTAIN WALL FORCE DISTRIBUTION

ES

IG

SA

PL

BENDING ON MULLION

SHEAR ON MULLION

ES

IG

Deflection of Mullion = 14.23mm < L/300 + 5 = 3100/300 + 5 = 15.33mm

SA

PL

ES

IG

1.1.2. SECTION PROPERTIES

Material properties (Alloy 6063-T6) E = 70000 Mpa G = 26600 Mpa = 2710 Kg/m3 = 160 Mpa = 95 Mpa = 175 Mpa Modulus of Elasticity Shear Modulus Density of Aluminum

Limiting Stress for Shear Limiting Stress for local capacity

d = 125 mm bf = 54 mm tf = 6 mm dw = 104 mm tw = 3 mm gr = 0.45 Cx = 30 mm Cy = 78 mm Ix = 325.31 cm Iy = 74.42 cm4 Zx = 41.71 cm3

4

Profile Depth Flange width Flange thickness Web Depth

Web Thickness

Zy = 24.81 cm3 A = 14.2 cm2

SA

PL

E

Cross-sectional area.

Stress gradient coefficient, figure 4.2 Distance from neutral y-axis to extreme fiber

Distance from neutral x-axis to extreme fiber Moment of Inertia at major axis.

Moment of inertia at minor axis.

Elastic Section modulus of inertia at major axis. Elastic Section modulus of inertia at minor axis.

ES

Dimension Properties b = 60 mm Profile Width

IG

Limiting Stress for bending and overall yielding

Section Classification and Local Buckling Fully Compact Semi-Compact Slender = 1.25 = 27.5 = 22.5 = 15.6 Slender limit Constant Limit for a semi compact section Limit for a fully compact section

Element isfully Compact = 4.05 Therefore the Section is compact

Flange element is fully compact

Material Factor Table 3.3 BS 8118.

My< MRX

Check for bending Moment Resistance for Mullion with reinforcement Material Factor Table 3.3 BS 8118. Maximum factored bending moment.

SA

My = 6.69KN.m Mym =

Mym< MRX

PL

My = 3.98KN.m

Maximum factored bending moment.

Factored Moment Resistance at major axis with reduction due

to slenderness. Section is Okay.

Factored Moment Resistance at major axis with reduction due to slenderness. Section is Okay.

Check for bending Moment Resistance for Mullion without reinforcement

ES

IG

Web Slenderness limit

SA M PL E D ES IG N

Check for Shear Resistance Fully compact section Slender

= 1.25

Slender limit Constant

Section is fully compact

Vmax = 11.87 KN Shear on mullion Vm = Nw = 2 Number of Webs Factored Shear Force

Effective Shear area of a mullion Factored Shear Load Resistance Vm< V Section is Okay Check for Tension Resistance

Tmax= 5.45 KN

Tension on mullion Tm =

SA

Tmax<

Check for Axial - Bending Resistance Section is Okay.

PL

Material Factor Table 3.3 BS 8118.

Maximum factored Tension Force.

Factored Tension Resistance at major axis. Section is Okay.

ES

IG

REINFORECEMENT SECTION PROPERTIES (FW 60+ 324 320)

Material properties (Alloy 6063-T6) E = 70000 Mpa G = 26600 Mpa = 2710 Kg/m3 = 160 Mpa = 95 Mpa = 175 Mpa Modulus of Elasticity Shear Modulus Density of Aluminum Limiting Stress for bending and overall yielding Limiting Stress for Shear Limiting Stress for local capacity

d = 98 mm bf = 26 mm tf = 3 mm dw = 87 mm tw = 3 mm gr = 0.45 Cx = 13 mm Cy = 54 mm Ix = 125.80 cm4 Iy = 18.60 cm4

Profile Depth Flange width Flange thickness Web Depth

Zx = 23.30 cm3

SA

Zy = 14.31 cm3 A = 10.73 cm2

PL

E

Cross-sectional area.

Web Thickness

Stress gradient coefficient, figure 4.2 Distance from neutral y-axis to extreme fiber

Distance from neutral x-axis to extreme fiber Moment of Inertia at major axis.

Moment of inertia at minor axis. Elastic Section modulus of inertia at major axis. Elastic Section modulus of inertia at minor axis.

ES

Dimension Properties b = 53 mm

Profile Width

IG

Section Classification and Local Buckling Fully Compact Semi-Compact Slender = 1.25 = 27.5 = 22.5 = 13.05 Slender limit Constant Limit for a semi compact section Limit for a fully compact section

Web Slenderness limit

Element isfully Compact = 3.9

Flange element is fully compact

Material Factor Table 3.3 BS 8118.

Myr =

SA

Myr< MRX

PL

My = 6.69KN.m

Maximum factored bending moment.

Factored Moment Resistance at major axis with reduction due

to slenderness. Section is Okay.

Check for bending Moment Resistance for Mullion Reinforcement

ES

IG

Check for Shear Resistance Fully compact section Slender

Vmax = 11.87 KN Shear on Reinf.,Vr = Nw = 2

Factored Shear Force

Number of Webs

Effective Shear area of a mullion Factored Shear Load Resistance

Check for Tension Resistance

Tmax= 5.45 KN

Tension on Reinf.,Tr =

SA

Tr<

Check for Axial - Bending Resistance Section is Okay.

PL

E

Material Factor Table 3.3 BS 8118. Maximum factored Tension Force. Factored Tension Resistance at major axis. Section is Okay.

Vmax< V

Section is Okay

ES

IG

Section is fully compact

= 1.25

Slender limit Constant

1.2. TRANSOM DESIGN Transom shall be designed on the maximum panel size against 3.3KPa Wind Pressure.

SA

PL

Transom Load distribution

ES

IG

TRANSOM PROPERTIES (FW 60+ 320 480) Material properties (Alloy 6063-T6) E = 70000 Mpa G = 26600 Mpa = 2710 Kg/m3 = 160 Mpa = 95 Mpa = 175 Mpa Dimension Properties A = 12.13cm2 Iy = 270.93 cm4 Ix = 71.30 cm4 Cx = 73 mm Cy = 30mm b = 60 mm d = 140 mm bf 1= 54 mm bf 2= 52 mm tf = 2.1 mm Cross-sectional area. Modulus of Elasticity Shear Modulus Density of Aluminum Limiting Stress for bending and overall yielding Limiting Stress for Shear Limiting Stress for local capacity

Moment of Inertia at minor axis. Moment of inertia at major axis.

Distance from neutral y-axis to extreme fiber Distance from neutral x-axis to extreme fiber

Profile Depth

dw= 125.8 mm tw = 3.1 mm gr = 0.45

SA

PL

Flange width Web Depth Profile Web thickness

Element width for Mode 1* Element width for Mode 2*

Stress gradient coefficient figure 4.2 in appendix

Profile Width

ES

IG

1.2.1.LOAD ANALYSIS Wind Load W = 3.3 x (1.0 + 0.49) = 4.92 KN/m Wf = 4.92 x 1.2 =5.90 KN/m Dead Load Wind load value on transom. Factored wind load

For typical curtain wall: Typical Length of transom. Maximum Glass panel height. Unit Weight of Glass.

Location of setting block. DLg = Weight of Glass panel at each glazing support DLg = = 53.55 Kg = 0.53 KN

DLft =

PL

DLfg=

KN

SA

D

Load factor Factored weight of glass. Factored weight of Transom.

ES

Thickness of Glass without air space

IG

SA

PL

WIND LOAD DIAGRAM

ES

DEAD LOAD DIAGRAM

IG

1.2.2.DESIGN Vw = 5.90x2/2 = 5.9 KN

Maximum shear due to wind load on the transom. Moment due to Wind load on transom.

Vd = 0.024x2.1/2 + 1.30 = 1.33 KN

Shear due to dead load on the transom. Moment due to Dead load

y=

= 6.48 mm

Normal Deflection to the plane of glass.

y< yallowable z= = 0.18 mm

Zallowable = min (L/500; 3.0 mm) = 3 mm z< Zallowable

SA

PL

ES

Section is Okay Section is Okay

yallowable = L/200 = 10 mm

Normal Deflection Allowed

Normal Deflection to the plane of glass. Normal Deflection Allowed

IG

Check for Deflection

Section Classification and Local Buckling

Fully Compact Semi-Compact Slender = 1.25 = 27.5 = 22.5 = 8.75 = 7.5 = 11.57< = 10.89< = 17.85 Slender limit Constant Limit for a semi compact section for internal element (Mode 1) Limit for a fully compact section for internal element (Mode1)

Limit for a semi compact section for outstand element (Mode2) Limit for a fully compact section for outstand elements (Mode2) Flange slenderness parameter Mode 1, fully compact element Flange slenderness parameter Mode 2, slender

Md = 0.12 x 1.2 = 0.144KN.m Mw = 2.95 x 1.2 = 3.54KN.m

PL

SA

Md<MRd

Mw <MRw

Check for Bending moment resistance

Section is Okay

Web slenderness parameter, fully compact element

Material Factor Table 3.3 BS 8118.

Maximum factored bending moment parallel to plane. Maximum factored bending moment normal to plane. Factored Moment Resistance at major axis. Factored Moment Resistance at major axis.

ES

IG

Check for Shear Resistance

Web Element Fully compact section Slender

Section is Compact Vw= 5.9 KN Nw = 2 Factored Shear Force Number of Webs

( Factored Shear Load Resistance Vrw = 43.28 KN

Flange Element

PL

Section is Okay

= 1.25

SA

Vd= 1.33 KN Nf = 2

Factored Shear Force Number of flanges (considering both of 2.1 mm Effective Shear area of a mullion Factored Shear Load Resistance

SHEAR CHECK

D

Fully compact section Slender Slender limit Constant Section is fully compact

ES

)

Effective Shear area of a mullion

IG

= 1.25

Slender limit Constant

SA M PL E D ES IG N

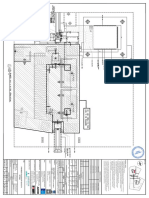

1.3. MULLION ANCHORAGE VE RIFICATION 1.3.1.REACTIONS ON POINTS OF SUPPORT

SA

PL

ES

IG

1.3.2.TOP BRACKET VERIFICA TION

SA

PL

ES

IG

Thread and Nuts Design:

Q, Shear on bolt = 10.592 + 2.982= 11.00 KN Use M12 Grade 8.8 threaded rod with nut on both sides of shear capacity = 375 N/mm2: Ps (for double shear plane of bolts) = 2 x Shear Capacity x Effective shear area = 2 x 375x (0.74 x 3.14 x 122/4) = 62.74 KN> 11.00 KN. Mullion Checking Against Bearing (BS 8118): Q/2 = 5.5 KN Bearing strength of mullion = min (BRP1; BRP2) BRP1 = c x df x t x Pa / 1.2 c = 2 where df/t < 10 df = Nominal bolt diameter = 12 mm.

t = mullion thickness + thickness of reinforcement = 3.1 + 2.9 = 6 mm. Pa = Limiting Stress of Alloy 6063-T6 (BS 8118-table 4.1) = 175Mpa. BRP1 =21KN. BRP2 = e x t x Pa / 1.2 e= edge distance = 34 mm BRP2 = 29.75 KN.

Therefore Bearing strength of the mullion = 21 KN >5.5 KN .. Accepted

Steel Bracket Thickness:

SA

Tbolt =Applied tension on one bolt =

PL

+

Anchors Design:

Strength of bolt will be computed in Fischer Software.

E

= 15.63 KN.

ES

IG

You might also like

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- Static Calculation CWDocument64 pagesStatic Calculation CWCatalin Bunescu100% (2)

- Load Calculation for Glass Panel DesignDocument1 pageLoad Calculation for Glass Panel DesignAnonymous YDwBCtsNo ratings yet

- Structural Glass Design-BS6399Document6 pagesStructural Glass Design-BS6399msiddiq1100% (2)

- Structural Glass Design-UBCDocument6 pagesStructural Glass Design-UBCmsiddiq1100% (1)

- Facade SpecificationDocument150 pagesFacade SpecificationKavi PrakashNo ratings yet

- Calculation of Glass & MullionDocument4 pagesCalculation of Glass & MullionThành KC75% (4)

- ASTM E1300-09A GLASS DEFLECTION CALCULATIONDocument1 pageASTM E1300-09A GLASS DEFLECTION CALCULATIONwaweng22No ratings yet

- Structural Calculation of Curtain WallDocument118 pagesStructural Calculation of Curtain Wallzfrl100% (23)

- Fin DesignDocument12 pagesFin DesignMuraleedharanNo ratings yet

- Aluminium Mullion AnalysissDocument24 pagesAluminium Mullion Analysissvtalex100% (4)

- Sg12 Frameless Balustrades Structural CalculationsDocument12 pagesSg12 Frameless Balustrades Structural CalculationsAhmed Mohamed LabibNo ratings yet

- Glass FinDocument6 pagesGlass FinSethusweet SethuramanNo ratings yet

- Facade CalculationDocument60 pagesFacade CalculationPrabartak Das100% (2)

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Project Name: Glass BalustradeDocument11 pagesProject Name: Glass BalustradeNp Pw100% (1)

- Structural Calculation Curtain WallDocument93 pagesStructural Calculation Curtain Wallashaswamy100% (1)

- Bolted Connection in Glass StructureDocument52 pagesBolted Connection in Glass StructureCristiana Gruia-Paun100% (2)

- Curtain Wall Calculation PDFDocument134 pagesCurtain Wall Calculation PDFAlaaBadwy100% (1)

- SKYLIGHT REPORT - Rev 01Document16 pagesSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- Advanced Design of Glass Structures and FinsDocument7 pagesAdvanced Design of Glass Structures and FinsAmro Ahmad Ali100% (2)

- Paseo Curtain Wall Strutural CalculationDocument79 pagesPaseo Curtain Wall Strutural CalculationVictor Dlreyes100% (1)

- Design of Curtain Walls For Wind Loads - Details and CalculationsDocument9 pagesDesign of Curtain Walls For Wind Loads - Details and CalculationsJustin Musopole100% (1)

- Section Classification BS 8118-1-1991Document1 pageSection Classification BS 8118-1-1991AthumizNo ratings yet

- Prj03 Glass Canopy (Mepla)Document32 pagesPrj03 Glass Canopy (Mepla)Filip RisteskiNo ratings yet

- Calculation Curtain WallDocument4 pagesCalculation Curtain WallMcr Kumara100% (1)

- Lusail Facade Structural Design ParametersDocument34 pagesLusail Facade Structural Design Parametersddevilived0% (1)

- Glass Laminate Thicknesses and PropertiesDocument1 pageGlass Laminate Thicknesses and PropertiesLaurence Sarmiento100% (1)

- GLASS BALUSTRADE DESIGN CALCULATIONSDocument8 pagesGLASS BALUSTRADE DESIGN CALCULATIONSmsiddiq1100% (2)

- Point Fixing GlassDocument135 pagesPoint Fixing GlassAnthony Ruth0% (1)

- Glass Laminate Thicness - No Reduc For Cantilever GlassDocument1 pageGlass Laminate Thicness - No Reduc For Cantilever GlassLaurence Sarmiento100% (1)

- Design Wind Loads For Aluminum Curtain Walls (1975)Document21 pagesDesign Wind Loads For Aluminum Curtain Walls (1975)Alberto GonzalezNo ratings yet

- 10-1-17 Struc Calc UCW T2Document2,832 pages10-1-17 Struc Calc UCW T2ady pramanaNo ratings yet

- Louver Report Rev02Document12 pagesLouver Report Rev02MuraleedharanNo ratings yet

- Design of Mullion-BS enDocument16 pagesDesign of Mullion-BS enPrasad kapure100% (1)

- Glass Design CalculationDocument15 pagesGlass Design CalculationAnand100% (1)

- Screw Capacity According To Aama Tir-A9 and Tir-A9-Add: Material ParametersDocument2 pagesScrew Capacity According To Aama Tir-A9 and Tir-A9-Add: Material Parameterswaweng22No ratings yet

- Glass Balustrade Design EN 16612Document2 pagesGlass Balustrade Design EN 16612Ciprian POPANo ratings yet

- 10th Aug. 2011 Structural Calculation (For Sub.) - 03Document29 pages10th Aug. 2011 Structural Calculation (For Sub.) - 03Nguyễn Tiến Việt100% (1)

- Facade ManualDocument124 pagesFacade ManualDhana Shekar100% (1)

- Glass PanelDocument2 pagesGlass PanelEIWAA50% (2)

- Design Components For Structural GlazingDocument8 pagesDesign Components For Structural GlazingnonspodNo ratings yet

- Facade NotesDocument303 pagesFacade NotesKho C Ahl100% (2)

- Calculation Profile Curtain WallDocument91 pagesCalculation Profile Curtain WallEren BoyaciNo ratings yet

- Glass CalculationDocument2 pagesGlass Calculationpradeeshpg50% (2)

- Design of Glass ColumnDocument8 pagesDesign of Glass ColumnCristiana Gruia-PaunNo ratings yet

- Structural Design of A Glass FacadeDocument6 pagesStructural Design of A Glass Facadecomandos882010No ratings yet

- Glass Aluminum Curtain Wall SystemsDocument20 pagesGlass Aluminum Curtain Wall Systemsliuqian100% (1)

- Static Calculation CWDocument64 pagesStatic Calculation CWR KNo ratings yet

- 200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Document74 pages200205-MYH-MYS-000-021 Structural Analysis of Aluminum Cladding Under Co...Dana KadriNo ratings yet

- Curtain Wall CalculationDocument8 pagesCurtain Wall CalculationKenneth OkoyeNo ratings yet

- Chapter 3 - Example 3Document6 pagesChapter 3 - Example 3NIBEDITA DEYNo ratings yet

- Rectangular Beam 1VB16-300x800mm - Sagging: InputDocument4 pagesRectangular Beam 1VB16-300x800mm - Sagging: InputSiti Fatimah MokhtarNo ratings yet

- CSE 362 Design of Steel Structures Section Properties and CapacitiesDocument19 pagesCSE 362 Design of Steel Structures Section Properties and CapacitiesRufus ChengNo ratings yet

- Cross-Section Parameter Input: Zee-Section Cold-Form Seel Calculation ACCORDING TO BS-EN1993-1-3 (EC3)Document6 pagesCross-Section Parameter Input: Zee-Section Cold-Form Seel Calculation ACCORDING TO BS-EN1993-1-3 (EC3)Minh Tâm TrầnNo ratings yet

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- SS EN 1992-1-1:2008 Beam Design Section and Shear TorsionDocument4 pagesSS EN 1992-1-1:2008 Beam Design Section and Shear TorsionSiti Fatimah MokhtarNo ratings yet

- 8b.design of Control Room BuildingDocument49 pages8b.design of Control Room BuildingNuru TwahaNo ratings yet

- Aluminium DesignDocument9 pagesAluminium Designikanyu79No ratings yet

- Front Bracket Check: LC 1.0DL + 1.5WL+ (1.35DL Lessens The Tension On The Anchor Thus Is Not Governing)Document10 pagesFront Bracket Check: LC 1.0DL + 1.5WL+ (1.35DL Lessens The Tension On The Anchor Thus Is Not Governing)Laurence SarmientoNo ratings yet

- Intro To Pmbok PDFDocument3 pagesIntro To Pmbok PDFLaurence SarmientoNo ratings yet

- Check For Upper ConnectionDocument3 pagesCheck For Upper ConnectionLaurence SarmientoNo ratings yet

- Check for the anchorage to concrete back bracket maximum reactionDocument11 pagesCheck for the anchorage to concrete back bracket maximum reactionLaurence SarmientoNo ratings yet

- Det 1025Document1 pageDet 1025Laurence SarmientoNo ratings yet

- Bottom Bracket Design: For The Analysis of The Thru Bolt, See The Pervious SectionDocument6 pagesBottom Bracket Design: For The Analysis of The Thru Bolt, See The Pervious SectionLaurence SarmientoNo ratings yet

- Standards & Software ReferencesDocument4 pagesStandards & Software ReferencesLaurence SarmientoNo ratings yet

- Loadings and steel checks for stone claddingDocument3 pagesLoadings and steel checks for stone claddingLaurence SarmientoNo ratings yet

- Steel FrameDocument2 pagesSteel FrameLaurence SarmientoNo ratings yet

- Project Integration Management: U U U U U U U U U UDocument3 pagesProject Integration Management: U U U U U U U U U ULaurence SarmientoNo ratings yet

- Glass Fin Support Design CheckDocument7 pagesGlass Fin Support Design CheckLaurence SarmientoNo ratings yet

- Det 1024Document1 pageDet 1024Laurence SarmientoNo ratings yet

- Verification For The Front GlassDocument6 pagesVerification For The Front GlassLaurence SarmientoNo ratings yet

- Roles of The PMDocument6 pagesRoles of The PMLaurence SarmientoNo ratings yet

- Project Schedule Management: GuideDocument3 pagesProject Schedule Management: GuideLaurence SarmientoNo ratings yet

- Det 1022Document1 pageDet 1022Laurence SarmientoNo ratings yet

- Projects Operating EnvironmentsDocument5 pagesProjects Operating EnvironmentsLaurence SarmientoNo ratings yet

- Cleat and SupportDocument2 pagesCleat and SupportLaurence SarmientoNo ratings yet

- Bracket FemDocument3 pagesBracket FemLaurence SarmientoNo ratings yet

- Det 1021Document1 pageDet 1021Laurence SarmientoNo ratings yet

- Det 1023Document1 pageDet 1023Laurence SarmientoNo ratings yet

- Det 1020 PDFDocument1 pageDet 1020 PDFLaurence SarmientoNo ratings yet

- 2.14. Check For Steel Beam at Above Revolving Door: StaadDocument2 pages2.14. Check For Steel Beam at Above Revolving Door: StaadLaurence SarmientoNo ratings yet

- KOCO - Threaded Studs - Load ChartDocument3 pagesKOCO - Threaded Studs - Load ChartLaurence SarmientoNo ratings yet

- Steel Transom Check Force CalculationsDocument2 pagesSteel Transom Check Force CalculationsLaurence SarmientoNo ratings yet

- BALUSTDocument1 pageBALUSTLaurence SarmientoNo ratings yet

- Load Share FactorDocument1 pageLoad Share FactorLaurence SarmientoNo ratings yet

- Load Share Factor 2Document1 pageLoad Share Factor 2Laurence SarmientoNo ratings yet

- Glass Nominal ThicknessDocument1 pageGlass Nominal ThicknessLaurence SarmientoNo ratings yet

- WIP CaseStudyDocument3 pagesWIP CaseStudypaul porrasNo ratings yet

- Steel 17-4PH MmpdsDocument18 pagesSteel 17-4PH MmpdsManoj ManoharanNo ratings yet

- Higher-Order InteractionsDocument6 pagesHigher-Order Interactions山木No ratings yet

- Research Article (Lavandula Angustifolia) Essential Oil On: Effect of Lavender Acute Inflammatory ResponseDocument10 pagesResearch Article (Lavandula Angustifolia) Essential Oil On: Effect of Lavender Acute Inflammatory ResponseAndreeaNo ratings yet

- THEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsDocument17 pagesTHEORY of METAL CUTTING-Cutting Tool, Cutting Fluid & Machining EconomicsIzi75% (4)

- Advanced Technologies of CDQ Plant Advanced Technologies of CDQ PlantDocument12 pagesAdvanced Technologies of CDQ Plant Advanced Technologies of CDQ Plant조기현No ratings yet

- Specification IC DK112Document10 pagesSpecification IC DK112ROlando EskadabaichoNo ratings yet

- Steam Turbine Unloading and Shut-Down of Operation Turbine/Generator Shut-Down Diagram (General)Document1 pageSteam Turbine Unloading and Shut-Down of Operation Turbine/Generator Shut-Down Diagram (General)parthibanemails5779No ratings yet

- AUS Triboard ManuaDocument112 pagesAUS Triboard ManuaWan RidsNo ratings yet

- What Is RTN/Microwave TechnologyDocument27 pagesWhat Is RTN/Microwave TechnologyRavan AllahverdiyevNo ratings yet

- Structural Notes SampleDocument14 pagesStructural Notes SampleNicole FrancisNo ratings yet

- Đánh giá chế độ ăn kiêng: Nhịn ăn gián đoạn để giảm cân- wed HarvardDocument14 pagesĐánh giá chế độ ăn kiêng: Nhịn ăn gián đoạn để giảm cân- wed HarvardNam NguyenHoangNo ratings yet

- Schneider Power Supply PhaseoDocument26 pagesSchneider Power Supply PhaseoScott EnnisNo ratings yet

- Adobe Scan 12 Aug 2022Document3 pagesAdobe Scan 12 Aug 2022surabhi kalitaNo ratings yet

- M700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Document601 pagesM700-70 Series Programming Manual (M-Type) - IB1500072-F (ENG)Mert SertNo ratings yet

- CV of Shaila (Me)Document4 pagesCV of Shaila (Me)Masud RanaNo ratings yet

- 2tak Vs 4takDocument3 pages2tak Vs 4takTaufiq AlhakimNo ratings yet

- Maize Package of Practices in BriefDocument3 pagesMaize Package of Practices in Briefkomandla venkatkiran reddyNo ratings yet

- Being and Nothingness The Look SartreDocument3 pagesBeing and Nothingness The Look Sartremaximomore50% (4)

- AWWA M28 Rehabilitation of Water Mains 3rd Ed 2014Document133 pagesAWWA M28 Rehabilitation of Water Mains 3rd Ed 2014millini67% (3)

- Boston Acoustic PDFDocument12 pagesBoston Acoustic PDFAdam StarkNo ratings yet

- IB Chemistry HL Test 2nd FEBDocument13 pagesIB Chemistry HL Test 2nd FEBprasad100% (1)

- Mic ProjectDocument12 pagesMic Projectsarthakjoshi012No ratings yet

- WHO Blocks Nanosilver Shipments to Treat Ebola in AfricaDocument2 pagesWHO Blocks Nanosilver Shipments to Treat Ebola in AfricaTamas ZefferNo ratings yet

- Durango GS 6-7 Helitack OutreachDocument4 pagesDurango GS 6-7 Helitack OutreachdcgmNo ratings yet

- RESISTANCEDocument9 pagesRESISTANCERohit SahuNo ratings yet

- March 17, 2016 Strathmore TimesDocument24 pagesMarch 17, 2016 Strathmore TimesStrathmore TimesNo ratings yet

- Motherboards Tuf z270 Mark 2Document70 pagesMotherboards Tuf z270 Mark 2Jonah HexNo ratings yet

- Business Plan of Easy Meal ServiceDocument41 pagesBusiness Plan of Easy Meal ServiceCeddie UnggayNo ratings yet

- BC230XL Literature 12-11 SpreadslrDocument5 pagesBC230XL Literature 12-11 SpreadslrCiprian Petrule0% (1)