Professional Documents

Culture Documents

Tipos de Calentadores

Uploaded by

Jhon H.E.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tipos de Calentadores

Uploaded by

Jhon H.E.Copyright:

Available Formats

Perfected down to the last detail:

FEEDWATER HEATER

Since the beginning of the last centur y, we have focused intensively on the design of heat exchangers to regeneratively heat and deaerate feedwater. Having our own manufacturing facilities right from the start, we were able to significantly shape the technological development of feedwater heaters and nowadays we rate as one of the most highly reputed international suppliers and licensors. Worldwide we offer like no other company the complete range of feedwater heater and deaerator variants for nuclear and large-scale conventional power plants: U-type feedwater heaters or header-type feedwater heaters Duplex heaters with U-tube bundles or straight-tube bundles Feedwater heaters with spray-type deaerators or tray-type deaerators Drain coolers and steam desuperheaters Our product portfolio also includes larger heaters for district heating and closed cooling water coolers. PROFILE

3D model of a high pressure heater

Only supplier worldwide with a complete range of feedwater heaters Design and construction of the first feedwater and deaerator system in the year 1920 Specialized in nuclear and conventional large-scale power plants More than 1,200 references for header-type HP heaters Supplied the complete feedwater heater train for the first 1,600 MW EPR nuclear power plant in the world Special constructions such as U-tube or straight-tube duplex heaters Optimized tube bundle venting system to enhance performance of nuclear power plants Proprietary sprayer design for spray-type deaerators tried and tested in nuclear power plants Design, manufacture and erection from one source

Tube bundle of a duplex heater

TECHNOLOGY With their perfected technology, our feedwater heaters reliably increase the efficiency of thermal power plants. Conservatively designed tube bundles and proven venting concepts provide permanent protection against damage and guarantee optimal heat transfer. Our header-type feedwater heaters are used principally in the high pressure section of large-scale fossil-fired power plants; the design of such heaters is characterized by snake-shaped tubes and two headers. Their exceptional thermoelasticity, long service life and profitability make them stand out from U-type heaters. In the low pressure section, our duplex heaters allow the extraction steam piping to be routed in a functional and space-saving manner. They unite two heater stages in one single shell and replace two heaters arranged in a row. To deaerate the feedwater, we supply tray-type deaerators or spray-type deaerators in combination with heaters. Nowadays spray-type deaerators are predominantly used in power plants. They are integrated in the feedwater tank and have either a disc type sprayer or spring-type sprayer as a spray device.

APPLICATION 750 MW Wilhelmshaven coal-fired power plant, Germany: A 32m long feedwater tank with spray-type deaerator supplied in the year 1976.

Feedwater tank during commissioning

1,600 MW Olkiluoto 3 nuclear power plant, Finland: Drain cooler, LP and HP heaters for the European Pressur ized Water Reactor (2007).

Shipment of an HP heater from the Nigel works (South Africa)

3D model of a feedwater tank with spray-type deaerator

2 x 1,100 MW Neurath F+G lignite-fired power plant, Germany: The largest HP heaters in the world with an empty weight of more than 270 t supplied in the year 2008.

Disc-t ype sprayers consist of disc-shaped elements placed in pairs resting against one another. They are serrated at the outer circumference to generate a water spray screen and the water flow causes them to bend open flexibly. Our spring-type sprayers have a spring coil which opens to a greater or lesser extent depending on the differential water pressure to generate the spray. Both types of sprayer are dirt-resistant, self-cleaning and available for capacities of up to 1,200 t/h per sprayer. They operate in a range between 10 and 110% of the nominal capacity.

BALCKE-DRR AMERICAS A DIVISION OF SPX COOLING TECHNOLOGIES, INC. 7401 W 129 STREET OVERLAND PARK, KANSAS 66213 In the interest of technological progress, UNITED STATES all products are subject to design and/or 913 664 7428 material change without notice. bdinfousa@spx.com 2009 SPX Cooling Technologies, Inc. balcke-duerr.com Printed in USA | brochure_na_159

HP heater during erection at the power plant

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Z-8000-BB-4076 - Water Injection SystemDocument158 pagesZ-8000-BB-4076 - Water Injection Systembhuvanchaudhari100% (2)

- Spray-Type Deaerator: Installation and Operating Service ManualDocument19 pagesSpray-Type Deaerator: Installation and Operating Service Manualak_thimiriNo ratings yet

- Sellers .005 Pressurized Deaerator Model DescriptionDocument9 pagesSellers .005 Pressurized Deaerator Model DescriptionarjmandquestNo ratings yet

- IO List for Instrumentation Process OverviewDocument7 pagesIO List for Instrumentation Process OverviewPapcel InstrumentNo ratings yet

- Fully Automated Burner Management System Using PLCDocument80 pagesFully Automated Burner Management System Using PLCGanesh Seetharaman100% (1)

- AP GencoDocument23 pagesAP GencoBhanu PrakashNo ratings yet

- Operating Performance of Large Steam TurbinesDocument6 pagesOperating Performance of Large Steam TurbinesLTE002No ratings yet

- Training Boiler Water TreatmentDocument17 pagesTraining Boiler Water TreatmentBabis PapadopoulosNo ratings yet

- Power Plant QuestionsDocument20 pagesPower Plant QuestionsSubhransu Mohapatra50% (2)

- Determination of Steam and Makeup Water Requirements of A Deaerator by EMEMERURAI ODocument45 pagesDetermination of Steam and Makeup Water Requirements of A Deaerator by EMEMERURAI OMohammad Ali ZamanNo ratings yet

- Ajeet Singh Iffco PDFDocument38 pagesAjeet Singh Iffco PDFAjeet SinghNo ratings yet

- EPRI - Guidelines For Controlling Flow Accelerated CorrosionDocument154 pagesEPRI - Guidelines For Controlling Flow Accelerated CorrosionJimmie Perez100% (4)

- LuenenDocument21 pagesLuenenstarengineer3473No ratings yet

- Power Plant Engineering Slide Part1Document500 pagesPower Plant Engineering Slide Part1Arliel John GarboNo ratings yet

- Duyen Hai 3 Thermal Power Project Commissioning ProcedureDocument24 pagesDuyen Hai 3 Thermal Power Project Commissioning ProcedureLan Rung100% (1)

- Condensate System Components and FunctionsDocument49 pagesCondensate System Components and FunctionsBalendraShahNo ratings yet

- Glaxo Vol IDocument164 pagesGlaxo Vol IPrakash WarrierNo ratings yet

- Boilerasn 160513140404Document17 pagesBoilerasn 160513140404jeremygilbertNo ratings yet

- S 110 1224 0901S - 1 - 0001Document27 pagesS 110 1224 0901S - 1 - 0001duongtuongNo ratings yet

- Feed Water SystemDocument18 pagesFeed Water SystempajriramadhanNo ratings yet

- High Pressure (HPR) : Condensate Return SystemDocument4 pagesHigh Pressure (HPR) : Condensate Return SystemCarlos Andres RojasNo ratings yet

- Tray-Type Deaerator: A. Parallel DownflowDocument4 pagesTray-Type Deaerator: A. Parallel DownflowMuhammad Fakhriy IndallahNo ratings yet

- Filosofia Standard Operacion Caldera ThermaxDocument37 pagesFilosofia Standard Operacion Caldera ThermaxAndújar Báez CésarNo ratings yet

- Steam System Basics: Watertube BoilersDocument4 pagesSteam System Basics: Watertube BoilersNaNo ratings yet

- VLSU Construction Schedule for SMP 1Document6 pagesVLSU Construction Schedule for SMP 1hoang nguyenNo ratings yet

- Emergency Operations: Shaikh Feroz AliDocument15 pagesEmergency Operations: Shaikh Feroz AliEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Boiler Tuning BasicDocument25 pagesBoiler Tuning Basictrung2iNo ratings yet

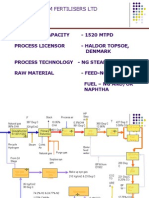

- KRIBHCO SHYAM FERTILISERS LTD AMMONIA PROCESS OVERVIEWDocument51 pagesKRIBHCO SHYAM FERTILISERS LTD AMMONIA PROCESS OVERVIEWSaad Khan89% (9)

- HRSG Lay-Up PracticesDocument4 pagesHRSG Lay-Up PracticesSundar MoorthyNo ratings yet